NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 2071 of 3833

SHIFT CONTROL

MT-95

D

E

F

G

H

I

J

K

L

MA

B

MT

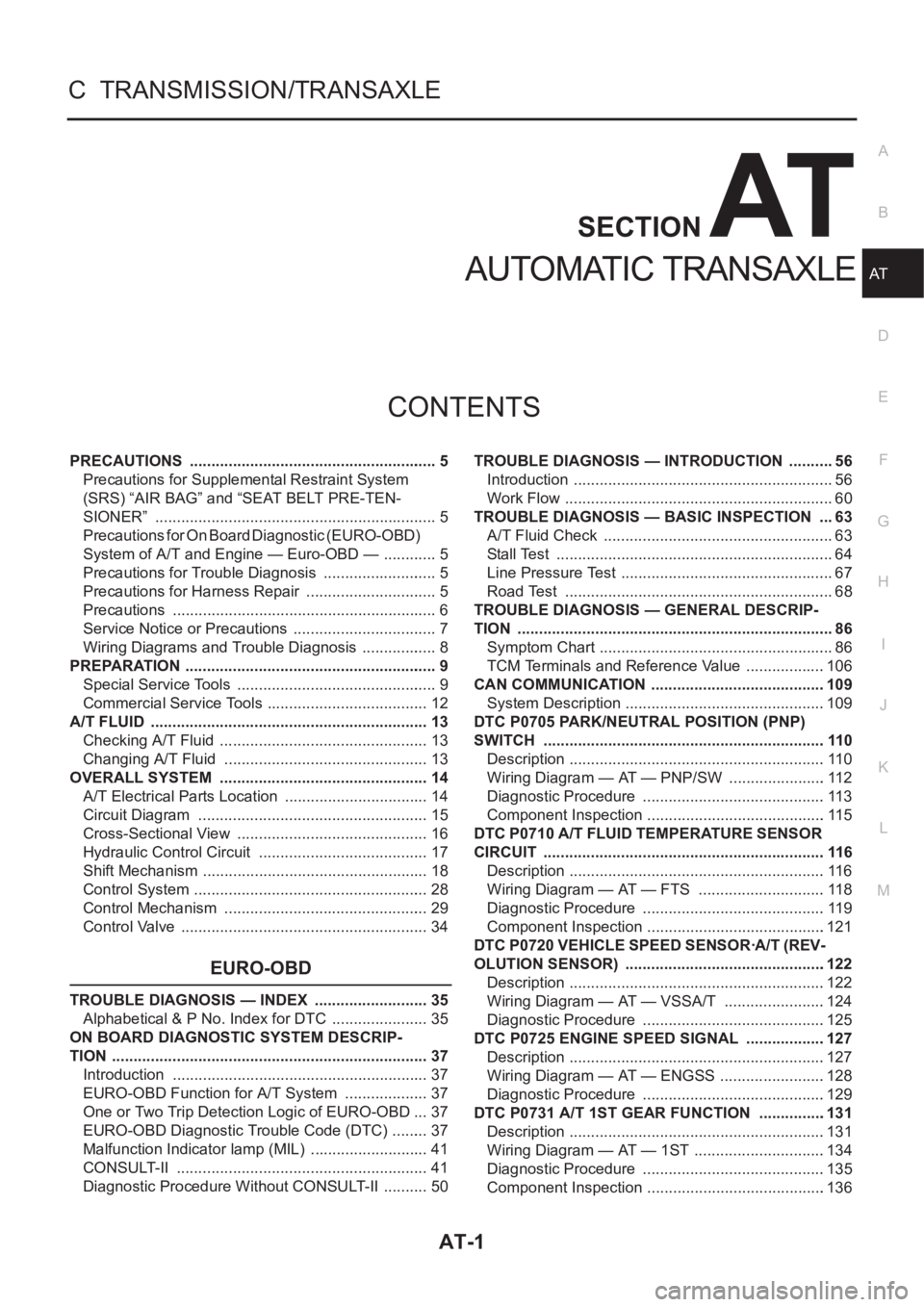

SHIFT CONTROLPFP:32982

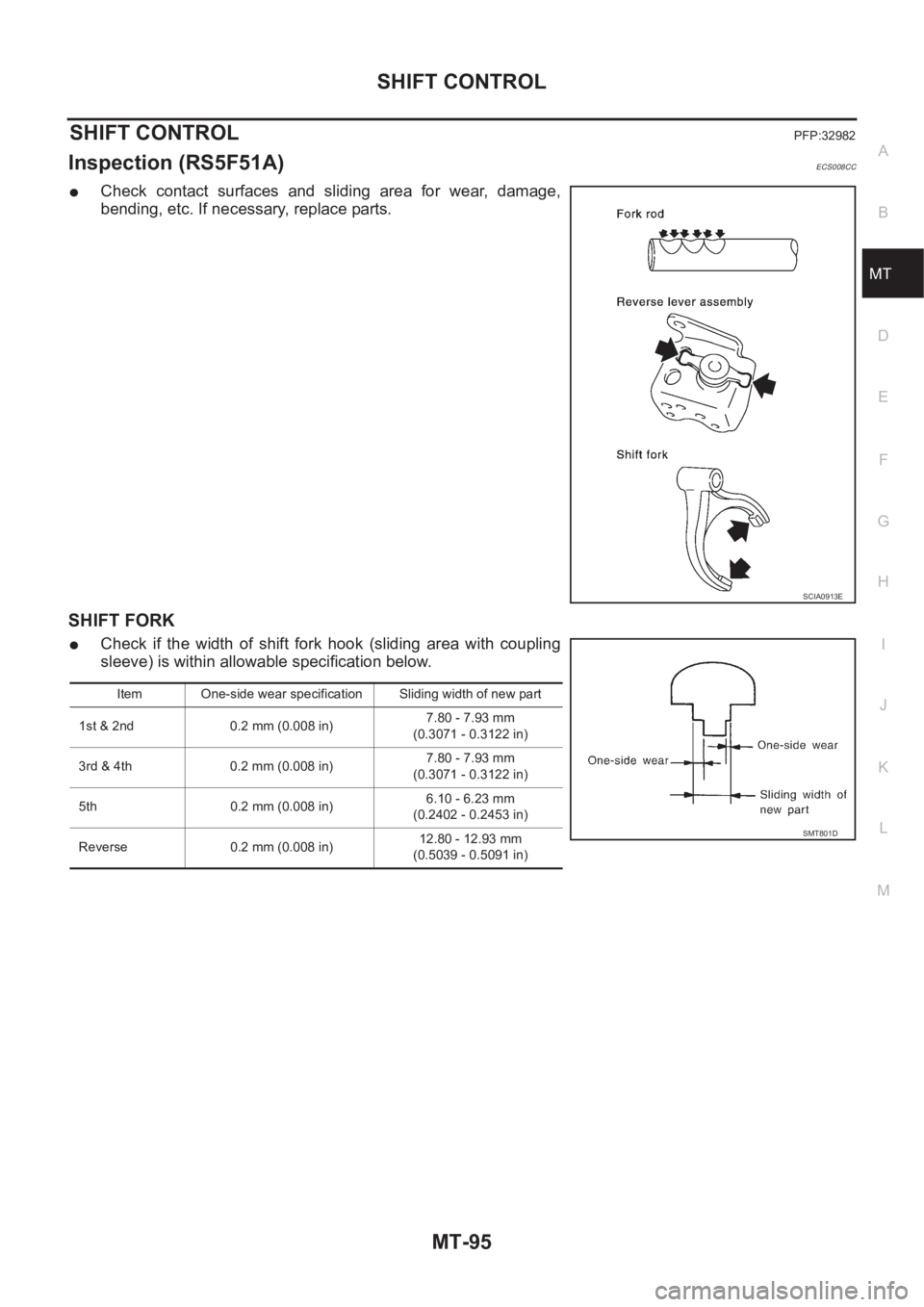

Inspection (RS5F51A)ECS008CC

●Check contact surfaces and sliding area for wear, damage,

bending, etc. If necessary, replace parts.

SHIFT FORK

●Check if the width of shift fork hook (sliding area with coupling

sleeve) is within allowable specification below.

SCIA0913E

Item One-side wear specification Sliding width of new part

1st & 2nd 0.2 mm (0.008 in)7.80 - 7.93 mm

(0.3071 - 0.3122 in)

3rd & 4th 0.2 mm (0.008 in)7.80 - 7.93 mm

(0.3071 - 0.3122 in)

5th 0.2 mm (0.008 in)6.10 - 6.23 mm

(0.2402 - 0.2453 in)

Reverse 0.2 mm (0.008 in)12.80 - 12.93 mm

(0.5039 - 0.5091 in)

SMT801D

Page 2072 of 3833

MT-96

SHIFT CONTROL

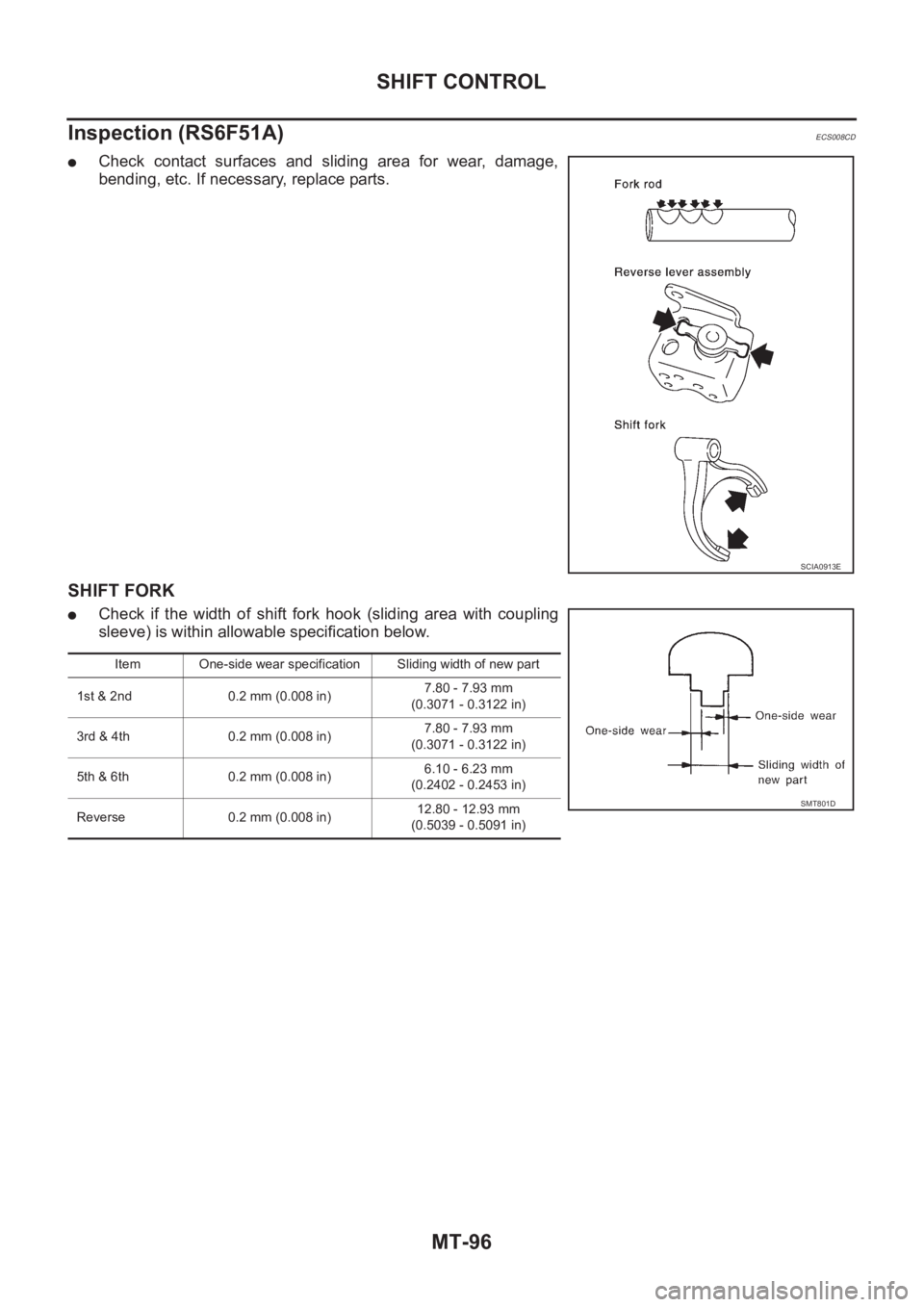

Inspection (RS6F51A)

ECS008CD

●Check contact surfaces and sliding area for wear, damage,

bending, etc. If necessary, replace parts.

SHIFT FORK

●Check if the width of shift fork hook (sliding area with coupling

sleeve) is within allowable specification below.

SCIA0913E

Item One-side wear specification Sliding width of new part

1st & 2nd 0.2 mm (0.008 in)7.80 - 7.93 mm

(0.3071 - 0.3122 in)

3rd & 4th 0.2 mm (0.008 in)7.80 - 7.93 mm

(0.3071 - 0.3122 in)

5th & 6th 0.2 mm (0.008 in)6.10 - 6.23 mm

(0.2402 - 0.2453 in)

Reverse 0.2 mm (0.008 in)12.80 - 12.93 mm

(0.5039 - 0.5091 in)

SMT801D

Page 2073 of 3833

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-97

D

E

F

G

H

I

J

K

L

MA

B

MT

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

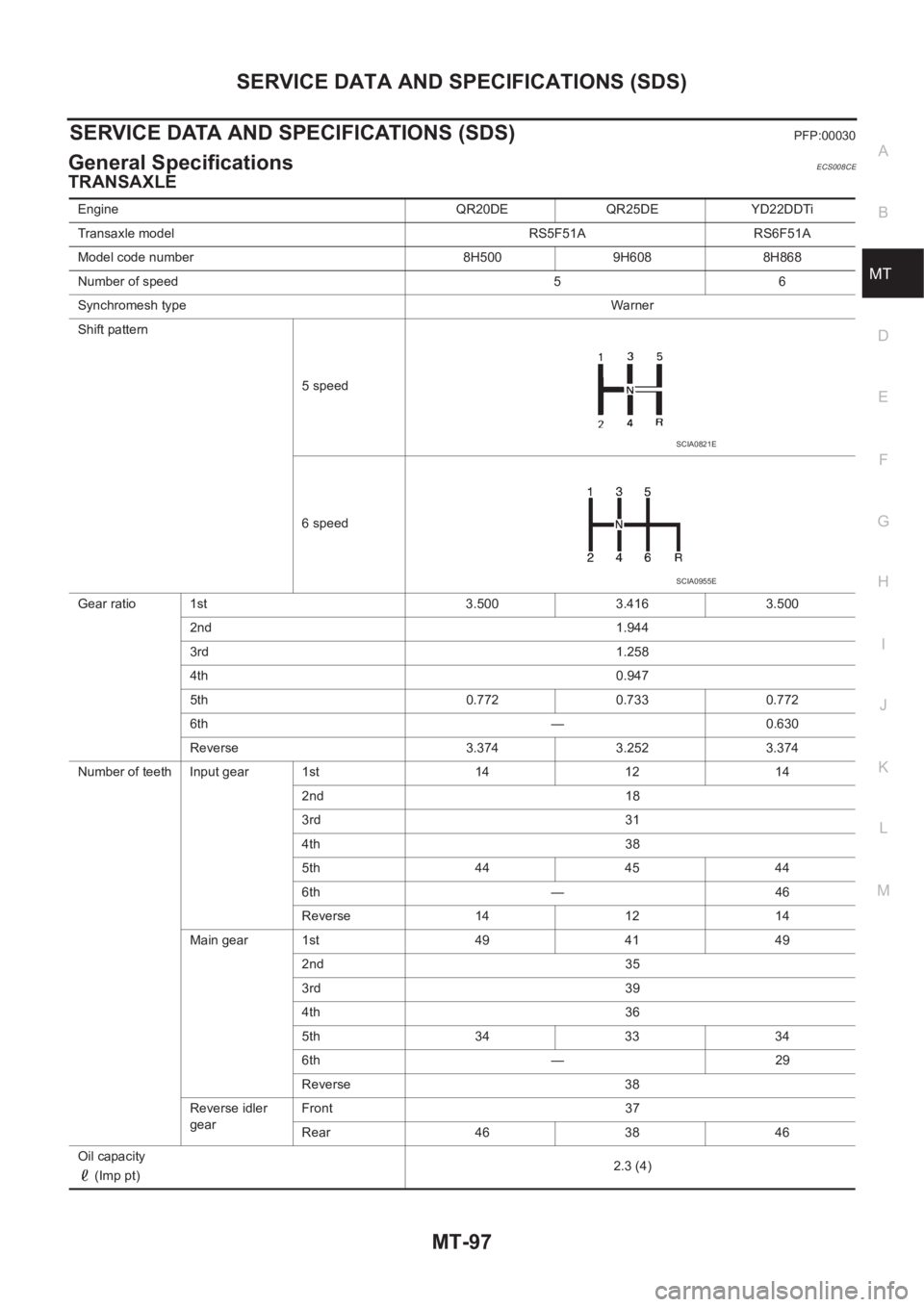

General SpecificationsECS008CE

TRANSAXLE

Engine QR20DE QR25DE YD22DDTi

Transaxle model RS5F51A RS6F51A

Model code number 8H500 9H608 8H868

Number of speed 5 6

Synchromesh typeWarner

Shift pattern

5 speed

6 speed

Gear ratio 1st 3.500 3.416 3.500

2nd 1.944

3rd 1.258

4th 0.947

5th 0.772 0.733 0.772

6th — 0.630

Reverse 3.374 3.252 3.374

Number of teeth Input gear 1st 14 12 14

2nd 18

3rd 31

4th 38

5th 444544

6th — 46

Reverse 14 12 14

Main gear 1st 49 41 49

2nd 35

3rd 39

4th 36

5th 343334

6th — 29

Reverse 38

Reverse idler

gearFront 37

Rear 46 38 46

Oil capacity

(Imp pt)2.3 (4)

SCIA0821E

SCIA0955E

Page 2074 of 3833

MT-98

SERVICE DATA AND SPECIFICATIONS (SDS)

FINAL GEAR

Gear End PlayECS008CF

Unit: mm (in)

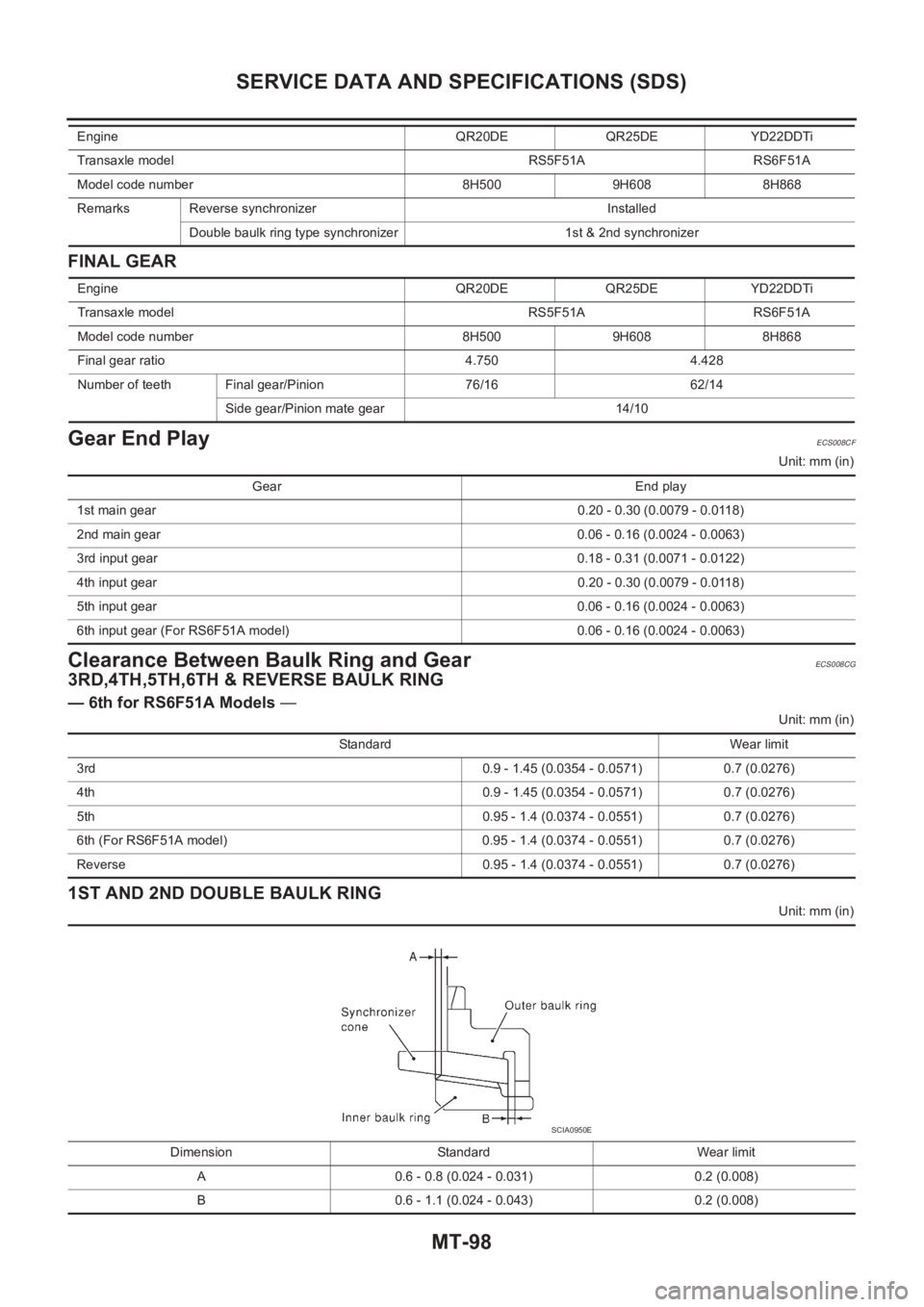

Clearance Between Baulk Ring and GearECS008CG

3RD,4TH,5TH,6TH & REVERSE BAULK RING

— 6th for RS6F51A Models —

Unit: mm (in)

1ST AND 2ND DOUBLE BAULK RING

Unit: mm (in) Remarks Reverse synchronizer Installed

Double baulk ring type synchronizer 1st & 2nd synchronizer Engine QR20DE QR25DE YD22DDTi

Transaxle model RS5F51A RS6F51A

Model code number 8H500 9H608 8H868

Engine QR20DE QR25DE YD22DDTi

Transaxle model RS5F51A RS6F51A

Model code number 8H500 9H608 8H868

Final gear ratio 4.750 4.428

Number of teeth Final gear/Pinion 76/16 62/14

Side gear/Pinion mate gear 14/10

Gear End play

1st main gear0.20 - 0.30 (0.0079 - 0.0118)

2nd main gear 0.06 - 0.16 (0.0024 - 0.0063)

3rd input gear0.18 - 0.31 (0.0071 - 0.0122)

4th input gear0.20 - 0.30 (0.0079 - 0.0118)

5th input gear0.06 - 0.16 (0.0024 - 0.0063)

6th input gear (For RS6F51A model) 0.06 - 0.16 (0.0024 - 0.0063)

Standard Wear limit

3rd 0.9 - 1.45 (0.0354 - 0.0571) 0.7 (0.0276)

4th 0.9 - 1.45 (0.0354 - 0.0571) 0.7 (0.0276)

5th 0.95 - 1.4 (0.0374 - 0.0551) 0.7 (0.0276)

6th (For RS6F51A model) 0.95 - 1.4 (0.0374 - 0.0551) 0.7 (0.0276)

Reverse 0.95 - 1.4 (0.0374 - 0.0551) 0.7 (0.0276)

Dimension Standard Wear limit

A 0.6 - 0.8 (0.024 - 0.031) 0.2 (0.008)

B 0.6 - 1.1 (0.024 - 0.043) 0.2 (0.008)

SCIA0950E

Page 2075 of 3833

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-99

D

E

F

G

H

I

J

K

L

MA

B

MT

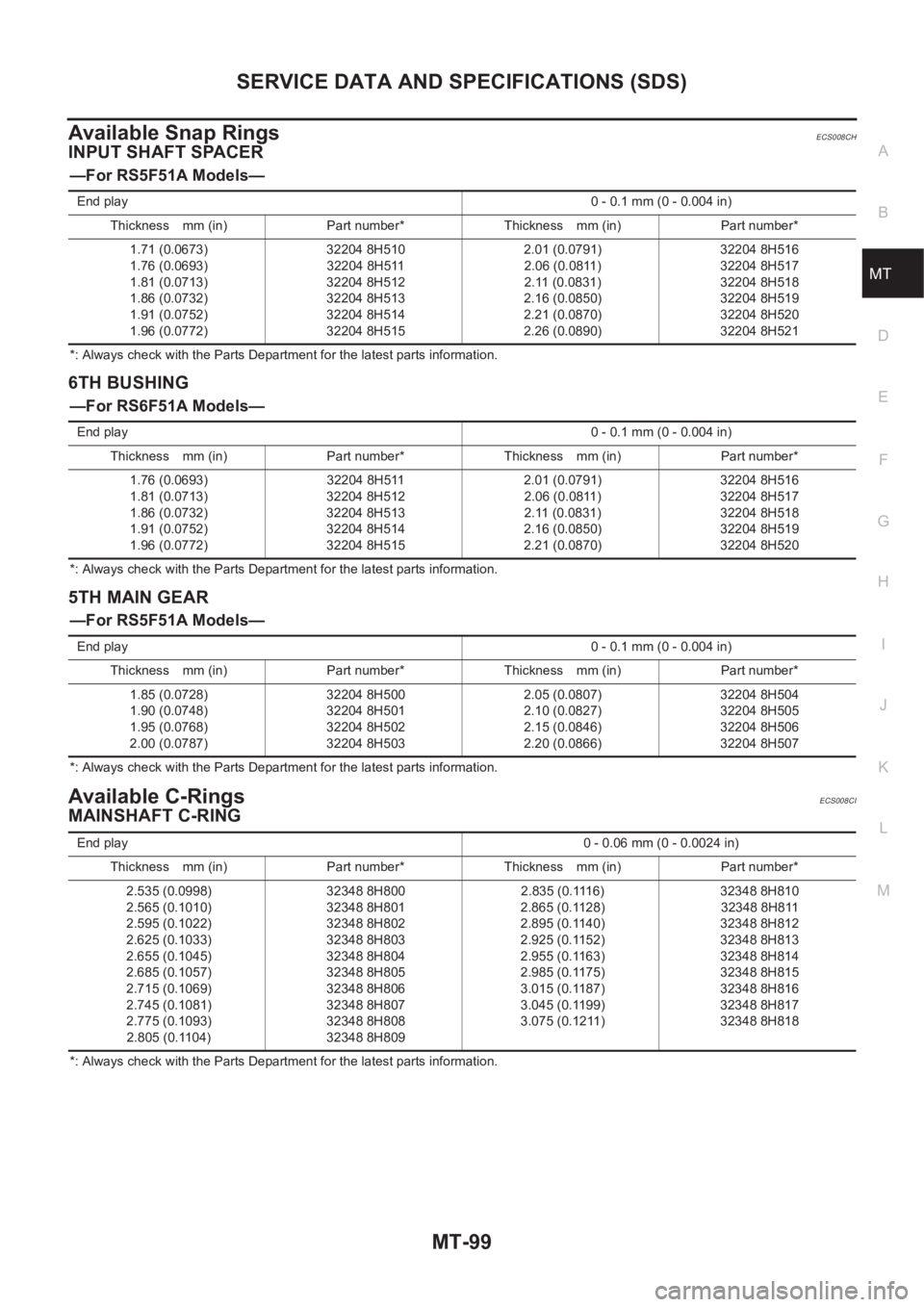

Available Snap RingsECS008CH

INPUT SHAFT SPACER

—For RS5F51A Models—

*: Always check with the Parts Department for the latest parts information.

6TH BUSHING

—For RS6F51A Models—

*: Always check with the Parts Department for the latest parts information.

5TH MAIN GEAR

—For RS5F51A Models—

*: Always check with the Parts Department for the latest parts information.

Available C-RingsECS008CI

MAINSHAFT C-RING

*: Always check with the Parts Department for the latest parts information. End play0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number* Thickness mm (in) Part number*

1.71 (0.0673)

1.76 (0.0693)

1.81 (0.0713)

1.86 (0.0732)

1.91 (0.0752)

1.96 (0.0772)32204 8H510

32204 8H511

32204 8H512

32204 8H513

32204 8H514

32204 8H5152.01 (0.0791)

2.06 (0.0811)

2.11 (0.0831)

2.16 (0.0850)

2.21 (0.0870)

2.26 (0.0890)32204 8H516

32204 8H517

32204 8H518

32204 8H519

32204 8H520

32204 8H521

End play0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number* Thickness mm (in) Part number*

1.76 (0.0693)

1.81 (0.0713)

1.86 (0.0732)

1.91 (0.0752)

1.96 (0.0772)32204 8H511

32204 8H512

32204 8H513

32204 8H514

32204 8H5152.01 (0.0791)

2.06 (0.0811)

2.11 (0.0831)

2.16 (0.0850)

2.21 (0.0870)32204 8H516

32204 8H517

32204 8H518

32204 8H519

32204 8H520

End play0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number* Thickness mm (in) Part number*

1.85 (0.0728)

1.90 (0.0748)

1.95 (0.0768)

2.00 (0.0787)32204 8H500

32204 8H501

32204 8H502

32204 8H5032.05 (0.0807)

2.10 (0.0827)

2.15 (0.0846)

2.20 (0.0866)32204 8H504

32204 8H505

32204 8H506

32204 8H507

End play0 - 0.06 mm (0 - 0.0024 in)

Thickness mm (in) Part number* Thickness mm (in) Part number*

2.535 (0.0998)

2.565 (0.1010)

2.595 (0.1022)

2.625 (0.1033)

2.655 (0.1045)

2.685 (0.1057)

2.715 (0.1069)

2.745 (0.1081)

2.775 (0.1093)

2.805 (0.1104)32348 8H800

32348 8H801

32348 8H802

32348 8H803

32348 8H804

32348 8H805

32348 8H806

32348 8H807

32348 8H808

32348 8H8092.835 (0.1116)

2.865 (0.1128)

2.895 (0.1140)

2.925 (0.1152)

2.955 (0.1163)

2.985 (0.1175)

3.015 (0.1187)

3.045 (0.1199)

3.075 (0.1211)32348 8H810

32348 8H811

32348 8H812

32348 8H813

32348 8H814

32348 8H815

32348 8H816

32348 8H817

32348 8H818

Page 2076 of 3833

MT-100

SERVICE DATA AND SPECIFICATIONS (SDS)

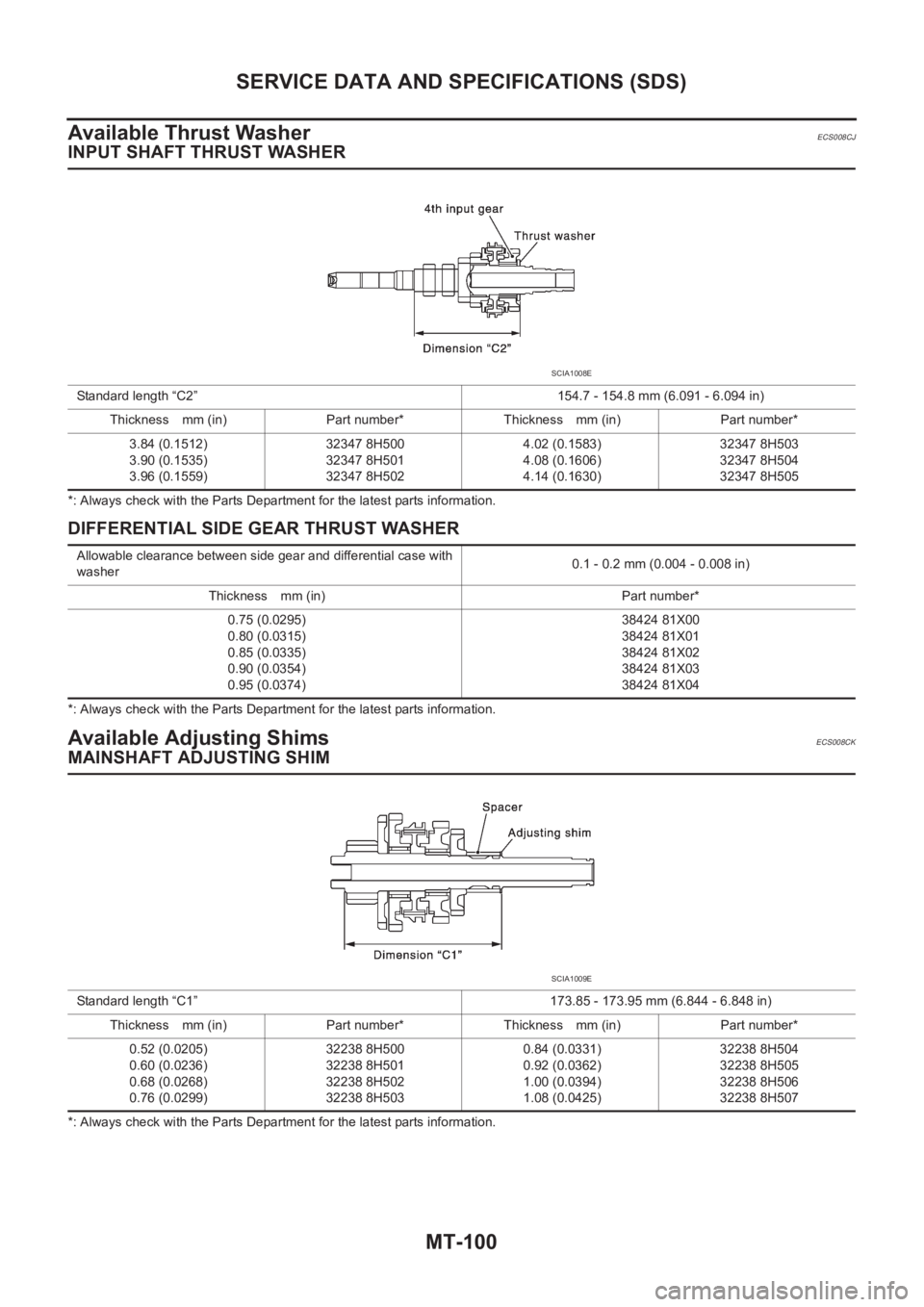

Available Thrust Washer

ECS008CJ

INPUT SHAFT THRUST WASHER

*: Always check with the Parts Department for the latest parts information.

DIFFERENTIAL SIDE GEAR THRUST WASHER

*: Always check with the Parts Department for the latest parts information.

Available Adjusting ShimsECS008CK

MAINSHAFT ADJUSTING SHIM

*: Always check with the Parts Department for the latest parts information. Standard length “C2” 154.7 - 154.8 mm (6.091 - 6.094 in)

Thickness mm (in) Part number* Thickness mm (in) Part number*

3.84 (0.1512)

3.90 (0.1535)

3.96 (0.1559)32347 8H500

32347 8H501

32347 8H5024.02 (0.1583)

4.08 (0.1606)

4.14 (0.1630)32347 8H503

32347 8H504

32347 8H505

SCIA1008E

Allowable clearance between side gear and differential case with

washer0.1 - 0.2 mm (0.004 - 0.008 in)

Thickness mm (in) Part number*

0.75 (0.0295)

0.80 (0.0315)

0.85 (0.0335)

0.90 (0.0354)

0.95 (0.0374)38424 81X00

38424 81X01

38424 81X02

38424 81X03

38424 81X04

Standard length “C1” 173.85 - 173.95 mm (6.844 - 6.848 in)

Thickness mm (in) Part number* Thickness mm (in) Part number*

0.52 (0.0205)

0.60 (0.0236)

0.68 (0.0268)

0.76 (0.0299)32238 8H500

32238 8H501

32238 8H502

32238 8H5030.84 (0.0331)

0.92 (0.0362)

1.00 (0.0394)

1.08 (0.0425)32238 8H504

32238 8H505

32238 8H506

32238 8H507

SCIA1009E

Page 2077 of 3833

SERVICE DATA AND SPECIFICATIONS (SDS)

MT-101

D

E

F

G

H

I

J

K

L

MA

B

MT

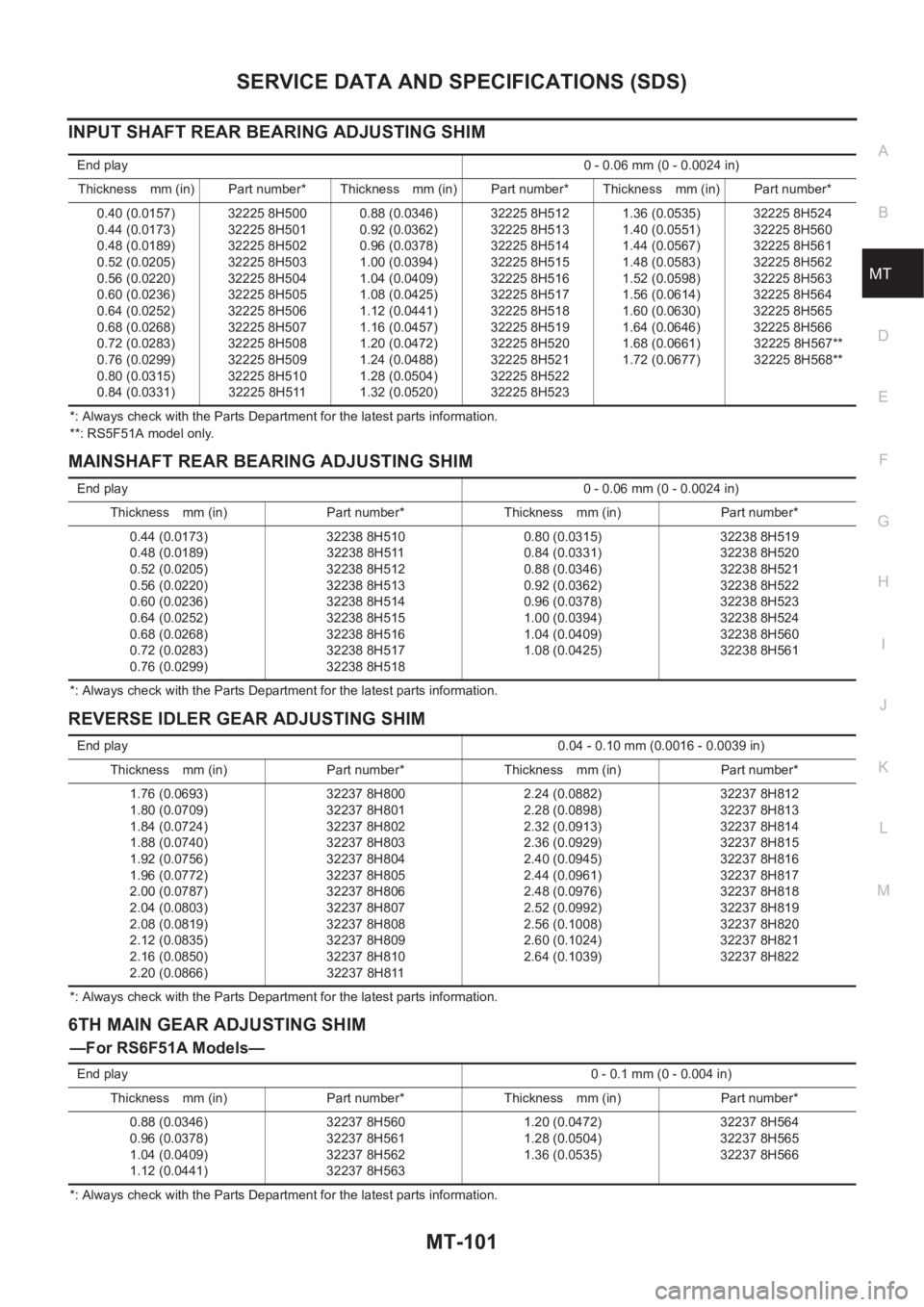

INPUT SHAFT REAR BEARING ADJUSTING SHIM

*: Always check with the Parts Department for the latest parts information.

**: RS5F51A model only.

MAINSHAFT REAR BEARING ADJUSTING SHIM

*: Always check with the Parts Department for the latest parts information.

REVERSE IDLER GEAR ADJUSTING SHIM

*: Always check with the Parts Department for the latest parts information.

6TH MAIN GEAR ADJUSTING SHIM

—For RS6F51A Models—

*: Always check with the Parts Department for the latest parts information. End play0 - 0.06 mm (0 - 0.0024 in)

Thickness mm (in) Part number* Thickness mm (in) Part number* Thickness mm (in) Part number*

0.40 (0.0157)

0.44 (0.0173)

0.48 (0.0189)

0.52 (0.0205)

0.56 (0.0220)

0.60 (0.0236)

0.64 (0.0252)

0.68 (0.0268)

0.72 (0.0283)

0.76 (0.0299)

0.80 (0.0315)

0.84 (0.0331)32225 8H500

32225 8H501

32225 8H502

32225 8H503

32225 8H504

32225 8H505

32225 8H506

32225 8H507

32225 8H508

32225 8H509

32225 8H510

32225 8H5110.88 (0.0346)

0.92 (0.0362)

0.96 (0.0378)

1.00 (0.0394)

1.04 (0.0409)

1.08 (0.0425)

1.12 (0.0441)

1.16 (0.0457)

1.20 (0.0472)

1.24 (0.0488)

1.28 (0.0504)

1.32 (0.0520)32225 8H512

32225 8H513

32225 8H514

32225 8H515

32225 8H516

32225 8H517

32225 8H518

32225 8H519

32225 8H520

32225 8H521

32225 8H522

32225 8H5231.36 (0.0535)

1.40 (0.0551)

1.44 (0.0567)

1.48 (0.0583)

1.52 (0.0598)

1.56 (0.0614)

1.60 (0.0630)

1.64 (0.0646)

1.68 (0.0661)

1.72 (0.0677)32225 8H524

32225 8H560

32225 8H561

32225 8H562

32225 8H563

32225 8H564

32225 8H565

32225 8H566

32225 8H567**

32225 8H568**

End play0 - 0.06 mm (0 - 0.0024 in)

Thickness mm (in) Part number* Thickness mm (in) Part number*

0.44 (0.0173)

0.48 (0.0189)

0.52 (0.0205)

0.56 (0.0220)

0.60 (0.0236)

0.64 (0.0252)

0.68 (0.0268)

0.72 (0.0283)

0.76 (0.0299)32238 8H510

32238 8H511

32238 8H512

32238 8H513

32238 8H514

32238 8H515

32238 8H516

32238 8H517

32238 8H5180.80 (0.0315)

0.84 (0.0331)

0.88 (0.0346)

0.92 (0.0362)

0.96 (0.0378)

1.00 (0.0394)

1.04 (0.0409)

1.08 (0.0425)32238 8H519

32238 8H520

32238 8H521

32238 8H522

32238 8H523

32238 8H524

32238 8H560

32238 8H561

End play0.04 - 0.10 mm (0.0016 - 0.0039 in)

Thickness mm (in) Part number* Thickness mm (in) Part number*

1.76 (0.0693)

1.80 (0.0709)

1.84 (0.0724)

1.88 (0.0740)

1.92 (0.0756)

1.96 (0.0772)

2.00 (0.0787)

2.04 (0.0803)

2.08 (0.0819)

2.12 (0.0835)

2.16 (0.0850)

2.20 (0.0866)32237 8H800

32237 8H801

32237 8H802

32237 8H803

32237 8H804

32237 8H805

32237 8H806

32237 8H807

32237 8H808

32237 8H809

32237 8H810

32237 8H8112.24 (0.0882)

2.28 (0.0898)

2.32 (0.0913)

2.36 (0.0929)

2.40 (0.0945)

2.44 (0.0961)

2.48 (0.0976)

2.52 (0.0992)

2.56 (0.1008)

2.60 (0.1024)

2.64 (0.1039)32237 8H812

32237 8H813

32237 8H814

32237 8H815

32237 8H816

32237 8H817

32237 8H818

32237 8H819

32237 8H820

32237 8H821

32237 8H822

End play0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number* Thickness mm (in) Part number*

0.88 (0.0346)

0.96 (0.0378)

1.04 (0.0409)

1.12 (0.0441)32237 8H560

32237 8H561

32237 8H562

32237 8H5631.20 (0.0472)

1.28 (0.0504)

1.36 (0.0535)32237 8H564

32237 8H565

32237 8H566

Page 2078 of 3833

MT-102

SERVICE DATA AND SPECIFICATIONS (SDS)

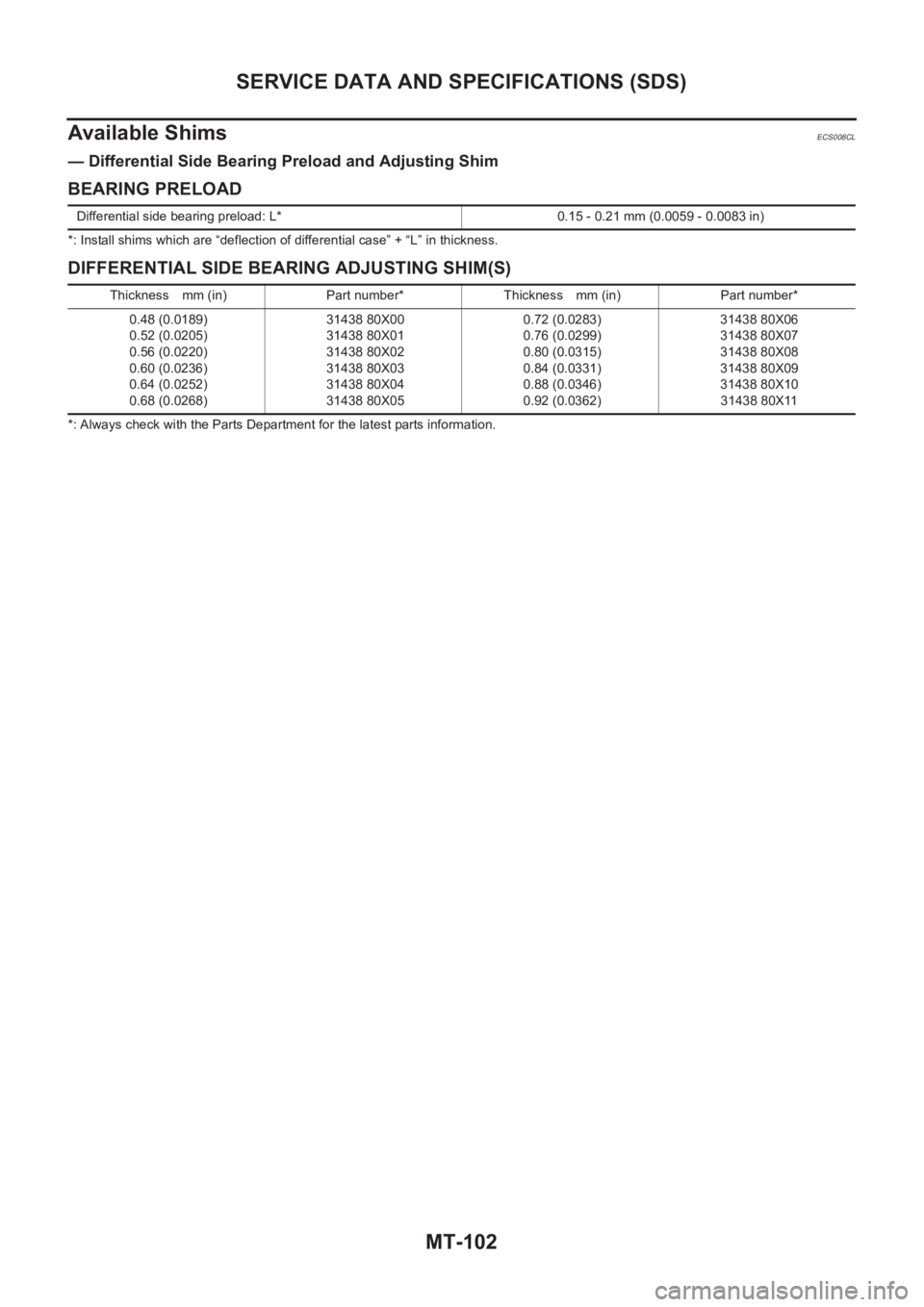

Available Shims

ECS008CL

— Differential Side Bearing Preload and Adjusting Shim

BEARING PRELOAD

*: Install shims which are “deflection of differential case” + “L” in thickness.

DIFFERENTIAL SIDE BEARING ADJUSTING SHIM(S)

*: Always check with the Parts Department for the latest parts information. Differential side bearing preload: L* 0.15 - 0.21 mm (0.0059 - 0.0083 in)

Thickness mm (in) Part number* Thickness mm (in) Part number*

0.48 (0.0189)

0.52 (0.0205)

0.56 (0.0220)

0.60 (0.0236)

0.64 (0.0252)

0.68 (0.0268)31438 80X00

31438 80X01

31438 80X02

31438 80X03

31438 80X04

31438 80X050.72 (0.0283)

0.76 (0.0299)

0.80 (0.0315)

0.84 (0.0331)

0.88 (0.0346)

0.92 (0.0362)31438 80X06

31438 80X07

31438 80X08

31438 80X09

31438 80X10

31438 80X11

Page 2079 of 3833

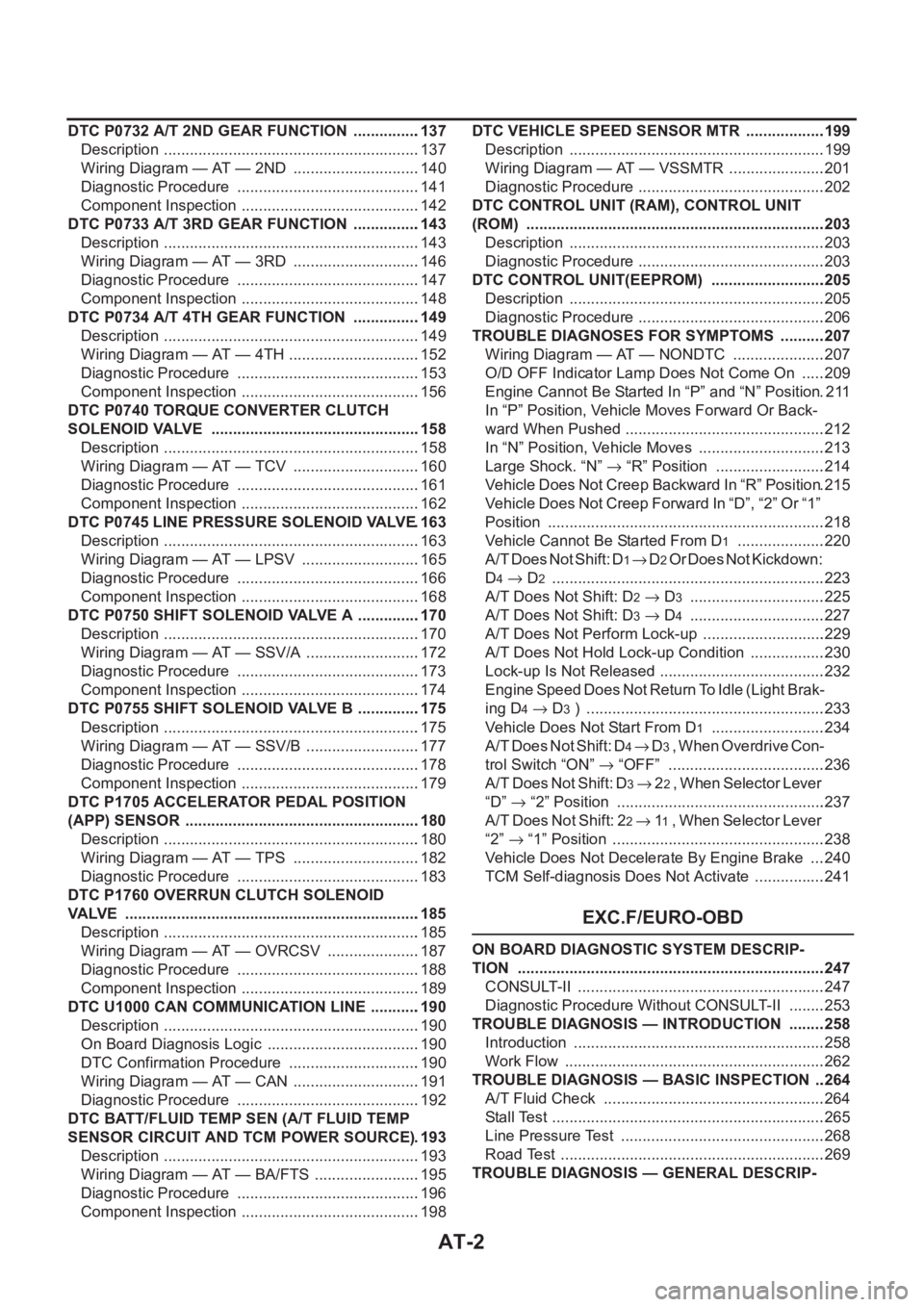

AT-1

AUTOMATIC TRANSAXLE

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTION

A

B

AT

AUTOMATIC TRANSAXLE

PRECAUTIONS .......................................................... 5

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 5

Precautions for On Board Diagnostic (EURO-OBD)

System of A/T and Engine — Euro-OBD — ............. 5

Precautions for Trouble Diagnosis ........................... 5

Precautions for Harness Repair ............................... 5

Precautions .............................................................. 6

Service Notice or Precautions .................................. 7

Wiring Diagrams and Trouble Diagnosis .................. 8

PREPARATION ........................................................... 9

Special Service Tools ............................................... 9

Commercial Service Tools ...................................... 12

A/T FLUID ................................................................. 13

Checking A/T Fluid ................................................. 13

Changing A/T Fluid ............................................. ... 13

OVERALL SYSTEM ................................................. 14

A/T Electrical Parts Location .................................. 14

Circuit Diagram ...................................................... 15

Cross-Sectional View ............................................. 16

Hydraulic Control Circuit ........................................ 17

Shift Mechanism ..................................................... 18

Control System ....................................................... 28

Control Mechanism ................................................ 29

Control Valve .......................................................... 34

EURO-OBD

TROUBLE DIAGNOSIS — INDEX ........................... 35

Alphabetical & P No. Index for DTC ....................... 35

ON BOARD DIAGNOSTIC SYSTEM DESCRIP-

TION .......................................................................... 37

Introduction ............................................................ 37

EURO-OBD Function for A/T System .................... 37

One or Two Trip Detection Logic of EURO-OBD ... 37

EURO-OBD Diagnostic Trouble Code (DTC) ......... 37

Malfunction Indicator lamp (MIL) ............................ 41

CONSULT-II ........................................................... 41

Diagnostic Procedure Without CONSULT-II ........... 50TROUBLE DIAGNOSIS — INTRODUCTION ........... 56

Introduction ............................................................. 56

Work Flow ............................................................... 60

TROUBLE DIAGNOSIS — BASIC INSPECTION .... 63

A/T Fluid Check ...................................................... 63

Stall Test ................................................................. 64

Line Pressure Test .................................................. 67

Road Test ............................................................... 68

TROUBLE DIAGNOSIS — GENERAL DESCRIP-

TION .......................................................................... 86

Symptom Chart ....................................................... 86

TCM Terminals and Reference Value ...................106

CAN COMMUNICATION .........................................109

System Description ...............................................109

DTC P0705 PARK/NEUTRAL POSITION (PNP)

SWITCH ..................................................................110

Description ............................................................110

Wiring Diagram — AT — PNP/SW .......................112

Diagnostic Procedure ...........................................113

Component Inspection ..........................................115

DTC P0710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT ..................................................................116

Description ............................................................116

Wiring Diagram — AT — FTS ..............................118

Diagnostic Procedure ...........................................119

Component Inspection ..........................................121

DTC P0720 VEHICLE SPEED SENSOR·A/T (REV-

OLUTION SENSOR) ...............................................122

Description ............................................................122

Wiring Diagram — AT — VSSA/T ........................124

Diagnostic Procedure ...........................................125

DTC P0725 ENGINE SPEED SIGNAL ...................127

Description ............................................................127

Wiring Diagram — AT — ENGSS .........................128

Diagnostic Procedure ...........................................129

DTC P0731 A/T 1ST GEAR FUNCTION ...............

.131

Description ............................................................131

Wiring Diagram — AT — 1ST ...............................134

Diagnostic Procedure ...........................................135

Component Inspection ..........................................136

Page 2080 of 3833

AT-2

DTC P0732 A/T 2ND GEAR FUNCTION ................137

Description ............................................................137

Wiring Diagram — AT — 2ND ..............................140

Diagnostic Procedure ...........................................141

Component Inspection ..........................................142

DTC P0733 A/T 3RD GEAR FUNCTION ................143

Description ............................................................143

Wiring Diagram — AT — 3RD ..............................146

Diagnostic Procedure ...........................................147

Component Inspection ..........................................148

DTC P0734 A/T 4TH GEAR FUNCTION ................149

Description ............................................................149

Wiring Diagram — AT — 4TH ...............................152

Diagnostic Procedure ...........................................153

Component Inspection ..........................................156

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE .................................................158

Description ............................................................158

Wiring Diagram — AT — TCV ..............................160

Diagnostic Procedure ...........................................161

Component Inspection ..........................................162

DTC P0745 LINE PRESSURE SOLENOID VALVE .163

Description ............................................................163

Wiring Diagram — AT — LPSV ............................165

Diagnostic Procedure ...........................................166

Component Inspection ..........................................168

DTC P0750 SHIFT SOLENOID VALVE A ...............170

Description ............................................................170

Wiring Diagram — AT — SSV/A ...........................172

Diagnostic Procedure ...........................................173

Component Inspection ..........................................174

DTC P0755 SHIFT SOLENOID VALVE B ...............175

Description ............................................................175

Wiring Diagram — AT — SSV/B ...........................177

Diagnostic Procedure ...........................................178

Component Inspection ..........................................179

DTC P1705 ACCELERATOR PEDAL POSITION

(APP) SENSOR .......................................................180

Description ............................................................180

Wiring Diagram — AT — TPS ..............................182

Diagnostic Procedure ...........................................183

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE .....................................................................185

Description ............................................................185

Wiring Diagram — AT — OVRCSV ......................187

Diagnostic Procedure ...........................................188

Component Inspection ..........................................189

DTC U1000 CAN COMMUNICATION LINE ...........

.190

Description ............................................................190

On Board Diagnosis Logic ....................................190

DTC Confirmation Procedure ...............................190

Wiring Diagram — AT — CAN ..............................191

Diagnostic Procedure ...........................................192

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE) .193

Description ............................................................193

Wiring Diagram — AT — BA/FTS .........................195

Diagnostic Procedure ...........................................196

Component Inspection ..........................................198DTC VEHICLE SPEED SENSOR MTR ...................199

Description ............................................................199

Wiring Diagram — AT — VSSMTR .......................201

Diagnostic Procedure ............................................202

DTC CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ......................................................................203

Description ............................................................203

Diagnostic Procedure ............................................203

DTC CONTROL UNIT(EEPROM) ...........................205

Description ............................................................205

Diagnostic Procedure ............................................206

TROUBLE DIAGNOSES FOR SYMPTOMS ...........207

Wiring Diagram — AT — NONDTC ......................207

O/D OFF Indicator Lamp Does Not Come On ......209

Engine Cannot Be Started In “P” and “N” Position .211

In “P” Position, Vehicle Moves Forward Or Back-

ward When Pushed ...............................................212

In “N” Position, Vehicle Moves ..............................213

Large Shock. “N” → “R” Position ..........................214

Vehicle Does Not Creep Backward In “R” Position .215

Vehicle Does Not Creep Forward In “D”, “2” Or “1”

Position .................................................................218

Vehicle Cannot Be Started From D

1 .....................220

A/T Does Not Shift: D

1→ D2 Or Does Not Kickdown:

D

4→ D2 ...............................................................

.223

A/T Does Not Shift: D

2→ D3 ................................225

A/T Does Not Shift: D

3→ D4 ................................227

A/T Does Not Perform Lock-up .............................229

A/T Does Not Hold Lock-up Condition ..................230

Lock-up Is Not Released .......................................232

Engine Speed Does Not Return To Idle (Light Brak-

ing D

4→ D3 ) ........................................................233

Vehicle Does Not Start From D

1 ...........................234

A / T D o e s N o t S h i f t : D

4→ D3 , W h e n O v e r d r i v e C o n -

trol Switch “ON” → “OFF” .....................................236

A/T Does Not Shift: D

3→ 22 , W h e n S e l e c t o r L e v e r

“D” → “2” Position .................................................237

A/T Does Not Shift: 2

2→ 11 , When Selector Lever

“2” → “1” Position ..................................................238

Vehicle Does Not Decelerate By Engine Brake ....240

TCM Self-diagnosis Does Not Activate .................241

EXC.F/EURO-OBD

ON BOARD DIAGNOSTIC SYSTEM DESCRIP-

TION ........................................................................247

CONSULT-II ..........................................................247

Diagnostic Procedure Without CONSULT-II .........253

TROUBLE DIAGNOSIS — INTRODUCTION .........258

Introduction ...........................................................258

Work Flow .............................................................262

TROUBLE DIAGNOSIS — BASIC INSPECTION ...264

A/T Fluid Check ....................................................264

Stall Test ................................................................265

Line Pressure Test ................................................268

Road Test ..............................................................269

TROUBLE DIAGNOSIS — GENERAL DESCRIP-