NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 2041 of 3833

INPUT SHAFT AND GEARS

MT-65

D

E

F

G

H

I

J

K

L

MA

B

MT

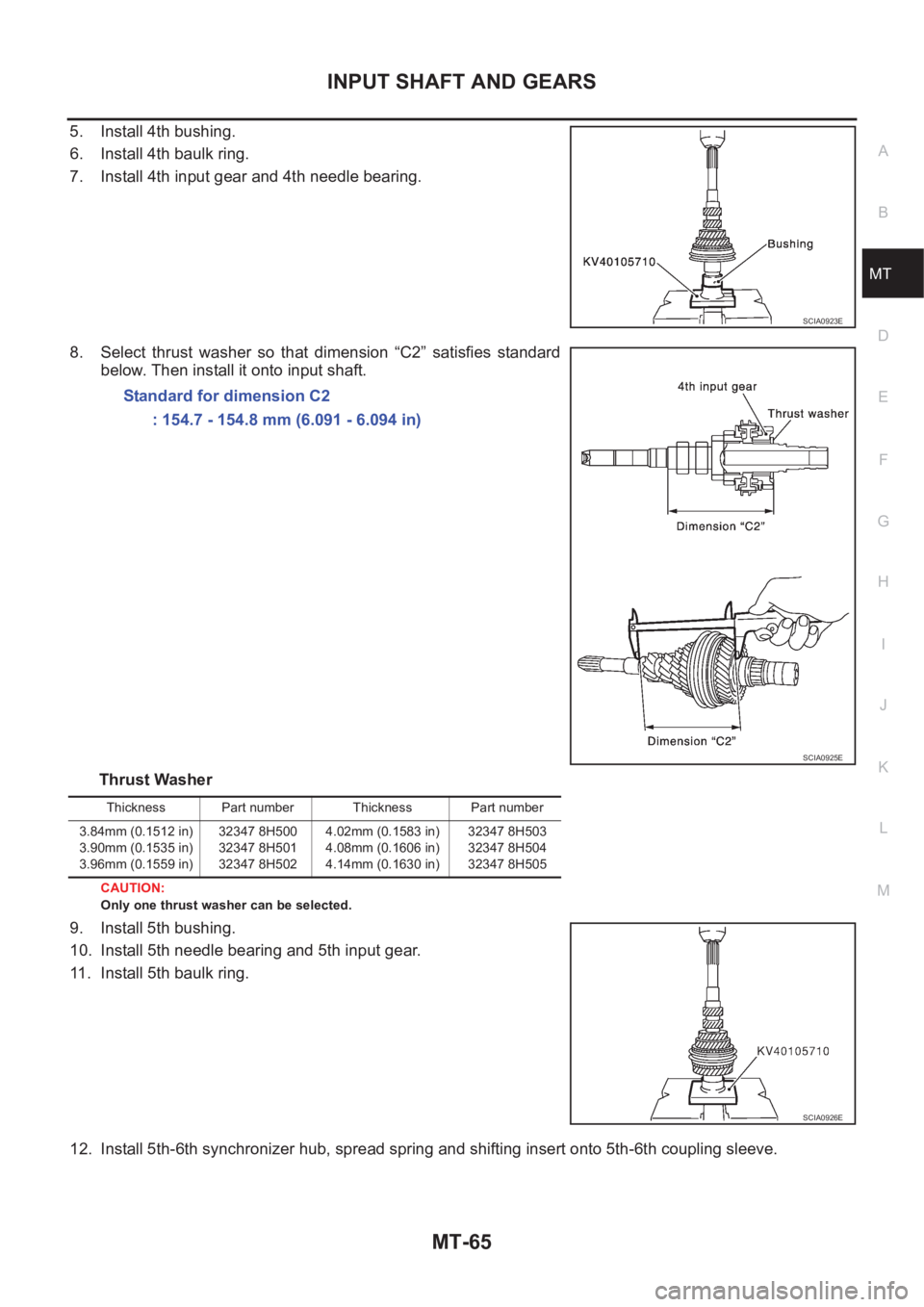

5. Install 4th bushing.

6. Install 4th baulk ring.

7. Install 4th input gear and 4th needle bearing.

8. Select thrust washer so that dimension “C2” satisfies standard

below. Then install it onto input shaft.

Thrust Washer

CAUTION:

Only one thrust washer can be selected.

9. Install 5th bushing.

10. Install 5th needle bearing and 5th input gear.

11. Install 5th baulk ring.

12. Install 5th-6th synchronizer hub, spread spring and shifting insert onto 5th-6th coupling sleeve.

SCIA0923E

Standard for dimension C2

: 154.7 - 154.8 mm (6.091 - 6.094 in)

SCIA0925E

Thickness Part number Thickness Part number

3.84mm (0.1512 in)

3.90mm (0.1535 in)

3.96mm (0.1559 in)32347 8H500

32347 8H501

32347 8H5024.02mm (0.1583 in)

4.08mm (0.1606 in)

4.14mm (0.1630 in)32347 8H503

32347 8H504

32347 8H505

SCIA0926E

Page 2042 of 3833

MT-66

INPUT SHAFT AND GEARS

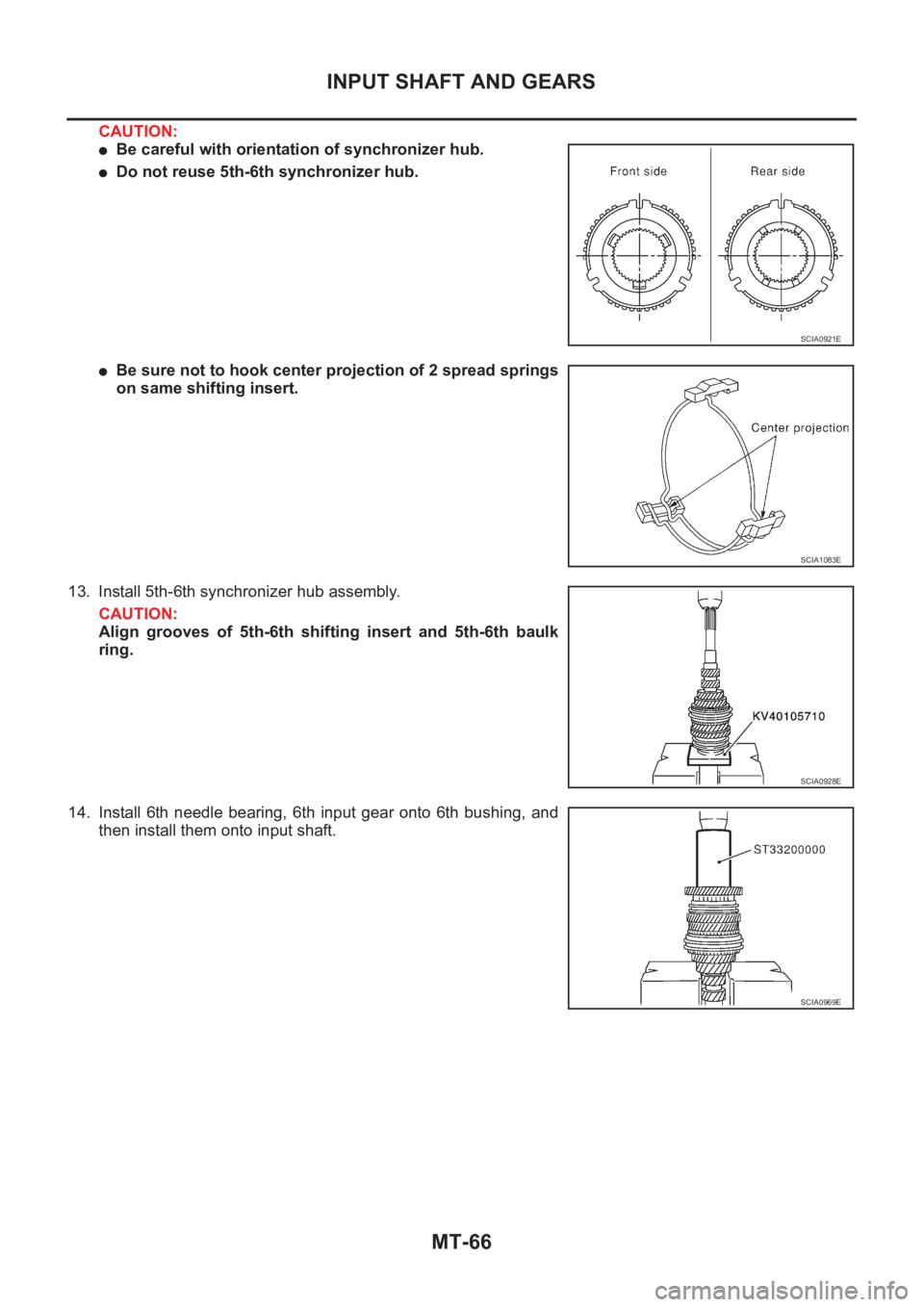

CAUTION:

●Be careful with orientation of synchronizer hub.

●Do not reuse 5th-6th synchronizer hub.

●Be sure not to hook center projection of 2 spread springs

on same shifting insert.

13. Install 5th-6th synchronizer hub assembly.

CAUTION:

Align grooves of 5th-6th shifting insert and 5th-6th baulk

ring.

14. Install 6th needle bearing, 6th input gear onto 6th bushing, and

then install them onto input shaft.

SCIA0921E

SCIA1083E

SCIA0928E

SCIA0969E

Page 2043 of 3833

INPUT SHAFT AND GEARS

MT-67

D

E

F

G

H

I

J

K

L

MA

B

MT

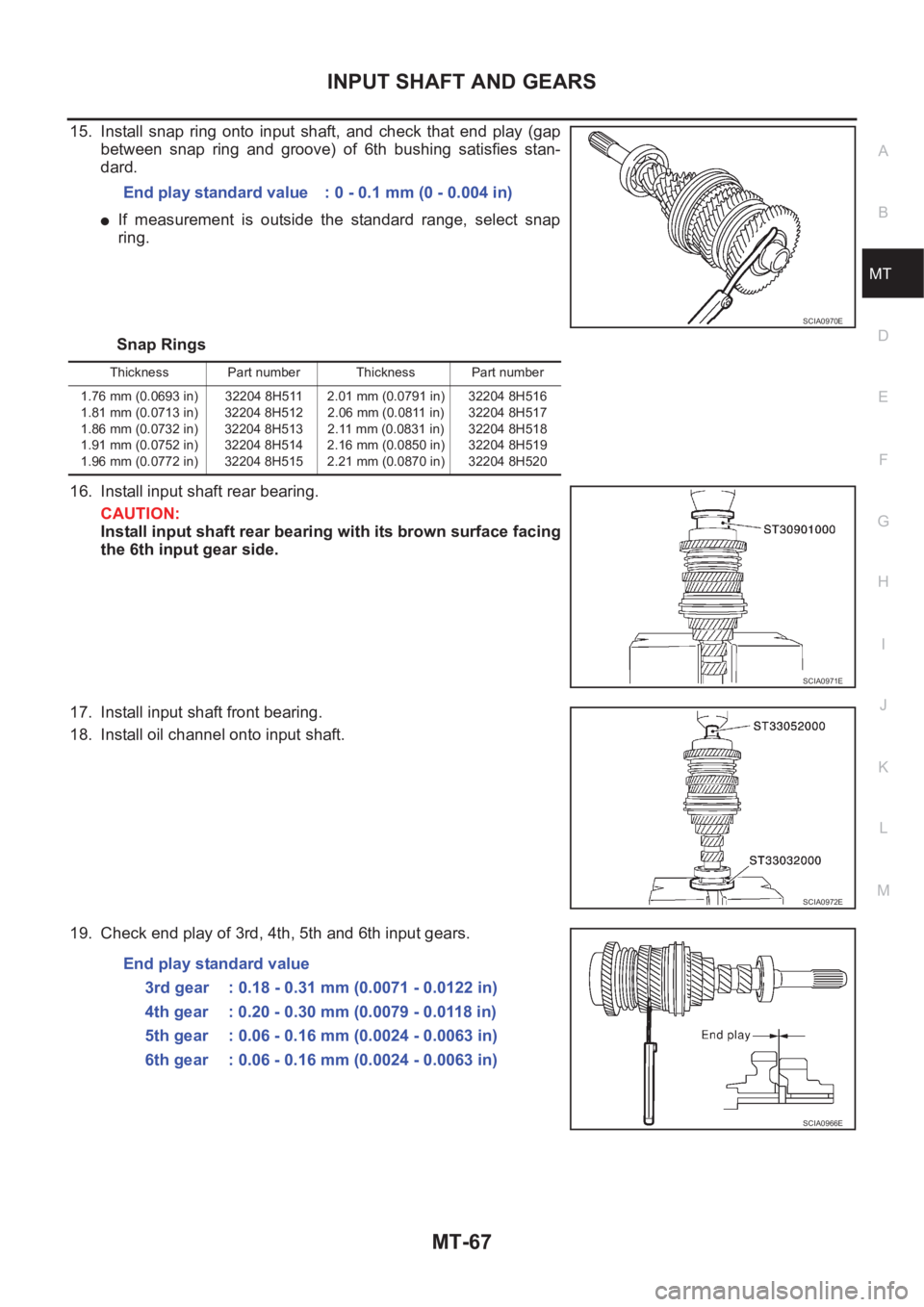

15. Install snap ring onto input shaft, and check that end play (gap

between snap ring and groove) of 6th bushing satisfies stan-

dard.

●If measurement is outside the standard range, select snap

ring.

Snap Rings

16. Install input shaft rear bearing.

CAUTION:

Install input shaft rear bearing with its brown surface facing

the 6th input gear side.

17. Install input shaft front bearing.

18. Install oil channel onto input shaft.

19. Check end play of 3rd, 4th, 5th and 6th input gears.End play standard value : 0 - 0.1 mm (0 - 0.004 in)

SCIA0970E

Thickness Part number Thickness Part number

1.76 mm (0.0693 in)

1.81 mm (0.0713 in)

1.86 mm (0.0732 in)

1.91 mm (0.0752 in)

1.96 mm (0.0772 in)32204 8H511

32204 8H512

32204 8H513

32204 8H514

32204 8H5152.01 mm (0.0791 in)

2.06 mm (0.0811 in)

2.11 mm (0.0831 in)

2.16 mm (0.0850 in)

2.21 mm (0.0870 in)32204 8H516

32204 8H517

32204 8H518

32204 8H519

32204 8H520

SCIA0971E

SCIA0972E

End play standard value

3rd gear : 0.18 - 0.31 mm (0.0071 - 0.0122 in)

4th gear : 0.20 - 0.30 mm (0.0079 - 0.0118 in)

5th gear : 0.06 - 0.16 mm (0.0024 - 0.0063 in)

6th gear : 0.06 - 0.16 mm (0.0024 - 0.0063 in)

SCIA0966E

Page 2044 of 3833

MT-68

MAINSHAFT AND GEARS

MAINSHAFT AND GEARS

PFP:32241

Assembly and Disassembly (RS5F51A)ECS008C6

DISASSEMBLY

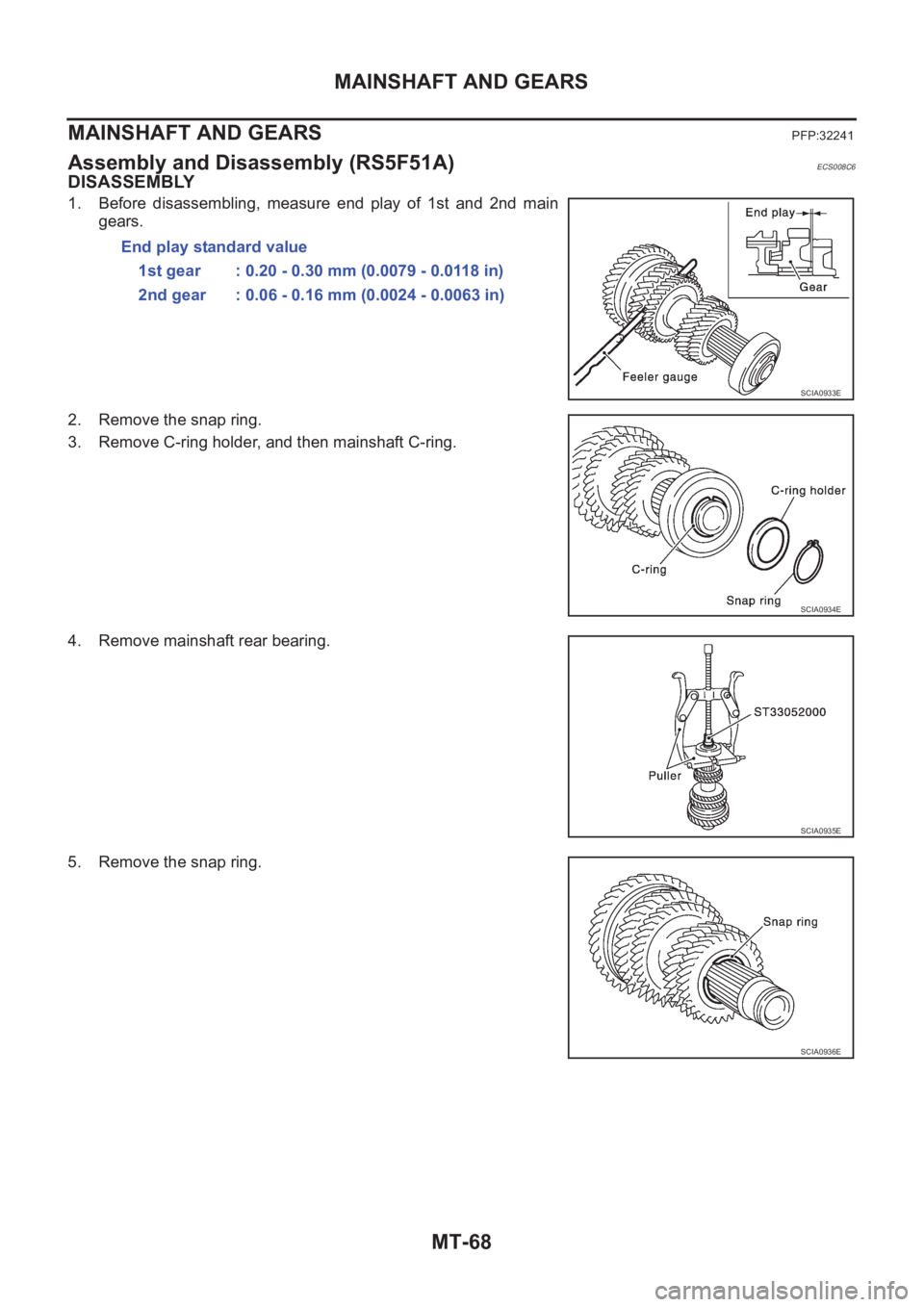

1. Before disassembling, measure end play of 1st and 2nd main

gears.

2. Remove the snap ring.

3. Remove C-ring holder, and then mainshaft C-ring.

4. Remove mainshaft rear bearing.

5. Remove the snap ring.End play standard value

1st gear : 0.20 - 0.30 mm (0.0079 - 0.0118 in)

2nd gear : 0.06 - 0.16 mm (0.0024 - 0.0063 in)

SCIA0933E

SCIA0934E

SCIA0935E

SCIA0936E

Page 2045 of 3833

MAINSHAFT AND GEARS

MT-69

D

E

F

G

H

I

J

K

L

MA

B

MT

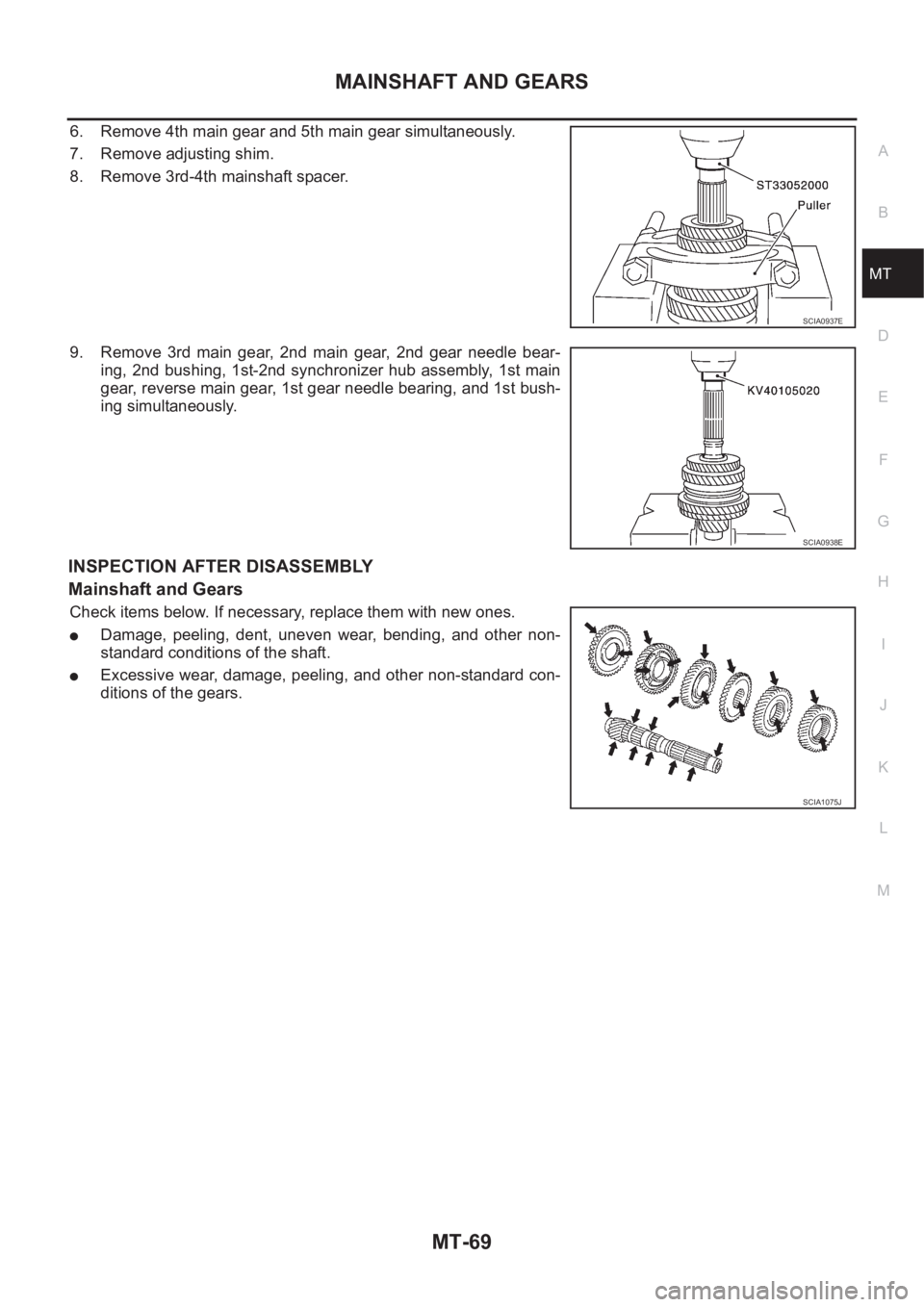

6. Remove 4th main gear and 5th main gear simultaneously.

7. Remove adjusting shim.

8. Remove 3rd-4th mainshaft spacer.

9. Remove 3rd main gear, 2nd main gear, 2nd gear needle bear-

ing, 2nd bushing, 1st-2nd synchronizer hub assembly, 1st main

gear, reverse main gear, 1st gear needle bearing, and 1st bush-

ing simultaneously.

INSPECTION AFTER DISASSEMBLY

Mainshaft and Gears

Check items below. If necessary, replace them with new ones.

●Damage, peeling, dent, uneven wear, bending, and other non-

standard conditions of the shaft.

●Excessive wear, damage, peeling, and other non-standard con-

ditions of the gears.

SCIA0937E

SCIA0938E

SCIA1075J

Page 2046 of 3833

MT-70

MAINSHAFT AND GEARS

Synchronizer

Check items below. If necessary, replace them with new ones.

●Damage and unusual wear on contact surfaces of coupling

sleeve, synchronizer hub, and shifting insert.

●Coupling sleeve and synchronizer hub must move smoothly.

●If any crack, damage, or excessive wear is found on cam face of

baulk ring or working face of insert, replace it.

Baulk ring clearance

●Double cone synchronizer (1st and 2nd)

Check clearance of outer baulk ring, synchronizer cone, and

inner baulk ring of 1st and 2nd double cone synchronizers, fol-

lowing procedure below.

CAUTION:

Outer baulk ring, synchronizer cone, and inner baulk ring

as a set control clearance A and B. If measurement exceeds

service limit value, replace all of them as a set.

1. Using a dial gauge, measure clearance A at 2 or more points

diagonally opposite, and calculate mean value.

SMT387A

SMT867D

SCIA0950E

Clearance A

Standard : 0.6 - 0.8 mm (0.024 - 0.031 in)

Limit value : 0.2 mm (0.008 in) or less

SCIA0951E

Page 2047 of 3833

MAINSHAFT AND GEARS

MT-71

D

E

F

G

H

I

J

K

L

MA

B

MT

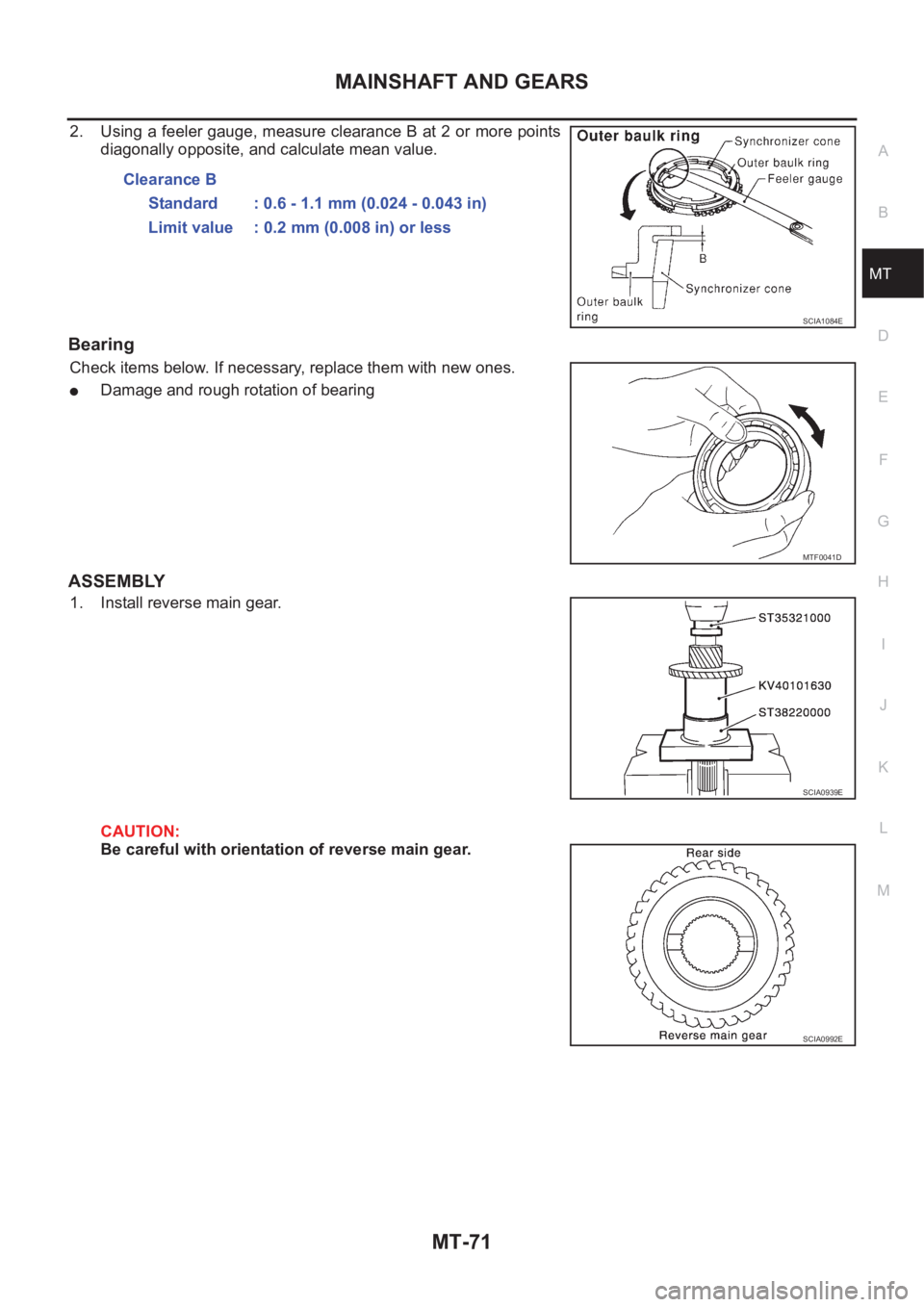

2. Using a feeler gauge, measure clearance B at 2 or more points

diagonally opposite, and calculate mean value.

Bearing

Check items below. If necessary, replace them with new ones.

●Damage and rough rotation of bearing

ASSEMBLY

1. Install reverse main gear.

CAUTION:

Be careful with orientation of reverse main gear.Clearance B

Standard : 0.6 - 1.1 mm (0.024 - 0.043 in)

Limit value : 0.2 mm (0.008 in) or less

SCIA1084E

MTF0041D

SCIA0939E

SCIA0992E

Page 2048 of 3833

MT-72

MAINSHAFT AND GEARS

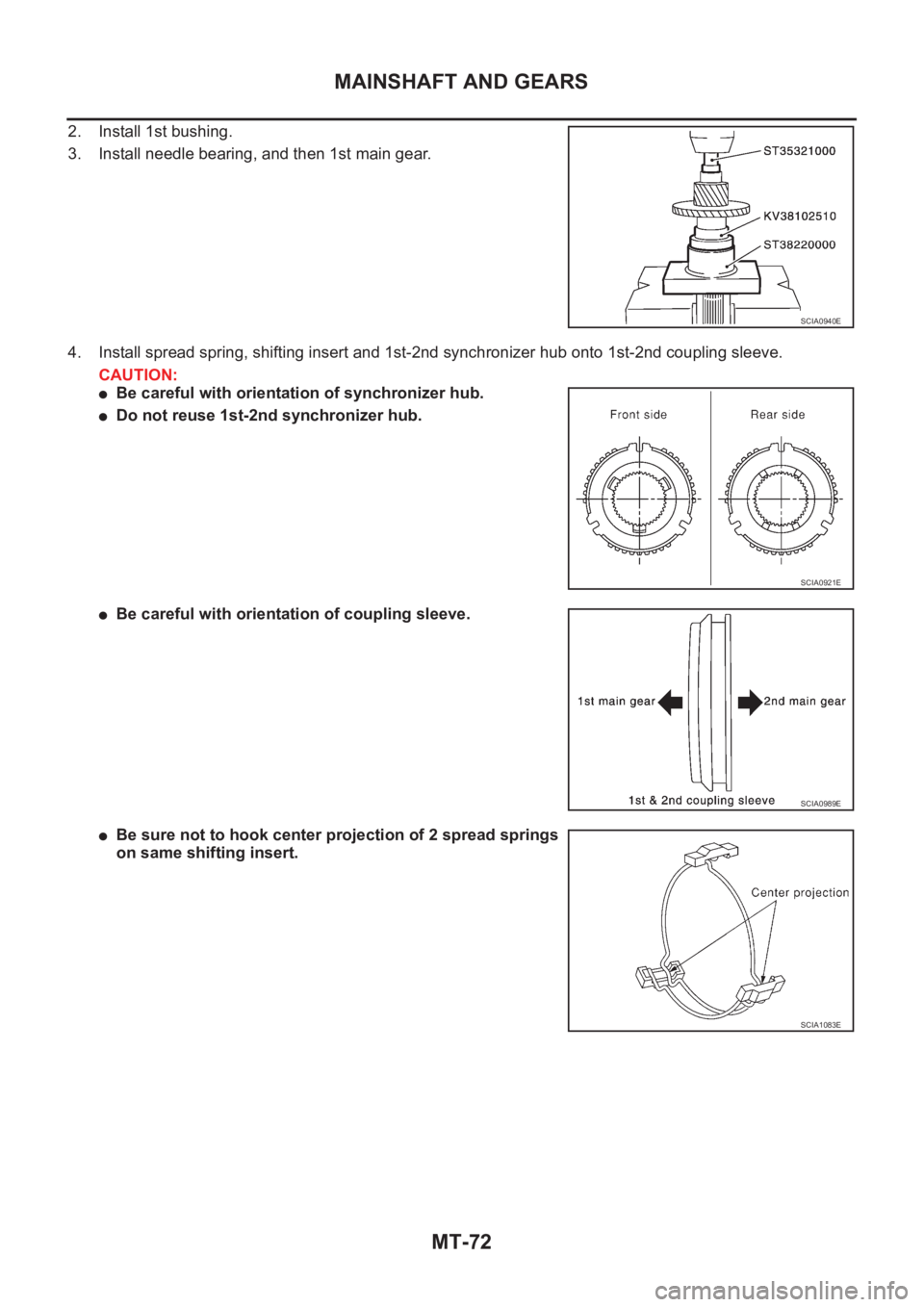

2. Install 1st bushing.

3. Install needle bearing, and then 1st main gear.

4. Install spread spring, shifting insert and 1st-2nd synchronizer hub onto 1st-2nd coupling sleeve.

CAUTION:

●Be careful with orientation of synchronizer hub.

●Do not reuse 1st-2nd synchronizer hub.

●Be careful with orientation of coupling sleeve.

●Be sure not to hook center projection of 2 spread springs

on same shifting insert.

SCIA0940E

SCIA0921E

SCIA0989E

SCIA1083E

Page 2049 of 3833

MAINSHAFT AND GEARS

MT-73

D

E

F

G

H

I

J

K

L

MA

B

MT

5. Install 1st gear synchronizer assembly onto mainshaft, and syn-

chronizer hub assembly onto mainshaft.

CAUTION:

●Outer baulk ring, synchronizer cone, and inner baulk ring

on 2nd gear-side must have been removed.

●Be careful with orientation of coupling sleeve.

6. Install 2nd bushing.

7. Install outer baulk ring, synchronizer cone, and inner baulk ring

on 2nd gear-side.

8. Install 2nd needle bearing and 2nd gear.

9. Install 3rd main gear.

CAUTION:

Be careful with orientation of 3rd main gear.

10. Install 3rd-4th mainshaft spacer.

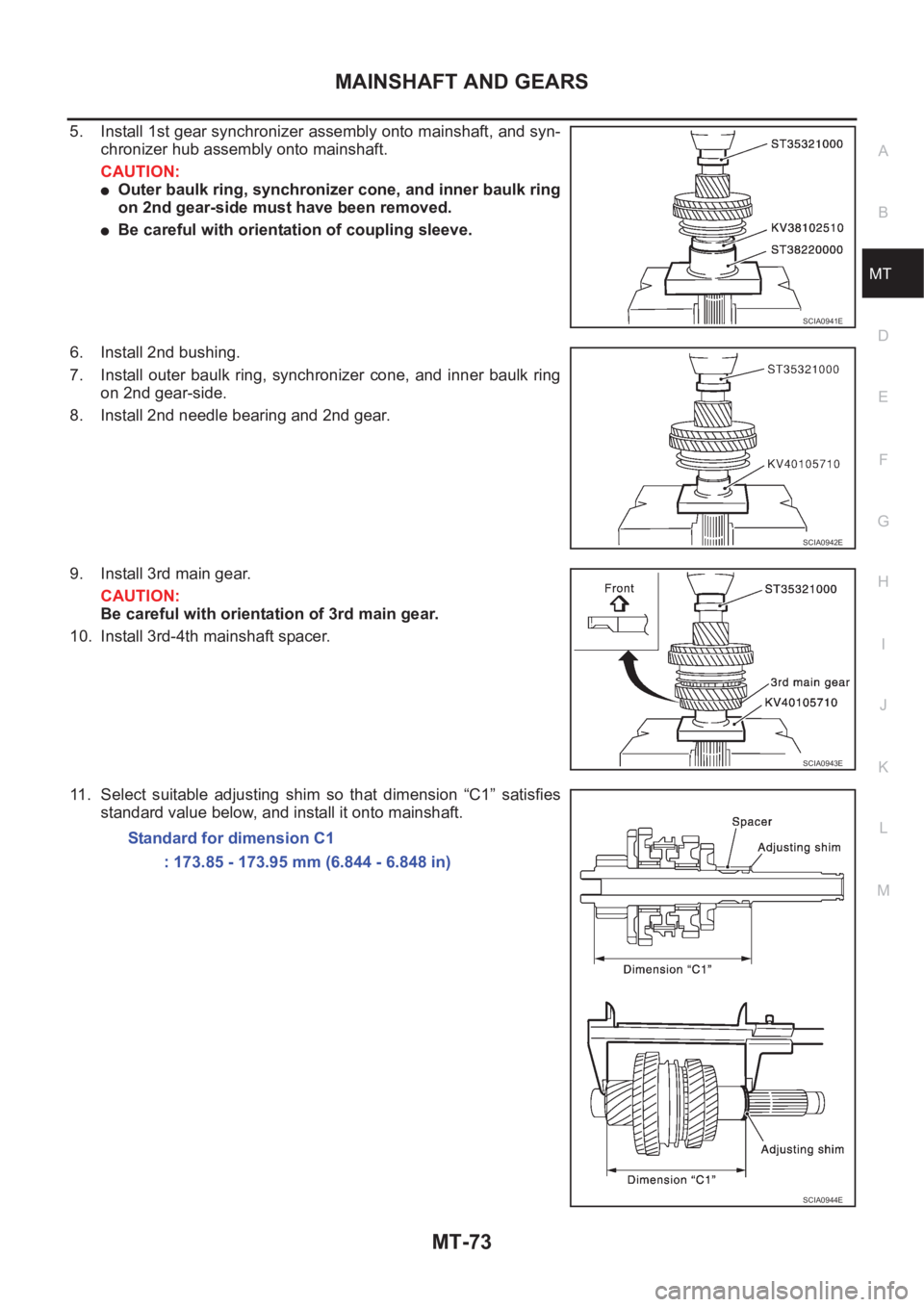

11. Select suitable adjusting shim so that dimension “C1” satisfies

standard value below, and install it onto mainshaft.

SCIA0941E

SCIA0942E

SCIA0943E

Standard for dimension C1

: 173.85 - 173.95 mm (6.844 - 6.848 in)

SCIA0944E

Page 2050 of 3833

MT-74

MAINSHAFT AND GEARS

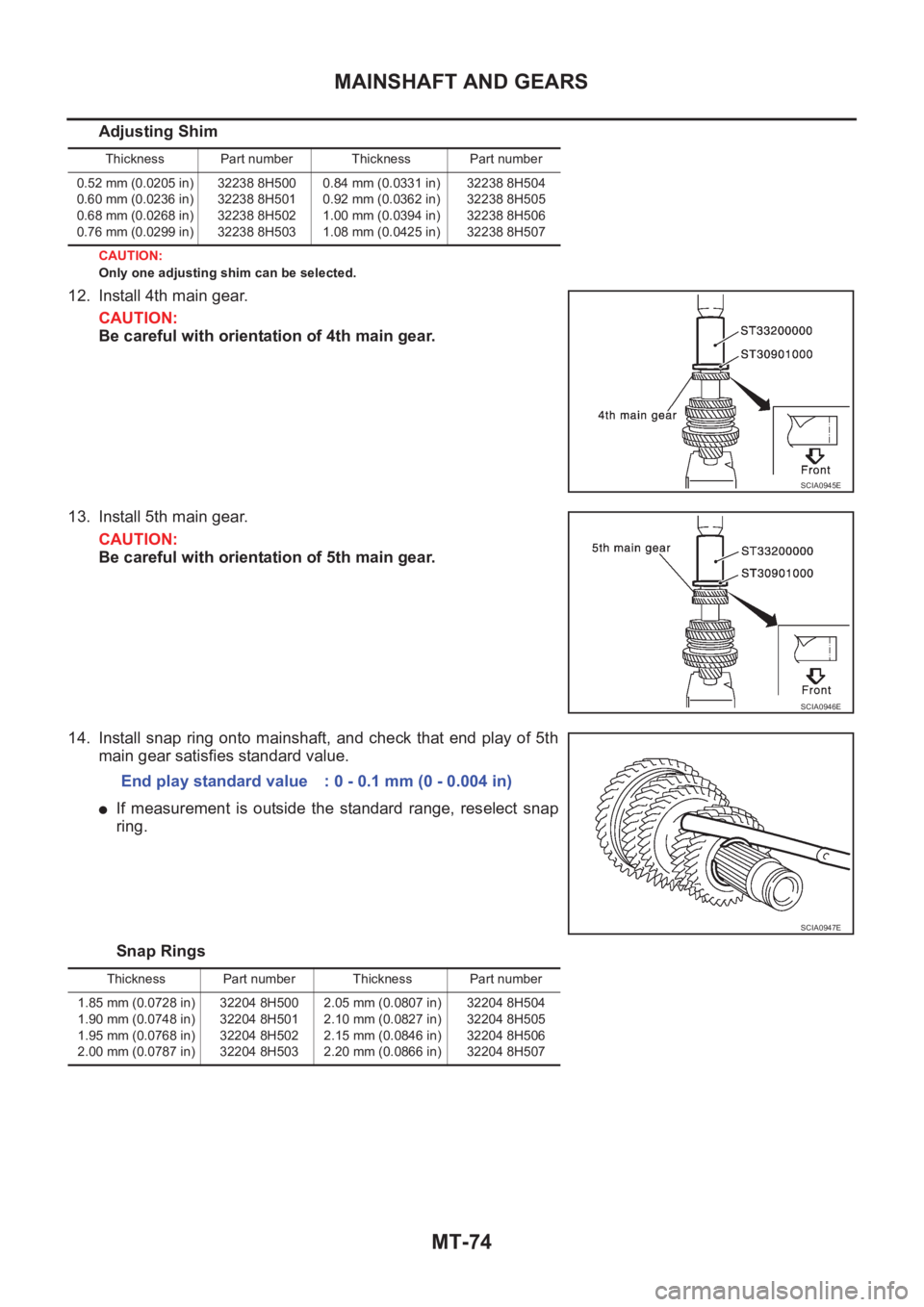

Adjusting Shim

CAUTION:

Only one adjusting shim can be selected.

12. Install 4th main gear.

CAUTION:

Be careful with orientation of 4th main gear.

13. Install 5th main gear.

CAUTION:

Be careful with orientation of 5th main gear.

14. Install snap ring onto mainshaft, and check that end play of 5th

main gear satisfies standard value.

●If measurement is outside the standard range, reselect snap

ring.

Snap Rings

Thickness Part number Thickness Part number

0.52 mm (0.0205 in)

0.60 mm (0.0236 in)

0.68 mm (0.0268 in)

0.76 mm (0.0299 in)32238 8H500

32238 8H501

32238 8H502

32238 8H5030.84 mm (0.0331 in)

0.92 mm (0.0362 in)

1.00 mm (0.0394 in)

1.08 mm (0.0425 in)32238 8H504

32238 8H505

32238 8H506

32238 8H507

SCIA0945E

SCIA0946E

End play standard value : 0 - 0.1 mm (0 - 0.004 in)

SCIA0947E

Thickness Part number Thickness Part number

1.85 mm (0.0728 in)

1.90 mm (0.0748 in)

1.95 mm (0.0768 in)

2.00 mm (0.0787 in)32204 8H500

32204 8H501

32204 8H502

32204 8H5032.05 mm (0.0807 in)

2.10 mm (0.0827 in)

2.15 mm (0.0846 in)

2.20 mm (0.0866 in)32204 8H504

32204 8H505

32204 8H506

32204 8H507