NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 2061 of 3833

REVERSE IDLER SHAFT AND GEARS

MT-85

D

E

F

G

H

I

J

K

L

MA

B

MT

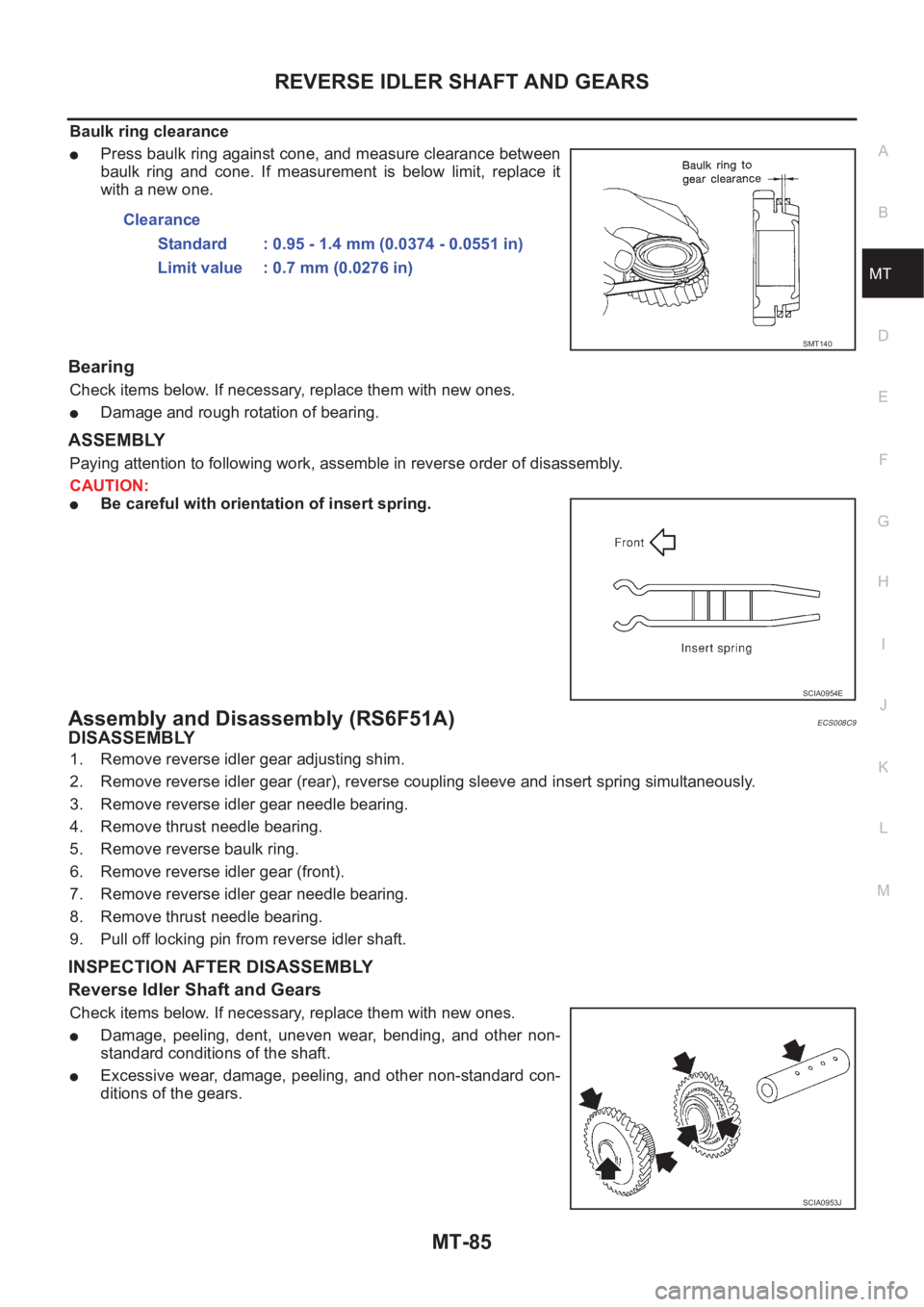

Baulk ring clearance

●Press baulk ring against cone, and measure clearance between

baulk ring and cone. If measurement is below limit, replace it

with a new one.

Bearing

Check items below. If necessary, replace them with new ones.

●Damage and rough rotation of bearing.

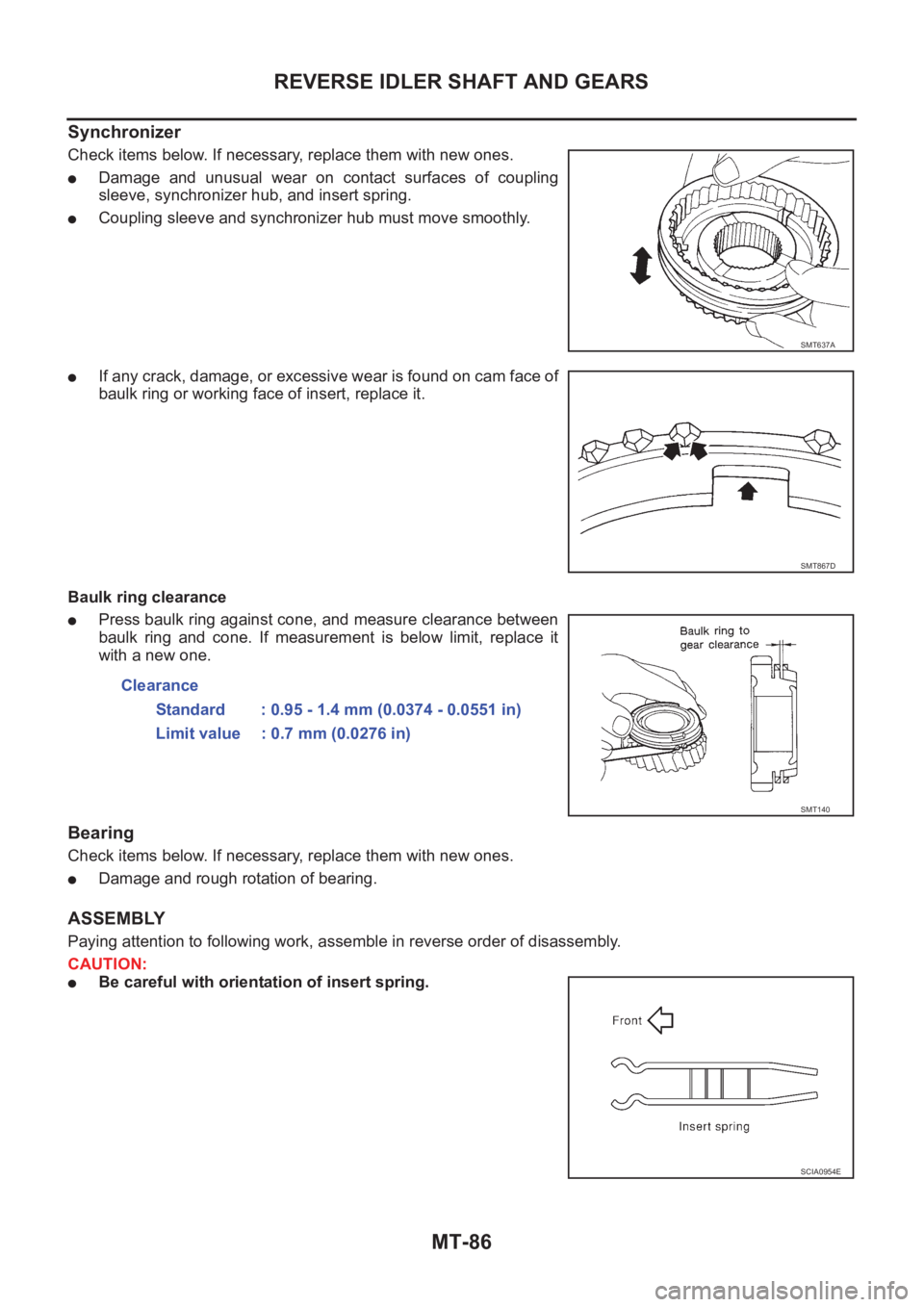

ASSEMBLY

Paying attention to following work, assemble in reverse order of disassembly.

CAUTION:

●Be careful with orientation of insert spring.

Assembly and Disassembly (RS6F51A)ECS008C9

DISASSEMBLY

1. Remove reverse idler gear adjusting shim.

2. Remove reverse idler gear (rear), reverse coupling sleeve and insert spring simultaneously.

3. Remove reverse idler gear needle bearing.

4. Remove thrust needle bearing.

5. Remove reverse baulk ring.

6. Remove reverse idler gear (front).

7. Remove reverse idler gear needle bearing.

8. Remove thrust needle bearing.

9. Pull off locking pin from reverse idler shaft.

INSPECTION AFTER DISASSEMBLY

Reverse Idler Shaft and Gears

Check items below. If necessary, replace them with new ones.

●Damage, peeling, dent, uneven wear, bending, and other non-

standard conditions of the shaft.

●Excessive wear, damage, peeling, and other non-standard con-

ditions of the gears.Clearance

Standard : 0.95 - 1.4 mm (0.0374 - 0.0551 in)

Limit value : 0.7 mm (0.0276 in)

SMT140

SCIA0954E

SCIA0953J

Page 2062 of 3833

MT-86

REVERSE IDLER SHAFT AND GEARS

Synchronizer

Check items below. If necessary, replace them with new ones.

●Damage and unusual wear on contact surfaces of coupling

sleeve, synchronizer hub, and insert spring.

●Coupling sleeve and synchronizer hub must move smoothly.

●If any crack, damage, or excessive wear is found on cam face of

baulk ring or working face of insert, replace it.

Baulk ring clearance

●Press baulk ring against cone, and measure clearance between

baulk ring and cone. If measurement is below limit, replace it

with a new one.

Bearing

Check items below. If necessary, replace them with new ones.

●Damage and rough rotation of bearing.

ASSEMBLY

Paying attention to following work, assemble in reverse order of disassembly.

CAUTION:

●Be careful with orientation of insert spring.

SMT637A

SMT867D

Clearance

Standard : 0.95 - 1.4 mm (0.0374 - 0.0551 in)

Limit value : 0.7 mm (0.0276 in)

SMT140

SCIA0954E

Page 2063 of 3833

FINAL DRIVE

MT-87

D

E

F

G

H

I

J

K

L

MA

B

MT

FINAL DRIVEPFP:38411

Assembly and Disassembly (RS5F51A)ECS008CA

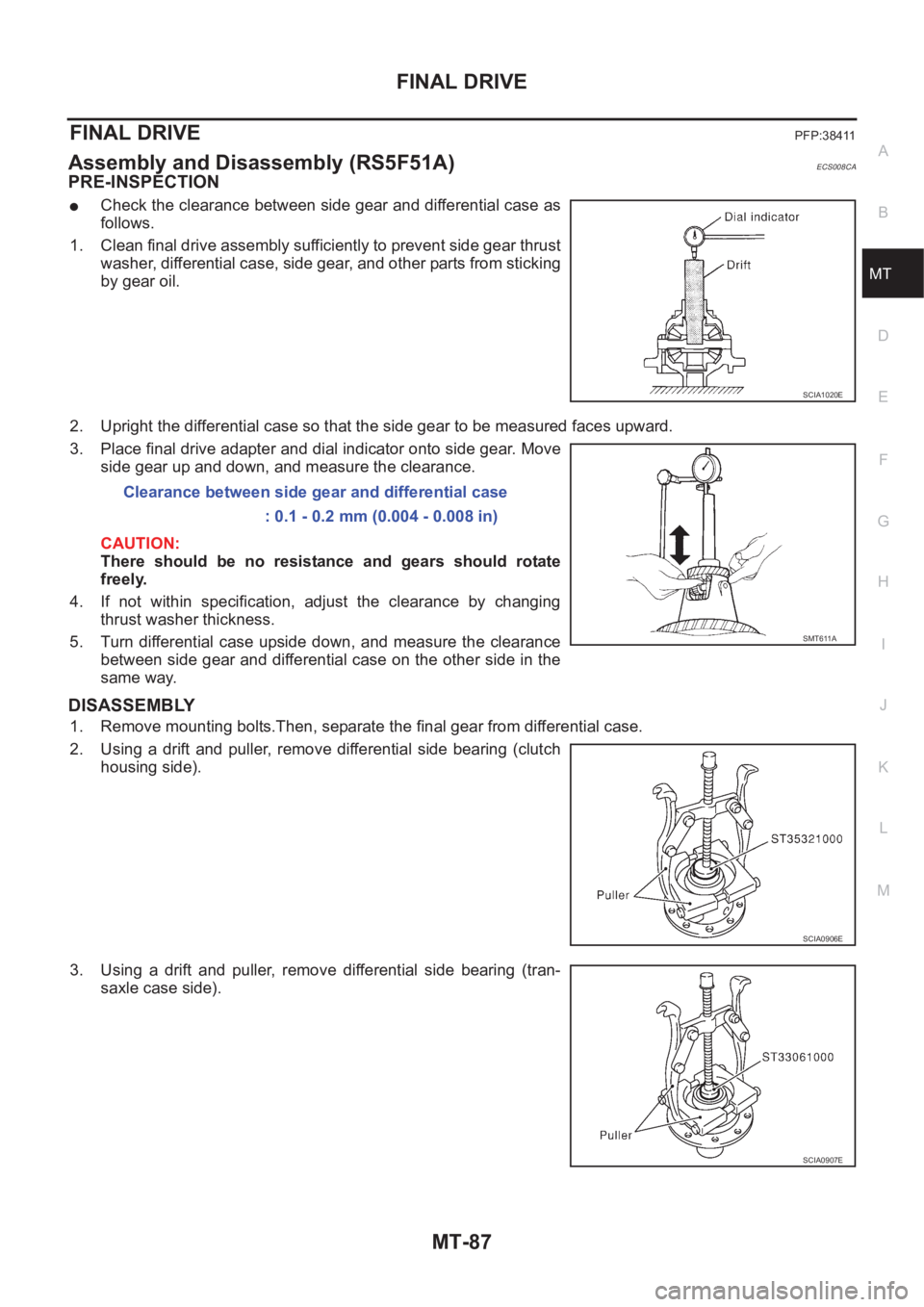

PRE-INSPECTION

●Check the clearance between side gear and differential case as

follows.

1. Clean final drive assembly sufficiently to prevent side gear thrust

washer, differential case, side gear, and other parts from sticking

by gear oil.

2. Upright the differential case so that the side gear to be measured faces upward.

3. Place final drive adapter and dial indicator onto side gear. Move

side gear up and down, and measure the clearance.

CAUTION:

There should be no resistance and gears should rotate

freely.

4. If not within specification, adjust the clearance by changing

thrust washer thickness.

5. Turn differential case upside down, and measure the clearance

between side gear and differential case on the other side in the

same way.

DISASSEMBLY

1. Remove mounting bolts.Then, separate the final gear from differential case.

2. Using a drift and puller, remove differential side bearing (clutch

housing side).

3. Using a drift and puller, remove differential side bearing (tran-

saxle case side).

SCIA1020E

Clearance between side gear and differential case

: 0.1 - 0.2 mm (0.004 - 0.008 in)

SMT611A

SCIA0906E

SCIA0907E

Page 2064 of 3833

MT-88

FINAL DRIVE

4. Using a pin punch, pull out lock pin and pinion mate shaft.

5. Rotate pinion mate gears, and remove pinion mate gears, pinion

mate thrust washers, side gears, and side gear thrust washers

from differential case.

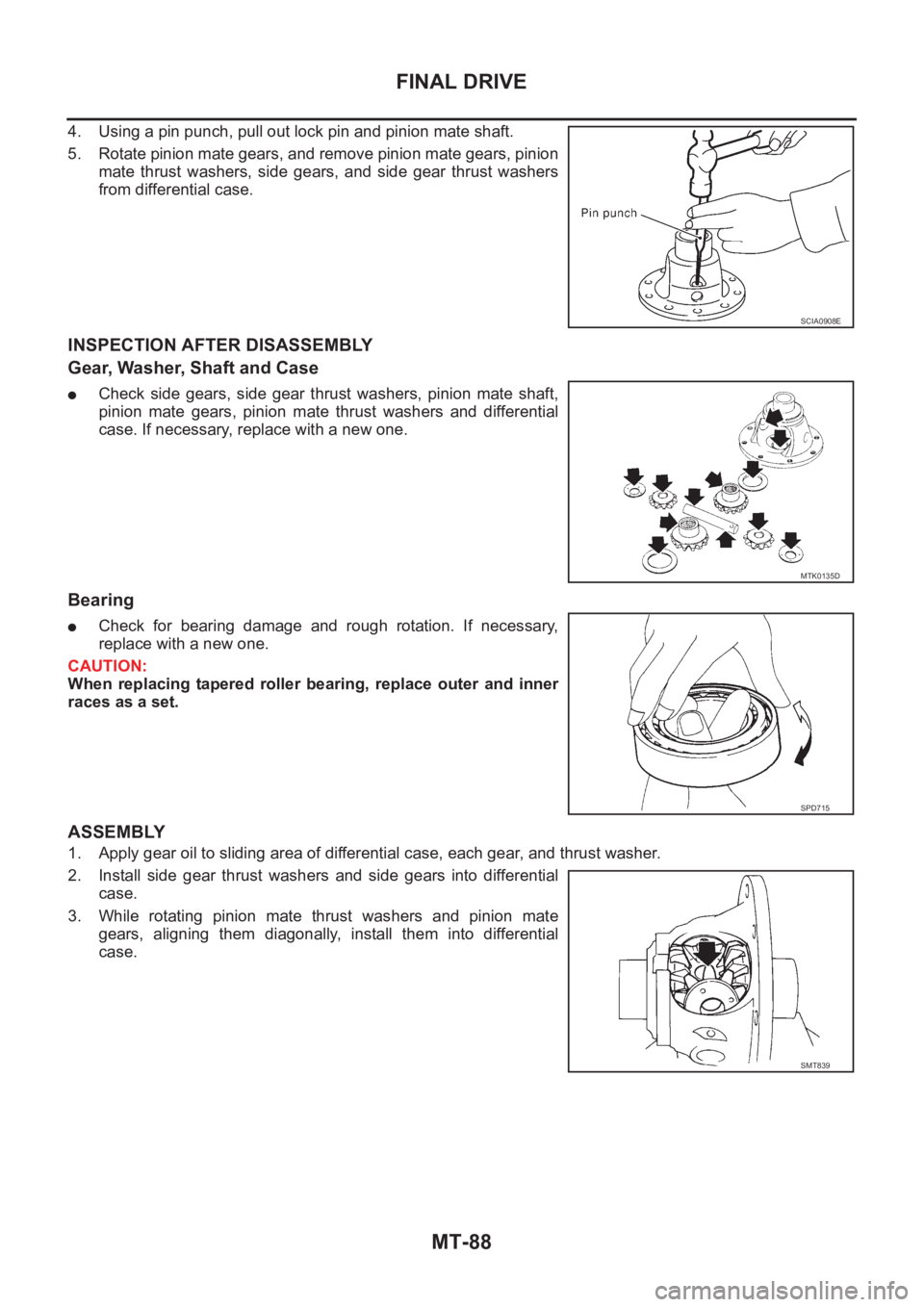

INSPECTION AFTER DISASSEMBLY

Gear, Washer, Shaft and Case

●Check side gears, side gear thrust washers, pinion mate shaft,

pinion mate gears, pinion mate thrust washers and differential

case. If necessary, replace with a new one.

Bearing

●Check for bearing damage and rough rotation. If necessary,

replace with a new one.

CAUTION:

When replacing tapered roller bearing, replace outer and inner

races as a set.

ASSEMBLY

1. Apply gear oil to sliding area of differential case, each gear, and thrust washer.

2. Install side gear thrust washers and side gears into differential

case.

3. While rotating pinion mate thrust washers and pinion mate

gears, aligning them diagonally, install them into differential

case.

SCIA0908E

MTK0135D

SPD715

SMT839

Page 2065 of 3833

FINAL DRIVE

MT-89

D

E

F

G

H

I

J

K

L

MA

B

MT

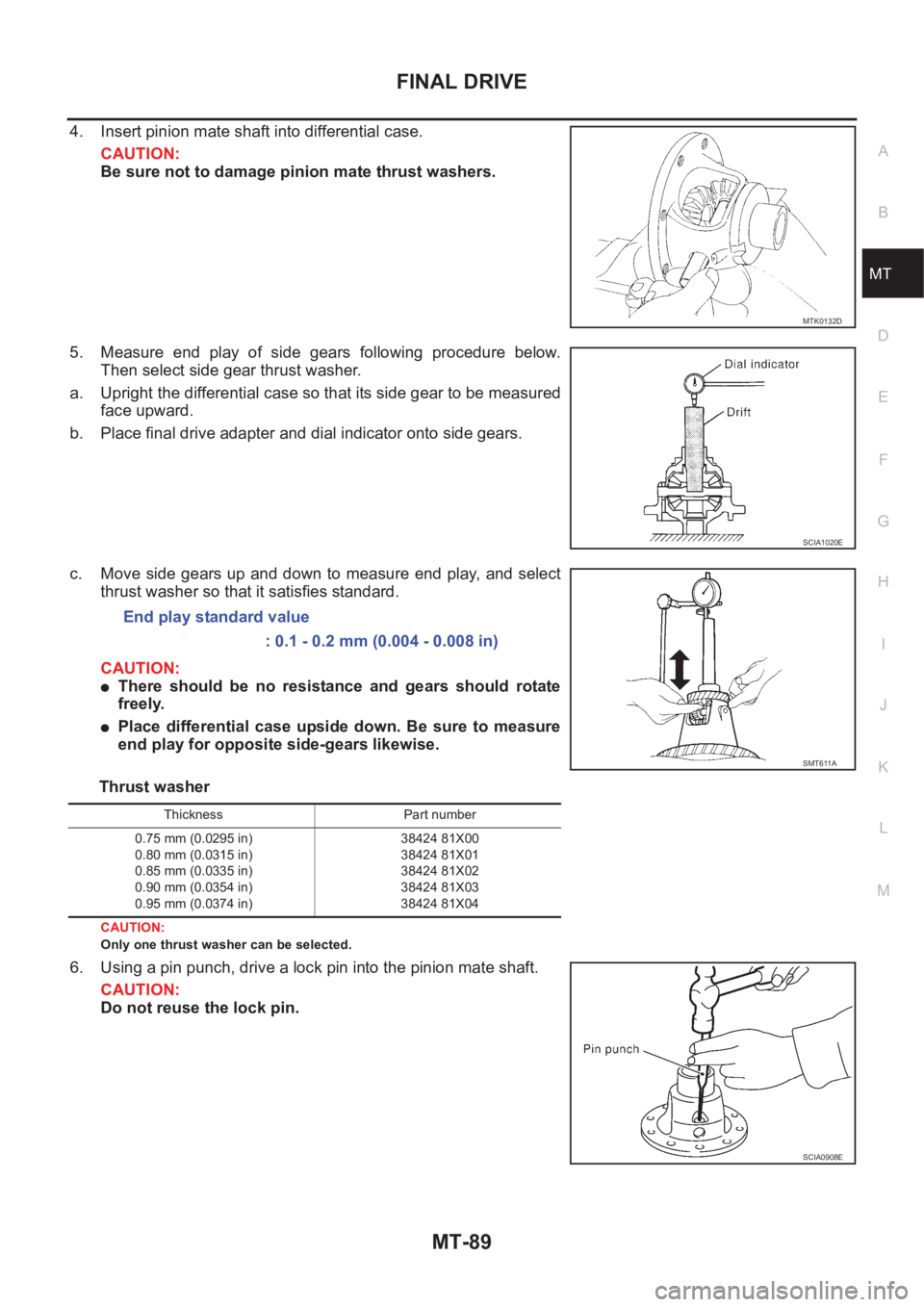

4. Insert pinion mate shaft into differential case.

CAUTION:

Be sure not to damage pinion mate thrust washers.

5. Measure end play of side gears following procedure below.

Then select side gear thrust washer.

a. Upright the differential case so that its side gear to be measured

face upward.

b. Place final drive adapter and dial indicator onto side gears.

c. Move side gears up and down to measure end play, and select

thrust washer so that it satisfies standard.

CAUTION:

●There should be no resistance and gears should rotate

freely.

●Place differential case upside down. Be sure to measure

end play for opposite side-gears likewise.

Thrust washer

CAUTION:

Only one thrust washer can be selected.

6. Using a pin punch, drive a lock pin into the pinion mate shaft.

CAUTION:

Do not reuse the lock pin.

MTK0132D

SCIA1020E

End play standard value

: 0.1 - 0.2 mm (0.004 - 0.008 in)

SMT611A

Thickness Part number

0.75 mm (0.0295 in)

0.80 mm (0.0315 in)

0.85 mm (0.0335 in)

0.90 mm (0.0354 in)

0.95 mm (0.0374 in)38424 81X00

38424 81X01

38424 81X02

38424 81X03

38424 81X04

SCIA0908E

Page 2066 of 3833

MT-90

FINAL DRIVE

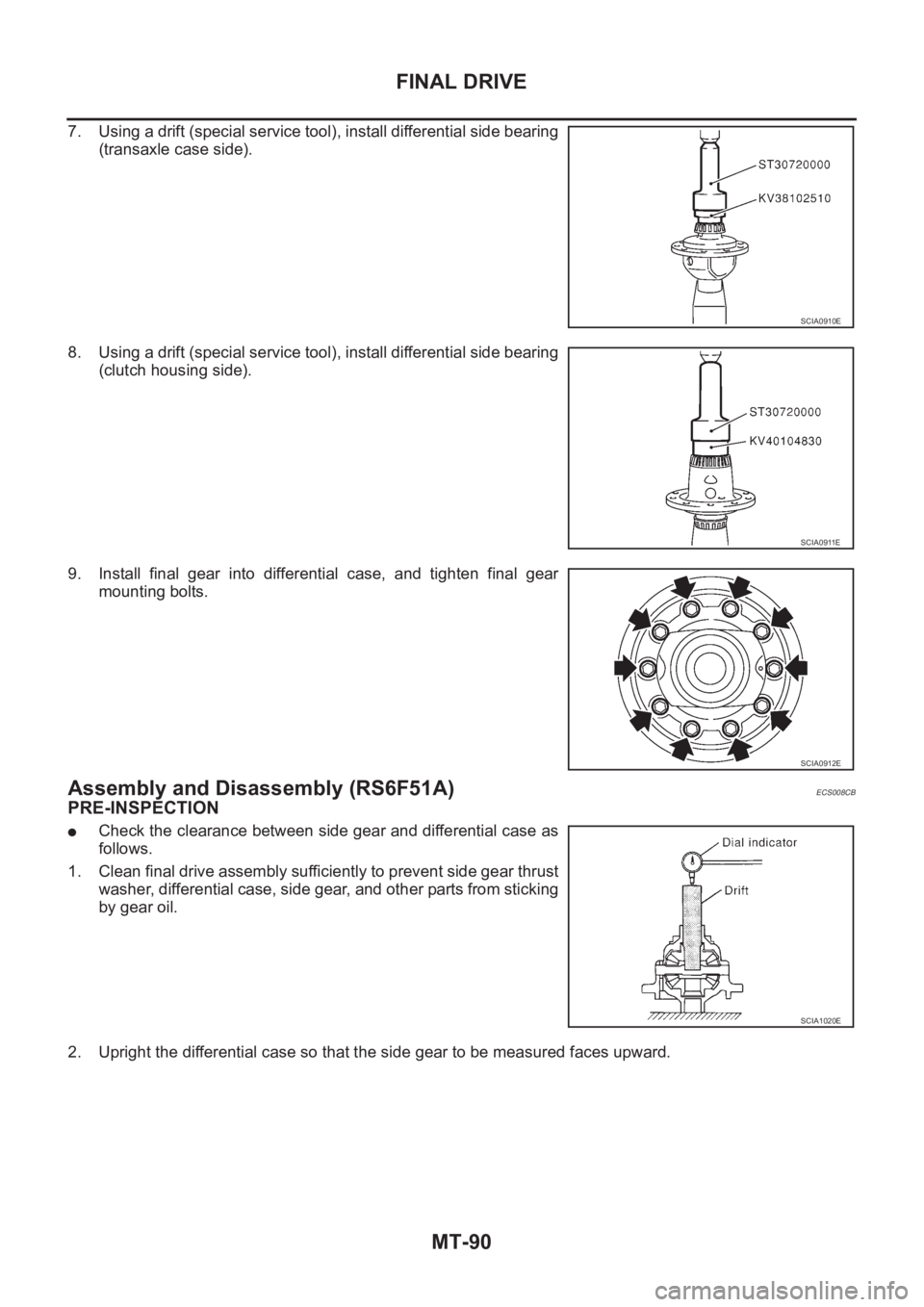

7. Using a drift (special service tool), install differential side bearing

(transaxle case side).

8. Using a drift (special service tool), install differential side bearing

(clutch housing side).

9. Install final gear into differential case, and tighten final gear

mounting bolts.

Assembly and Disassembly (RS6F51A)ECS008CB

PRE-INSPECTION

●Check the clearance between side gear and differential case as

follows.

1. Clean final drive assembly sufficiently to prevent side gear thrust

washer, differential case, side gear, and other parts from sticking

by gear oil.

2. Upright the differential case so that the side gear to be measured faces upward.

SCIA0910E

SCIA0911E

SCIA0912E

SCIA1020E

Page 2067 of 3833

FINAL DRIVE

MT-91

D

E

F

G

H

I

J

K

L

MA

B

MT

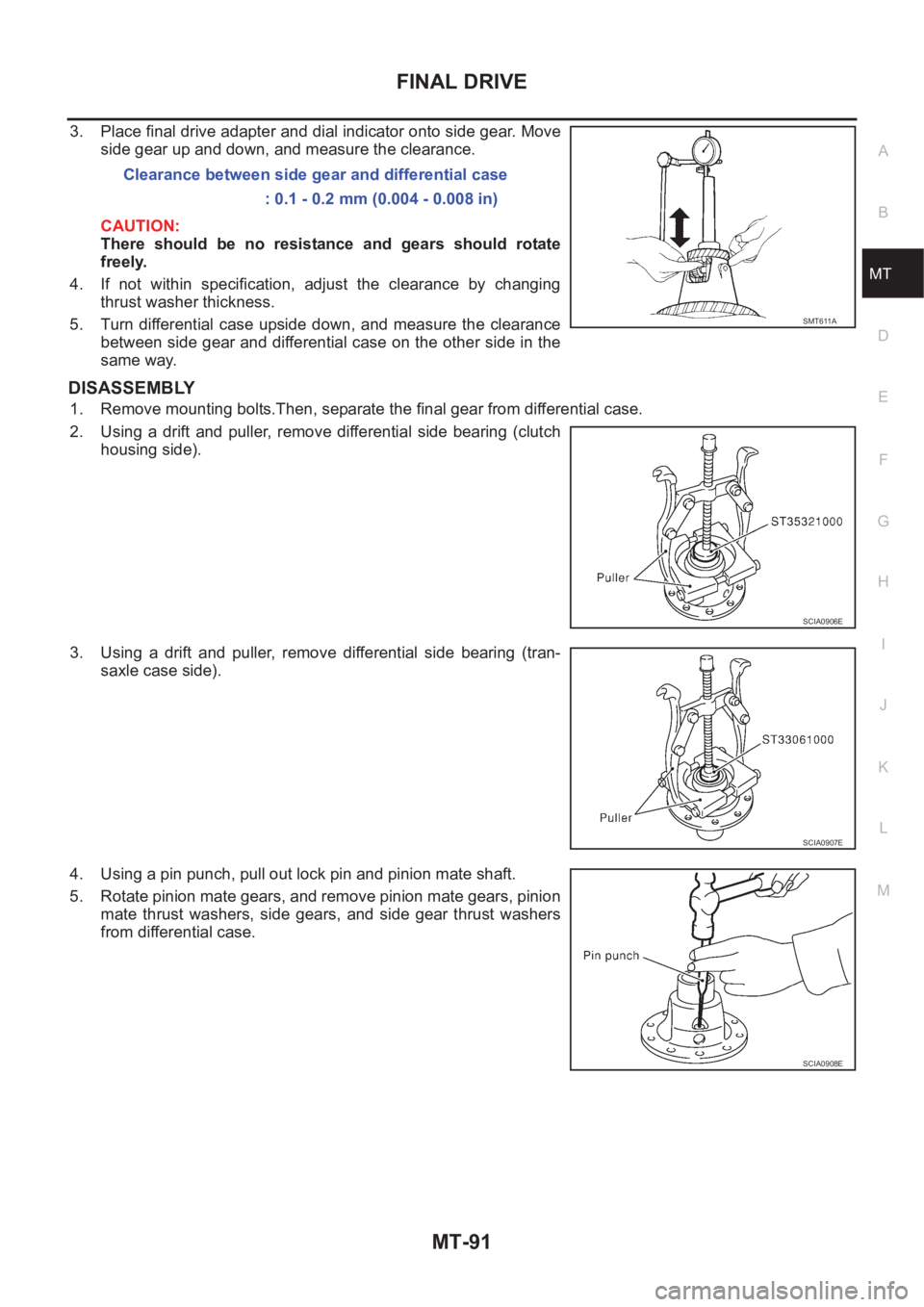

3. Place final drive adapter and dial indicator onto side gear. Move

side gear up and down, and measure the clearance.

CAUTION:

There should be no resistance and gears should rotate

freely.

4. If not within specification, adjust the clearance by changing

thrust washer thickness.

5. Turn differential case upside down, and measure the clearance

between side gear and differential case on the other side in the

same way.

DISASSEMBLY

1. Remove mounting bolts.Then, separate the final gear from differential case.

2. Using a drift and puller, remove differential side bearing (clutch

housing side).

3. Using a drift and puller, remove differential side bearing (tran-

saxle case side).

4. Using a pin punch, pull out lock pin and pinion mate shaft.

5. Rotate pinion mate gears, and remove pinion mate gears, pinion

mate thrust washers, side gears, and side gear thrust washers

from differential case.Clearance between side gear and differential case

: 0.1 - 0.2 mm (0.004 - 0.008 in)

SMT611A

SCIA0906E

SCIA0907E

SCIA0908E

Page 2068 of 3833

MT-92

FINAL DRIVE

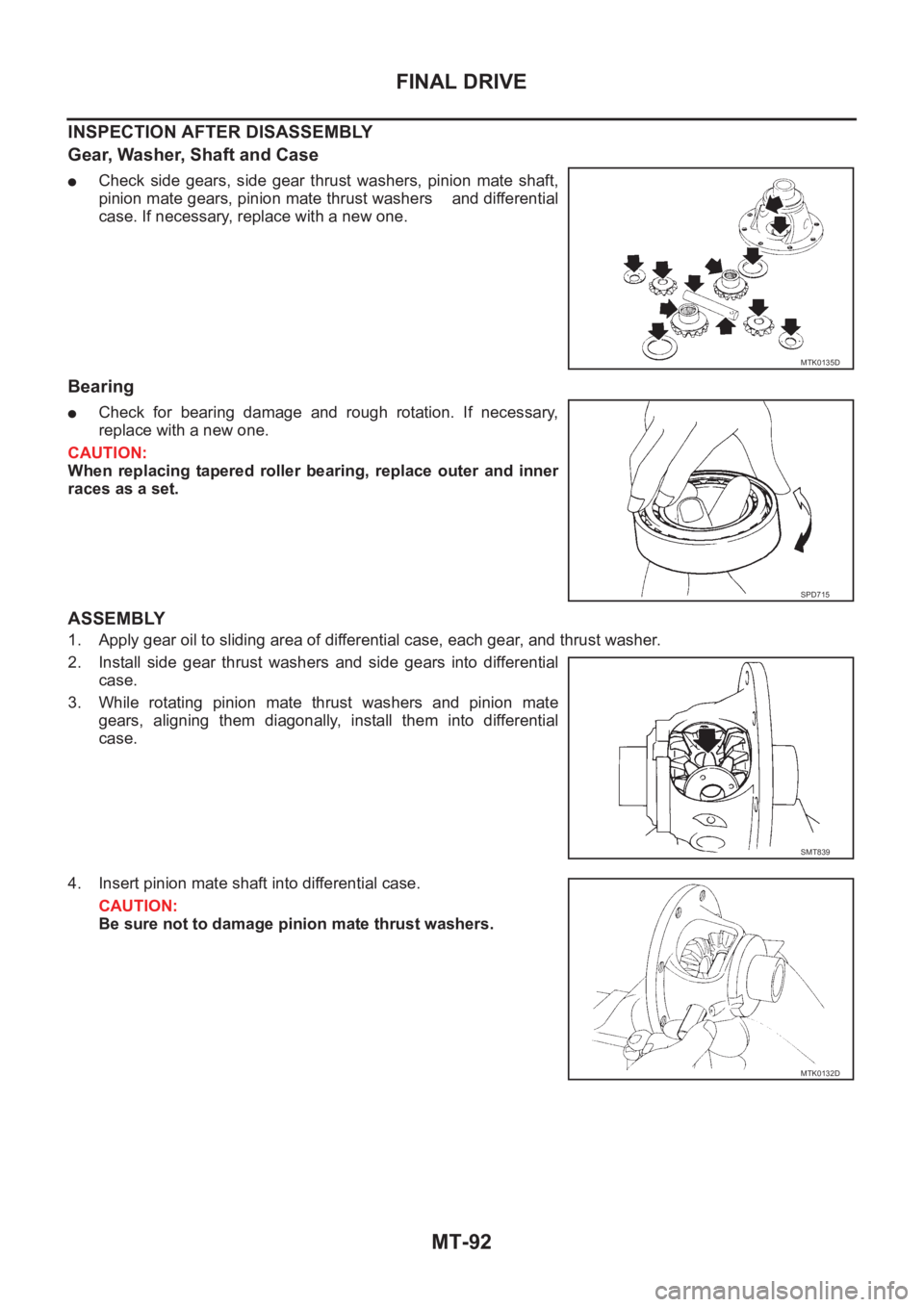

INSPECTION AFTER DISASSEMBLY

Gear, Washer, Shaft and Case

●Check side gears, side gear thrust washers, pinion mate shaft,

pinion mate gears, pinion mate thrust washers and differential

case. If necessary, replace with a new one.

Bearing

●Check for bearing damage and rough rotation. If necessary,

replace with a new one.

CAUTION:

When replacing tapered roller bearing, replace outer and inner

races as a set.

ASSEMBLY

1. Apply gear oil to sliding area of differential case, each gear, and thrust washer.

2. Install side gear thrust washers and side gears into differential

case.

3. While rotating pinion mate thrust washers and pinion mate

gears, aligning them diagonally, install them into differential

case.

4. Insert pinion mate shaft into differential case.

CAUTION:

Be sure not to damage pinion mate thrust washers.

MTK0135D

SPD715

SMT839

MTK0132D

Page 2069 of 3833

FINAL DRIVE

MT-93

D

E

F

G

H

I

J

K

L

MA

B

MT

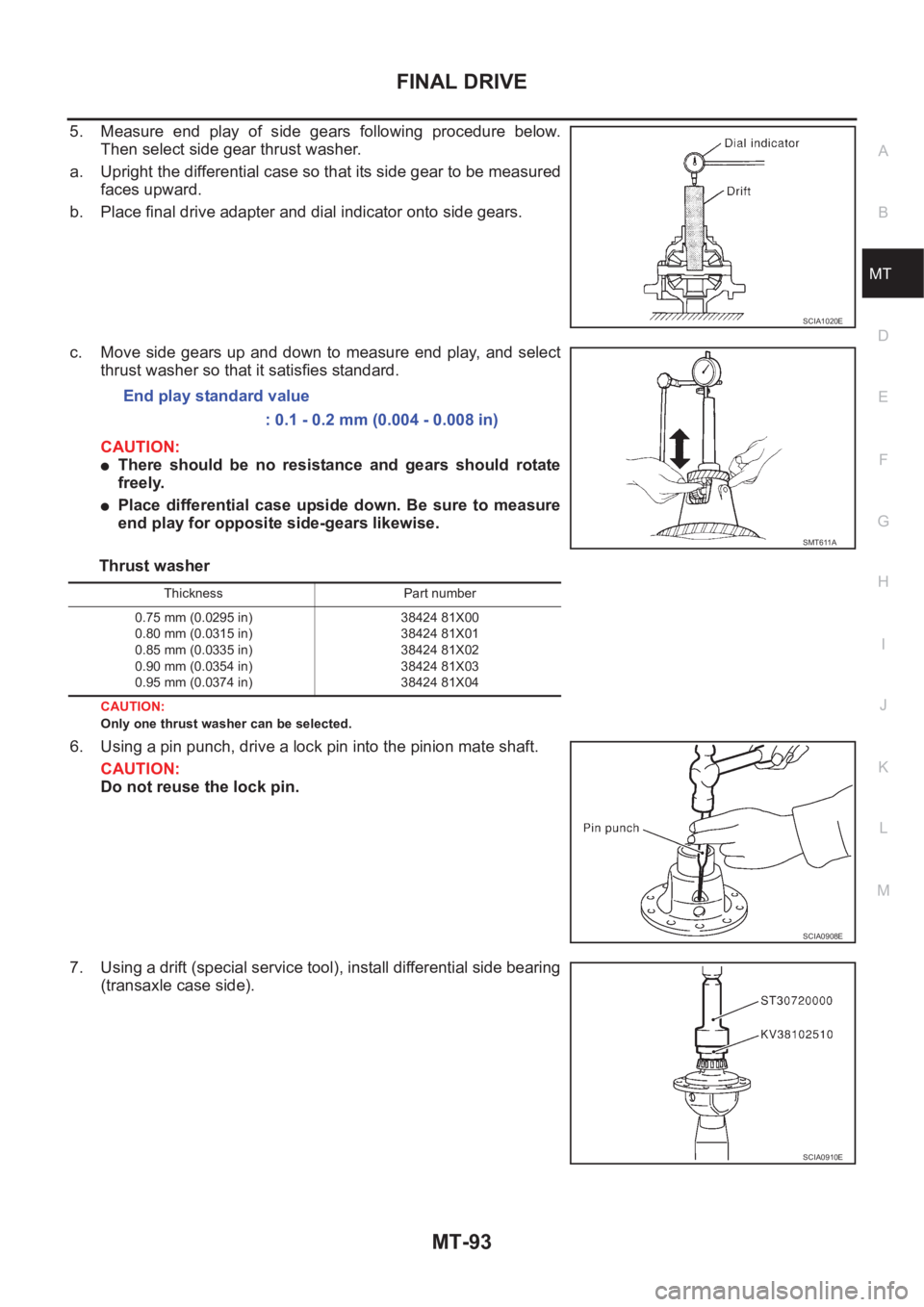

5. Measure end play of side gears following procedure below.

Then select side gear thrust washer.

a. Upright the differential case so that its side gear to be measured

faces upward.

b. Place final drive adapter and dial indicator onto side gears.

c. Move side gears up and down to measure end play, and select

thrust washer so that it satisfies standard.

CAUTION:

●There should be no resistance and gears should rotate

freely.

●Place differential case upside down. Be sure to measure

end play for opposite side-gears likewise.

Thrust washer

CAUTION:

Only one thrust washer can be selected.

6. Using a pin punch, drive a lock pin into the pinion mate shaft.

CAUTION:

Do not reuse the lock pin.

7. Using a drift (special service tool), install differential side bearing

(transaxle case side).

SCIA1020E

End play standard value

: 0.1 - 0.2 mm (0.004 - 0.008 in)

SMT611A

Thickness Part number

0.75 mm (0.0295 in)

0.80 mm (0.0315 in)

0.85 mm (0.0335 in)

0.90 mm (0.0354 in)

0.95 mm (0.0374 in)38424 81X00

38424 81X01

38424 81X02

38424 81X03

38424 81X04

SCIA0908E

SCIA0910E

Page 2070 of 3833

MT-94

FINAL DRIVE

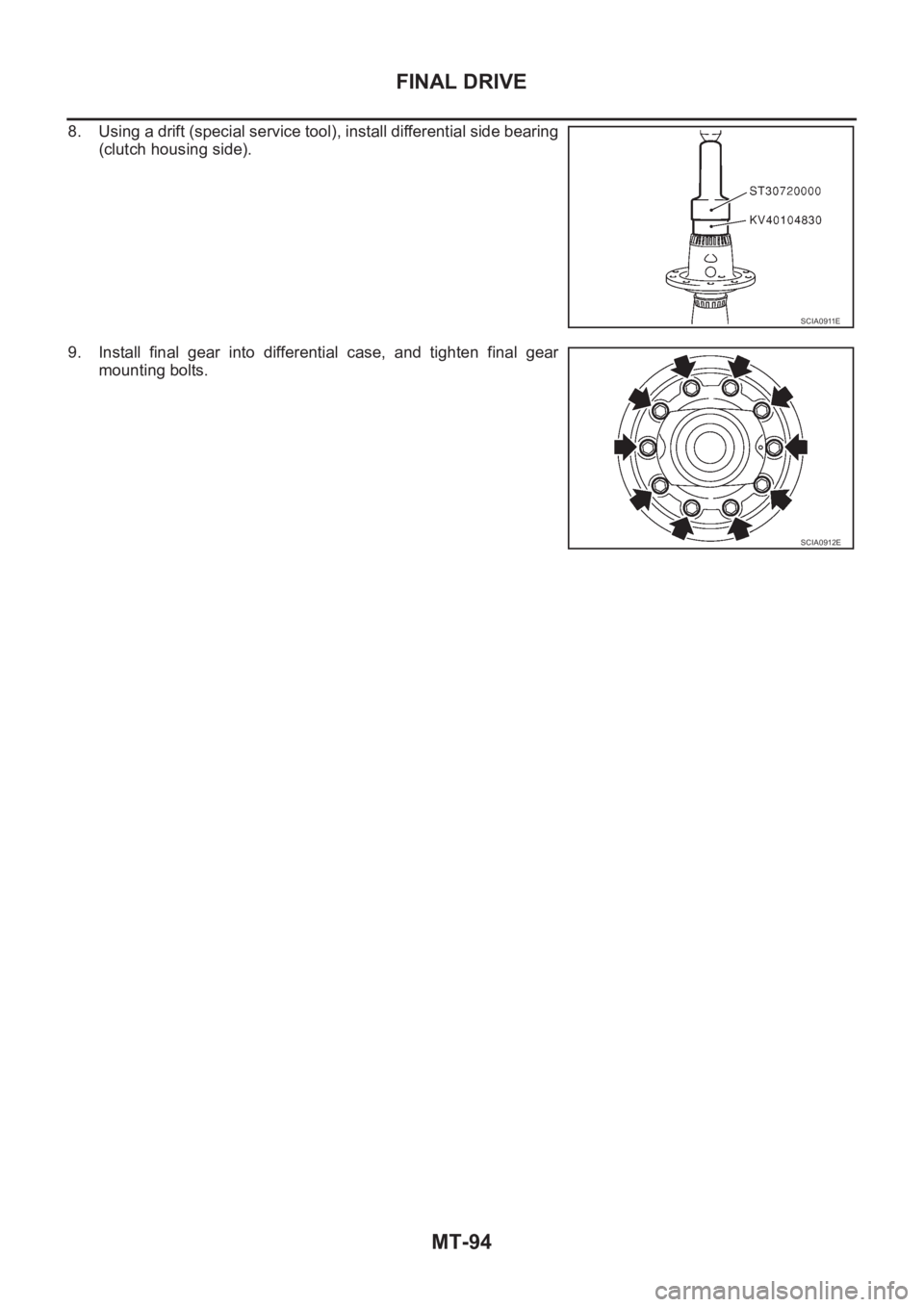

8. Using a drift (special service tool), install differential side bearing

(clutch housing side).

9. Install final gear into differential case, and tighten final gear

mounting bolts.

SCIA0911E

SCIA0912E