brake NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 1 of 3833

MODEL T30 SERIES

© 2002 NISSAN EUROPE S.A.S.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan

Europe S.A.S., Paris, France.

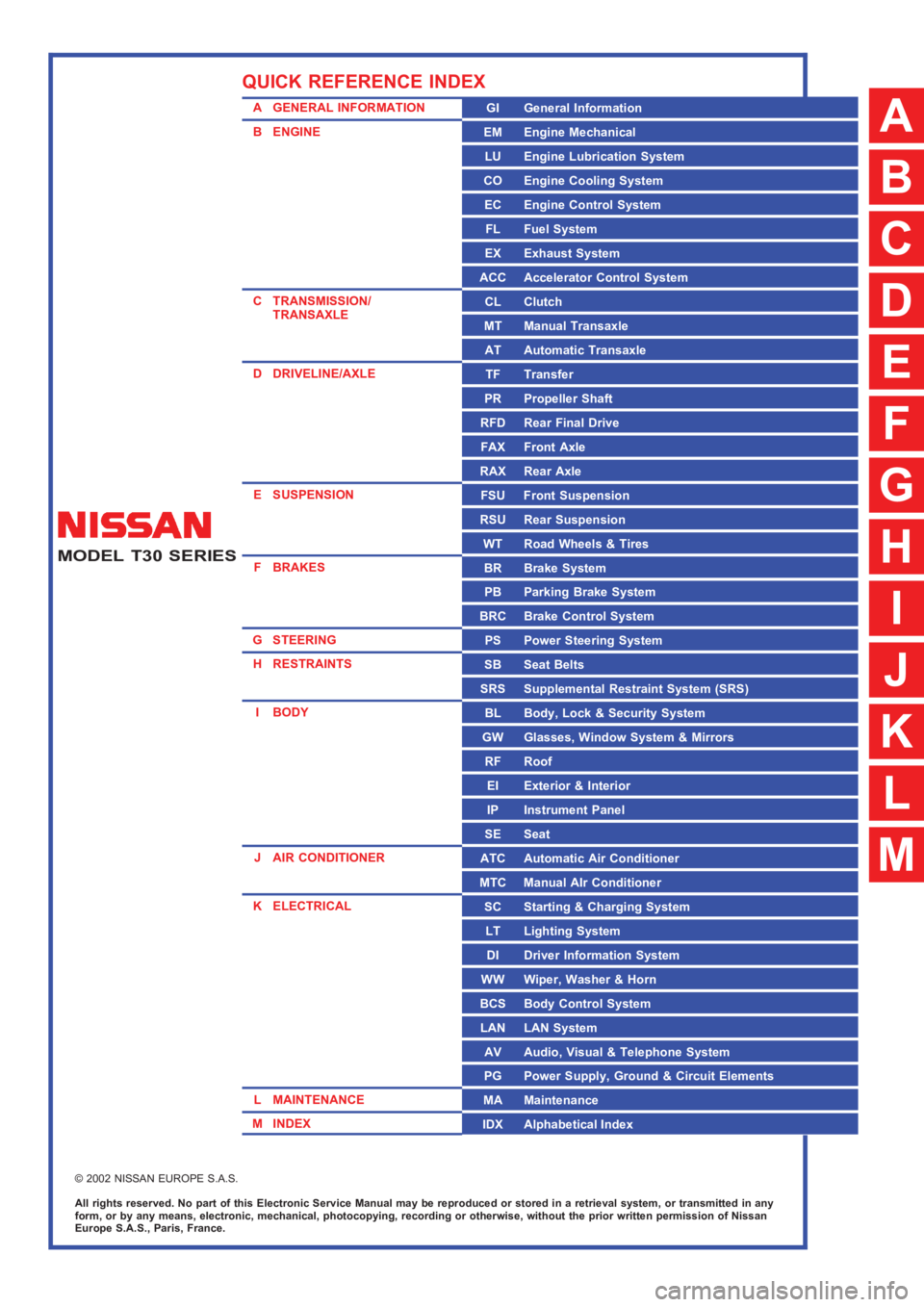

A GENERAL INFORMATION

B ENGINE

C TRANSMISSION/

TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

IBODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEXGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

ACC Accelerator Control System

CL Clutch

MT Manual Transaxle

AT Automatic Transaxle

TF Transfer

PR Propeller Shaft

RFD Rear Final Drive

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

PS Power Steering System

SB Seat Belts

SRS Supplemental Restraint System (SRS)

BL Body, Lock & Security System

GW Glasses, Window System & Mirrors

RF Roof

EI Exterior & Interior

IP Instrument Panel

SE Seat

ATC Automatic Air Conditioner

MTC Manual AIr Conditioner

SC Starting & Charging System

LT Lighting System

DI Driver Information System

WW Wiper, Washer & Horn

BCS Body Control System

LAN LAN System

AV Audio, Visual & Telephone System

PG Power Supply, Ground & Circuit Elements

MA Maintenance

IDX Alphabetical Index

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 15 of 3833

HOW TO USE THIS MANUAL

GI-13

C

D

E

F

G

H

I

J

K

L

MB

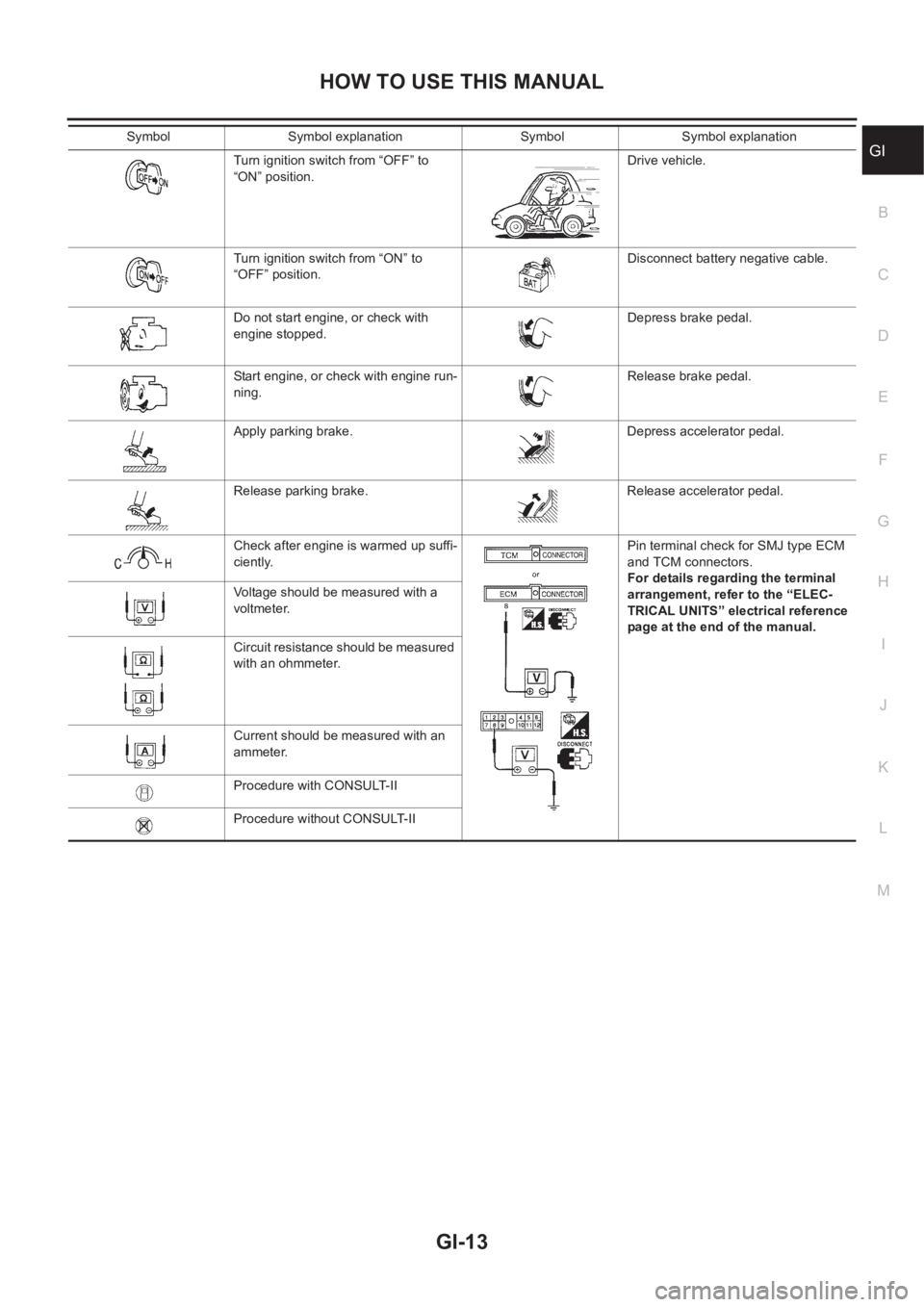

GITurn ignition switch from “OFF” to

“ON” position.Drive vehicle.

Turn ignition switch from “ON” to

“OFF” position.Disconnect battery negative cable.

Do not start engine, or check with

engine stopped.Depress brake pedal.

Start engine, or check with engine run-

ning.Release brake pedal.

Apply parking brake. Depress accelerator pedal.

Release parking brake. Release accelerator pedal.

Check after engine is warmed up suffi-

ciently.Pin terminal check for SMJ type ECM

and TCM connectors.

For details regarding the terminal

arrangement, refer to the “ELEC-

TRICAL UNITS” electrical reference

page at the end of the manual. Voltage should be measured with a

voltmeter.

Circuit resistance should be measured

with an ohmmeter.

Current should be measured with an

ammeter.

Procedure with CONSULT-II

Procedure without CONSULT-II Symbol Symbol explanation Symbol Symbol explanation

Page 20 of 3833

GI-18

HOW TO USE THIS MANUAL

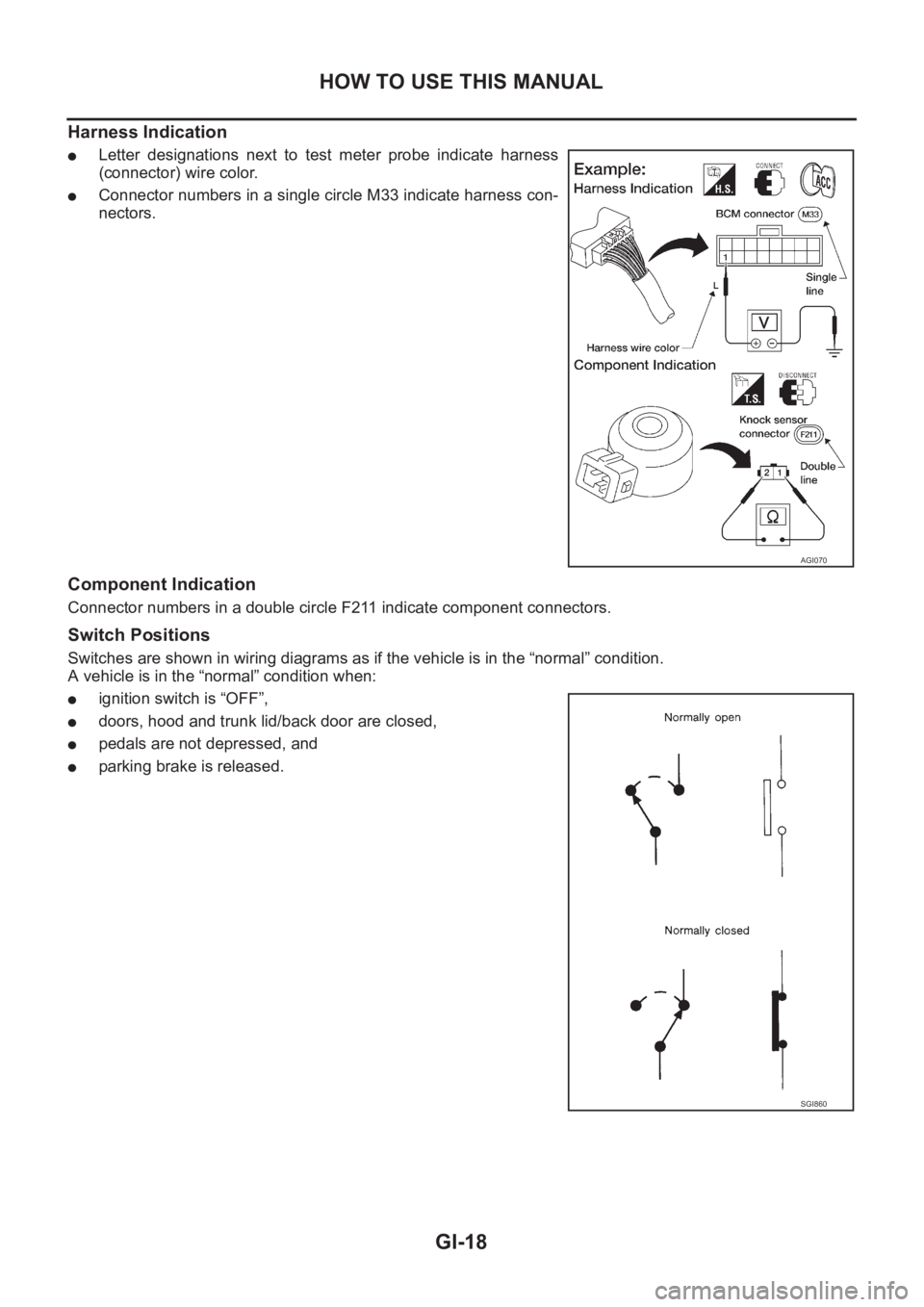

Harness Indication

●Letter designations next to test meter probe indicate harness

(connector) wire color.

●Connector numbers in a single circle M33 indicate harness con-

nectors.

Component Indication

Connector numbers in a double circle F211 indicate component connectors.

Switch Positions

Switches are shown in wiring diagrams as if the vehicle is in the “normal” condition.

A vehicle is in the “normal” condition when:

●ignition switch is “OFF”,

●doors, hood and trunk lid/back door are closed,

●pedals are not depressed, and

●parking brake is released.

AGI070

SGI860

Page 38 of 3833

GI-36

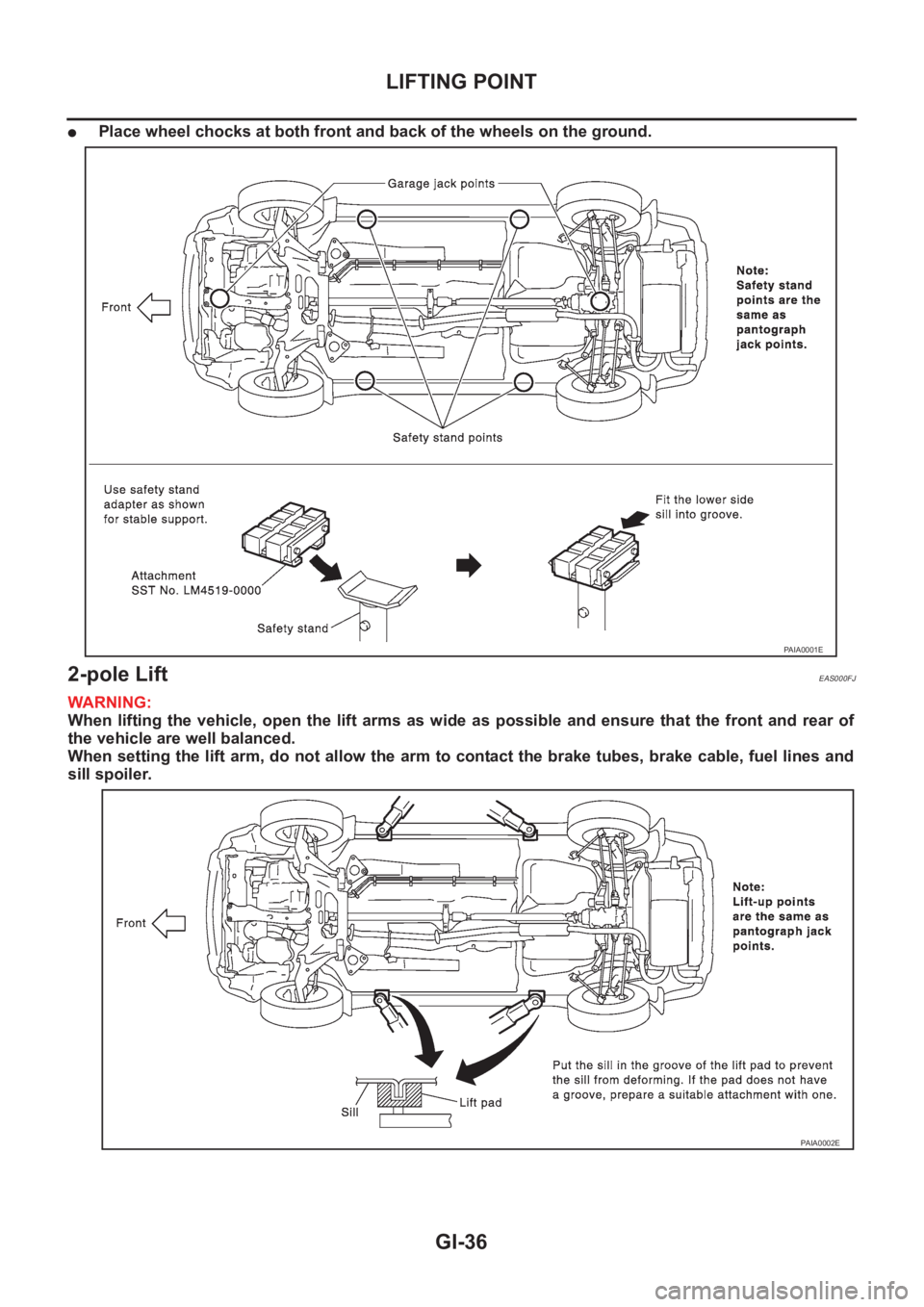

LIFTING POINT

●Place wheel chocks at both front and back of the wheels on the ground.

2-pole Lift EAS000FJ

WARNING:

When lifting the vehicle, open the lift arms as wide as possible and ensure that the front and rear of

the vehicle are well balanced.

When setting the lift arm, do not allow the arm to contact the brake tubes, brake cable, fuel lines and

sill spoiler.

PAIA0001E

PAIA0002E

Page 120 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-70

[QR]

ENGINE ASSEMBLY

1. Release fuel pressure. Refer to EC-775, "FUEL PRESSURE RELEASE" [QR20DE (WITH EURO-OBD)],

EC-1139, "

FUEL PRESSURE RELEASE" [QR20DE (WITHOUT EURO NISSAN X-TRAIL 2001 Service Repair Manual EM-70

[QR]

ENGINE ASSEMBLY

1. Release fuel pressure. Refer to EC-775, "FUEL PRESSURE RELEASE" [QR20DE (WITH EURO-OBD)],

EC-1139, "

FUEL PRESSURE RELEASE" [QR20DE (WITHOUT EURO](/img/5/57405/w960_57405-119.png)

EM-70

[QR]

ENGINE ASSEMBLY

1. Release fuel pressure. Refer to EC-775, "FUEL PRESSURE RELEASE" [QR20DE (WITH EURO-OBD)],

EC-1139, "

FUEL PRESSURE RELEASE" [QR20DE (WITHOUT EURO-OBD)], EC-42, "FUEL PRES-

SURE RELEASE" [QR25DE (WITH EURO-OBD)] or EC-452, "FUEL PRESSURE RELEASE" [QR25DE

(WITHOUT EURO-OBD)].

2. Remove engine hood.

3. Drain engine coolant from radiator drain plug. Refer to CO-9, "

DRAINING ENGINE COOLANT" .

4. Remove the following parts.

●LH/RH undercovers

●LH/RH front wheels

●Battery

●Drive belts; Refer to EM-12, "REMOVAL" .

●Air duct and air cleaner case assembly; Refer to EM-14, "REMOVAL" .

●Alternator

●Radiator and radiator fan assembly; Refer to CO-11, "RADIATOR" .

5. Disconnect engine room harness from the engine side and set it aside for easier work.

6. Disconnect all the body-side vacuum hoses and air hoses at engine side.

Engine room LH

7. Disconnect fuel hose, and plug it to prevent fuel from draining. Refer to EM-16, "

INTAKE MANIFOLD"

8. Disconnect heater hose, and install plug it to prevent engine coolant from draining.

9. Disconnect select cable from transaxle (A/T models).

10. Remove clutch operating cylinder from transaxle, and move it aside (M/T models).

11. Disconnect shift cable from transaxle (M/T models).

Engine room RH

12. Remove engine coolant reservoir tank.

13. Remove air conditioner compressor with piping connected from engine. Temporarily secure it on body

with a rope to avoid putting load on it.

Vehicle underbody

14. Remove exhaust front tube.

15. Remove propeller shaft.

16. Remove steering shaft from steering gear.

17. Disconnect power steering fluid cooler piping at a point between body and engine.

18. Remove ABS sensor from brake caliper.

19. Remove brake caliper with piping connected from steering knuckle. Temporarily secure it on body with a

rope to avoid load on it.

20. Remove LH/RH suspensions from steering knuckle under strut.

Removal

21. Install engine slingers into front left of cylinder head and rear right of cylinder head.

●Use alternator bracket mounting bolt holes for the front side.

22. Lift with hoist and secure the engine in position.Slinger bolts:

Front

: 51.0 - 64.7 N·m (5.2 - 6.6 kg-m, 38 - 47 ft-lb)

Rear

: 24.5 - 31.4 N·m (2.5 - 3.2 kg-m, 18 - 23 ft-lb)

SBIA0271E

Page 244 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-194

[YD22DDTi]

ENGINE ASSEMBLY

REMOVAL

Description of work

Remove engine, transaxle and transfer assembly with front suspension member from vehicle down ward.

Separate suspension membe NISSAN X-TRAIL 2001 Service Repair Manual EM-194

[YD22DDTi]

ENGINE ASSEMBLY

REMOVAL

Description of work

Remove engine, transaxle and transfer assembly with front suspension member from vehicle down ward.

Separate suspension membe](/img/5/57405/w960_57405-243.png)

EM-194

[YD22DDTi]

ENGINE ASSEMBLY

REMOVAL

Description of work

Remove engine, transaxle and transfer assembly with front suspension member from vehicle down ward.

Separate suspension member, and then separate engine and transaxle.

Preparation

1. Remove engine hood.

2. Drain engine coolant from radiator drain plug.

3. Remove the following parts.

●LH/RH undercovers

●LH/RH front wheels

●Battery

●Drive belts; Refer to EM-119, "Removal and Installation" .

●Air duct and air cleaner case assembly; Refer to EM-120, "Removal and Installation" .

●Alternator

●Radiator and radiator fan assembly; Refer to CO-32, "Removal and Installation" .

●Charge air cooler

4. Disconnect engine room harness from the engine side and set it aside for easier work.

5. Disconnect all the body-side vacuum hoses and air hoses at engine side.

Engine room LH

6. Disconnect fuel feed and return hoses, and plug it to prevent fuel from draining.

7. Disconnect heater hose, and install plug it to prevent engine coolant from draining.

8. Remove clutch operating cylinder from transaxle, and move it aside.

9. Disconnect shift cable from transaxle.

Engine room RH

10. Remove engine coolant reservoir tank.

11. Remove air conditioner compressor with piping connected from engine. Temporarily secure it on body

with a rope to avoid putting load on it.

Vehicle underbody

12. Remove exhaust front tube.

13. Remove propeller shaft.

14. Remove steering shaft from steering gear.

15. Disconnect power steering fluid cooler piping at a point between body and engine.

16. Remove ABS sensor from brake caliper.

17. Remove brake caliper with piping connected from steering knuckle. Temporarily secure it on body with a

rope to avoid load on it.

18. Remove LH/RH suspensions from steering knuckle under strut.

Removal

19. Install engine slingers into front right of cylinder head and rear

left of cylinder head.

20. Lift with hoist and secure the engine in position.Slinger bolts:

: 30 - 37 N·m (3.0 - 3.8 kg-m, 22 - 27 ft-lb)

SBIA0191E

Page 312 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CO-6

[QR]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at e NISSAN X-TRAIL 2001 Service Repair Manual CO-6

[QR]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at e](/img/5/57405/w960_57405-311.png)

CO-6

[QR]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system mal-

function

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator —

Blocked condenser

Blocked air flow

Installed large fog lamp Symptom Check items

Page 332 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CO-26

[YD22DDTi]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Drivi NISSAN X-TRAIL 2001 Service Repair Manual CO-26

[YD22DDTi]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Drivi](/img/5/57405/w960_57405-331.png)

CO-26

[YD22DDTi]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system mal-

function

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator —

Blocked condenser

Blocked air flow

Installed large fog lamp Symptom Check items

Page 355 of 3833

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA Wiring Diagram .................................................... 342

Diagnostic Procedure ........................................... 343

DTC P1706 PNP SWITCH ...................................... 345

Component Description ........................................ 345

CONSULT-II Reference Value in Data Monitor Mode

. 345

ECM Terminals and Reference Value .................. 345

On Board Diagnosis Logic ................................... 345

DTC Confirmation Procedure ............................... 345

Overall Function Check ........................................ 346

Wiring Diagram .................................................... 347

Diagnostic Procedure ........................................... 348

DTC P1805 BRAKE SWITCH ................................ 349

Description ........................................................... 349

CONSULT-II Reference Value in Data Monitor Mode

. 349

ECM Terminals and Reference Value .................. 349

On Board Diagnosis Logic ................................... 349

DTC Confirmation Procedure ............................... 349

Wiring Diagram .................................................... 351

Diagnostic Procedure ........................................... 352

Component Inspection ......................................... 353

DTC P2122, P2123 APP SENSOR ........................ 355

Component Description ........................................ 355

CONSULT-II Reference Value in Data Monitor Mode

. 355

ECM Terminals and Reference Value .................. 355

On Board Diagnosis Logic ................................... 356

DTC Confirmation Procedure ............................... 356

Wiring Diagram .................................................... 357

Diagnostic Procedure ........................................... 358

Component Inspection ......................................... 360

Remove and Installation ....................................... 360

DTC P2127, P2128 APP SENSOR ........................ 361

Component Description ........................................ 361

CONSULT-II Reference Value in Data Monitor Mode

. 361

ECM Terminals and Reference Value .................. 361

On Board Diagnosis Logic ................................... 362

DTC Confirmation Procedure ............................... 362

Wiring Diagram .................................................... 363

Diagnostic Procedure ........................................... 364

Component Inspection ......................................... 366

Remove and Installation ....................................... 366

DTC P2135 TP SENSOR ........................................ 367

Component Description ........................................ 367

CONSULT-II Reference Value in Data Monitor Mode

. 367

ECM Terminals and Reference Value .................. 367

On Board Diagnosis Logic ................................... 368

DTC Confirmation Procedure ............................... 368

Wiring Diagram ................................................

.... 369

Diagnostic Procedure ........................................... 370

Component Inspection ......................................... 372

Remove and Installation ....................................... 372

DTC P2138 APP SENSOR ..................................... 373

Component Description ........................................ 373

CONSULT-II Reference Value in Data Monitor Mode

. 373ECM Terminals and Reference Value ...................373

On Board Diagnosis Logic ....................................374

DTC Confirmation Procedure ...............................374

Wiring Diagram .....................................................375

Diagnostic Procedure ...........................................376

Component Inspection ..........................................378

Remove and Installation .......................................378

IGNITION SIGNAL ..................................................379

Component Description ........................................379

ECM Terminals and Reference Value ...................379

Wiring Diagram .....................................................380

Diagnostic Procedure ...........................................382

Component Inspection ..........................................386

Removal and Installation ......................................387

INJECTOR CIRCUIT ...............................................388

Component Description ........................................388

CONSULT-II Reference Value in Data Monitor Mode

.388

ECM Terminals and Reference Value ...................388

Wiring Diagram .....................................................389

Diagnostic Procedure ...........................................390

Component Inspection ..........................................392

Removal and Installation ......................................392

VIAS ........................................................................393

Description ............................................................393

CONSULT-II Reference Value in Data Monitor Mode

.394

ECM Terminals and Reference Value ...................394

Wiring Diagram .....................................................395

Diagnostic Procedure ...........................................396

Component Inspection ..........................................399

Removal and Installation ......................................400

START SIGNAL ......................................................401

CONSULT-II Reference Value in Data Monitor Mode

.401

ECM Terminals and Reference Value ...................401

Wiring Diagram .....................................................402

Diagnostic Procedure ...........................................403

FUEL PUMP CIRCUIT ............................................405

Description ............................................................405

CONSULT-II Reference Value in Data Monitor Mode

.405

ECM Terminals and Reference Value ..................

.405

Wiring Diagram .....................................................407

Diagnostic Procedure ...........................................408

Component Inspection ..........................................410

Removal and Installation ......................................411

REFRIGERANT PRESSURE SENSOR ..................412

Component Description ........................................412

ECM Terminals and Reference Value ...................412

Wiring Diagram .....................................................413

Diagnostic Procedure ...........................................414

Removal and Installation ......................................415

ELECTRICAL LOAD SIGNAL ................................416

CONSULT-II Reference Value in Data Monitor Mode

.416

ECM Terminals and Reference Value ...................416

Wiring Diagram .....................................................417

Diagnostic Procedure ...........................................419

Page 358 of 3833

EC-8

Wiring Diagram .....................................................595

Diagnostic Procedure ...........................................596

Component Inspection ..........................................597

DTC P1128 THROTTLE CONTROL MOTOR .........598

Component Description ........................................598

ECM Terminals and Reference Value ...................598

On Board Diagnosis Logic ....................................598

DTC Confirmation Procedure ...............................598

Wiring Diagram .....................................................600

Diagnostic Procedure ...........................................601

Component Inspection ..........................................602

Remove and Installation .......................................602

DTC P1217 ENGINE OVER TEMPERATURE ........603

System Description ...............................................603

CONSULT-II Reference Value in Data Monitor Mode

.603

ECM Terminals and Reference Value ...................604

On Board Diagnosis Logic ....................................604

Overall Function Check ........................................605

Wiring Diagram .....................................................607

Diagnostic Procedure ...........................................608

Main 12 Causes of Overheating ...........................615

Component Inspection ..........................................616

DTC P1225 TP SENSOR ........................................617

Component Description ........................................617

On Board Diagnosis Logic ....................................617

DTC Confirmation Procedure ...............................617

Diagnostic Procedure ...........................................618

Remove and Installation .......................................618

DTC P1226 TP SENSOR ........................................619

Component Description ........................................619

On Board Diagnosis Logic ....................................619

DTC Confirmation Procedure ...............................619

Diagnostic Procedure ...........................................620

Remove and Installation .......................................620

DTC P1229 SENSOR POWER SUPPLY ................621

On Board Diagnosis Logic ....................................621

DTC Confirmation Procedure ...............................621

Wiring Diagram .....................................................622

Diagnostic Procedure ...........................................623

DTC P1805 BRAKE SWITCH .................................625

Description ............................................................625

CONSULT-II Reference Value in Data Monitor Mode

.625

ECM Terminals and Reference Value ...................625

On Board Diagnosis Logic ....................................625

DTC Confirmation Procedure ...............................625

Wiring Diagram .....................................................627

Diagnostic Procedure ...........................................628

Component Inspection ..........................................629

DTC P2122, P2123 APP SENSOR .........................631

Component Description ........................................631

CONSULT-II Reference Value in Data Monitor Mode

.631

ECM Terminals and Reference Value ...................631

On Board Diagnosis Logic ....................................632

DTC Confirmation Procedure ...............................632

Wiring Diagram .....................................................633

Diagnostic Procedure ...........................................634Component Inspection ..........................................636

Remove and Installation .......................................636

DTC P2127, P2128 APP SENSOR .........................637

Component Description ........................................637

CONSULT-II Reference Value in Data Monitor Mode

.637

ECM Terminals and Reference Value ...................637

On Board Diagnosis Logic ....................................638

DTC Confirmation Procedure ................................639

Wiring Diagram .....................................................640

Diagnostic Procedure ............................................641

Component Inspection ..........................................643

Remove and Installation .......................................643

DTC P2135 TP SENSOR ........................................644

Component Description ........................................644

CONSULT-II Reference Value in Data Monitor Mode

.644

ECM Terminals and Reference Value ...................644

On Board Diagnosis Logic ....................................645

DTC Confirmation Procedure ................................645

Wiring Diagram .....................................................647

Diagnostic Procedure ............................................648

Component Inspection ..........................................650

Remove and Installation .......................................650

DTC P2138 APP SENSOR ......................................651

Component Description ........................................651

CONSULT-II Reference Value in Data Monitor Mode

.651

ECM Terminals and Reference Value ...................651

On Board Diagnosis Logic ....................................652

DTC Confirmation Procedure ................................652

Wiring Diagram .....................................................653

Diagnostic Procedure ............................................654

Component Inspection ..........................................656

Remove and Installation .......................................656

HO2S1 HEATER ......................................................657

Description ............................................................657

CONSULT-II Reference Value in Data Monitor Mode

.657

ECM Terminals and Reference Value ...................657

Wiring Diagram ....................................................

.658

Diagnostic Procedure ............................................659

Component Inspection ..........................................661

Removal and Installation .......................................661

HO2S2 HEATER ......................................................662

Description ............................................................662

CONSULT-II Reference Value in Data Monitor Mode

.662

ECM Terminals and Reference Value ...................662

Wiring Diagram .....................................................663

Diagnostic Procedure ............................................664

Component Inspection ..........................................666

Removal and Installation .......................................666

IAT SENSOR ...........................................................667

Component Description ........................................667

Wiring Diagram .....................................................668

Diagnostic Procedure ............................................669

Component Inspection ..........................................670

Removal and Installation .......................................670