tow NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 3 of 3833

GI-1

GENERAL INFORMATION

A GENERAL INFORMATION

CONTENTS

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTION

GENERAL INFORMATION

PRECAUTIONS .......................................................... 3

Description ............................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for NATS (NISSAN ANTI-THEFT SYS-

TEM) ........................................................................ 3

General Precautions ................................................ 4

Precautions for All Mode 4 × 4 System .................... 5

Precautions for Three Way Catalyst ......................... 5

Precautions for Fuel ................................................. 5

GASOLINE ENGINE ............................................. 5

DIESEL ENGINE ................................................... 5

Precautions for Multiport Fuel Injection System or

Engine Control System ............................................ 6

Precautions for Turbocharger (If Equipped) ............. 6

Precautions for Hoses .............................................. 6

HOSE REMOVAL AND INSTALLATION ............... 6

HOSE CLAMPING ................................................ 7

Precautions for Engine Oils ...................................... 7

HEALTH PROTECTION PRECAUTIONS ............. 7

ENVIRONMENTAL PROTECTION PRECAU-

TIONS ................................................................... 7

Precautions for Air Conditioning ............................... 7

HOW TO USE THIS MANUAL ................................... 8

Description ............................................................... 8

Terms ....................................................................... 8

Units ......................................................................... 8

Contents ................................................................... 8

Components ............................................................. 8

SYMBOLS ............................................................. 9

How to Follow Trouble Diagnoses ............................ 9

DESCRIPTION ...................................................... 9

HOW TO FOLLOW TEST GROUPS IN TROU-

BLE DIAGNOSES ............................................... 10

HARNESS WIRE COLOR AND CONNECTOR

NUMBER INDICATION ........................................ 11

KEY TO SYMBOLS SIGNIFYING MEASURE-

MENTS OR PROCEDURES ............................... 12

How to Read Wiring Diagrams ............................... 14CONNECTOR SYMBOLS ................................... 14

SAMPLE/WIRING DIAGRAM - EXAMPL - .......... 15

DESCRIPTION .................................................... 16

Abbreviations .......................................................... 22

SERVICE INFORMATION FOR ELECTRICAL INCI-

DENT ......................................................................... 23

How to Perform Efficient Diagnosis for an Electrical

Incident ................................................................... 23

WORK FLOW ...................................................... 23

INCIDENT SIMULATION TESTS ........................ 23

CIRCUIT INSPECTION ....................................... 26

Control Units and Electrical Parts ........................

... 31

PRECAUTIONS .................................................. 31

CONSULT-II CHECKING SYSTEM .......................... 33

Description .............................................................. 33

Function and System Application ........................... 33

Nickel Metal Hydride Battery Replacement ............ 33

Checking Equipment .............................................. 34

CONSULT-II Data Link Connector (DLC) Circuit .... 34

INSPECTION PROCEDURE .............................. 34

LIFTING POINT ......................................................... 35

Special Service Tools ............................................. 35

Garage Jack and Safety Stand ............................... 35

2-pole Lift ................................................................ 36

Board-on Lift ........................................................... 37

TOW TRUCK TOWING ............................................. 38

Tow Truck Towing ................................................... 38

TOWING AN AUTOMATIC TRANSAXLE

MODEL WITH FOUR WHEELS ON GROUND ... 38

T O W I N G T H E V E H I C L E W I T H R E A R W H E E L S

R A I S E D ( W I T H F R O N T W H E E L S O N G R O U N D )

OR FRONT WHEELS RAISED ........................... 39

Vehicle Recovery (Freeing a stuck vehicle) ............ 39

TIGHTENING TORQUE OF STANDARD BOLTS .... 40

Tightening Torque Table ......................................... 40

IDENTIFICATION INFORMATION ............................ 41

Model Variation ....................................................... 41

IDENTIFICATION NUMBER ................................ 42

IDENTIFICATION PLATE .................................... 43

ENGINE SERIAL NUMBER ................................ 43

Page 40 of 3833

GI-38

TOW TRUCK TOWING

TOW TRUCK TOWING

PFP:00000

Tow Truck TowingEAS000FL

CAUTION:

●All applicable local laws regarding the towing operation must be obeyed.

●It is necessary to use proper towing equipment to avoid possible damage to the vehicle during

towing operation. Towing is in accordance with Towing Procedure Manual at dealer.

●Always attach safety chains before towing.

●When towing, make sure that the transmission, steering system and power train are in good order.

If any unit is damaged, dollies must be used.

●Never tow an automatic transmission model from the rear (that is backward) with four wheels on

the ground. This may cause serious and expensive damage to the transmission.

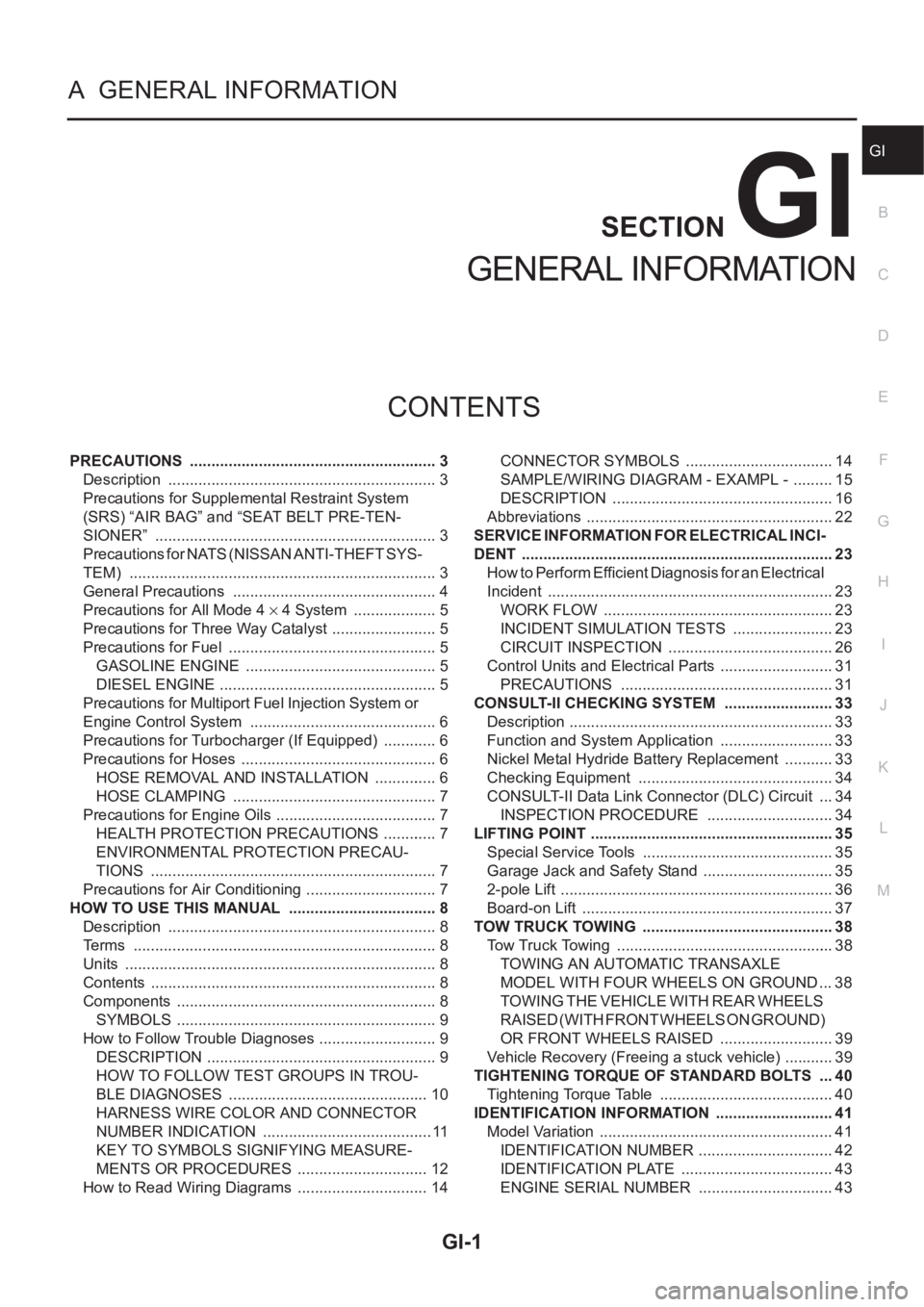

NISSAN recommends that towing dollies be used when towing your

vehicle beplaced on a flat bed truck as illustrated.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH FOUR WHEELS ON GROUND

Observe the following restricted towing speeds and distances.

CAUTION:

Never tow an automatic transaxle model from the rear (i.e., backward) with four wheels on the ground

as this may cause serious and expensive damage to the transaxle.

PAIA0012E

Speed :Below 50 km/h (30 MPH)

Distance :Less than 65 km(40 miles)

Page 41 of 3833

TOW TRUCK TOWING

GI-39

C

D

E

F

G

H

I

J

K

L

MB

GI

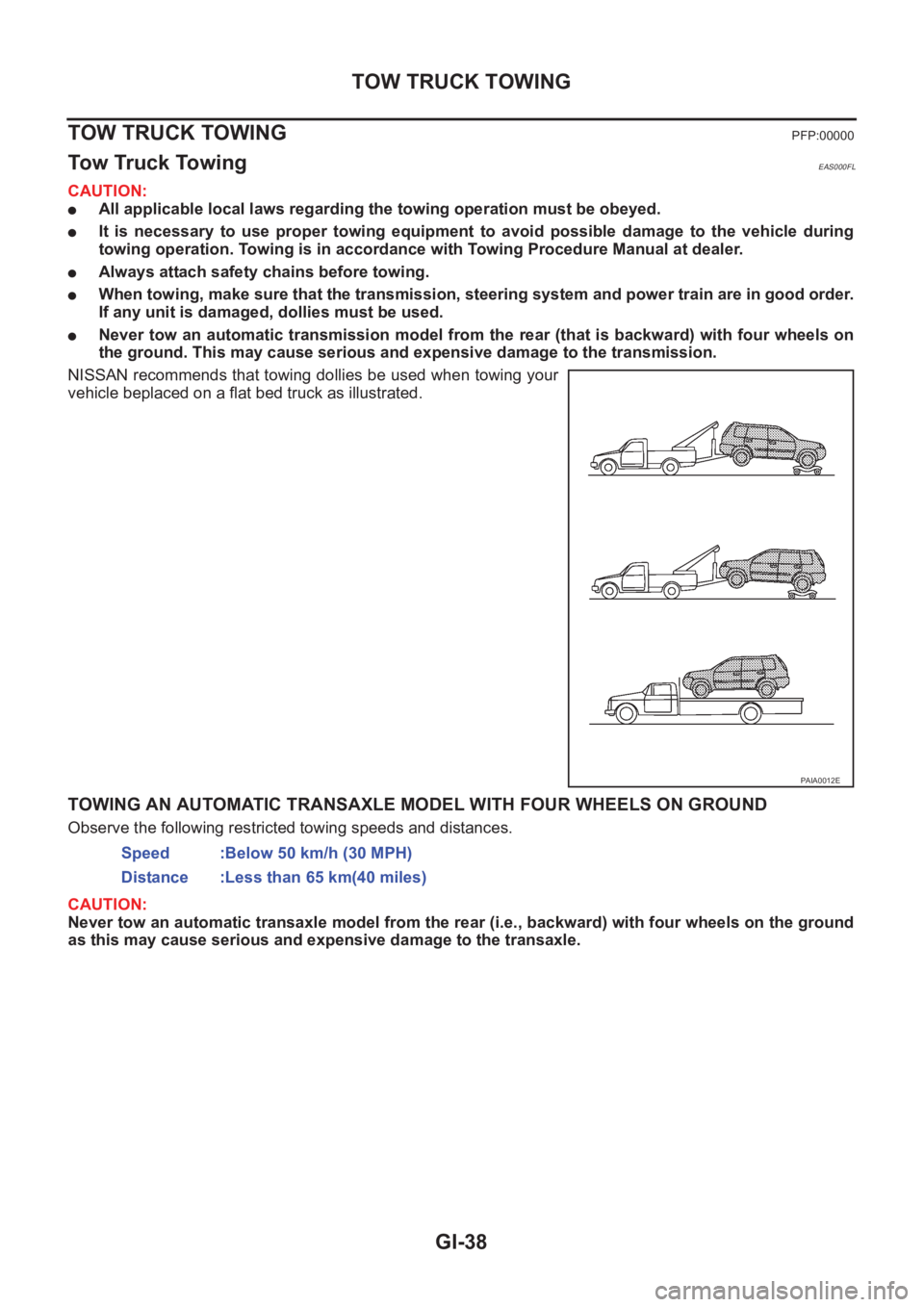

TOWING THE VEHICLE WITH REAR WHEELS RAISED (WITH FRONT WHEELS ON GROUND)

OR FRONT WHEELS RAISED

Never tow the vehicle with rear wheels raised (with front wheels on

ground) or front wheels raised as this may cause serious and expen-

sive damage to the transaxle. If it is necessary to tow it with rear

wheels raised or front wheels raised, always use a towing dolly

under the front wheels.

If the speed or distance must necessarily be greater, remove the

front and rear propeller shafts beforehand to prevent damage to the

transaxle.

Vehicle Recovery (Freeing a stuck vehicle) EAS000FM

●Use the towing hook only, not other parts of the vehicle. Other-

wise, the vehicle body will be damaged.

●Use the towing hook only to free a vehicle stuck in sand, snow,

mud, etc. Never tow the vehicle for a long distance using only

the towing hook.

●The towing hook is under tremendous force when used to free a

stuck vehicle. Always pull the cable straight out from the front or

rear of the vehicle. Never pull on the hook at an angle.

●Stand clear of a stuck vehicle.

WARNING:

●Do not spin the tires at high speed. This could cause them

to explode and result in serious injury. Parts of the vehicle

could also overheat and be damaged.

PAIA0013E

PAIA0014E

Page 115 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER HEAD

EM-65

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

VALVE GUIDE CLEARANCE

Perform this inspection before removing valve guide.

1. Make sure that the valve stem diameter is within the specification.

2. NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER HEAD

EM-65

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

VALVE GUIDE CLEARANCE

Perform this inspection before removing valve guide.

1. Make sure that the valve stem diameter is within the specification.

2.](/img/5/57405/w960_57405-114.png)

CYLINDER HEAD

EM-65

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

VALVE GUIDE CLEARANCE

Perform this inspection before removing valve guide.

1. Make sure that the valve stem diameter is within the specification.

2. Push the valve out by approx. 15 mm (0.59 in) toward the combustion chamber side to measure the

valve's run-out volume (in the direction of dial gauge) with dial gauge.

3. The half of the run-out volume accounts for the valve guide

clearance.

VALVE GUIDE REPLACEMENT

When valve guide is removed, replace with oversized [0.2 mm (0.008 in)] valve guide.

1. To remove valve guide, heat cylinder head to 110 to 130°C (230

to 266°F) by soaking in heated oil.

2. Drive out valve guide with a press [under a 20 kN (2 ton, 2.2 US

ton, 2.0 lmp ton) pressure] or hammer and suitable tool.

CAUTION:

Cylinder head contains heat, when working, wear protective

equipment to avoid getting burned.

3. Ream cylinder head valve guide hole.

4. Heat cylinder head to 110 to 130°C (230 to 266°F) by soaking in

heated oil.Standard

Intake : 0.020 - 0.053 mm (0.0008 - 0.0021 in)

Exhaust : 0.030 - 0.063 mm (0.0012 - 0.0025 in)

PBIC0077E

SEM008A

SEM931C

Valve guide hole diameter (for service parts)

Intake and exhaust:

10.175 - 10.196 mm (0.4006 - 0.4014 in)

SEM932C

Page 201 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual FUEL SUPPLY PUMP

EM-151

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

21. Using the extension bar [SST: whole length 43 mm (1.69 in)] and

the TORX socket (Q6-E12: commercially available), remove the

mounting NISSAN X-TRAIL 2001 Service Repair Manual FUEL SUPPLY PUMP

EM-151

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

21. Using the extension bar [SST: whole length 43 mm (1.69 in)] and

the TORX socket (Q6-E12: commercially available), remove the

mounting](/img/5/57405/w960_57405-200.png)

FUEL SUPPLY PUMP

EM-151

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

21. Using the extension bar [SST: whole length 43 mm (1.69 in)] and

the TORX socket (Q6-E12: commercially available), remove the

mounting bolts, them remove the fuel supply pump toward the

rear of the engine

CAUTION:

Do not disassemble or adjust the fuel supply pump.

22. Remove the fuel supply pump mounting bolts.

NOTE:

The seal washer of the mounting bolts cannot be reused.

CAUTION:

For removal, be careful not to drop the seal washer into the

engine.

23. Remove adjusting shim.

24. Attach a suitable tool in the M8 bolt hole on coupling.

25. Loosen sprocket nut with the TORX wrench (SST).

26. Remove coupling with a suitable puller.

27. Remove fuel supply pump housing.

●Using a hexagon-head wrench [face to face 5mm (0.20in)

SST], remove bolt to remove fuel supply pump housing.

28. Remove O-rings from fuel supply pump housing.

SBIA0220E

SBIA0221E

PBIC0902E

PBIC0903E

PBIC0904E

Page 237 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER HEAD

EM-187

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Disassembly and AssemblyEBS00LRX

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

DISASSEMBLY

1. Remove adju NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER HEAD

EM-187

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Disassembly and AssemblyEBS00LRX

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

DISASSEMBLY

1. Remove adju](/img/5/57405/w960_57405-236.png)

CYLINDER HEAD

EM-187

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Disassembly and AssemblyEBS00LRX

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

DISASSEMBLY

1. Remove adjusting shims and valve lifters.

●Check the installation positions, and keep them to avoid being

confused.

2. Remove valve.

●Using valve spring compressor, compress valve spring. Using

magnetic hand, remove valve collets.

3. Remove valve spring retainers and valve springs.

4. Remove valves as pressing valve stems toward combustion

chamber.

●Before removing the valve, check the valve guide clearance.

Refer to EM-189, "

Valve Guide Clearance" .

●Check installation positions, and keep them to avoid being

confused.

NOTE:

Refer to the figure for intake and exhaust valve positions.

Intake and exhaust valve driving cams are provided alter-

nately for each camshaft.

SBIA0194E

SBIA0195E

SBIA0196E

Page 239 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER HEAD

EM-189

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Valve Dimension

Check dimensions of each valve. For dimensions, refer to SDS, EM-

221, "Va l v e" .

When valve head has been worn down NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER HEAD

EM-189

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Valve Dimension

Check dimensions of each valve. For dimensions, refer to SDS, EM-

221, "Va l v e" .

When valve head has been worn down](/img/5/57405/w960_57405-238.png)

CYLINDER HEAD

EM-189

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Valve Dimension

Check dimensions of each valve. For dimensions, refer to SDS, EM-

221, "Va l v e" .

When valve head has been worn down to 1 mm (0.039 in) in margin

thickness, replace valve.

Grinding allowance for valve stem tip is 0.2 mm (0.008 in) or

less.

Valve Guide Clearance

●Perform the inspection before removing valve guides.

●Check that the valve stem diameter is within specifications.

●Push valve approximately 25 mm (0.98 in) toward combustion

chamber, move valve toward dial indicator to measure valve

movement.

●Valve guide clearance is 1/2 of movement on dial indicator.

●If the measured value exceeds the limit, replace valve guide.

Valve Guide Replacement

When removing valve guide, replace it with oversized [0.2 mm

(0.0008 in)] valve guide.

1. Heat cylinder head to 110 to 130°C (230 to 266°F) in oil bath.

2. Using valve guide drift, tap valve guides out from the combus-

tion chamber side.

CAUTION:

Cylinder head contains heat, when working, wear protective

equipment to avoid getting burned.

SEM188A

Standard:

I n t a k e : 0 . 0 2 0 - 0 . 0 5 3 m m ( 0 . 0 0 0 8 - 0 . 0 0 2 1 i n )

Exhaust : 0.040 - 0.073 mm (0.0016 - 0.0029 in)

Limit:

Intake : 0.08 mm (0.0031 in)

Exhaust : 0.10 mm (0.0039 in)

PBIC0414E

SEM008A

SEM931C

Page 253 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-203

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

8. Tighten the main bearing cap bolts according to the following

procedure:

a. Apply engine oil to the threaded part and sea NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-203

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

8. Tighten the main bearing cap bolts according to the following

procedure:

a. Apply engine oil to the threaded part and sea](/img/5/57405/w960_57405-252.png)

CYLINDER BLOCK

EM-203

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

8. Tighten the main bearing cap bolts according to the following

procedure:

a. Apply engine oil to the threaded part and seat surface of each

bolt.

b. Tighten to 25 to 30 N·m (2.5 to 3.1 kg-m, 18 to 22 ft-lb) in the

numerical order shown in the figure.

c. Put alignment marks (with paint) on each bolt and the main

bearing cap, all in the same direction. (When using a protractor)

d. Then, tighten 90° to 95° [target: 90°].

●Always use either an angle wrench (SST) or protractor

during angular tightening. Avoid tightening based on

visual checks alone.

●After tightening bolts to specified torque, make sure that

crankshaft rotates smoothly.

●Check crankshaft end side clearance. Refer to EM-210,

"CRANKSHAFT END PLAY" .

9. Check the outer diameter of connecting rod bolts. Refer to EM-

217, "CONNECTING ROD BOLT DEFORMATION" .

10. Install pistons to connecting rod.

a. Using long nose pliers, install snap rings to grooves on piston rear side.

●Fit snap rings correctly into grooves.

b. Install pistons to connecting rods.

●Using industrial dryer, heat pistons up to approx. 60 to 70°C (140 to 158°F) until piston pin can be

pressed down by finger touch. Then insert piston pins into piston and connecting rod from front side of

piston toward rear.

●Assemble piston and connecting rod with front mark of piston

crown and cylinder No. stamped on connecting rod being

positioned as shown in the figure.

c. Install snap rings to front side of pistons.

●Refer to above step a for precaution on snap ring installation.

●After installation, check connecting rods for smooth move-

ment.

11. Use piston ring expander to install piston rings.

CAUTION:

When installing, prevent piston from being damaged.

●Install top ring and second ring with stamped surfaces facing

upward.

●Install rings so that three closed gap position 120° apart one

another.

●Closed gaps do not need to face in a specific directions, as long as each are positioned 120° apart.

JEM200G

JEM226G

JEM227G

Identification stamp:

To p r i n g : R To p

Second ring : R2nd

JEM228G

Page 254 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-204

[YD22DDTi]

CYLINDER BLOCK

12. Install connecting rod bearings to connecting rods and caps.

●While installing connecting rod bearings, apply engine oil to

bearing surfaces (inside). Do NISSAN X-TRAIL 2001 Service Repair Manual EM-204

[YD22DDTi]

CYLINDER BLOCK

12. Install connecting rod bearings to connecting rods and caps.

●While installing connecting rod bearings, apply engine oil to

bearing surfaces (inside). Do](/img/5/57405/w960_57405-253.png)

EM-204

[YD22DDTi]

CYLINDER BLOCK

12. Install connecting rod bearings to connecting rods and caps.

●While installing connecting rod bearings, apply engine oil to

bearing surfaces (inside). Do not apply engine oil to rear sur-

faces, but clean them completely.

●Align stoppers on connecting rod bearings with connecting

rod stopper notches to install connecting rod bearings.

13. Install piston and connecting rod assembly to crankshaft.

●Move crankshaft pin to be assembled to BDC.

●Align cylinder position with cylinder No. on connecting rod to

install piston and connecting rod assembly.

●Using piston ring compressor, install piston and connecting

rod assembly with front mark on piston crown facing toward

the front side of engine.

CAUTION:

When installing piston and connecting rod assembly, pre-

vent the big end of connecting rod from interfering with

oil jet.

14. Install connecting rod caps and mounting nuts.

●Align cylinder No. stamped on connecting rod with that on cap

to install connecting rod cap.

●Make sure that the front mark on connecting rod cap faces

towards the front of the engine.

15. Tighten connecting rod nuts according to the following proce-

dure:

a. Apply engine oil on bolt threads and seat surface of nuts.

b. Tighten to 29 to 30 N·m (2.9 to 3.1 kg-m, 21 to 22 ft-lb).

c. Loosen completely to 0 N·m (0 kg-m, 0 in-lb).

d. Tighten to 19 to 20 N·m (1.9 to 2.1 kg-m, 14 to 15 ft-lb).

e. Tighten 120° to 125° [target: 120°]. (angular tightening)

●Always use either an angle wrench (SST) or protractor

during angular tightening. Avoid tightening based on

visual checks alone.

●After tightening nuts, check that crankshaft rotates smoothly.

●Check connecting rod side clearance. Refer to EM-210,

"CONNECTING ROD SIDE CLEARANCE" .

16. Press fit rear oil seal into rear oil seal retainer.

●Using a drift [105 mm (4.13 in) dia.], press fit so that the

dimension is as specified in the figure.

●Avoid inclined fitting. Force fit perpendicularly.

JEM229G

JEM230G

JEM227G

JEM231G

JEM232G

Page 448 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EC-98

[QR25(WITH EURO-OBD)]

TROUBLE DIAGNOSIS

*1: The items are the same as those of 1st trip freeze frame data.

DATA MONITOR MODE

Monitored Item

×: Applicable CAL/LD VALUE [%]

●The calculated load NISSAN X-TRAIL 2001 Service Repair Manual EC-98

[QR25(WITH EURO-OBD)]

TROUBLE DIAGNOSIS

*1: The items are the same as those of 1st trip freeze frame data.

DATA MONITOR MODE

Monitored Item

×: Applicable CAL/LD VALUE [%]

●The calculated load](/img/5/57405/w960_57405-447.png)

EC-98

[QR25(WITH EURO-OBD)]

TROUBLE DIAGNOSIS

*1: The items are the same as those of 1st trip freeze frame data.

DATA MONITOR MODE

Monitored Item

×: Applicable CAL/LD VALUE [%]

●The calculated load value at the moment a malfunction is detected is displayed.

COOLANT TEMP [°C]

or [°F]

●The engine coolant temperature at the moment a malfunction is detected is displayed.

S-FUEL TRIM-B1 [%]

●“Short-term fuel trim” at the moment a malfunction is detected is displayed.

●The short-term fuel trim indicates dynamic or instantaneous feedback compensation to the base fuel

schedule.

L-FUEL TRIM-B1 [%]

●“Long-term fuel trim” at the moment a malfunction is detected is displayed.

●The long-term fuel trim indicates much more gradual feedback compensation to the base fuel schedule

than short-term fuel trim.

ENGINE SPEED

[rpm]

●The engine speed at the moment a malfunction is detected is displayed.

VHCL SPEED [km/h]

or [mph]

●The vehicle speed at the moment a malfunction is detected is displayed.

B/FUEL SCHDL

[msec]

●The base fuel schedule at the moment a malfunction is detected is displayed.

INT/A TEMP SE [°C]

or [°F]

●The intake air temperature at the moment a malfunction is detected is displayed. Freeze frame data

item*1Description

Monitored item

[Unit]ECM

INPUT

SIG-

NALSMAIN

SIG-

NALSCAN

DIAG

SUP-

PORT

MNTRDescription Remarks

ENG SPEED [rpm]××

●Indicates the engine speed computed

from the signals of the crankshaft posi-

tion sensor (POS) and camshaft posi-

tion sensor (PHASE).●Accuracy becomes poor if engine

speed drops below the idle rpm.

●If the signal is interrupted while the

engine is running, an abnormal

value may be indicated.

MAS A/F SE-B1 [V]××

●The signal voltage of the mass air flow

sensor is displayed.●When the engine is stopped, a

certain value is indicated.

COOLAN TEMP/S

[°C] or [°F]××

●The engine coolant temperature (deter-

mined by the signal voltage of the

engine coolant temperature sensor) is

displayed.

●When the engine coolant tempera-

ture sensor is open or short-cir-

cuited, ECM enters fail-safe mode.

The engine coolant temperature

determined by the ECM is dis-

played.

HO2S1 (B1) [V]××

●The signal voltage of the heated oxygen

sensor 1 is displayed.

HO2S2 (B1) [V]××

●The signal voltage of the heated oxygen

sensor 2 is displayed.

HO2S1 MNTR (B1)

[RICH/LEAN]××

●Display of heated oxygen sensor 1 sig-

nal during air-fuel ratio feedback control:

RICH ... means the mixture became

“rich”, and control is being affected

toward a leaner mixture.

LEAN ... means the mixture became

“lean”, and control is being affected

toward a rich mixture.●After turning ON the ignition

switch, “RICH” is displayed until

air-fuel mixture ratio feedback

control begins.

●When the air-fuel ratio feedback is

clamped, the value just before the

clamping is displayed continu-

ously.