NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 2781 of 3833

PARKING BRAKE SHOE

PB-7

C

D

E

G

H

I

J

K

L

MA

B

PB

INSPECTION

●Visually check lining for abnormal wear, damage, and peeling.

●Using a scale, check thickness of lining.

CAUTION:

If necessary, remove brake shoe, and check as follows.

●Check shoe sliding surface for abnormal wear and damage.

●Check anchor pin for abnormal wear and corrosion.

●Check return spring for sagging.

●Check adjuster for rough operation.

●Visually check inside of drum for abnormal wear, damage, and

cracks. Using a pair of vernier calipers, check inside of drum.

INSTALLATION

1. Apply brake grease to the contact area of show at left.Standard lining thickness : 3.5 mm (0.138 in)

Lining limit (A) : 1.5 mm (0.059 in)

Standard inner diameter : 172 mm (6.77 in)

Maximum inner diameter : 173 mm (6.81 in)

SBR021A

SBR768A

SBR047C

Page 2782 of 3833

PB-8

PARKING BRAKE SHOE

2. Attach upper-side return springs to brake shoe as shown in the

figure. Be sure to install return spring B over return spring A.

3. Orientation of adjusters is different for LH adjuster and RH

adjuster. Assemble adjusters so that threaded part is expanded

when rotating it to direction shown by arrow. Contract adjuster to

assemble.

CAUTION:

When adjuster was disassembled, apply brake grease to thread.

4. Assemble torque lever in direction of installation as shown in the

figure.

SFIA0281E

SFIA0153E

SBR096C

Page 2783 of 3833

PARKING BRAKE SHOE

PB-9

C

D

E

G

H

I

J

K

L

MA

B

PB

5. After assembly, be sure that each part is installed properly.

6. Fix disc rotor with wheel nut, and adjust brake shoe clearance.

Remove adjusting hole plug. Turn star wheel on adjuster in

direction A (for both wheels) until disc rotor locks. Then turn star

wheel in the opposite direction for 6 notches.

7. Rotate disc rotor to be sure that there is no drag. Then install

adjusting hole plug.

8. Adjust parking brake cable.

CAUTION:

If brake shoes were replaced with new ones. Carry out break-in

operation.

SBR048C

SBR097CA

Page 2784 of 3833

PB-10

SERVICE DATA AND SPECIFICATIONS (SDS)

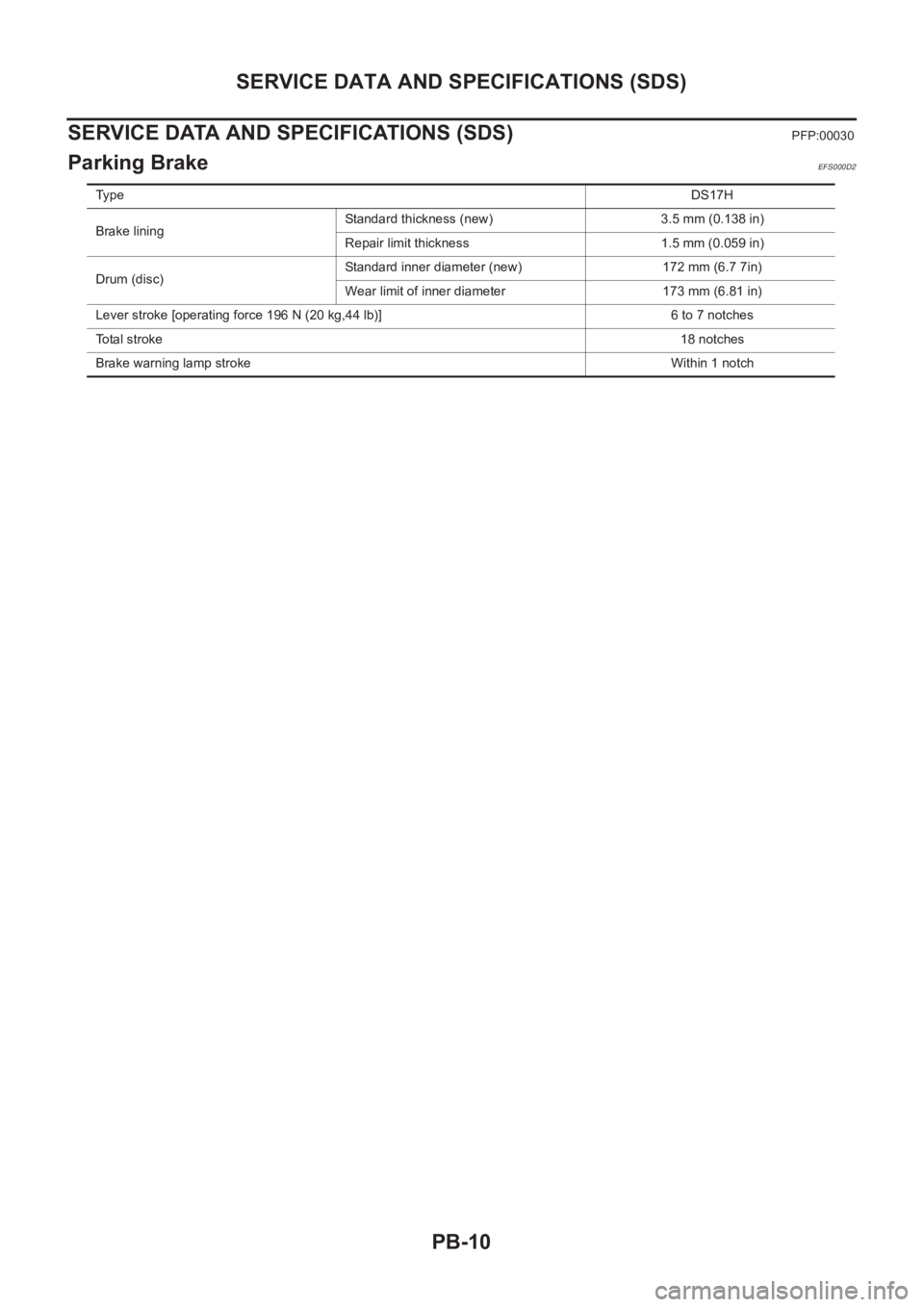

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Parking BrakeEFS000D2

Ty p eDS17H

Brake liningStandard thickness (new) 3.5 mm (0.138 in)

Repair limit thickness 1.5 mm (0.059 in)

Drum (disc)Standard inner diameter (new) 172 mm (6.7 7in)

Wear limit of inner diameter 173 mm (6.81 in)

Lever stroke [operating force 196 N (20 kg,44 lb)] 6 to 7 notches

To t a l s t r o k e18 notches

Brake warning lamp strokeWithin 1 notch

Page 2785 of 3833

BRC-1

BRAKE CONTROL SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTION

A

B

BRC

BRAKE CONTROL SYSTEM

4WD/ABS

PRECAUTIONS .......................................................... 4

Precautions for brake system ................................... 4

Precautions for brake control ................................... 4

PREPARATION ........................................................... 5

Special Service Tool ................................................. 5

Commercial Service Tool ......................................... 5

ALL MODE 4X4 SYSTEM .......................................... 6

System Description .................................................. 6

ABS FUNCTION ................................................... 6

4WD FUNCTION ................................................... 6

Control System Diagram .......................................... 6

TROUBLE DIAGNOSIS .............................................. 7

Fail-safe Function ..................................................... 7

How to Proceed with Trouble Diagnosis .................. 7

BASIC CONCEPT ................................................. 7

DIAGNOSIS FLOW ............................................... 8

ASKING COMPLAINTS ........................................ 9

TROUBLE DIAGNOSIS SHEET - EXAMPLE ....... 9

Component Parts Location ..................................... 10

Schematic ............................................................... 11

Wiring Diagram — ABS — ..................................... 12

Trouble Diagnosis Chart by Symptom .................... 18

4WD/ABS Control Unit Input/Output Signal Stan-

dard ........................................................................ 19

4WD/ABS CONTROL UNIT CONNECTOR TER-

MINAL ARRANGEMENT .................................... 19

REFERENCE STANDARD TABLE ..................... 19

CONSULT-II Functions ........................................... 23

CONSULT-II FUNCTION APPLICATION TABLE ... 23

SELF-DIAGNOSIS .............................................. 24

DATA MONITOR ................................................. 26

ACTIVE TEST ..................................................... 29

Component Inspection ........................................... 30

ABS ACTUATOR ................................................ 30

4WD SOLENOID VALVE .................................... 32

Basic Inspection ..................................................... 32

BASIC INSPECTION 1 BRAKE FLUID LEVEL

AND LEAKAGE INSPECTION ............................ 32

BASIC INSPECTION 2 INSPECTION FOR LOOSE POWER SUPPLY TERMINAL ............... 32

BASIC INSPECTION 3 ABS/4WD WARNING

LAMP INSPECTION ............................................ 32

Wheel Sensor System ............................................ 32

INSPECTION PROCEDURE .............................. 32

Control Unit Power Supply System ........................ 34

INSPECTION PROCEDURE .............................. 34

G -Sensor System (4WD models) .......................... 34

INSPECTION PROCEDURE .............................. 34

4WD Solenoid, Actuator Relay System .................. 35

4WD Mode Switch System ..................................... 37

Trouble Diagnoses for Symptoms .......................

... 38

4WD INDICATOR LAMP DOES NOT COME ON

FOR APPROXIMATELY 1 SECOND WHEN THE

IGNITION SWITCH IS TURNED TO ON ............. 38

4WD WARNING LAMP DOES NOT ILLUMINATE

WITH IGNITION ON ............................................ 39

4WD WARNING LAMP DOES NOT GO OUT

SEVERAL SECONDS AFTER ENGINE

STARTED.(4WD MODE INDICATOR LAMP

GOES OUT) ........................................................ 39

HEAVY TIGHT-CORNER BRAKING SYMPTOM

OCCURS WHEN THE VEHICLE IS DRIVEN IN

AUTO MODE AND THE STEERING WHEEL IS

TURNED FULLY TO EITHER SIDE AFTER THE

ENGINE IS STARTED ......................................... 39

4WD MODES CANNOT BE SWITCHED AFTER

ENGINE IS STARTED ......................................... 41

WHILE DRIVING, 4WD WARNING LAMP

FLASHES RAPIDLY. (WHEN IT FLASHERS FOR

APPROX. ONE MINUTE, THEN DOES NOT

ILLUMINATE.) ..................................................... 41

WHILE DRIVING, 4WD WARNING LAMP

FLASHES SLOWLY. (WHEN IT CONTINUES TO

ILLUMINATE UNTIL ENGINE TURNS OFF.) ...... 41

VEHICLE DOES NOT ENTER 4WD MODE

EVEN THOUGH 4WD WARNING LAMP IS OFF. ... 41

TIGHT-CORNER BRAKING SYMPTOM

OCCURS WHEN THE VEHICLE IS STARTED IN

AUTO WARNING LAMP REMAIN OFF). ............ 42

Page 2786 of 3833

BRC-2

4WD ACTUATOR RELAY (4WD SOLENOID

A C T U AT O R R E L AY ) T U R N S O N / O F F F R E -

QUENTLY ............................................................ 42

ABS Warning Lamp Does Not Illuminate. (ABS

Warning Lamp Does Not Come On When The Igni-

tion Switch Is Turned ON.) ...................................... 42

ABS Warning Lamp Illuminates With Ignition ON,

But Does Not Illuminates After A Few Seconds.

(ABS Warning Lamp Has Illuminated.) ................... 42

4WD Warning Lamp Does Not Illuminate With Igni-

tion ON. .................................................................. 43

4WD Warning Lamp Does Not Go Out Several Sec-

onds After Engine Is Started. (Drive Mode Indicator

Lamp Goes Out.) .................................................... 43

Heavy Tight-corner Braking Symptom Occurs

When The Vehicle Is Driven In Auto Mode And The

Steering Wheel Is Turned Fully To Either Side After

The Engine Is Started. ............................................ 44

Drive Modes Cannot Be Switched After Engine Is

Started. ................................................................... 45

Wheel Driving, 4WD Warning Lamp Flashes Rap-

idly. (When It Flashes For Approx. One Minute, Then

Does Not Illuminate.) .............................................. 45

Wheel Driving, 4WD Warning Lamp Flashes Slowly.

(When It Continues To Illuminate Until Engine Turns

OFF.) ....................................................................... 45

Vehicle Does Not Enter 4WD Mode Even Though

4WD Warning Lamp Is OFF. ................................... 46

Tight-corner Braking Symptom Occurs When The

Vehicle Is Started In Auto Mode (4WD Warning

Lamp Remain OFF). ............................................... 46

E-TS Actuator Relay (4WD Solenoid Actuator

Relay) Turns ON/OFF Frequently. .......................... 46

Inspection Of Drive Mode Change-over Switch Path ... 47

4WD/ABS CONTROL UNIT ...................................... 48

Removal and Installation ........................................ 48

REMOVAL ........................................................... 48

INSTALLATION .................................................... 48

WHEEL SENSORS ................................................... 49

Removal and Installation ........................................ 49

G-SENSOR (4WD MODEL ONLY) ............................ 50

Removal and Installation ........................................ 50

SENSOR ROTOR ................................................... ... 51

Removal and Installation ........................................ 51

REMOVAL ........................................................... 51

INSTALLATION .................................................... 51

ACTUATOR ............................................................... 52

Removal and Installation ........................................ 52

REMOVAL ........................................................... 53

INSTALLATION .................................................... 53

ESP/TCS/ABS

PRECAUTIONS ......................................................... 54

Precautions for Brake System ................................ 54

Precautions for Brake Control ................................ 54

Precautions for CAN System .................................. 54

FOR INSPECTION .............................................. 54

FOR HARNESS REPAIR .................................... 55PREPARATION ......................................................... 56

Special Service Tool ................................................ 56

Commercial Service Tool ........................................ 56

ON-VEHICLE SERVICE ............................................ 57

Adjustment of Neutral Position of Steering Wheel

Angle Sensor .......................................................... 57

GENERAL INFORMATION ....................................... 59

Fail-Safe .................................................................. 59

ABS SYSTEM ...................................................... 59

ESP/TCS SYSTEM .............................................. 59

Hydraulic Circuit ...................................................... 59

ABS Functions ........................................................ 59

TCS Functions ........................................................ 60

ESP Functions ........................................................ 60

System Diagram ..................................................... 61

CAN COMMUNICATION ........................................... 62

System Description ................................................. 62

FOR A/T MODELS ............................................... 62

FOR M/T MODELS .............................................. 62

TROUBLE DIAGNOSIS ............................................ 64

How to Perform Trouble Diagnoses for Quick and

Accurate Repair ...................................................... 64

INTRODUCTION ................................................. 64

WORK FLOW ...................................................... 65

ASKING COMPLAINTS ....................................... 66

EXAMPLE OF DIAGNOSIS SHEET .................... 66

Component Parts and Harness Connector Location ... 67

Schematic ............................................................... 68

Wiring Diagram —ESP/TCS/ABS— ..................... 69

Control Unit Input/Output Signal Standard .............. 75

STANDARDS USING A CIRCUIT TESTER AND

OSCILLOSCOPE ................................................. 75

STANDARDS WITH CONSULT-II ........................ 78

Functions of CONSULT-II ....................................... 80

CONSULT-II MAINLY FUNCTION APPLICA-

TION TO ESP/TCS/ABS ...................................... 80

SELF-DIAGNOSIS ............................................... 81

DATA MONITOR .................................................. 83

ACTIVE TEST ...................................................... 87

For Correct and Quick Diagnosis ............................ 90

PRECAUTIONS FOR TROUBLE DIAGNOSIS ... 90

Basic Inspection ...................................................... 91

PRELIMINARY CHECK 1: (BRAKE FLUID

LEVEL AND LEAK INSPECTION) ....................... 91

PRELIMINARY CHECK 2: (INSPECTION FOR

LOOSE POWER SUPPLY TERMINAL) ............... 92

PRELIMINARY CHECK 3: (INSPECTION FOR

ABS WARNING LAMP, ESP OFF INDICATOR

LAMP, AND SLIP INDICATOR LAMP) ................. 92

Inspection 1 Wheel Sensor and Circuit ................... 92

Inspection 2 Engine System ................................... 94

Inspection 3 ESP/TCS/ABS Control Unit System ... 94

Inspection 4 Pressure Sensor and the Circuit

between Pressure Sensor and ESP/TCS/ABS Con-

trol Unit. ................................................................... 95

Inspection 5 Steering wheel Angle Sensor and the

Circuit between Steering Wheel Angle Sensor and

ESP/TCS/ABS Control Unit. ................................... 96

Inspection 6 Yaw Rate Sensor and Side G sensor

Page 2787 of 3833

BRC-3

C

D

E

G

H

I

J

K

L

MA

B

BRC and the Circuit between Yaw Rate Sensor and Side

G sensor and ESP/TCS/ABS Control Unit. ............ 98

Inspection 7 Solenoid Valve, ESP Switch-over Sole-

noid Valve and Circuit ......................................... ... 99

Inspection 8 Actuator Motor, Motor Relay and Circuit

. 102

Inspection 9 Actuator Relay and Circuit ............... 104

Inspection 10 Stop Lamp Switch and Circuit ........ 106

Inspection 11 ESP/TCS/ABS Control Unit Power

Supply Circuit ....................................................... 106

Inspection 12 When “EMERGENCY BRAKE” is

indicated in the Self-Diagnosis Results ................ 108

Inspection 13 When “ST ANG SEN SIGNAL” is Indi-

cated in the Self-Diagnosis Results .....................108

Inspection 14 Brake Fluid Level of Reservoir Tank,

Communication Circuit between ESP/TCS/ABS

Control Unit and Brake Fluid Level Warning Switch . 109

Inspection 15 CAN Communication Circuit, ESP/

TCS/ABS Control Unit and Steering Wheel Angle

Sensor ................................................................... 110

Component Check ............................................... . 111

ESP OFF SWITCH ............................................ . 111

ESP RELAY BOX .............................................. . 111

ESP ACTUATOR ............................................... 112

Symptom 1: ABS Works Frequently. ..................... 114

Symptom 2: Unexpected Pedal Action .................. 114

Symptom 3: Longer Stopping Distance ................. 115

Symptom 4: ABS Does Not Work. ........................ 116Symptom 5: Pedal Vibration and Noise ................116

Symptom 6: ESP OFF Indicator Lamp Does Not Illu-

minate ...................................................................117

Symptom 7: SLIP Indicator Lamp Does Not Illumi-

nate .......................................................................118

Symptom 8: During ESP/TCS/ABS Control, Vehicle

Behavior is Jerky. .................................................118

ESP/TCS/ABS CONTROL UNIT ............................120

Removal and Installation ......................................120

REMOVAL .........................................................120

INSTALLATION .................................................120

WHEEL SPEED SENSORS ....................................121

Removal and Installation ......................................121

SENSOR ROTOR ...................................................122

Removal and Installation ......................................122

REMOVAL .........................................................122

INSTALLATION .................................................122

ESP/TCS/ABS ACTUATOR AND RELAY BOX .....123

Removal and Installation ......................................123

YAW RATE/SIDE G SENSOR .................................124

Removal and Installation ......................................124

REMOVAL .........................................................124

INSTALLATION .................................................124

ESP OFF SWITCH ................................................. .125

Removal and Installation ......................................125

REMOVAL .........................................................125

INSTALLATION .................................................125

Page 2788 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

●Recommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

●Never reuse drained brake fluid.

●Be NISSAN X-TRAIL 2001 Service Repair Manual BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

●Recommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

●Never reuse drained brake fluid.

●Be](/img/5/57405/w960_57405-2787.png)

BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

●Recommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

●Never reuse drained brake fluid.

●Be careful not to splash brake fluid on painted areas.

●To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use clean brake fluid.

●Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

●Use flare nut wrench when removing and installing brake tube.

●Always torque brake lines when installing.

●Burnish the brake contact surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer to BR-10, "

Brake Burnishing

Procedure" .

●Before working, turn OFF ignition switch. Disconnect connectors

for ABS actuator and control module or battery terminals.

WARNING:

●Clean brake pads and shoes with a waste cloth, then wipe

with a dust collector.

Precautions for brake controlEFS001B7

●If malfunction is indicated by 4WD warning lamp and/or ABS warning lamp, collect necessary information

from customer (what symptoms are present under what conditions). Find out possible causes before start-

ing service. Besides electrical system inspection, check operation of ABS actuator.

●If malfunction is detected, proceed to trouble diagnosis after checking tire pressure and tire wear.

●Stopping distance or steering stability may be deteriorated by the following conditions. Tire size and type

are in improper combination. Brake pads are not Nissan genuine parts.

●Fitting tires of different size on vehicle can be cause of longitudinal vibration. Always use tires of the same

size and brand. Exchange front and rear tires on the following conditions: Longitudinal vibration occurs in

vehicle with tires of the same size and brand. After replacement, perform trouble diagnosis. 1580|None

●4WD/ABS function may have a failure or error under following condition: There is radio, antenna, or

antenna lead-in wire (including wiring) near control module.

●If aftermarket parts (e.g. Car stereo equipment, CD player) have been installed, check electrical har-

nesses for pinches, open, and improper wiring.

SBR820BA

Page 2789 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual PREPARATION

BRC-5

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

PREPARATIONPFP:00002

Special Service ToolEFS001B8

Commercial Service ToolEFS00216

Tool number

Tool nameDescription

GG9431 0000

Flare nut torque NISSAN X-TRAIL 2001 Service Repair Manual PREPARATION

BRC-5

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

PREPARATIONPFP:00002

Special Service ToolEFS001B8

Commercial Service ToolEFS00216

Tool number

Tool nameDescription

GG9431 0000

Flare nut torque](/img/5/57405/w960_57405-2788.png)

PREPARATION

BRC-5

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

PREPARATIONPFP:00002

Special Service ToolEFS001B8

Commercial Service ToolEFS00216

Tool number

Tool nameDescription

GG9431 0000

Flare nut torque wrench

a: 10mm (0.39 in)Removing and installing each brake

piping

NT406

Tool nameDescription

Brake fluid pressure gauge Measuring brake fluid pressure

S-NT151

Page 2790 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual BRC-6

[4WD/ABS]

ALL MODE 4X4 SYSTEM

ALL MODE 4X4 SYSTEM

PFP:47850

System DescriptionEFS001CJ

ABS FUNCTION

●During ABS operation, brake pedal lightly vibrates and its mechanical noise may be heard. T NISSAN X-TRAIL 2001 Service Repair Manual BRC-6

[4WD/ABS]

ALL MODE 4X4 SYSTEM

ALL MODE 4X4 SYSTEM

PFP:47850

System DescriptionEFS001CJ

ABS FUNCTION

●During ABS operation, brake pedal lightly vibrates and its mechanical noise may be heard. T](/img/5/57405/w960_57405-2789.png)

BRC-6

[4WD/ABS]

ALL MODE 4X4 SYSTEM

ALL MODE 4X4 SYSTEM

PFP:47850

System DescriptionEFS001CJ

ABS FUNCTION

●During ABS operation, brake pedal lightly vibrates and its mechanical noise may be heard. This is a nor-

mal condition.

●When starting engine, or just after starting vehicle, brake pedal may vibrate. Also motor operating noise

may be heard from engine compartment. This is a normal status of operation check.

● When vehicle drives on rough, gravel, or snowy (fresh deep snow) road, the following conditions occur.

Stopping distance may be longer than that of vehicles without ABS.

4WD FUNCTION

● Electronically controlled 4WD is controlled by the same control module as that for ABS (4WD/ABS control

unit). 4WD/ABS control unit controls both electronically-controlled 4WD and ABS, based on input signals

from several sensors.

●If electrical system-related malfunction occurred in 4WD/ABS system, control unit illuminates the following

lamps: 4WD warning lamp and/or ABS warning lamp on meter control unit assembly. This notifies driver of

malfunction. At the same time, control unit indicates malfunctioning part detected by self-diagnosis with

flashing pattern of LED. Indication on electronic system diagnosis tester (CONSULT) corresponds to this

flashing pattern as shown below.

Control System DiagramEFS001CK

Self-diagnostic test mode Remarks

Result of self-diagnosis Conformable to 4WD/ABS

Data monitor Conformable to 4WD/ABS

Active testChecks ABS solenoid valve ON/OFF, ABS motor ON/OFF, 4WD sole-

noid

Control unit part No. 4WD/ABS control unit

SFIA0350E