torque NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 3 of 3833

GI-1

GENERAL INFORMATION

A GENERAL INFORMATION

CONTENTS

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTION

GENERAL INFORMATION

PRECAUTIONS .......................................................... 3

Description ............................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for NATS (NISSAN ANTI-THEFT SYS-

TEM) ........................................................................ 3

General Precautions ................................................ 4

Precautions for All Mode 4 × 4 System .................... 5

Precautions for Three Way Catalyst ......................... 5

Precautions for Fuel ................................................. 5

GASOLINE ENGINE ............................................. 5

DIESEL ENGINE ................................................... 5

Precautions for Multiport Fuel Injection System or

Engine Control System ............................................ 6

Precautions for Turbocharger (If Equipped) ............. 6

Precautions for Hoses .............................................. 6

HOSE REMOVAL AND INSTALLATION ............... 6

HOSE CLAMPING ................................................ 7

Precautions for Engine Oils ...................................... 7

HEALTH PROTECTION PRECAUTIONS ............. 7

ENVIRONMENTAL PROTECTION PRECAU-

TIONS ................................................................... 7

Precautions for Air Conditioning ............................... 7

HOW TO USE THIS MANUAL ................................... 8

Description ............................................................... 8

Terms ....................................................................... 8

Units ......................................................................... 8

Contents ................................................................... 8

Components ............................................................. 8

SYMBOLS ............................................................. 9

How to Follow Trouble Diagnoses ............................ 9

DESCRIPTION ...................................................... 9

HOW TO FOLLOW TEST GROUPS IN TROU-

BLE DIAGNOSES ............................................... 10

HARNESS WIRE COLOR AND CONNECTOR

NUMBER INDICATION ........................................ 11

KEY TO SYMBOLS SIGNIFYING MEASURE-

MENTS OR PROCEDURES ............................... 12

How to Read Wiring Diagrams ............................... 14CONNECTOR SYMBOLS ................................... 14

SAMPLE/WIRING DIAGRAM - EXAMPL - .......... 15

DESCRIPTION .................................................... 16

Abbreviations .......................................................... 22

SERVICE INFORMATION FOR ELECTRICAL INCI-

DENT ......................................................................... 23

How to Perform Efficient Diagnosis for an Electrical

Incident ................................................................... 23

WORK FLOW ...................................................... 23

INCIDENT SIMULATION TESTS ........................ 23

CIRCUIT INSPECTION ....................................... 26

Control Units and Electrical Parts ........................

... 31

PRECAUTIONS .................................................. 31

CONSULT-II CHECKING SYSTEM .......................... 33

Description .............................................................. 33

Function and System Application ........................... 33

Nickel Metal Hydride Battery Replacement ............ 33

Checking Equipment .............................................. 34

CONSULT-II Data Link Connector (DLC) Circuit .... 34

INSPECTION PROCEDURE .............................. 34

LIFTING POINT ......................................................... 35

Special Service Tools ............................................. 35

Garage Jack and Safety Stand ............................... 35

2-pole Lift ................................................................ 36

Board-on Lift ........................................................... 37

TOW TRUCK TOWING ............................................. 38

Tow Truck Towing ................................................... 38

TOWING AN AUTOMATIC TRANSAXLE

MODEL WITH FOUR WHEELS ON GROUND ... 38

T O W I N G T H E V E H I C L E W I T H R E A R W H E E L S

R A I S E D ( W I T H F R O N T W H E E L S O N G R O U N D )

OR FRONT WHEELS RAISED ........................... 39

Vehicle Recovery (Freeing a stuck vehicle) ............ 39

TIGHTENING TORQUE OF STANDARD BOLTS .... 40

Tightening Torque Table ......................................... 40

IDENTIFICATION INFORMATION ............................ 41

Model Variation ....................................................... 41

IDENTIFICATION NUMBER ................................ 42

IDENTIFICATION PLATE .................................... 43

ENGINE SERIAL NUMBER ................................ 43

Page 10 of 3833

GI-8

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

PFP:00008

Description EAS000FY

This volume explains “Removal, Disassembly, Installation, Inspection and Adjustment” and “Trouble Diag-

noses”.

Te r m sEAS000FZ

●The captions WARNING and CAUTION warn you of steps that must be followed to prevent personal

injury and/or damage to some part of the vehicle.

WARNING indicates the possibility of personal injury if instructions are not followed.

CAUTION indicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTS except WARNING and CAUTION give you helpful information.

Standard value:Tolerance at inspection and adjustment.

Limit value:The maximum or minimum limit value that should not be exceeded at inspection and adjust-

ment.

UnitsEAS000G0

●The UNITS given in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

“Example”

ContentsEAS000G1

●ALPHABETICAL INDEX is provided at the end of this manual so that you can rapidly find the item and

page you are searching for.

●A QUICK REFERENCE INDEX, a black tab (e.g. ) is provided on the first page. You can quickly find

the first page of each section by matching it to the section's black tab.

●THE CONTENTS are listed on the first page of each section.

●THE TITLE is indicated on the upper portion of each page and shows the part or system.

●THE PAGE NUMBER of each section consists of two or three letters which designate the particular sec-

tion and a number (e.g. “BR-5”).

●THE SMALL ILLUSTRATIONS show the important steps such as inspection, use of special tools, knacks

of work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic tran-

saxle or transmission, etc. are presented in a step-by-step format where necessary.

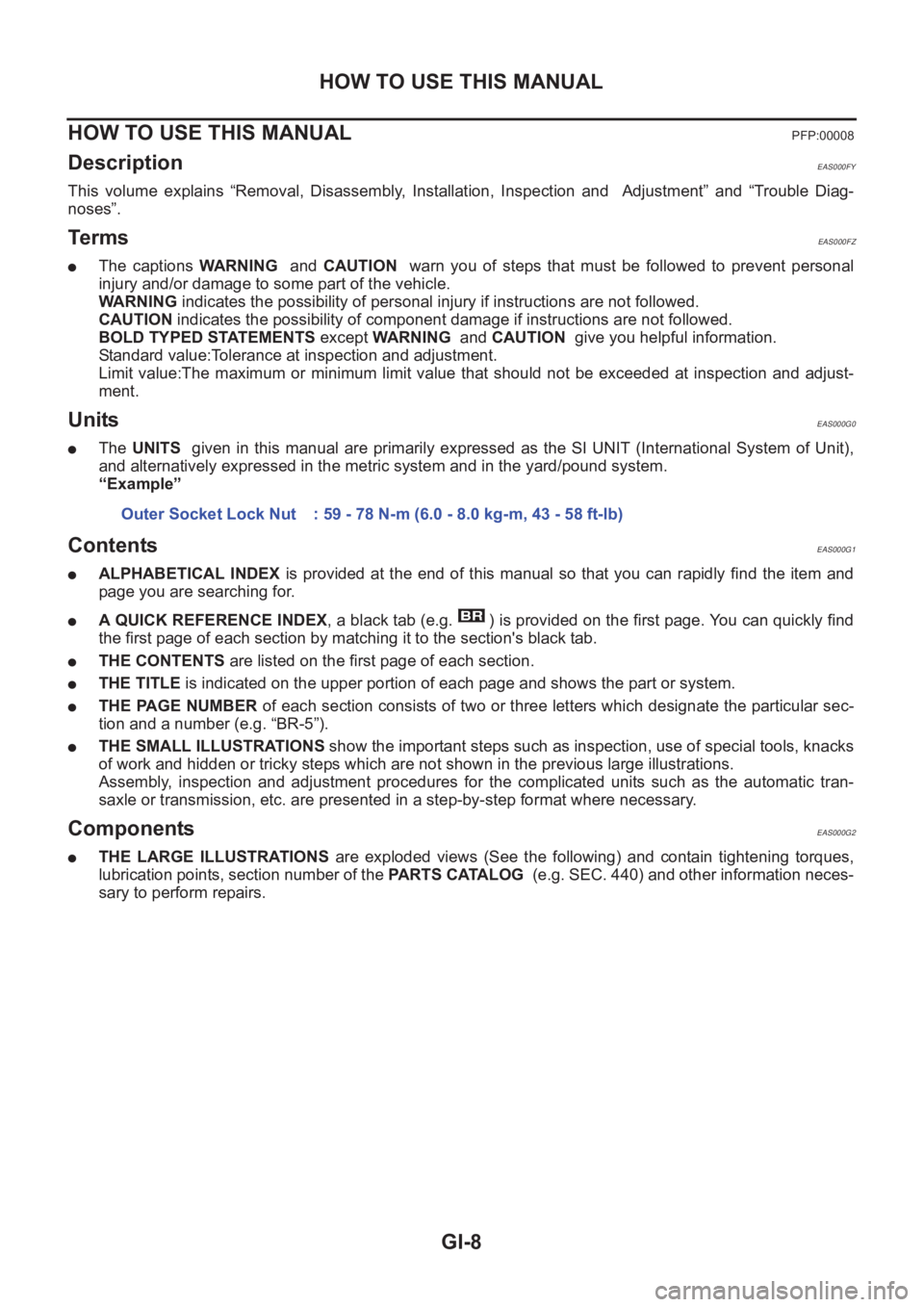

ComponentsEAS000G2

●THE LARGE ILLUSTRATIONS are exploded views (See the following) and contain tightening torques,

lubrication points, section number of the PARTS CATALOG (e.g. SEC. 440) and other information neces-

sary to perform repairs.Outer Socket Lock Nut : 59 - 78 N-m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

Page 11 of 3833

HOW TO USE THIS MANUAL

GI-9

C

D

E

F

G

H

I

J

K

L

MB

GI

The illustrations should be used in reference to service matters only. When ordering parts, refer to the

appropriate PARTS CATALOG .

SYMBOLS

How to Follow Trouble DiagnosesEAS000G3

DESCRIPTION

NOTICE:

Trouble diagnoses indicate work procedures required to diagnose problems effectively. Observe the following

instructions before diagnosing.

SBR364AC

SYMBOL DESCRIPTION

Tightening torque

Should be lubricated with grease. Unless otherwise indicated, use recommended multi-purpose grease.

Should be lubricated with oil.

Sealing point

Checking point

Always replace after every disassembly.

PApply petroleum jelly.

Apply ATF.

Select with proper thickness.

Adjustment is required.

Page 42 of 3833

GI-40

TIGHTENING TORQUE OF STANDARD BOLTS

TIGHTENING TORQUE OF STANDARD BOLTS

PFP:00000

Tightening Torque Table EAS000GD

*: Nominal diameter

1.Special parts are excluded.

2.This standard is applicable to bolts having the following marks embossed on the bolt head. Grade Bolt sizeBolt diam-

eter *

mmPitch

mmTightening torque (Without lubricant)

Hexagon head bolt Hexagon flange bolt

N·m kg-m ft-lb in-lb N·m kg-m ft-lb in-lb

4TM6 6.0 1.0 5.1 0.52 3.8 45.1 6.1 0.62 4.5 53.8

M8 8.01.25 13 1.3 9 — 15 1.5 11 —

1.0 13 1.3 9 — 16 1.6 12 —

M10 10.01.5 25 2.5 18 — 29 3.0 22 —

1.25 25 2.6 19 — 30 3.1 22 —

M12 12.01.75 42 4.3 31 — 51 5.2 38 —

1.25 46 4.7 34 — 56 5.7 41 —

M14 14.0 1.5 74 7.5 54 — 88 9.0 65 —

7TM6 6.0 1.0 8.4 0.86 6.2 74.6 10 1.0 7 87

M8 8.01.25 21 2.1 15 — 25 2.5 18 —

1.0 22 2.2 16 — 26 2.7 20 —

M10 10.01.5 41 4.2 30 — 48 4.9 35 —

1.25 43 4.4 32 — 51 5.2 38 —

M12 12.01.75 71 7.2 52 — 84 8.6 62 —

1.25 77 7.9 57 — 92 9.4 68 —

M14 14.0 1.5 127 13.0 94 — 147 15.0 108 —

9TM6 6.0 1.0 12 1.2 9 — 15 1.5 11 —

M8 8.01.25 29 3.0 22 — 35 3.6 26 —

1.0 31 3.2 23 — 37 3.8 27 —

M10 10.01.5 59 6.0 43 — 70 7.1 51 —

1.25 62 6.3 46 — 74 7.5 54 —

M12 12.01.75 98 10.0 72 — 118 12.0 87 —

1.25 108 11.0 80 — 137 14.0 101 —

M14 14.0 1.5 177 18.0 130 — 206 21.0 152 —

MGI044A

Page 49 of 3833

TERMINOLOGY

GI-47

C

D

E

F

G

H

I

J

K

L

MB

GI

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switchPark/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control sole-

noid valvePAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

Simultaneous multiport fuel injection sys-

tem*** Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

systemTWC + OC system ***

Throttle body TBThrottle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valveLock-up cancel solenoid

Lock-up solenoid NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 52 of 3833

EM-2

TIMING CHAIN .......................................................... 37

Removal and Installation ........................................ 37

REMOVAL ........................................................... 38

INSPECTION AFTER REMOVAL ........................ 41

INSTALLATION .................................................... 41

CAMSHAFT ............................................................... 46

Removal and Installation ........................................ 46

REMOVAL ........................................................... 46

INSTALLATION .................................................... 48

INSPECTION AFTER REMOVAL ........................ 51

Valve Clearance ...................................................... 53

INSPECTION ....................................................... 53

ADJUSTMENT .................................................... 54

OIL SEAL .................................................................. 56

Removal and Installation of Valve Oil Seal ............. 56

REMOVAL ........................................................... 56

INSTALLATION .................................................... 56

Removal and Installation of Front Oil Seal ............. 56

REMOVAL ........................................................... 56

INSTALLATION .................................................... 57

Removal and Installation of Rear Oil Seal .............. 57

REMOVAL ........................................................... 57

INSTALLATION .................................................... 57

CYLINDER HEAD .................................................. ... 59

On-Vehicle Service ................................................. 59

CHECKING COMPRESSION PRESSURE ......... 59

Removal and Installation ........................................ 60

REMOVAL ........................................................... 60

INSPECTION AFTER REMOVAL ........................ 61

INSTALLATION .................................................... 61

Disassembly and Assembly .................................... 62

DISASSEMBLY ................................................... 63

ASSEMBLY ......................................................... 63

Inspection After Disassembly ................................. 64

CYLINDER HEAD DISTORTION ........................ 64

VALVE DIMENSIONS .......................................... 64

VALVE GUIDE CLEARANCE .............................. 65

VALVE GUIDE REPLACEMENT ......................... 65

VALVE SEAT CONTACT ..................................... 66

VALVE SEAT REPLACEMENT ........................... 66

VALVE SPRING SQUARENESS ......................... 67

VALVE SPRING DIMENSIONS AND VALVE

SPRING PRESSURE LOAD ............................... 68

ENGINE ASSEMBLY ................................................ 69

Removal and Installation ........................................ 69

REMOVAL .......................................................

.... 69

INSTALLATION .................................................... 71

INSPECTION AFTER INSTALLATION ................ 71

CYLINDER BLOCK ................................................... 73

Disassembly and Assembly .................................... 73

DISASSEMBLY ................................................... 74

ASSEMBLY ......................................................... 78

How to Select Piston and Bearing .......................... 82

DESCRIPTION .................................................... 82

HOW TO SELECT PISTON ................................. 83

HOW TO SELECT CONNECTING ROD BEAR-

ING ...................................................................... 83HOW TO SELECT MAIN BEARING .................... 85

Inspection After Disassembly .................................. 88

CRANKSHAFT END PLAY .................................. 88

CONNECTING ROD SIDE CLEARANCE ........... 89

PISTON AND PISTON PIN CLEARANCE ........... 89

PISTON RING SIDE CLEARANCE ..................... 90

PISTON RING END GAP .................................... 90

CONNECTING ROD BEND AND TORSION ....... 91

CONNECTING ROD BEARING (BIG END) ........ 91

CONNECTING ROD BUSHING OIL CLEAR-

ANCE (SMALL END) ........................................... 91

CYLINDER BLOCK DISTORTION ...................... 92

INNER DIAMETER OF MAIN BEARING HOUS-

ING ....................................................................... 93

PISTON TO CYLINDER BORE CLEARANCE .... 93

OUTER DIAMETER OF CRANKSHAFT JOUR-

NAL ...................................................................... 94

OUTER DIAMETER OF CRANKSHAFT PIN ...... 94

OUT-OF-ROUND AND TAPER OF CRANK-

SHAFT ................................................................. 94

CRANKSHAFT RUNOUT .................................... 95

CONNECTING ROD BEARING OIL CLEAR-

ANCE ................................................................... 95

MAIN BEARING OIL CLEARANCE ..................... 95

MAIN BEARING CRUSH HEIGHT ...................... 96

OUTER DIAMETER OF LOWER CYLINDER

BLOCK MOUNTING BOLT .................................. 96

OUTER DIAMETER OF CONNECTING ROD

BOLT .................................................................... 96

MOVEMENT AMOUNT OF FLYWHEEL (M/T

MODELS) ............................................................. 97

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 98

Standard and Limit .................................................. 98

GENERAL SPECIFICATIONS ............................. 98

DRIVE BELTS ...................................................... 98

INTAKE MANIFOLD AND EXHAUST MANI-

FOLD ................................................................... 98

SPARK PLUG ...................................................... 98

CYLINDER HEAD ................................................ 98

VALVE .................................................................. 99

CAMSHAFT AND CAMSHAFT BEARING .........102

CYLINDER BLOCK ............................................102

PISTON, PISTON RING AND PISTON PIN .....

.103

CONNECTING ROD ..........................................104

CRANKSHAFT ...................................................105

MAIN BEARING .................................................106

CONNECTING ROD BEARING .........................107

Tightening Torque .................................................108

YD22DDTi

PRECAUTIONS .......................................................110

Precautions for Drain Engine Coolant ...................110

Precautions for Disconnecting Fuel Piping ...........110

Precautions for Removal and Disassembly ..........110

Precautions for Inspection, Repair and Replace-

ment ......................................................................110

Precautions for Assembly and Installation ............110

Page 54 of 3833

EM-4

INSPECTION AFTER REMOVAL ......................184

INSTALLATION ..................................................185

Disassembly and Assembly ..................................187

DISASSEMBLY .................................................187

ASSEMBLY .......................................................188

INSPECTION AFTER DISASSEMBLY ..............188

ENGINE ASSEMBLY ..............................................193

Removal and Installation ......................................193

REMOVAL .........................................................194

INSTALLATION ..................................................195

INSPECTION AFTER INSTALLATION ..............196

CYLINDER BLOCK .................................................197

Disassembly and Assembly ..................................197

DISASSEMBLY .................................................198

ASSEMBLY .......................................................202

How to Select Piston and Bearing ........................206

DESCRIPTION ..................................................206

HOW TO SELECT PISTON ...............................206

HOW TO SELECT CONNECTING ROD BEAR-

ING ....................................................................207

HOW TO SELECT MAIN BEARING ..................208

Inspection After Disassembly ...............................210

CRANKSHAFT END PLAY ................................210

CONNECTING ROD SIDE CLEARANCE .........210

PISTON TO PISTON PIN CLEARANCE ...........210

PISTON RING SIDE CLEARANCE ...................211

PISTON RING END GAP ..................................211

CONNECTING ROD BEND AND TORSION .....212

CONNECTING ROD BIG END INNER DIAME-

TER ...................................................................212

CONNECTING ROD BUSHING OIL CLEAR-

ANCE (SMALL END) .........................................212

CYLINDER BLOCK TOP SURFACE DISTOR-TION ..................................................................213

MAIN BEARING HOUSING INNER DIAMETER .213

PISTON TO CYLINDER BORE CLEARANCE ..214

CRANKSHAFT JOURNAL OUTER DIAMETER .215

CRANKSHAFT PIN OUTER DIAMETER ..........215

CRANKSHAFT OUT-OF-ROUND AND TAPER .215

CRANKSHAFT RUNOUT ..................................216

CONNECTING ROD BEARING OIL CLEAR-

ANCE .................................................................216

MAIN BEARING OIL CLEARANCE ...................216

MAIN BEARING CRUSH HEIGHT ....................217

MAIN BEARING CAP BOLT DEFORMATION ...217

CONNECTING ROD BOLT DEFORMATION ....217

OIL JET ..............................................................218

OIL JET RELIEF VALVE ....................................218

MOVEMENT AMOUNT OF FLYWHEEL ...........218

SERVICE DATA AND SPECIFICATIONS (SDS) ....220

Standard and Limit ...............................................

.220

GENERAL SPECIFICATIONS ...........................220

INTAKE MANIFOLD AND EXHAUST MANI-

FOLD .................................................................220

DRIVE BELTS ....................................................220

CYLINDER HEAD ..............................................221

VALVE ................................................................221

CAMSHAFT AND CAMSHAFT BEARING .........225

CYLINDER BLOCK ............................................225

PISTON, PISTON RING AND PISTON PIN ......226

CONNECTING ROD ..........................................227

CRANKSHAFT ...................................................227

AVAILABLE MAIN BEARING .............................228

AVAILABLE CONNECTING ROD BEARING .....228

MISCELLANEOUS COMPONENTS ..................228

Tightening Torque .................................................229

Page 55 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual PRECAUTIONS

EM-5

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

[QR]PRECAUTIONSPFP:00001

Precautions for Drain Engine CoolantEBS00KN0

Drain engine coolant when engine is cooled.

Precautions for Disconnecting Fuel Pip NISSAN X-TRAIL 2001 Service Repair Manual PRECAUTIONS

EM-5

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

[QR]PRECAUTIONSPFP:00001

Precautions for Drain Engine CoolantEBS00KN0

Drain engine coolant when engine is cooled.

Precautions for Disconnecting Fuel Pip](/img/5/57405/w960_57405-54.png)

PRECAUTIONS

EM-5

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

[QR]PRECAUTIONSPFP:00001

Precautions for Drain Engine CoolantEBS00KN0

Drain engine coolant when engine is cooled.

Precautions for Disconnecting Fuel PipingEBS00KN1

●Before starting work, make sure no fire or spark producing items are in the work area.

●Release fuel pressure before disassembly.

●After disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyEBS00KN2

●When instructed to use special service tools, use the specified tools. Always be careful to work safely,

avoid forceful or uninstructed operations.

●Exercise maximum care to avoid damage to mating or sliding surfaces.

●Cover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

●Mark and arrange disassembly parts in an organized way for easy troubleshooting and re-assembly.

●When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loosening is specified, do exactly as specified.

Precautions for Inspection, Repair and ReplacementEBS00KN3

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precautions for Assembly and InstallationEBS00MRZ

●Use torque wrench to tighten bolts or nuts to specification.

●When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is speci-

fied, do exactly as specified.

●Replace with new gasket, packing, oil seal or O-ring.

●Thoroughly wash, clean, and air-blow each part. Carefully check oil or coolant passages for any restriction

and blockage.

●Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

●Release air within route when refilling after draining coolant.

●Before starting engine, apply fuel pressure to fuel lines with turning ignition switch ON (with engine

stopped). Then mark sure that there are no leaks at fuel line connections.

●After repairing, start engine and increase engine speed to check coolant, fuel, oil, and exhaust systems

for leakage.

Parts Requiring Angular TighteningEBS00KN5

●Use an angle wrench for the final tightening of the following engine parts.

–Cylinder head bolts

–Lower cylinder block bolts

–Connecting rod cap bolts

–Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angular

tightening)

●Do not use a torque value for final tightening.

●The torque value for these parts are for a preliminary step.

●Ensure thread and seat surfaces are clean and coated with engine oil.

Page 75 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-25

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

c. Remove exhaust manifold cover upper.

d. Loosen nuts in reverse order of illustration to remove exhaust

manifold NISSAN X-TRAIL 2001 Service Repair Manual EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-25

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

c. Remove exhaust manifold cover upper.

d. Loosen nuts in reverse order of illustration to remove exhaust

manifold](/img/5/57405/w960_57405-74.png)

EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-25

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

c. Remove exhaust manifold cover upper.

d. Loosen nuts in reverse order of illustration to remove exhaust

manifold and catalytic converter.

●Disregard the numerical order No. 6 and 7 when loosening.

3. Remove exhaust manifold and three way catalyst loosening nuts

in reverse order in the figure.

INSPECTION AFTER REMOVAL

Surface Distortion

Use a reliable straightedge and feeler gauge to check the flatness of

exhaust manifold fitting surface.

INSTALLATION

Install in the reverse order of removal paying attention to the following.

Exhaust Manifold Nuts

●Tighten nuts in the numerical order shown in the figure.

●No. 6 and 7 indicate double tightening of bolts No. 1 and 3.

Heated Oxygen Sensor

CAUTION:

Do not over torque the heated oxygen sensor. Doing so may cause damage to the heated oxygen sen-

sor, resulting in the MIL coming on.

KBIA0045E

Standard: 0.3 mm (0.012 in)

KBIA0046E

KBIA0045E

Page 94 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-44

[QR]

TIMING CHAIN

d. Tighten mounting bolts in the numerical order shown in the fig-

ure.

e. After all bolts are tightened, retighten them to specified torque.

CAUTION:

Be sure to w NISSAN X-TRAIL 2001 Service Repair Manual EM-44

[QR]

TIMING CHAIN

d. Tighten mounting bolts in the numerical order shown in the fig-

ure.

e. After all bolts are tightened, retighten them to specified torque.

CAUTION:

Be sure to w](/img/5/57405/w960_57405-93.png)

EM-44

[QR]

TIMING CHAIN

d. Tighten mounting bolts in the numerical order shown in the fig-

ure.

e. After all bolts are tightened, retighten them to specified torque.

CAUTION:

Be sure to wipe off any excessive liquid gasket leaking to

surface for fitting oil pan.

8. Install chain guide between camshaft sprockets.

9. Install intake valve timing control cover with the following procedure.

a. Install intake valve timing control solenoid valves to intake valve timing control cover.

b. Install oil rings to the intake camshaft sprocket insertion points on intake valve timing control backside

cover.

c. Install O-ring to front cover.

d. Apply liquid gasket to the positions in the figure.

Use Genuine Liquid gasket or equivalent.

e. Tighten mounting bolts in the numerical order shown in the fig-

ure.

10. Insert crankshaft pulley by aligning with crankshaft key.

●Tap its center with a plastic hammer to insert.

●Do not tap belt hook.

11. Tighten crankshaft pulley mounting bolt.

KBIA0083E

SBIA0260E

KBIA0085E