NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 1961 of 3833

PREPARATION

CL-3

D

E

F

G

H

I

J

K

L

MA

B

CL

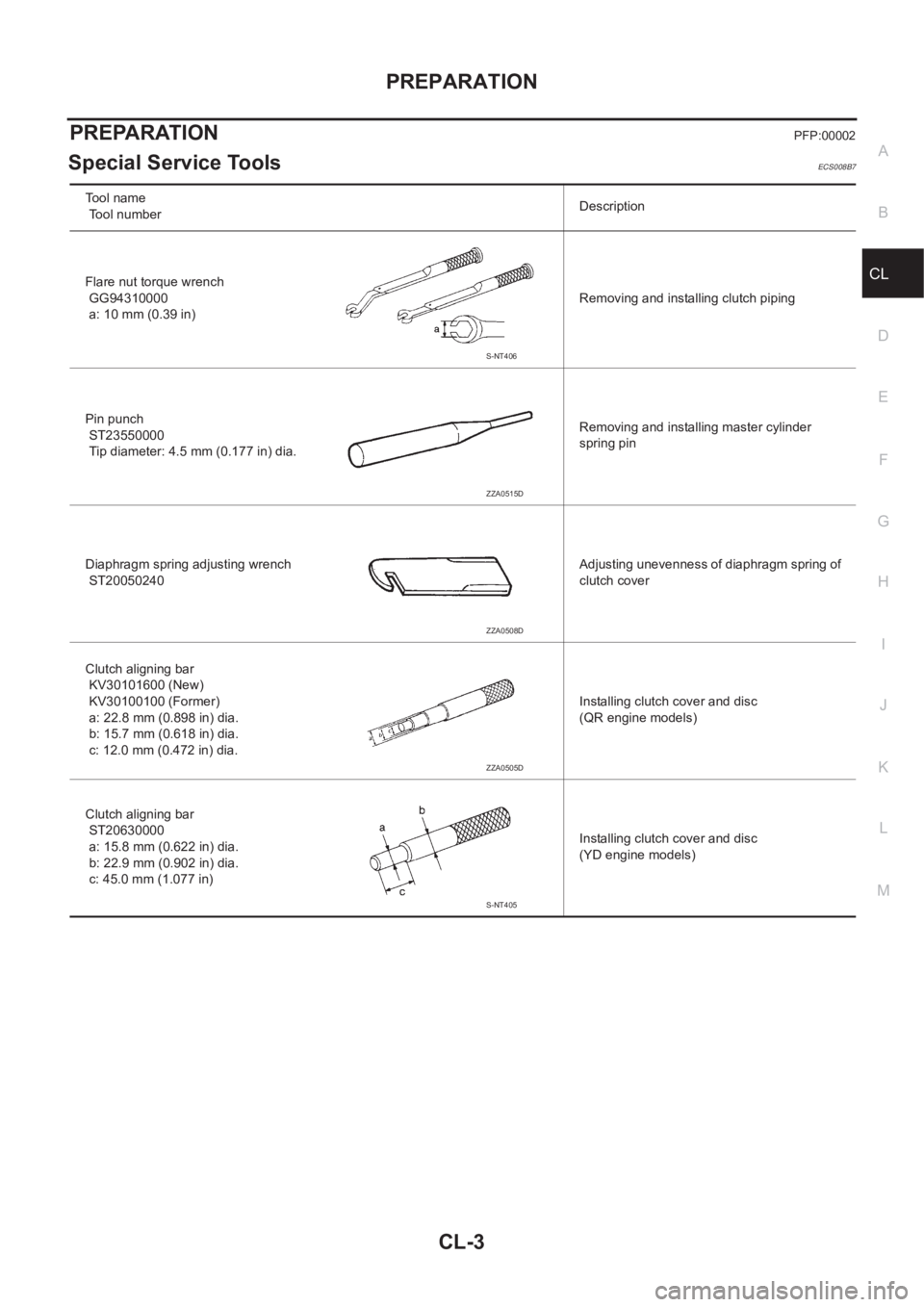

PREPARATIONPFP:00002

Special Service ToolsECS008B7

Tool name

Tool numberDescription

Flare nut torque wrench

GG94310000

a: 10 mm (0.39 in)Removing and installing clutch piping

Pin punch

ST23550000

Tip diameter: 4.5 mm (0.177 in) dia.Removing and installing master cylinder

spring pin

Diaphragm spring adjusting wrench

ST20050240Adjusting unevenness of diaphragm spring of

clutch cover

Clutch aligning bar

KV30101600 (New)

KV30100100 (Former)

a: 22.8 mm (0.898 in) dia.

b: 15.7 mm (0.618 in) dia.

c: 12.0 mm (0.472 in) dia.Installing clutch cover and disc

(QR engine models)

Clutch aligning bar

ST20630000

a: 15.8 mm (0.622 in) dia.

b: 22.9 mm (0.902 in) dia.

c: 45.0 mm (1.077 in)Installing clutch cover and disc

(YD engine models)

S-NT406

ZZA0515D

ZZA0508D

ZZA0505D

S-NT405

Page 1962 of 3833

CL-4

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

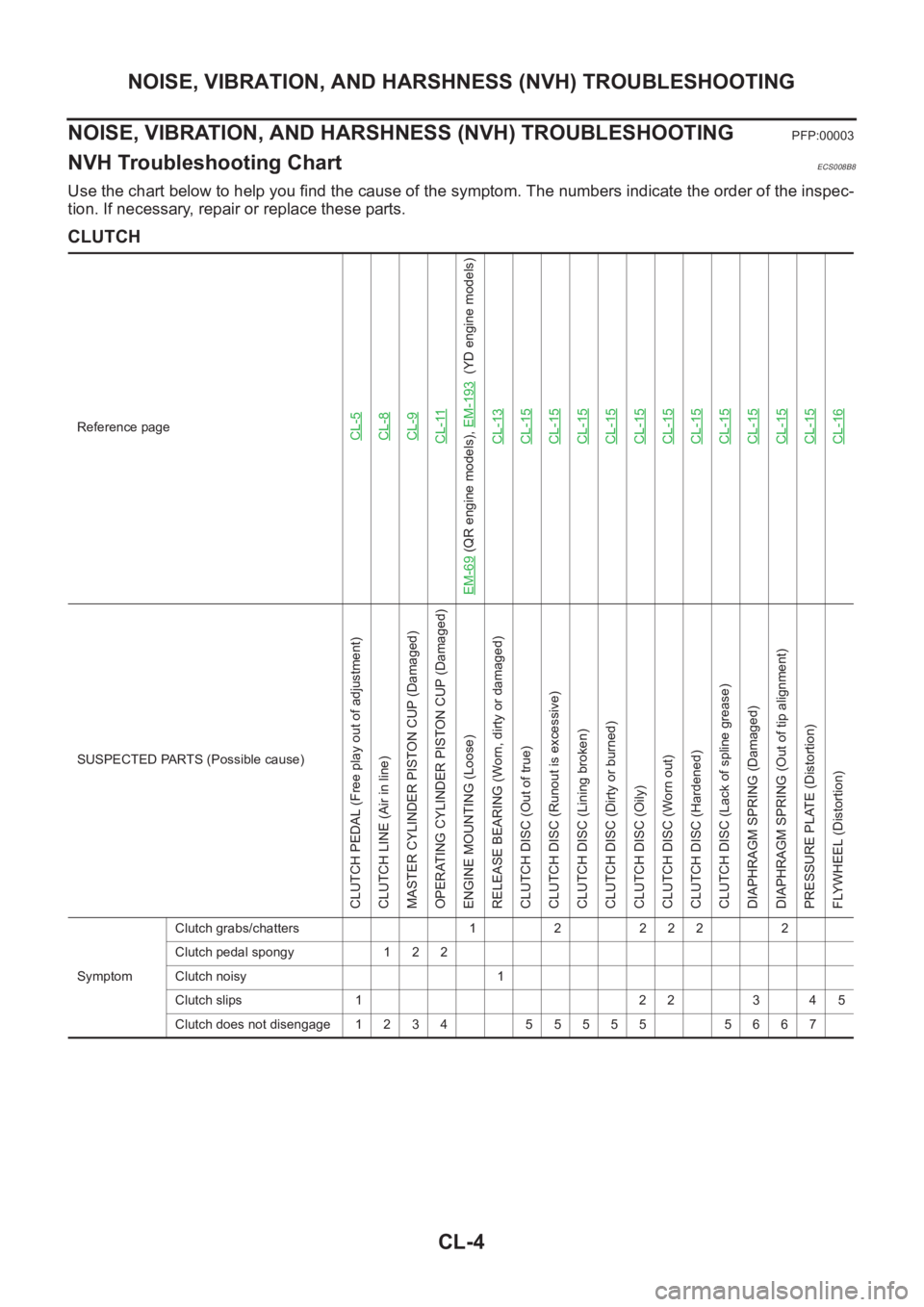

NVH Troubleshooting ChartECS008B8

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

CLUTCH

Reference pageCL-5CL-8CL-9CL-11

EM-69

(QR engine models), EM-193

(YD engine models)

CL-13

CL-15CL-15CL-15CL-15CL-15CL-15CL-15CL-15CL-15CL-15CL-15CL-16

SUSPECTED PARTS (Possible cause)

CLUTCH PEDAL (Free play out of adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

SymptomClutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disengage 1 2 3 4 5 5 5 5 5 5 6 6 7

Page 1963 of 3833

CLUTCH PEDAL

CL-5

D

E

F

G

H

I

J

K

L

MA

B

CL

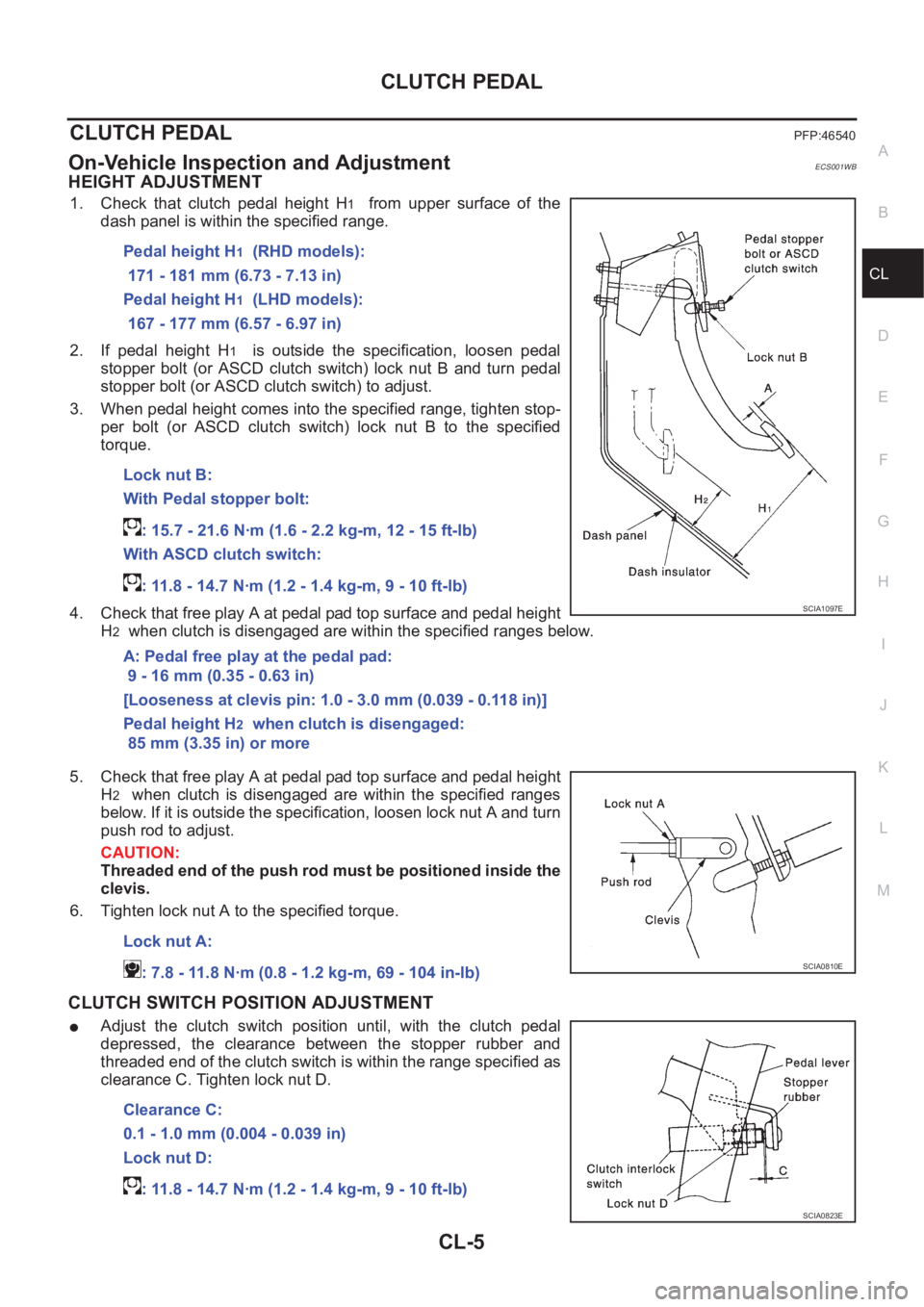

CLUTCH PEDALPFP:46540

On-Vehicle Inspection and AdjustmentECS001WB

HEIGHT ADJUSTMENT

1. Check that clutch pedal height H1 from upper surface of the

dash panel is within the specified range.

2. If pedal height H

1 is outside the specification, loosen pedal

stopper bolt (or ASCD clutch switch) lock nut B and turn pedal

stopper bolt (or ASCD clutch switch) to adjust.

3. When pedal height comes into the specified range, tighten stop-

per bolt (or ASCD clutch switch) lock nut B to the specified

torque.

4. Check that free play A at pedal pad top surface and pedal height

H

2 when clutch is disengaged are within the specified ranges below.

5. Check that free play A at pedal pad top surface and pedal height

H

2 when clutch is disengaged are within the specified ranges

below. If it is outside the specification, loosen lock nut A and turn

push rod to adjust.

CAUTION:

Threaded end of the push rod must be positioned inside the

clevis.

6. Tighten lock nut A to the specified torque.

CLUTCH SWITCH POSITION ADJUSTMENT

●Adjust the clutch switch position until, with the clutch pedal

depressed, the clearance between the stopper rubber and

threaded end of the clutch switch is within the range specified as

clearance C. Tighten lock nut D.Pedal height H

1 (RHD models):

171 - 181 mm (6.73 - 7.13 in)

Pedal height H

1 (LHD models):

167 - 177 mm (6.57 - 6.97 in)

Lock nut B:

With Pedal stopper bolt:

: 15.7 - 21.6 N·m (1.6 - 2.2 kg-m, 12 - 15 ft-lb)

With ASCD clutch switch:

: 11.8 - 14.7 N·m (1.2 - 1.4 kg-m, 9 - 10 ft-lb)

A: Pedal free play at the pedal pad:

9 - 16 mm (0.35 - 0.63 in)

[Looseness at clevis pin: 1.0 - 3.0 mm (0.039 - 0.118 in)]

Pedal height H

2 when clutch is disengaged:

85 mm (3.35 in) or more

SCIA1097E

Lock nut A:

: 7.8 - 11.8 N·m (0.8 - 1.2 kg-m, 69 - 104 in-lb)

SCIA0810E

Clearance C:

0.1 - 1.0 mm (0.004 - 0.039 in)

Lock nut D:

: 11.8 - 14.7 N·m (1.2 - 1.4 kg-m, 9 - 10 ft-lb)

SCIA0823E

Page 1964 of 3833

CL-6

CLUTCH PEDAL

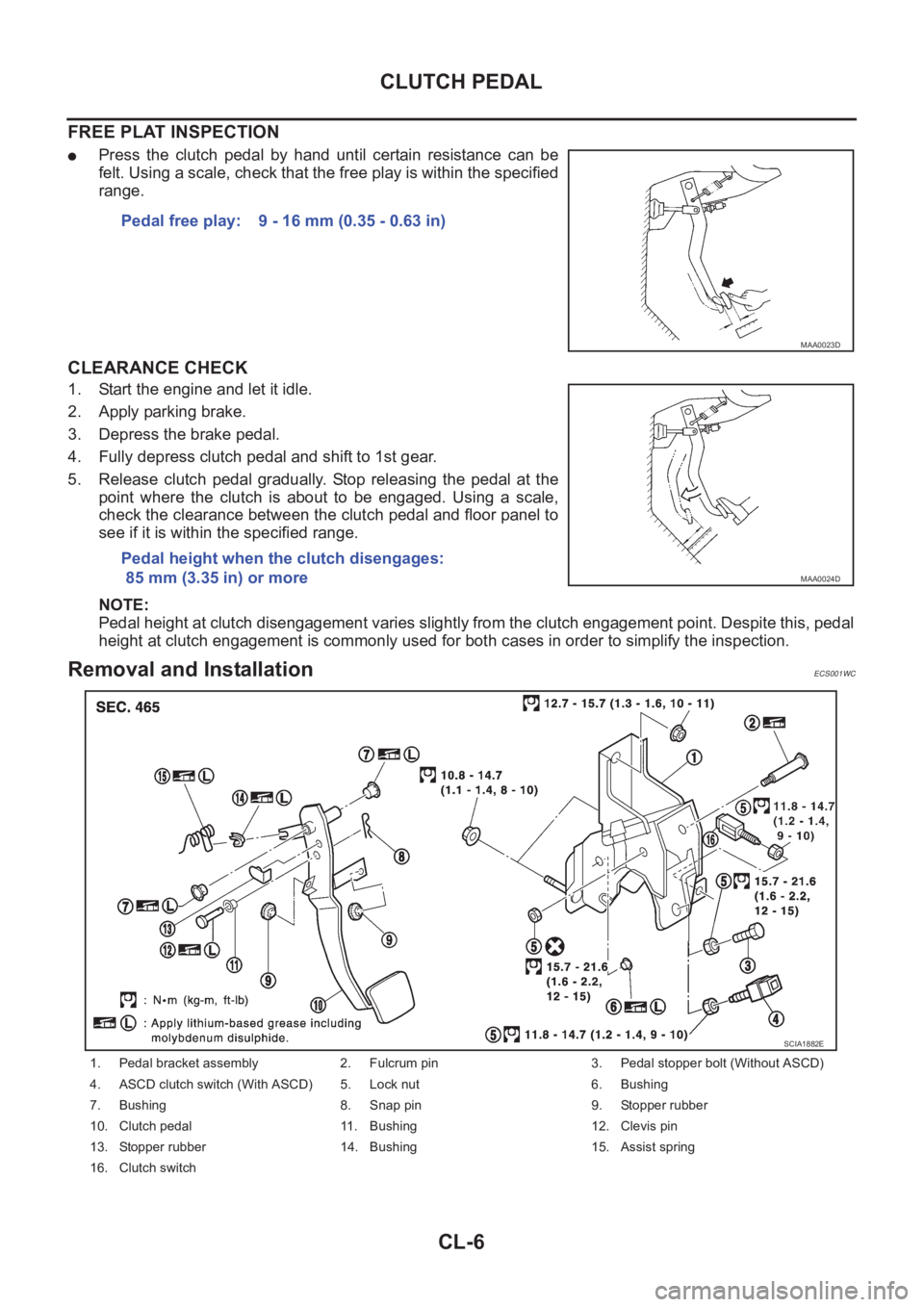

FREE PLAT INSPECTION

●Press the clutch pedal by hand until certain resistance can be

felt. Using a scale, check that the free play is within the specified

range.

CLEARANCE CHECK

1. Start the engine and let it idle.

2. Apply parking brake.

3. Depress the brake pedal.

4. Fully depress clutch pedal and shift to 1st gear.

5. Release clutch pedal gradually. Stop releasing the pedal at the

point where the clutch is about to be engaged. Using a scale,

check the clearance between the clutch pedal and floor panel to

see if it is within the specified range.

NOTE:

Pedal height at clutch disengagement varies slightly from the clutch engagement point. Despite this, pedal

height at clutch engagement is commonly used for both cases in order to simplify the inspection.

Removal and InstallationECS001WC

Pedal free play: 9 - 16 mm (0.35 - 0.63 in)

MAA0023D

Pedal height when the clutch disengages:

85 mm (3.35 in) or more

MAA0024D

1. Pedal bracket assembly 2. Fulcrum pin 3. Pedal stopper bolt (Without ASCD)

4. ASCD clutch switch (With ASCD) 5. Lock nut 6. Bushing

7. Bushing 8. Snap pin 9. Stopper rubber

10. Clutch pedal 11. Bushing 12. Clevis pin

13. Stopper rubber 14. Bushing 15. Assist spring

16. Clutch switch

SCIA1882E

Page 1965 of 3833

CLUTCH PEDAL

CL-7

D

E

F

G

H

I

J

K

L

MA

B

CL

NOTE:

Install clutch pedal assembly and adjust the pedal height. Tighten pedal stopper bolt (or ASCD clutch switch)

to the specified torque.

INSPECTION AFTER REMOVAL

●Check clutch pedal for bend, damage, or a cracked weld. If bend, damage, or a cracked weld is found,

replace the clutch pedal.

●Check assist spring for settling. If settling is found, replace the assist spring.

Page 1966 of 3833

CL-8

CLUTCH FLUID

CLUTCH FLUID

PFP:00017

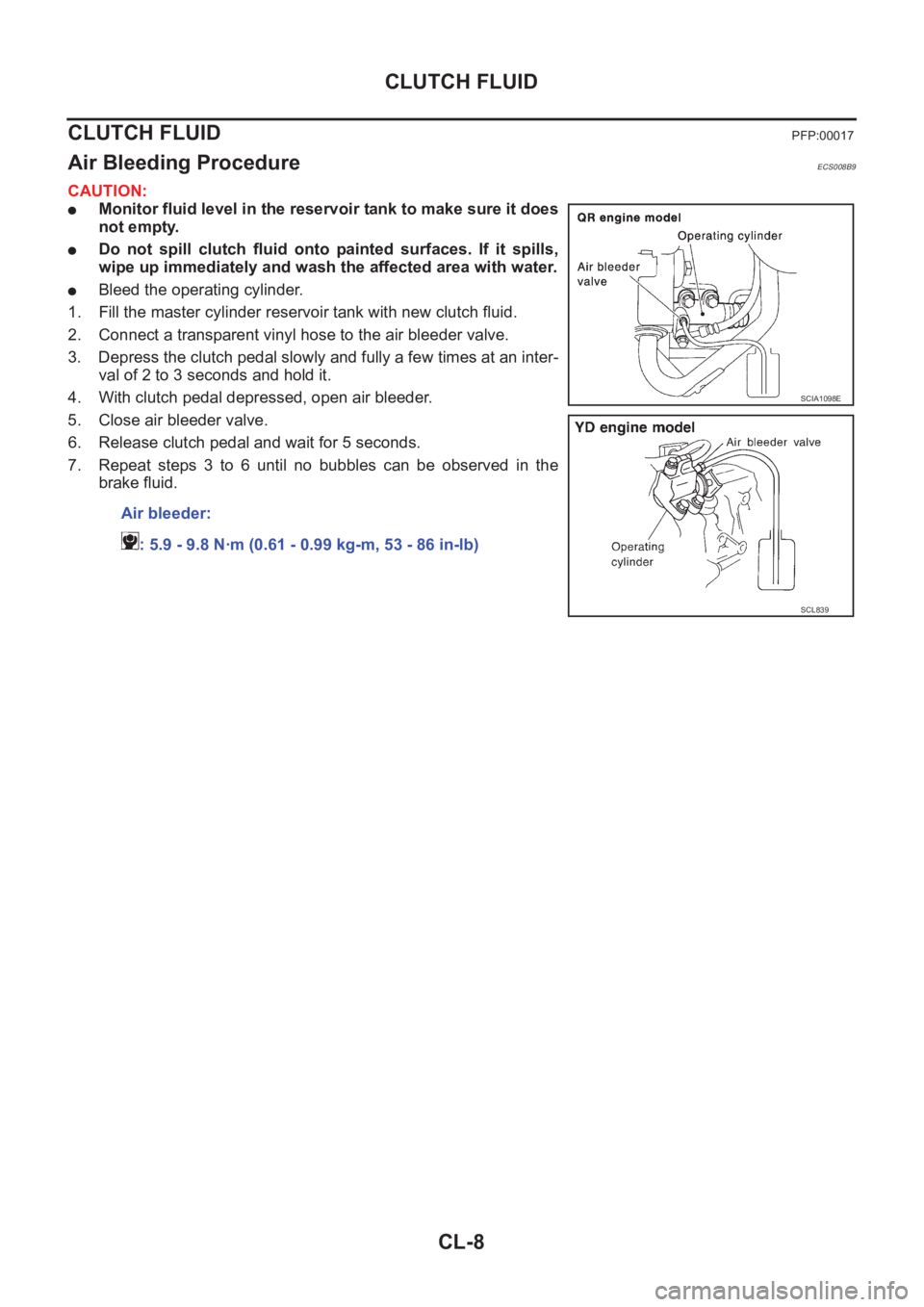

Air Bleeding ProcedureECS008B9

CAUTION:

●Monitor fluid level in the reservoir tank to make sure it does

not empty.

●Do not spill clutch fluid onto painted surfaces. If it spills,

wipe up immediately and wash the affected area with water.

●Bleed the operating cylinder.

1. Fill the master cylinder reservoir tank with new clutch fluid.

2. Connect a transparent vinyl hose to the air bleeder valve.

3. Depress the clutch pedal slowly and fully a few times at an inter-

val of 2 to 3 seconds and hold it.

4. With clutch pedal depressed, open air bleeder.

5. Close air bleeder valve.

6. Release clutch pedal and wait for 5 seconds.

7. Repeat steps 3 to 6 until no bubbles can be observed in the

brake fluid.

Air bleeder:

: 5.9 - 9.8 N·m (0.61 - 0.99 kg-m, 53 - 86 in-lb)

SCIA1098E

SCL839

Page 1967 of 3833

CLUTCH MASTER CYLINDER

CL-9

D

E

F

G

H

I

J

K

L

MA

B

CL

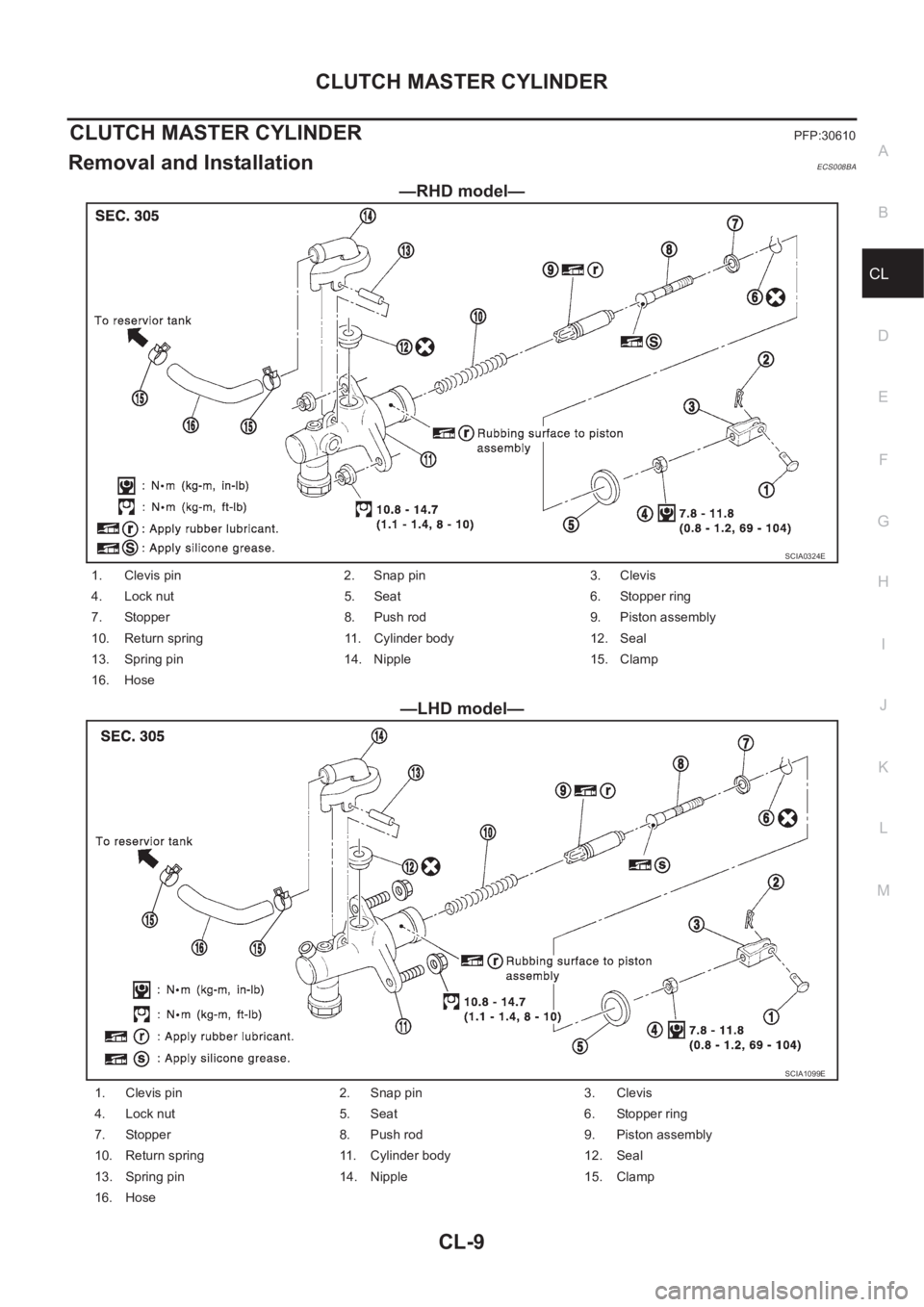

CLUTCH MASTER CYLINDERPFP:30610

Removal and InstallationECS008BA

—RHD model—

—LHD model—

SCIA0324E

1. Clevis pin 2. Snap pin 3. Clevis

4. Lock nut 5. Seat 6. Stopper ring

7. Stopper 8. Push rod 9. Piston assembly

10. Return spring 11. Cylinder body 12. Seal

13. Spring pin 14. Nipple 15. Clamp

16. Hose

SCIA1099E

1. Clevis pin 2. Snap pin 3. Clevis

4. Lock nut 5. Seat 6. Stopper ring

7. Stopper 8. Push rod 9. Piston assembly

10. Return spring 11. Cylinder body 12. Seal

13. Spring pin 14. Nipple 15. Clamp

16. Hose

Page 1968 of 3833

CL-10

CLUTCH MASTER CYLINDER

REMOVAL

1. Using one of the following methods, remove hose from the nipple.

●Drain clutch fluid from reservoir tank and remove hose.

●Remove hose from the nipple. Immediately plug hose and reservoir tank to prevent clutch fluid from

dripping.

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the

affected area with water.

2. Using a flare nut wrench, remove clutch tube.

3. Remove snap pin and clevis pin on clevis in passenger compartment to separate clutch pedal.

4. First remove the mounting nuts on the master cylinder assembly, and then the master cylinder assembly

from the vehicle.

INSTALLATION

1. Connect clutch tube to master cylinder assembly and temporarily tighten flare nut.

2. Install master cylinder assembly and tighten mounting nut to the specified torque.

3. Using a flare nut torque wrench, tighten clutch tube flare nut to the specified torque.

4. Attach clevis of the clevis pin to the clutch pedal.

5. Attach snap pin to the clevis pin.

6. Install hose to the nipple.

7. After completing this procedure, inspect and adjust pedal height and then bleed the clutch tube.

●Refer to CL-5, "On-Vehicle Inspection and Adjustment" , CL-8, "Air Bleeding Procedure" .

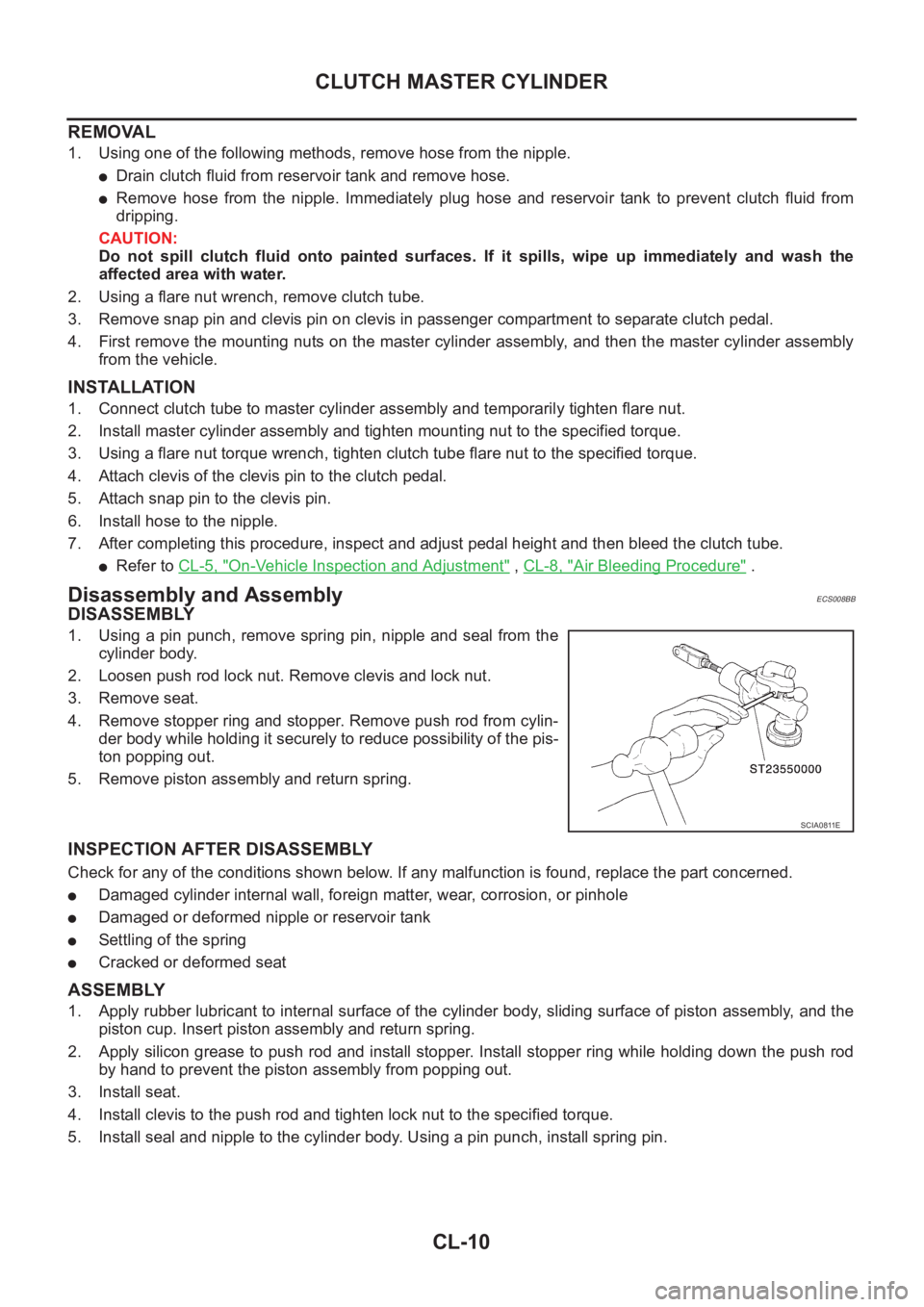

Disassembly and AssemblyECS008BB

DISASSEMBLY

1. Using a pin punch, remove spring pin, nipple and seal from the

cylinder body.

2. Loosen push rod lock nut. Remove clevis and lock nut.

3. Remove seat.

4. Remove stopper ring and stopper. Remove push rod from cylin-

der body while holding it securely to reduce possibility of the pis-

ton popping out.

5. Remove piston assembly and return spring.

INSPECTION AFTER DISASSEMBLY

Check for any of the conditions shown below. If any malfunction is found, replace the part concerned.

●Damaged cylinder internal wall, foreign matter, wear, corrosion, or pinhole

●Damaged or deformed nipple or reservoir tank

●Settling of the spring

●Cracked or deformed seat

ASSEMBLY

1. Apply rubber lubricant to internal surface of the cylinder body, sliding surface of piston assembly, and the

piston cup. Insert piston assembly and return spring.

2. Apply silicon grease to push rod and install stopper. Install stopper ring while holding down the push rod

by hand to prevent the piston assembly from popping out.

3. Install seat.

4. Install clevis to the push rod and tighten lock nut to the specified torque.

5. Install seal and nipple to the cylinder body. Using a pin punch, install spring pin.

SCIA0811E

Page 1969 of 3833

OPERATING CYLINDER

CL-11

D

E

F

G

H

I

J

K

L

MA

B

CL

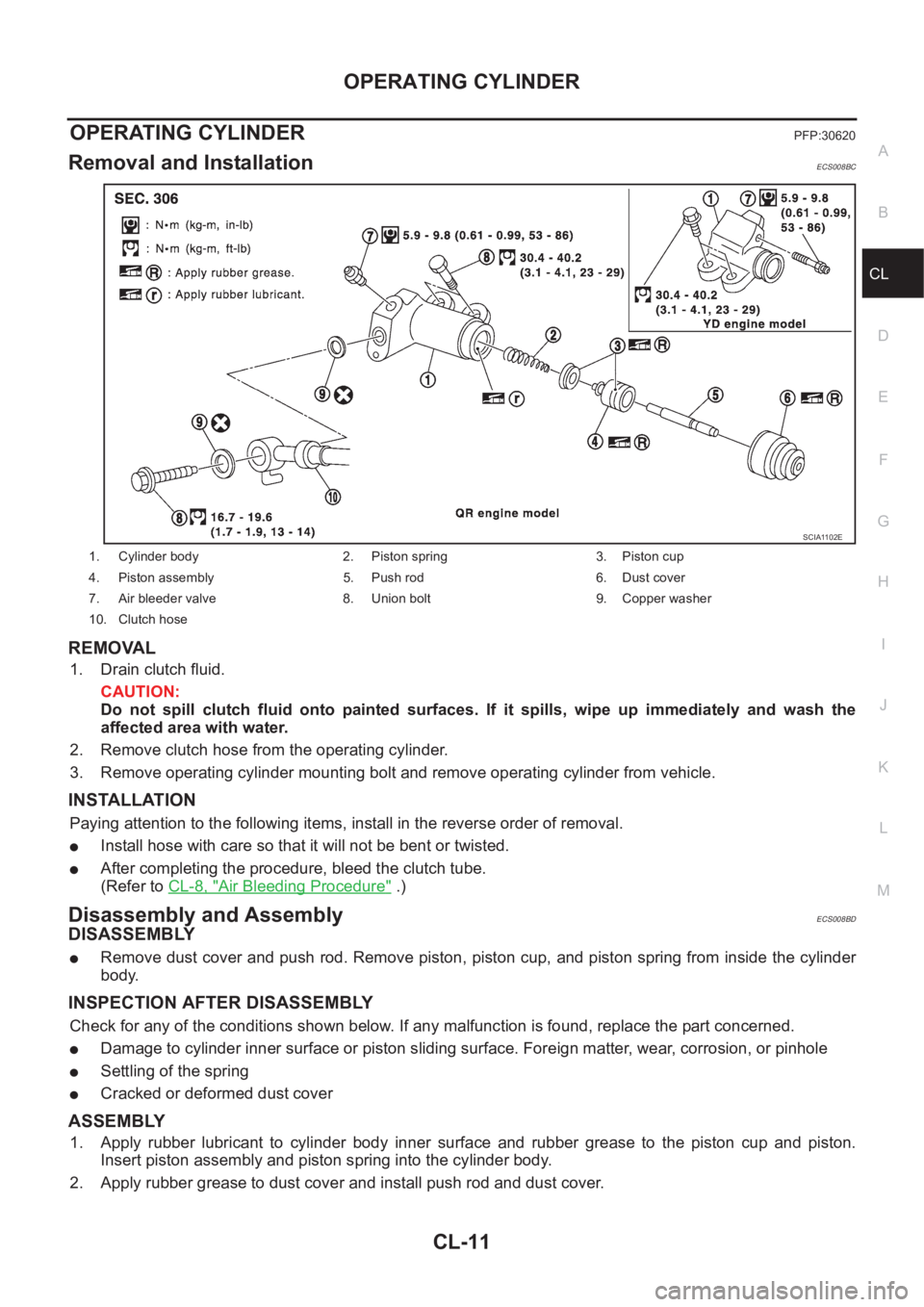

OPERATING CYLINDERPFP:30620

Removal and InstallationECS008BC

REMOVAL

1. Drain clutch fluid.

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the

affected area with water.

2. Remove clutch hose from the operating cylinder.

3. Remove operating cylinder mounting bolt and remove operating cylinder from vehicle.

INSTALLATION

Paying attention to the following items, install in the reverse order of removal.

●Install hose with care so that it will not be bent or twisted.

●After completing the procedure, bleed the clutch tube.

(Refer to CL-8, "

Air Bleeding Procedure" .)

Disassembly and AssemblyECS008BD

DISASSEMBLY

●Remove dust cover and push rod. Remove piston, piston cup, and piston spring from inside the cylinder

body.

INSPECTION AFTER DISASSEMBLY

Check for any of the conditions shown below. If any malfunction is found, replace the part concerned.

●Damage to cylinder inner surface or piston sliding surface. Foreign matter, wear, corrosion, or pinhole

●Settling of the spring

●Cracked or deformed dust cover

ASSEMBLY

1. Apply rubber lubricant to cylinder body inner surface and rubber grease to the piston cup and piston.

Insert piston assembly and piston spring into the cylinder body.

2. Apply rubber grease to dust cover and install push rod and dust cover.

1. Cylinder body 2. Piston spring 3. Piston cup

4. Piston assembly 5. Push rod 6. Dust cover

7. Air bleeder valve 8. Union bolt 9. Copper washer

10. Clutch hose

SCIA1102E

Page 1970 of 3833

CL-12

CLUTCH PIPING

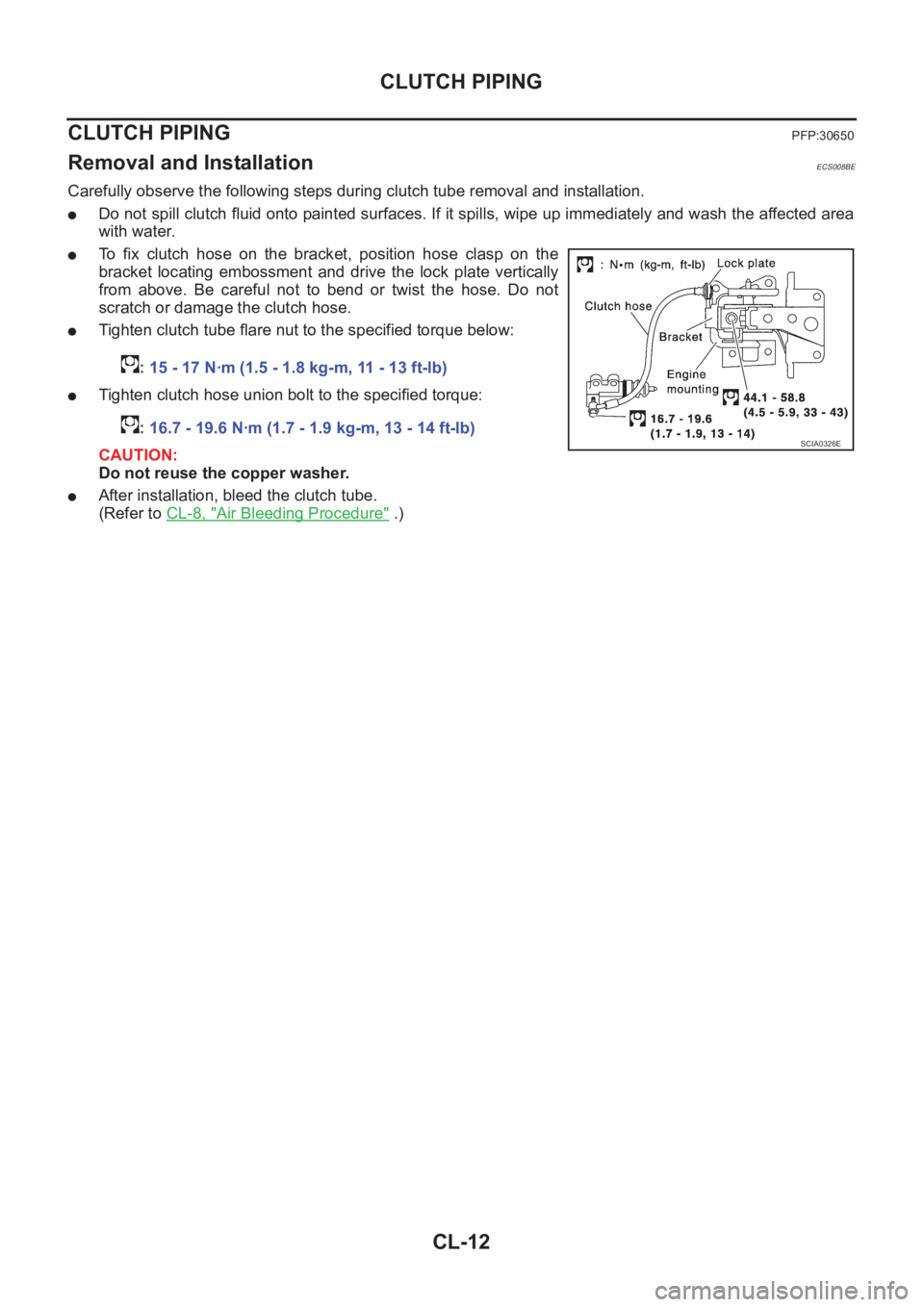

CLUTCH PIPING

PFP:30650

Removal and InstallationECS008BE

Carefully observe the following steps during clutch tube removal and installation.

●Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the affected area

with water.

●To fix clutch hose on the bracket, position hose clasp on the

bracket locating embossment and drive the lock plate vertically

from above. Be careful not to bend or twist the hose. Do not

scratch or damage the clutch hose.

●Tighten clutch tube flare nut to the specified torque below:

●Tighten clutch hose union bolt to the specified torque:

CAUTION:

Do not reuse the copper washer.

●After installation, bleed the clutch tube.

(Refer to CL-8, "

Air Bleeding Procedure" .) : 15 - 17 N·m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

: 16.7 - 19.6 N·m (1.7 - 1.9 kg-m, 13 - 14 ft-lb)

SCIA0326E