oil level NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 7 of 3833

PRECAUTIONS

GI-5

C

D

E

F

G

H

I

J

K

L

MB

GI

●Use approved bonding agent, sealants or their equivalents when required.

●Use tools and recommended special tools where specified for safe and efficient service repairs.

●When repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

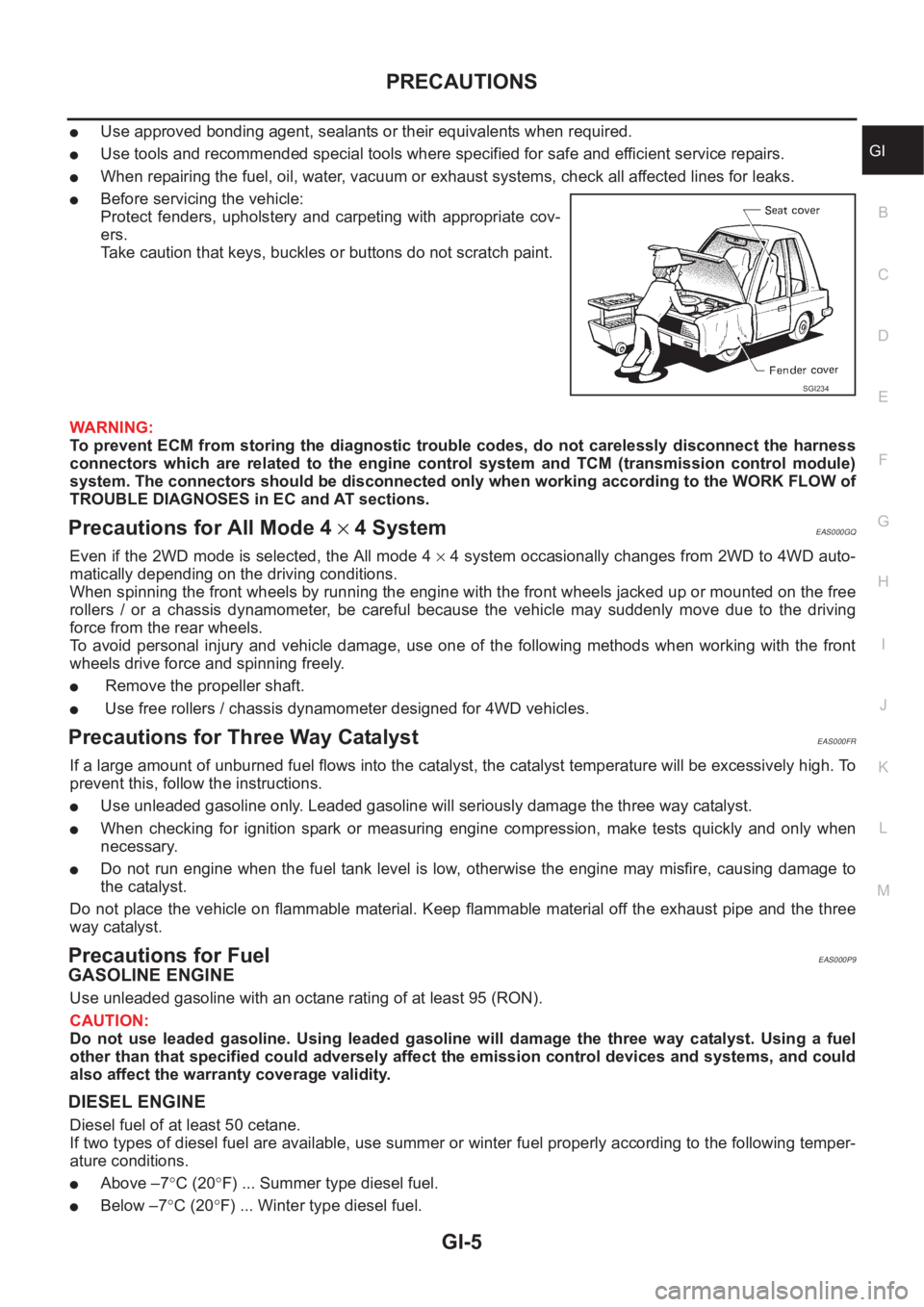

●Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precautions for All Mode 4 × 4 SystemEAS000GQ

Even if the 2WD mode is selected, the All mode 4 × 4 system occasionally changes from 2WD to 4WD auto-

matically depending on the driving conditions.

When spinning the front wheels by running the engine with the front wheels jacked up or mounted on the free

rollers / or a chassis dynamometer, be careful because the vehicle may suddenly move due to the driving

force from the rear wheels.

To avoid personal injury and vehicle damage, use one of the following methods when working with the front

wheels drive force and spinning freely.

● Remove the propeller shaft.

● Use free rollers / chassis dynamometer designed for 4WD vehicles.

Precautions for Three Way CatalystEAS000FR

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

●Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

●When checking for ignition spark or measuring engine compression, make tests quickly and only when

necessary.

●Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to

the catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precautions for FuelEAS000P9

GASOLINE ENGINE

Use unleaded gasoline with an octane rating of at least 95 (RON).

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Using a fuel

other than that specified could adversely affect the emission control devices and systems, and could

also affect the warranty coverage validity.

DIESEL ENGINE

Diesel fuel of at least 50 cetane.

If two types of diesel fuel are available, use summer or winter fuel properly according to the following temper-

ature conditions.

●Above –7°C (20°F) ... Summer type diesel fuel.

●Below –7°C (20°F) ... Winter type diesel fuel.

SGI234

Page 8 of 3833

GI-6

PRECAUTIONS

CAUTION:

●Do not use home heating oil, gasoline or other alternate fuels in your diesel engine. The use of

those can cause engine damage.

●Do not use summer fuel at temperatures below –7°C (20°F). The cold temperatures will cause wax

to form in the fuel. As a result, it may prevent the engine from running smoothly.

●Do not add gasoline or other alternate fuels to diesel fuel.

Precautions for Multiport Fuel Injection System or Engine Control SystemEAS000FT

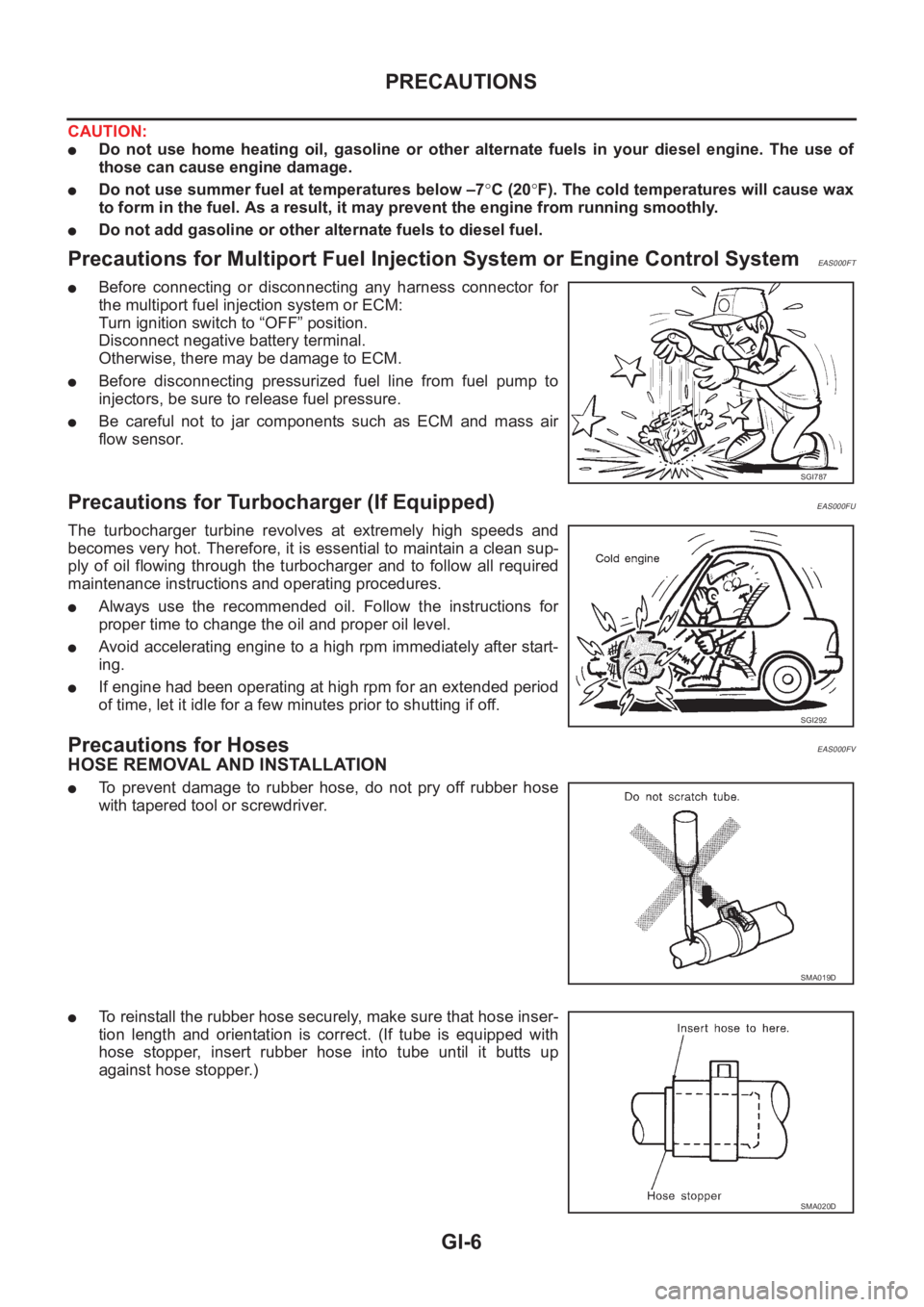

●Before connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

●Before disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

●Be careful not to jar components such as ECM and mass air

flow sensor.

Precautions for Turbocharger (If Equipped)EAS000FU

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean sup-

ply of oil flowing through the turbocharger and to follow all required

maintenance instructions and operating procedures.

●Always use the recommended oil. Follow the instructions for

proper time to change the oil and proper oil level.

●Avoid accelerating engine to a high rpm immediately after start-

ing.

●If engine had been operating at high rpm for an extended period

of time, let it idle for a few minutes prior to shutting if off.

Precautions for HosesEAS000FV

HOSE REMOVAL AND INSTALLATION

●To prevent damage to rubber hose, do not pry off rubber hose

with tapered tool or screwdriver.

●To reinstall the rubber hose securely, make sure that hose inser-

tion length and orientation is correct. (If tube is equipped with

hose stopper, insert rubber hose into tube until it butts up

against hose stopper.)

SGI787

SGI292

SMA019D

SMA020D

Page 76 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-26

[QR]

OIL PAN AND OIL STRAINER

OIL PAN AND OIL STRAINER

P F P : 1111 0

Removal and InstallationEBS00KNE

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the engine oil when the NISSAN X-TRAIL 2001 Service Repair Manual EM-26

[QR]

OIL PAN AND OIL STRAINER

OIL PAN AND OIL STRAINER

P F P : 1111 0

Removal and InstallationEBS00KNE

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the engine oil when the](/img/5/57405/w960_57405-75.png)

EM-26

[QR]

OIL PAN AND OIL STRAINER

OIL PAN AND OIL STRAINER

P F P : 1111 0

Removal and InstallationEBS00KNE

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the engine oil when the engine is hot.

1. Remove engine undercover both side.

2. Drain engine oil. Refer to LU-8, "

Changing Engine Oil" .

3. Remove lower oil pan bolts, Loosen bolts in the reverse order of

that shown in the figure.

KBIA0095E

1. Oil level gauge guide 2. Oil pan upper 3. Cylinder block

4. Oil filter 5. Oil strainer 6. Drain plug

7. Oil pan lower 8. Rear plate cover

KBIA0096E

Page 78 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-28

[QR]

OIL PAN AND OIL STRAINER

a. Apply liquid gasket thoroughly as in illustration.

Use Genuine Liquid Gasket or equivalent.

b. Install O-rings as front cover side.

c. Tighten bolts in numerical NISSAN X-TRAIL 2001 Service Repair Manual EM-28

[QR]

OIL PAN AND OIL STRAINER

a. Apply liquid gasket thoroughly as in illustration.

Use Genuine Liquid Gasket or equivalent.

b. Install O-rings as front cover side.

c. Tighten bolts in numerical](/img/5/57405/w960_57405-77.png)

EM-28

[QR]

OIL PAN AND OIL STRAINER

a. Apply liquid gasket thoroughly as in illustration.

Use Genuine Liquid Gasket or equivalent.

b. Install O-rings as front cover side.

c. Tighten bolts in numerical order as shown.

●No. 10, 11and 18 indicate double tightening of bolts No. 1, 2

and 3.

NOTE:

Refer to the below for locating bolts.

M6 × 20 mm (0.79 in): No. 18, 19

M8 × 25 mm (0.98 in): No. 1, 2, 3, 11

M8 x 45 mm (1.77 in): No. 4, 10, 13, 14, 15, 16

M8 x100 mm (3.97 in): No. 5, 6, 7, 8, 9

d. Tighten transmission joint bolts.

e. Install rear plate cover.

3. Install lower oil pan.

Use Genuine Liquid Gasket or equivalent.

●Tighten bolts in numerical order as shown.

4. Install oil pan drain plug.

●Refer to illustration of components of former page for installation direction of washer.

5. Install in the reverse order of removal after this step.

●Pour engine oil at least 30 minutes after oil pan is installed.

INSPECTION AFTER INSTALLATION

●Check engine oil level. Refer to LU-7, "ENGINE OIL" .

●Check for leakage of engine oil when engine is warmed.

SBIA0253E

SBIA0233E

SBIA0254E

KBIA0096E

Page 110 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-60

[QR]

CYLINDER HEAD

●If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine

speed again with normal battery gravity.

●If compression NISSAN X-TRAIL 2001 Service Repair Manual EM-60

[QR]

CYLINDER HEAD

●If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine

speed again with normal battery gravity.

●If compression](/img/5/57405/w960_57405-109.png)

EM-60

[QR]

CYLINDER HEAD

●If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine

speed again with normal battery gravity.

●If compression pressure is below minimum value, check valve clearances and parts associated with

combustion chamber (Valve, valve seat, piston, piston ring, cylinder bore, cylinder head, cylinder head

gasket). After the checking, measure compression pressure again.

●If some cylinders have low compression pressure, pour small amount of engine oil into the spark plug

hole of the cylinder to re-check it for compression.

–If the added engine oil improves the compression, the piston rings may be worn out or damaged. Check

the piston rings and replace if necessary.

–If the compression pressure remains at low level despite the addition of engine oil, the valves may be

malfunctioning. Check the valves for damage. Replace the valve or valve seat accordingly.

●If two adjacent cylinders have respectively low compression pressure and their compression remains

low even after the addition of engine oil, the gaskets are leaking. In such a case, replace the cylinder

head gaskets.

8. Install spark plug, ignition coil and harness connectors.

Removal and InstallationEBS00KNQ

REMOVAL

1. Release fuel pressure. Refer to EC-775, "FUEL PRESSURE RELEASE" [QR20DE (WITH EURO-OBD)],

EC-1139, "

FUEL PRESSURE RELEASE" [QR20DE (WITHOUT EURO-OBD)], EC-42, "FUEL PRES-

SURE RELEASE" [QR25DE (WITH EURO-OBD)] or EC-452, "FUEL PRESSURE RELEASE" [QR25DE

(WITHOUT EURO-OBD)].

2. Drain engine coolant and engine oil.

3. Remove the following components and related parts.

●Engine hood and engine undercover.

●Air cleaner case and air duct assembly; Refer to EM-14, "AIR CLEANER AND AIR DUCT" .

●Ignition coils; Refer to EM-29, "IGNITION COIL" .

●Rocker cover; Refer to EM-35, "ROCKER COVER" .

●Engine coolant reservoir tank

●Drive belt; Refer to EM-12, "REMOVAL" .

●Alternator

●Drive belt auto-tensioner; Refer to EM-13, "REMOVAL" .

●Exhaust front tube; Refer to EX-2, "Removal and Installation" .

●Exhaust manifold; Refer to EM-24, "EXHAUST MANIFOLD AND THREE WAY CATALYST" .

KBIA0250E

1. Cylinder head assembly 2. Cylinder head gasket 3. Cylinder head bolt

Page 121 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual ENGINE ASSEMBLY

EM-71

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

●Use a manual lift table caddy or equivalently rigid tool such as

a jack or trestle. Securely support bottom of engine and tran-

saxle, and simul NISSAN X-TRAIL 2001 Service Repair Manual ENGINE ASSEMBLY

EM-71

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

●Use a manual lift table caddy or equivalently rigid tool such as

a jack or trestle. Securely support bottom of engine and tran-

saxle, and simul](/img/5/57405/w960_57405-120.png)

ENGINE ASSEMBLY

EM-71

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

●Use a manual lift table caddy or equivalently rigid tool such as

a jack or trestle. Securely support bottom of engine and tran-

saxle, and simultaneously adjust hoist tension.

CAUTION:

Put a piece of wood or something similar as the support-

ing surface, secure a completely stable condition.

23. Remove RH engine mounting insulator.

24. Pull LH engine mounting through-bolt out.

25. Remove mounting bolts at front end of center member.

26. Remove front suspension member mounting bolts and nuts.

27. Remove engine, transaxle and transfer assembly with suspen-

sion member from vehicle downward by carefully operating sup-

porting tools.

CAUTION:

●During the operation, make sure that no part interferes

with body side.

●Before and during this lifting, always check if any har-

nesses are left connected.

●During the removal operation, always be careful to pre-

vent vehicle from falling off the lift due to changes in the center of gravity.

●If necessary, support vehicle by setting a jack or equivalent tool at the rear.

28. Remove power steering pump with piping connected from engine. Move it aside on suspension member.

29. Remove front engine mounting and rear engine mounting through-bolts to remove suspension member.

30. Remove starter motor.

31. Separate engine and transaxle. Refer to MT-15, "

TRANSAXLE ASSEMBLY" (M/T models) or AT- 4 1 8 ,

"REMOVAL AND INSTALLATION" (A/T models)

INSTALLATION

Install in the reverse order of removal.

●Do not allow engine oil to get on mounting insulator. Be careful not to damage mounting insulator.

●When installation directions are specified, install parts according to the direction marks on them referring

to components illustration.

●Make sure that each mounting insulator is seated properly, and tighten mounting bolts and nuts.

INSPECTION AFTER INSTALLATION

●Before starting engine, check the levels of engine coolant, lubrications and working engine oils. If less

than required quantity, fill to the specified level.

●Run engine to check for unusual noise and vibration.

●Warm up engine thoroughly to make sure there is no leakage of engine coolant, lubricants, working

engine oil, fuel and exhaust gas.

KBIA0256E

KBIA0257E

KBIA0270E

Page 158 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-108

[QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

Bearing Oil Clearance

Unit: mm (in)

Tightening TorqueEBS00KNY

Unit: N·m (kg-m, ft-lb)

Unit: N·m (kg-m, in-lb)*2

Connecting rod bearing oil clearance NISSAN X-TRAIL 2001 Service Repair Manual EM-108

[QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

Bearing Oil Clearance

Unit: mm (in)

Tightening TorqueEBS00KNY

Unit: N·m (kg-m, ft-lb)

Unit: N·m (kg-m, in-lb)*2

Connecting rod bearing oil clearance](/img/5/57405/w960_57405-157.png)

EM-108

[QR]

SERVICE DATA AND SPECIFICATIONS (SDS)

Bearing Oil Clearance

Unit: mm (in)

Tightening TorqueEBS00KNY

Unit: N·m (kg-m, ft-lb)

Unit: N·m (kg-m, in-lb)*2

Connecting rod bearing oil clearanceStandard 0.028 - 0.045 (0.0011 - 0.0018)

Limit 0.10 (0.0039)

*1: Parts to be tightened in particular orders.

1)-: Order of tightening when tightening two or more times separately.

Auto-tensioner 19.6 - 23.5 (2.0 - 2.4, 15 - 17)

Mass air flow sensor

3.8 - 4.5 (0.39 - 0.46, 34 - 39) *

2

Resonator

3.8 - 4.5 (0.39 - 0.46, 34 - 39)*2

Air cleaner case lower

3.8 - 4.5 (0.39 - 0.46, 34 - 39)*2

*1 Intake manifold17.6 - 21.6 (1.8 - 2.2, 13 - 15)

Intake manifold collector 17.6 - 21.6 (1.8 - 2.2, 13 - 15)

Intake manifold support 17.6 - 21.6 (1.8 - 2.2, 13 - 15)

Electric throttle control actuator

7.2 - 9.6 (0.74 - 0.98, 64 - 84) *

2

EVAP canister purge volume control solenoid valve

4.3 - 5.8 (0.44 - 0.59, 38 - 51) *2

*1 Exhaust manifold 39.2 - 44.1 (4.0 - 4.5, 29 - 32)

Exhaust manifold cover

5.1 - 6.5 (0.52 - 0.66, 46 - 57) *

2

Heated oxygen sensor 40 - 50 (4.1 - 5.1, 30 - 36)

*1 Oil pan upper M6 bolt

8.1 - 9.5 (0.83 - 0.97, 72 - 84) *

2

M8 bolt 19.6 - 23.5 (2.0 - 2.4, 15 - 17)

Oil pan upper to transmission joint bolts 39.2 - 46.1 (4.0 - 4.7, 29 - 34)

*1 Oil pan lower

6.4 - 7.5 (0.65 - 0.76, 57 - 66) *

2

Oil pan drain plug29.4 - 39.2 (3.0 - 4.0, 22 - 28)

Rear plate cover

6.4 - 7.5 (0.65 - 0.76, 57 - 66) *

2

Oil strainer M6 bolt

8.1 - 9.5 (0.83 - 0.97, 72 - 84) *2

M8 bolt 19.6 - 23.5 (2.0 - 2.4, 15 - 17)

Oil level gauge guide 19.6 - 23.5 (2.0 - 2.4, 15 - 17)

Ignition coil

5.4 - 7.3 (0.55 - 0.75, 48 - 64) *

2

Spark plug19.6 - 29.4 (2.0 - 3.0, 15 - 21)

*1 Fuel tube1)

2)9.3 - 10.8 (0.95 - 1.1, 0.7 - 0.8) *

2

20.6 - 26.5 (2.1 - 2.7, 16 - 19)

*1 Rocker cover1)

2)0.98 - 2.9 (0.1 - 0.3, 9 - 25) *

2

7.4 - 9.3 (0.75 - 0.95, 66 - 82) *2

PCV valve

1.96 - 2.94 (0.20 - 0.30, 18 - 26) *2

Intake valve timing control solenoid valve

5.4 - 7.3 (0.55 - 0.75, 48 - 64) *2

*1 Intake valve timing control cover 11.8 - 13.7 (1.2 - 1.4, 9 - 10)

Camshaft position sensor (PHASE)

5.4 - 7.3 (0.55 - 0.75, 48 - 64) *

2

Camshaft sprocket (Intake and Exhaust) 127- 157 (13.0 - 16.0, 94 - 115)

Chain tensioner

6.4 - 7.5 (0.65 - 0.76, 57 - 66) *

2

Page 182 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-132

[YD22DDTi]

EXHAUST MANIFOLD AND TURBOCHARGER

TROUBLE DIAGNOSIS OF TURBOCHARGER

Preliminary check:

●Check that the engine oil level is between MIN and MAX of the dipstick. (When the engine NISSAN X-TRAIL 2001 Service Repair Manual EM-132

[YD22DDTi]

EXHAUST MANIFOLD AND TURBOCHARGER

TROUBLE DIAGNOSIS OF TURBOCHARGER

Preliminary check:

●Check that the engine oil level is between MIN and MAX of the dipstick. (When the engine](/img/5/57405/w960_57405-181.png)

EM-132

[YD22DDTi]

EXHAUST MANIFOLD AND TURBOCHARGER

TROUBLE DIAGNOSIS OF TURBOCHARGER

Preliminary check:

●Check that the engine oil level is between MIN and MAX of the dipstick. (When the engine oil amount is

more than MAX, the engine oil flows into the inlet duct through the blow-by gas passage, and the turbo-

charger is misjudged failure.)

●Ask the customer if he/she always runs the vehicle in idle engine speed to cool the engine oil down after

driving.

●Replace the turbocharger assembly when any malfunction is found after unit inspections specified in the

table below.

●If no malfunction is found after the unit inspections, judge that the turbocharger body has no failure. Check

the other parts again.

A: Large possibility

B: Medium possibility

C: Small possibilityInspection item Inspection resultSymptom

(when each inspection item meets each inspection result)

Engine oil

leakageSmoke NoiseInsufficient power/

acceleration failure

Turbine wheelEngine oil leaks C A C C

Carbon is accumulated C A B B

Friction with housing C B A B

Blades are bent or broken — — A A

Compressor wheelInside the air inlet is seriously con-

taminated by engine oil.BB— —

Friction with housing C B A B

Blades are bent or broken — — A A

After checking both turbine and

compressor, inspect rotor shaft

end play.There is resistance when the rotor

shaft is rotated by your fingertips.—CC B

The rotor shaft sometimes does not

rotate by your fingertips.——— A

There is too much play in the bear-

ing.CCB C

Oil return portCarbon or sludge is accumulated in

the waste oil hole.CAC C

Page 187 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual OIL PAN AND OIL STRAINER

EM-137

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

b. Apply a continuous bead of liquid gasket to mating surface of

lower oil pan.

Use Genuine Liquid Gasket or equivalent.

NISSAN X-TRAIL 2001 Service Repair Manual OIL PAN AND OIL STRAINER

EM-137

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

b. Apply a continuous bead of liquid gasket to mating surface of

lower oil pan.

Use Genuine Liquid Gasket or equivalent.](/img/5/57405/w960_57405-186.png)

OIL PAN AND OIL STRAINER

EM-137

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

b. Apply a continuous bead of liquid gasket to mating surface of

lower oil pan.

Use Genuine Liquid Gasket or equivalent.

●Be sure liquid gasket is 3.5 to 4.5 mm (0.138 to 0.177 in)

wide.

●Attaching should be done within 5 minutes after coating.

8. Install oil pan drain plug.

●Refer to illustration of components parts for installation direc-

tion of washer.

9. Install in the reverse order of removal after this step.

●Pour engine oil or start engine at least 30 minutes after

oil pan is installed.

INSPECTION AFTER INSTALLATION

●Check engine oil level. Refer to LU-18, "ENGINE OIL" .

●Check for leakage of engine oil when engine is warmed.

SEM159F

SBIA0164E

SBIA0161E

Page 246 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-196

[YD22DDTi]

ENGINE ASSEMBLY

INSPECTION AFTER INSTALLATION

●Before starting engine check the levels of engine coolant, lubrications and working engine oils. If less than

required quantity, fill NISSAN X-TRAIL 2001 Service Repair Manual EM-196

[YD22DDTi]

ENGINE ASSEMBLY

INSPECTION AFTER INSTALLATION

●Before starting engine check the levels of engine coolant, lubrications and working engine oils. If less than

required quantity, fill](/img/5/57405/w960_57405-245.png)

EM-196

[YD22DDTi]

ENGINE ASSEMBLY

INSPECTION AFTER INSTALLATION

●Before starting engine check the levels of engine coolant, lubrications and working engine oils. If less than

required quantity, fill to the specified level.

●Before starting engine, bleed air from fuel piping. Refer to FL-16, "Air Bleeding" .

●Run engine to check for unusual noise and vibration.

●Warm up engine thoroughly to make sure there is no leakage of engine coolant, lubricants, working

engine oil, fuel and exhaust gas.

●Bleed air from passages in pipes and tubes of applicable lines.