reset NISSAN X-TRAIL 2001 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 1480 of 3833

![NISSAN X-TRAIL 2001 Service User Guide EC-1130

[QR20(WITHOUT EURO-OBD)]

ENGINE CONTROL SYSTEM

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve rem NISSAN X-TRAIL 2001 Service User Guide EC-1130

[QR20(WITHOUT EURO-OBD)]

ENGINE CONTROL SYSTEM

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve rem](/img/5/57405/w960_57405-1479.png)

EC-1130

[QR20(WITHOUT EURO-OBD)]

ENGINE CONTROL SYSTEM

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

●During warm-up

●When starting the engine

●During acceleration

●Hot-engine operation

●When selector lever is changed from “N” to “D”

●High-load, high-speed operation

●During deceleration

●During high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can then better reduce CO, HC and NOx emissions. This system uses

heated oxygen sensor 1 in the exhaust manifold to monitor if the engine operation is rich or lean. The ECM

adjusts the injection pulse width according to the sensor voltage signal. For more information about heated

oxygen sensor 1, refer to EC-1229

. This maintains the mixture ratio within the range of stoichiometric (ideal

air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the three way catalyst (manifold). Even if the switching

characteristics of heated oxygen sensor 1 shift, the air-fuel ratio is controlled to stoichiometric by the signal

from heated oxygen sensor 2.

Open Loop Control

The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

●Deceleration and acceleration

●High-load, high-speed operation

●Malfunction of heated oxygen sensor 1 or its circuit

●Insufficient activation of heated oxygen sensor 1 at low engine coolant temperature

●High engine coolant temperature

●During warm-up

●After shifting from “N” to “D”

●When starting the engine

PBIB0121E

Page 1532 of 3833

![NISSAN X-TRAIL 2001 Service User Guide EC-1182

[QR20(WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

–While trying to detect the DTC/1st trip DTC by performing the “DTC Confirmation Procedure”, be sure to

select to “DATA MONITOR (AUTO TRIG)� NISSAN X-TRAIL 2001 Service User Guide EC-1182

[QR20(WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

–While trying to detect the DTC/1st trip DTC by performing the “DTC Confirmation Procedure”, be sure to

select to “DATA MONITOR (AUTO TRIG)�](/img/5/57405/w960_57405-1531.png)

EC-1182

[QR20(WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

–While trying to detect the DTC/1st trip DTC by performing the “DTC Confirmation Procedure”, be sure to

select to “DATA MONITOR (AUTO TRIG)” mode. You can confirm the malfunction at the moment it is

detected.

–While narrowing down the possible causes, CONSULT-II should be set in “DATA MONITOR (AUTO

TRIG)” mode, especially in case the incident is intermittent.

When you are inspecting the circuit by gently shaking (or twisting) the suspicious connectors, components

and harness in the “DTC Confirmation Procedure”, the moment a malfunction is found the DTC/1st trip

DTC will be displayed. (Refer to “Incident Simulation Tests” in GI-23, "

How to Perform Efficient Diagnosis

for an Electrical Incident" .)

2. “MANU TRIG”

–If the malfunction is displayed as soon as “DATA MONITOR” is selected, reset CONSULT-II to “MANU

TRIG”. By selecting “MANU TRIG” you can monitor and store the data. The data can be utilized for further

diagnosis, such as a comparison with the value for the normal operating condition.

CONSULT-II Reference Value in Data MonitorEBS00N46

Remarks:

● Specification data are reference values.

● Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

i.e. Adjust ignition timing with a timing light before monitoring IGN TIMING, because the monitor may show the specification data in

spite of the ignition timing not being adjusted to the specification data. This IGN TIMING monitors the data calculated by the ECM

according to the signals input from the camshaft position sensor and other ignition timing related sensors.

PBIB0197E

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED

●Run engine and compare the CONSULT-II value with tachometer indica-

tion.Almost the same speed as the

tachometer indication.

MAS A/F SE-B1

●Engine: After warming up

●Air conditioner switch: OFF

●Shift lever: N

●No-loadIdle Approx. 1.0 - 1.5V

2,500 rpm Approx. 1.6 - 2.0V

Page 1749 of 3833

![NISSAN X-TRAIL 2001 Service User Guide ENGINE CONTROL SYSTEM

EC-1399

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

System ChartEBS0037B

*: The input signals are sent to the ECM through CAN communication line.

Fuel Injection Control SystemEBS0036G

SYSTEM NISSAN X-TRAIL 2001 Service User Guide ENGINE CONTROL SYSTEM

EC-1399

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

System ChartEBS0037B

*: The input signals are sent to the ECM through CAN communication line.

Fuel Injection Control SystemEBS0036G

SYSTEM](/img/5/57405/w960_57405-1748.png)

ENGINE CONTROL SYSTEM

EC-1399

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

System ChartEBS0037B

*: The input signals are sent to the ECM through CAN communication line.

Fuel Injection Control SystemEBS0036G

SYSTEM DESCRIPTION

Three types of fuel injection control are provided to accommodate engine operating conditions; normal control,

idle control and start control. The ECM determines the appropriate fuel injection control. Under each control,

the amount of fuel injected is adjusted to improve engine performance.

Pulse signals are exchanged between ECM and Electronic Drive Unit (EDU). EDU controls fuel injectors

according to the input signals to adjust the amount of fuel injected to the preset value.

START CONTROL

Input/Output Signal Chart

When the ECM receives a start signal from the ignition switch, the

ECM adapts the fuel injection system for the start control. The

amount of fuel injected at engine starting is a preset program value

in the ECM. The program is determined by the engine speed, engine

coolant temperature and common rail fuel pressure.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches the specific value, and shifts the control to the normal or idle

control.

Input (Sensor) ECM Function Output (Actuator)

●Accelerator pedal position sensor

●Accelerator pedal released position switch

●Common rail fuel pressure sensor

●Fuel temperature sensor

●Engine coolant temperature sensor

●Crankshaft position sensor (TDC)

●Camshaft position sensor

●Vehicle speed sensor

●ESP/TCS/ABS control unit*

●Ignition switch

●Stop L amp s witch

●Air conditioner switch

●Mass air flow sensor

●Park/neutral position switch

●Battery voltage

●Power steering oil pressure switch Fuel injection controlEDU, Fuel injectors and Suction control

valve

Fuel injection timing controlEDU, Fuel injectors and Suction control

valve

Fuel cut controlEDU, Fuel injectors and Suction control

valve

Glow control system Glow relay & glow indictor lamp

On board diagnostic system Malfunction indicator (MI)

EGR volume control EGR volume control valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection

control (start

control)EDU

Fuel injectors

Suction control valve Crankshaft position sensor (TDC) Engine speed

Camshaft position sensor Piston position

Ignition switch Start signal

Common rail fuel pressure sensor Common rail fuel pressure

SEF648S

Page 1787 of 3833

![NISSAN X-TRAIL 2001 Service User Guide TROUBLE DIAGNOSIS

EC-1437

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

–While narrowing down the possible causes, CONSULT-II should be set in “DATA MONITOR (AUTO

TRIG)” mode, especially in case th NISSAN X-TRAIL 2001 Service User Guide TROUBLE DIAGNOSIS

EC-1437

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

–While narrowing down the possible causes, CONSULT-II should be set in “DATA MONITOR (AUTO

TRIG)” mode, especially in case th](/img/5/57405/w960_57405-1786.png)

TROUBLE DIAGNOSIS

EC-1437

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

–While narrowing down the possible causes, CONSULT-II should be set in “DATA MONITOR (AUTO

TRIG)” mode, especially in case the incident is intermittent.

When you are inspecting the circuit by gently shaking (or twisting) the suspicious connectors, components

and harness in the “DTC Confirmation Procedure”, the moment a malfunction is found the DTC will be dis-

played. Refer to GI-23, "

How to Perform Efficient Diagnosis for an Electrical Incident" , “INCIDENT SIMU-

LATION TESTS”.

2. “MANU TRIG”

–If the malfunction is displayed as soon as “DATA MONITOR” is selected, reset CONSULT-II to “MANU

TRIG”. By selecting “MANU TRIG” you can monitor and store the data. The data can be utilized for further

diagnosis, such as a comparison with the value for the normal operating condition.

FUNCTION TEST

This mode is used to inform customers of their vehicle condition of periodic maintenance.

CONSULT-II Reference Value in Data Monitor ModeEBS0037I

Remarks:

● Specification data are reference values.

● Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

SEF720X

MONITOR ITEM CONDITION SPECIFICATION

CKPS-RPM (TDC)

●Tachometer: Connect

●Run engine and compare CONSULT-II value with the tachometer

indicationAlmost the same speed as the

tachometer indication

COOLAN TEMP/S

●Engine: After warming up More than 70°C (158°F)

VHCL SPEED SE

●Turn drive wheels and compare CONSULT-II value with the speed-

ometer indicationAlmost the same speed as the

speedometer indication

FUEL TEMP SEN

●Engine: After warming up More than 40°C (104°F)

ACCEL POS SEN*

●Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released 0.8 - 1.3V

Accelerator pedal: fully depressed More than 3.5V

Page 2666 of 3833

TF-56

TROUBLE DIAGNOSIS

2. COMBINATION METER POWER SUPPLY CIRCUIT INSPECTION

1. Disconnect combination meter connector.

2. Check voltage between the combination meter harness connector M46 terminal No. LHD models: 46 (W/

L) RHD models: 59 (W/L) and body ground.

OK or NG

OK >> Malfunctioning combination meter.

NG >> Check fuse 10A [#11] to combination meter harness and connector.

4WD WARNING LAMP DOES NOT GO OUT SEVERAL SECONDS AFTER ENGINE

STARTED.(4WD MODE INDICATOR LAMP GOES OUT)

1. PERFORM SELF-DIAGNOSIS

Using CONSULT-II perform self-diagnosis.

OK or NG

OK >> No malfunction detected. Perform inspection again.

NG >>

●Determine the location of the malfunction according to the result of Self-diagnosis using CON-

SULT-II. (Malfunction is present in the 4WD system.)

●CONSULT-II does not display 4WD system-related trouble codes. GO TO 2.

2. 4WD CONTROL UNIT CONNECTOR CONNECTION INSPECTION

●Check 4WD control unit connector for proper connection.

OK or NG

OK >> Reconnect the 4WD control unit connector properly and perform inspection again.

NG >> Repair or replace the connector.

HEAVY TIGHT-CORNER BRAKING SYMPTOM OCCURS WHEN THE VEHICLE IS DRIVEN IN

AUTO MODE AND THE STEERING WHEEL IS TURNED FULLY TO EITHER SIDE AFTER THE

ENGINE IS STARTED

1. PERFORM SELF-DIAGNOSIS.

Using CONSULT-II perform self-diagnosis.

OK or NG

OK >> GO TO 2. (No self-diagnosis malfunction indicated.)

NG >> Determine the location of the malfunction according to the result of self-diagnosis using CON-

SULT-II. (Malfunction is present in the 4WD system.)

2. CHECK USING THE DATA MONITOR FUNCTION OF THE CONSULT- II.

●Perform inspection by the data monitor function of the CONSULT-II.

●Check that the operation is in AUTO mode.

●Measure voltage when the accelerator pedal is not depressed. (Accelerator pedal not depressed: approx.

0.5V or lower)

●Measure the current supplied to the 4WD solenoid valve. (Accelerator pedal not depressed: approx. 0A)

OK or NG

OK >> GO TO 3. (No self-diagnosis malfunction indicated.)

NG >>

●Not in AUTO mode. GO TO 3.

●Voltage when accelerator pedal is not depressed is higher than approximately 0.5V.

●4WD solenoid valve current when the accelerator pedal is not depressed is other than 0A.

●Countermeasure: Keep the vehicle idling for approximately 15 minutes before checking again.

(Voltage when accelerator pedal is not depressed will be automatically reset to zero during this

period.)

Page 2726 of 3833

RSU-6

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and Service

EES0007F

Check axle and suspension parts for excessive play, wear, and damage.

●Move rear wheels (RH/LH) to check abnormal free play.

●Retighten all nuts and bolts to the specified torque.

●Check strut for oil leakage and damage.

Wheel AlignmentEES0007G

DESCRIPTION

●Measure wheel alignment under unladen conditions. “Unladen conditions” means that fuel, coolant, and

lubricant are full. However, spare tire, jack, and hand tools should be unloaded.

PRELIMINARY INSPECTION

1. Check the tires for improper air pressure and wear.

2. Check road wheels for runout.

3. Check wheel bearing axial endplay.

4. Check strut operation.

5. Check each mounting point of axle and suspension for looseness and deformation.

6. Check each link and arm for cracks, deformation, and other damage.

7. Check the vehicle posture.

CAMBER

Camber is preset at factory and cannot be adjusted.

●If the camber is not within specification, inspect and replace any damaged or worn rear suspension parts.

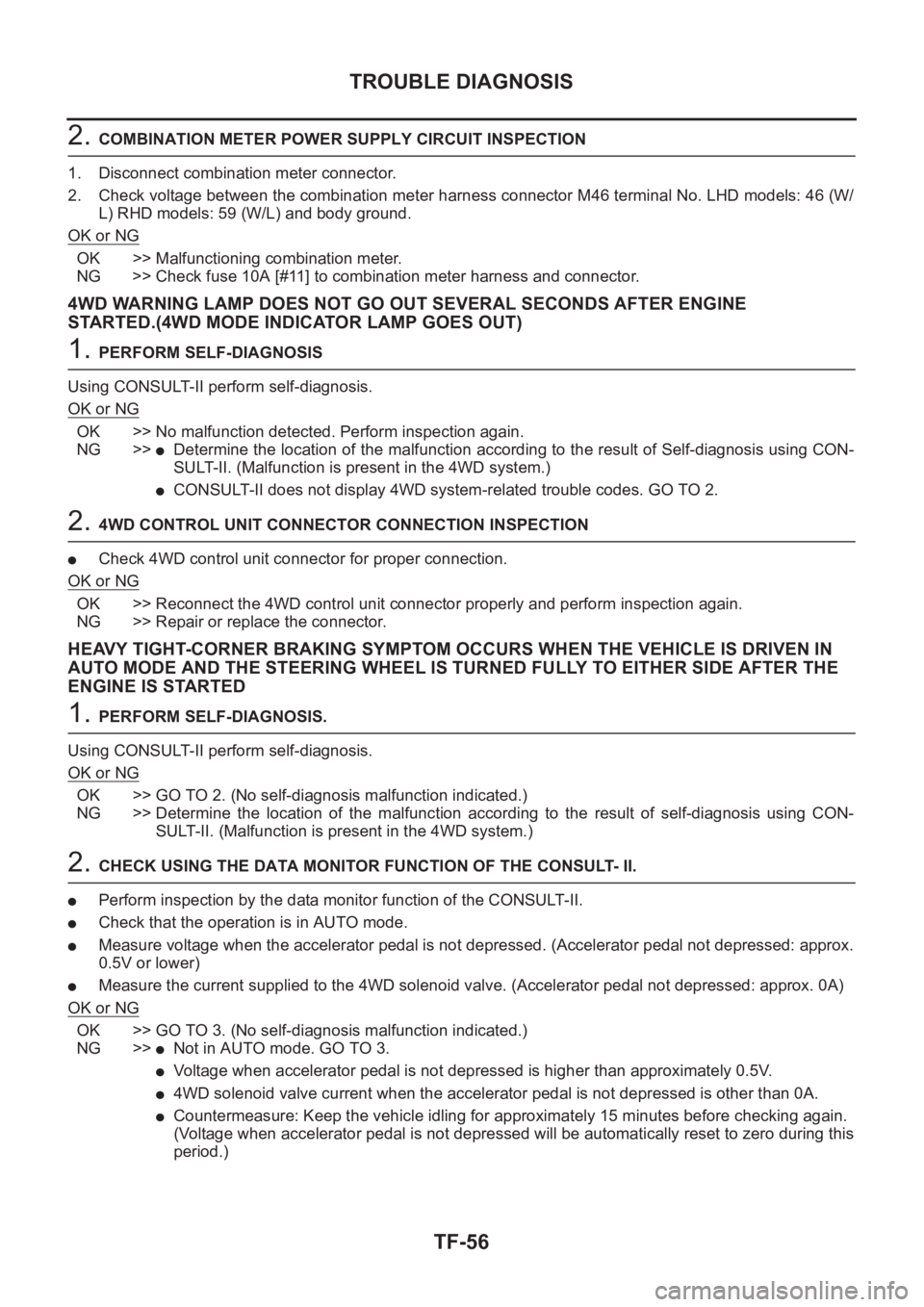

TOE-IN

Measure toe-in using the following procedure.

●Always perform following procedure on a flat surface.

●Make sure that no person is in front of the vehicle before push-

ing it.

1. Bounce rear of vehicle up and down to stabilize the posture.

2. Push the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of tread (rear side) of both tires at the

same height as hub center. This mark is a measuring points.

1. Strut spacer 2. Strut mounting insulator 3. Spring upper seat

4. Upper rubber seat 5. Bound bumper 6. Coil spring

7. Strut 8. Rear axle assembly 9. Rear suspension member

10. Stopper 11. Stopper 12. Eccentric disc

13. Rear parallel link 14. Toe-in adjusting bolt 15. Front parallel link

16. Radius rod 17. Stabilizer bar 18. Clamp

19. Bushing 20. Connecting rod

Camber : RSU-14, "SERVICE DATA AND SPECIFICATIONS (SDS)"

AFA050

Page 2824 of 3833

![NISSAN X-TRAIL 2001 Service User Guide BRC-40

[4WD/ABS]

TROUBLE DIAGNOSIS

2. CHECK USING THE DATA MONITOR FUNCTION OF THE CONSULT- II

●Perform inspection by the data monitor function of the CONSULT-II.

●Check that the operation is in A NISSAN X-TRAIL 2001 Service User Guide BRC-40

[4WD/ABS]

TROUBLE DIAGNOSIS

2. CHECK USING THE DATA MONITOR FUNCTION OF THE CONSULT- II

●Perform inspection by the data monitor function of the CONSULT-II.

●Check that the operation is in A](/img/5/57405/w960_57405-2823.png)

BRC-40

[4WD/ABS]

TROUBLE DIAGNOSIS

2. CHECK USING THE DATA MONITOR FUNCTION OF THE CONSULT- II

●Perform inspection by the data monitor function of the CONSULT-II.

●Check that the operation is in AUTO mode.

●Measure voltage when the accelerator pedal is not depressed. (Accelerator pedal not depressed: Approx.

0.5V or lower)

●Measure the current supplied to the E-TS solenoid valve. (Accelerator pedal not depressed: Approx. 0A)

OK or NG

OK >> GO TO 3. (No self-diagnosis malfunction indicated.)

NG >>

●Not in AUTO mode. GO TO 3.

●Voltage when accelerator pedal is not depressed is higher than approximately 0.5V.

●4WD solenoid valve current when the accelerator pedal is not depressed is other than 0A.

●Countermeasure: Keep the vehicle idling for approximately 15 minutes before checking again.

(Voltage when accelerator pedal is not depressed will be automatically reset to zero during this

period.)

3. INSPECTION USING 4WD MODE CHANGE-OVER SWITCH

●On data monitor screen of the CONSULT-II, check 4WD mode switch.

●Check if the display changes from ## to 2WD mode when the 2WD switch is pressed.

●Check if the display changes from ## to AUTO mode when the AUTO switch is pressed.

●Check if the display changes from ## to LOCK mode when the LOCK switch is pressed.

OK or NG

OK >> No malfunction detected.

NG >>

●Not in AUTO mode. (In 2WD or LOCK mode)

Countermeasure: Slightly depress the accelerator pedal and check that the operation mode

changes to LOCK mode.

●Check circuit between 4WD mode switch harness connector M39 terminal No.1 (BR) and

4WD control unit harness connector E122 terminal No. 27 (BR).

(AUTO mode is not available because a malfunction is present in the 2WD mode harness.)

NOTICE:

Mechanism of 4WD mode change-over

●2WD mode: Operation changes to 2WD mode when 4WD/ABS control unit harness connector

E122 terminal No. 27 (BR) is shorted to ground.

●AUTO mode: Operation changes to AUTO mode when 4WD/ABS control unit harness connec-

tor E122 terminals No. 27 (BR) and No. 26 (L) is shorted to ground.

●LOCK mode: Operation changes to LOCK mode when 4WD/ABS control unit harness connec-

tor E122 terminal No. 26 (L) is shorted to ground.

Page 2828 of 3833

![NISSAN X-TRAIL 2001 Service User Guide BRC-44

[4WD/ABS]

TROUBLE DIAGNOSIS

2. 4WD/ABS CONTROL UNIT CONNECTOR CONNECTION INSPECTION

●Remove glove box on the passenger side and check 4WD/ABS control unit connector for proper connec-

tion.

I NISSAN X-TRAIL 2001 Service User Guide BRC-44

[4WD/ABS]

TROUBLE DIAGNOSIS

2. 4WD/ABS CONTROL UNIT CONNECTOR CONNECTION INSPECTION

●Remove glove box on the passenger side and check 4WD/ABS control unit connector for proper connec-

tion.

I](/img/5/57405/w960_57405-2827.png)

BRC-44

[4WD/ABS]

TROUBLE DIAGNOSIS

2. 4WD/ABS CONTROL UNIT CONNECTOR CONNECTION INSPECTION

●Remove glove box on the passenger side and check 4WD/ABS control unit connector for proper connec-

tion.

Is inspection result OK?

YES >> 4WD/ABS control unit connector is properly connected.

NO >> Reconnect the 4WD/ABS control module connector properly and perform inspection again.

Heavy Tight-corner Braking Symptom Occurs When The Vehicle Is Driven In

Auto Mode And The Steering Wheel Is Turned Fully To Either Side After The

Engine Is Started.

EFS001BT

1. USING CONSULT, PERFORM OR SELF-DIAGNOSIS

Heavy tight-corner braking symptom occurs when the vehicle is driven in AUTO mode and the steering wheel

is turned fully to either side after the engine is started.

Is inspection result OK?

YES >> GO TO 2. (No self-diagnosis malfunction indicated.)

NO >> Determine the location of the malfunction according to the result of self-diagnosis using CON-

SULT-II. (Malfunction is present in the 4WD system.)

2. CHECK USING THE DATA MONITOR FUNCTION OF THE CONSULT-II

●Perform inspection by the data monitor function of the CONSULT-II.

●Check that the operation is in AUTO mode.

●Measure voltage when the accelerator pedal is not depressed. (Accelerator pedal not depressed: Approx.

0.5V or lower)

●Measure the current supplied to the E-TS solenoid valve. (Accelerator pedal not depressed: Approx. 0A)

Is inspection result OK?

YES >> GO TO 3. (No self-diagnosis malfunction indicated.)

NO >>

●Not in AUTO mode. GO TO 3.

●Voltage when accelerator pedal is not depressed is higher than approximately 0.5V.

●E-TS solenoid valve current when accelerator pedal is not depressed is other than 0A.

●Countermeasure: Keep the vehicle idling for approximately 15 minutes before checking again.

(Voltage when accelerator pedal is not depressed will be automatically reset to zero during this

period.)

Page 2917 of 3833

STEERING WHEEL

PS-7

C

D

E

F

H

I

J

K

L

MA

B

PS

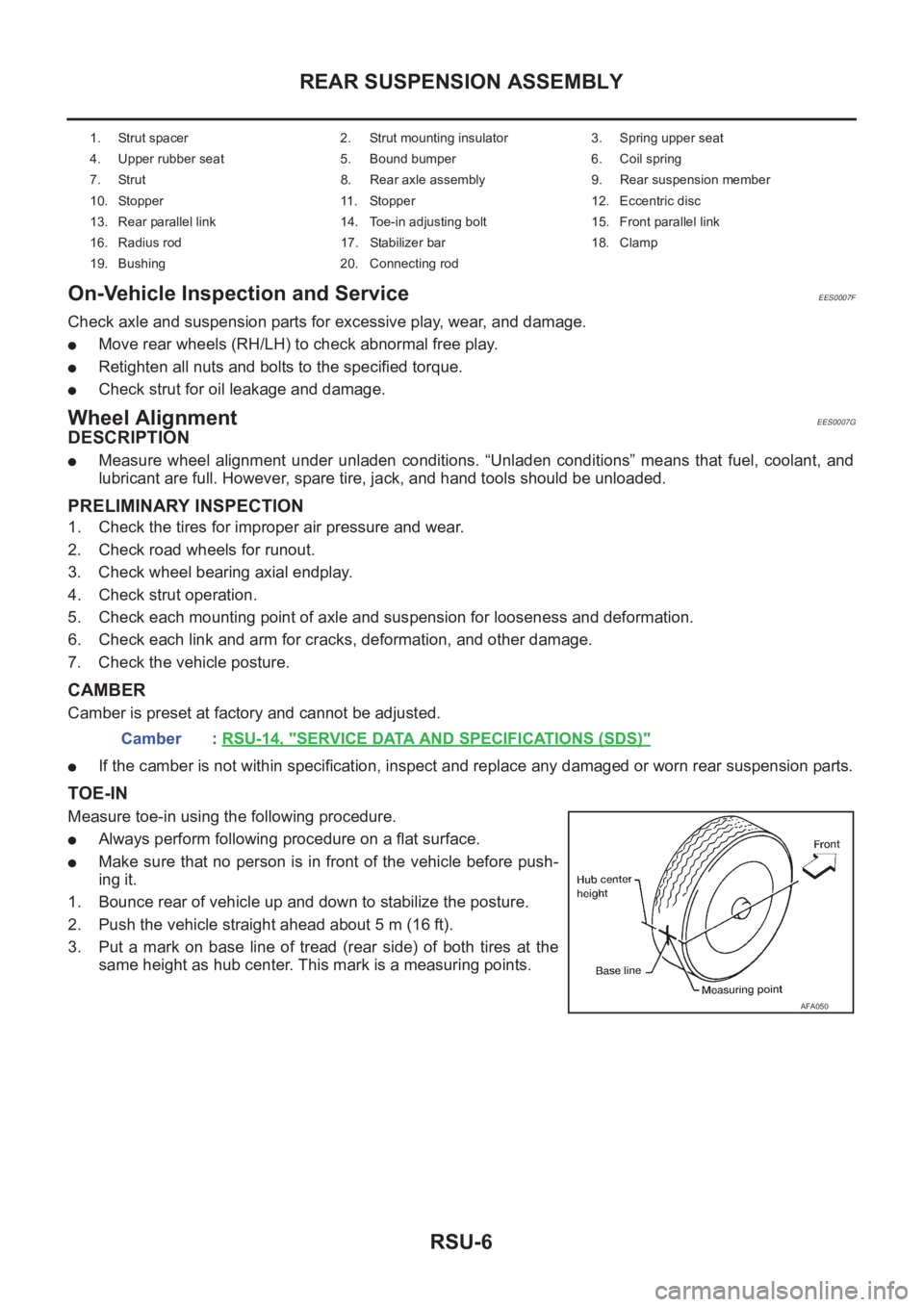

●Start engine. With engine at idle, turn steering wheel from stop

to stop and measure steering angles.

●If angles are outside specification, measure rack stroke.

●If rack stroke is outside of specification, disassemble steering

gear to check rack stroke.

●Steering angles are not adjustable. If any of steering angles is different from specified value, check steer-

ing gear, the column and the front suspension components for wear or damage. If any abnormality exists,

replace the malfunctioning parts.

Removal and InstallationEGS0004F

REMOVAL

1. Remove air bag module. Refer to SRS-29, "DRIVER AIR BAG MODULE" .

2. Remove horn connector.

3. Remove steering wheel mounting nut and paint mating marks on steering wheel body and top of column

shaft.

4. Using a steering wheel puller, remove steering wheel.

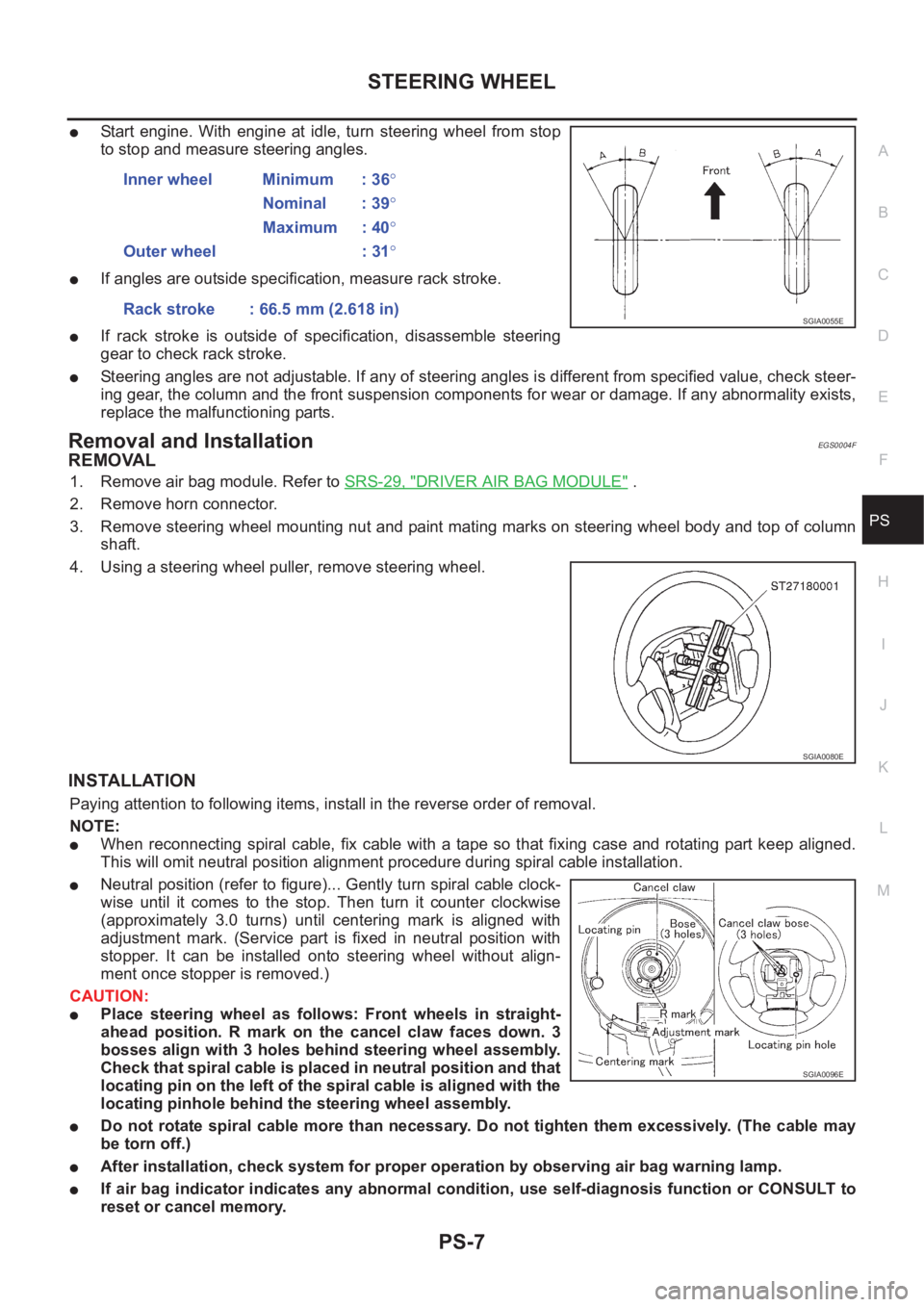

INSTALLATION

Paying attention to following items, install in the reverse order of removal.

NOTE:

●When reconnecting spiral cable, fix cable with a tape so that fixing case and rotating part keep aligned.

This will omit neutral position alignment procedure during spiral cable installation.

●Neutral position (refer to figure)... Gently turn spiral cable clock-

wise until it comes to the stop. Then turn it counter clockwise

(approximately 3.0 turns) until centering mark is aligned with

adjustment mark. (Service part is fixed in neutral position with

stopper. It can be installed onto steering wheel without align-

ment once stopper is removed.)

CAUTION:

●Place steering wheel as follows: Front wheels in straight-

ahead position. R mark on the cancel claw faces down. 3

bosses align with 3 holes behind steering wheel assembly.

Check that spiral cable is placed in neutral position and that

locating pin on the left of the spiral cable is aligned with the

locating pinhole behind the steering wheel assembly.

●Do not rotate spiral cable more than necessary. Do not tighten them excessively. (The cable may

be torn off.)

●After installation, check system for proper operation by observing air bag warning lamp.

●If air bag indicator indicates any abnormal condition, use self-diagnosis function or CONSULT to

reset or cancel memory.Inner wheel Minimum : 36°

Nominal : 39°

Maximum : 40°

Outer wheel : 31°

Rack stroke : 66.5 mm (2.618 in)

SGIA0055E

SGIA0080E

SGIA0096E

Page 3016 of 3833

![NISSAN X-TRAIL 2001 Service User Guide SRS-14

TROUBLE DIAGNOSIS

CONSULT-II Function

EHS000O6

DIAGNOSIS MODE FOR CONSULT-II

●“SELF-DIAG [CURRENT]”

A current Self-diagnosis result (also indicated by the number of warning lam NISSAN X-TRAIL 2001 Service User Guide SRS-14

TROUBLE DIAGNOSIS

CONSULT-II Function

EHS000O6

DIAGNOSIS MODE FOR CONSULT-II

●“SELF-DIAG [CURRENT]”

A current Self-diagnosis result (also indicated by the number of warning lam](/img/5/57405/w960_57405-3015.png)

SRS-14

TROUBLE DIAGNOSIS

CONSULT-II Function

EHS000O6

DIAGNOSIS MODE FOR CONSULT-II

●“SELF-DIAG [CURRENT]”

A current Self-diagnosis result (also indicated by the number of warning lamp flashes in the Diagnosis

mode) is displayed on the CONSULT-II screen in real time. This refers to a malfunctioning part requiring

repairs.

●“SELF-DIAG [PAST]”

Diagnosis results previously stored in the memory are displayed on the CONSULT-II screen. The stored

results are not erased until memory erasing is executed.

●“TROUBLE DIAG RECORD”

With TROUBLE DIAG RECORD, diagnosis results previously erased by a reset operation can be dis-

played on the CONSULT-II screen.

●“ECU DISCRIMINATED NO.”

The diagnosis sensor unit for each vehicle model is assigned with its own, individual classification num-

ber. Refer to SRS-40, "

ECU DISCRIMINATED NO." This number will be displayed on the CONSULT-II

screen. When replacing the diagnosis sensor unit, refer to the part number for the compatibility. After

installation, replacement with a correct unit can be checked by confirming this classification number on the

CONSULT-II screen.

HOW TO CHANGE SELF-DIAGNOSIS MODE WITH CONSULT-II

From User Mode to Diagnosis Mode

After selecting “AIR BAG” on the “SELECT SYSTEM” screen, User mode automatically changes to Diagnosis

mode.

From Diagnosis Mode to User Mode

To return to User mode from Diagnosis mode, touch “BACK” key of CONSULT-II until “SELECT SYSTEM”

appears, Diagnosis mode automatically changes to User mode.

SRS803

SRS804