engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2383 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CAN SYSTEM (FOR A/T MODELS)

LAN-7

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Work FlowEKS002AG

1. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE” and “A/T” displayed on NISSAN X-TRAIL 2003 Electronic Repair Manual CAN SYSTEM (FOR A/T MODELS)

LAN-7

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Work FlowEKS002AG

1. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE” and “A/T” displayed on](/img/5/57402/w960_57402-2382.png)

CAN SYSTEM (FOR A/T MODELS)

LAN-7

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Work FlowEKS002AG

1. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE” and “A/T” displayed on

CONSULT-II. Refer toEC-114, "

DTC U1000 CAN COMMUNICATION LINE"(WITH EURO-OBD) orEC-

460, "DTC U1000 CAN COMMUNICATION LINE"(WITHOUT EURO-OBD) for “ENGINE” and Refer to

AT-213, "

DTC U1000 CAN COMMUNICATION LINE"(EURO-OBD) orAT-443, "CAN CAMMUNICATION

LINE"(EXC.F/EURO-OBD) for “A/T”.

2. Attach the printed sheet of “SELF-DIAG RESULTS” and “DATA MONITOR” onto the check sheet. Refer to

LAN-8, "

CHECK SHEET"

3. Based on the data monitor results, put “v” marks onto the items with “UNKWN” or “NG” in the check sheet

table. Refer toLAN-8, "

CHECK SHEET"

NOTE:

If “NG” is displayed on “CAN COMM” for the diagnosed control unit, replace the control unit.

4. According to the check sheet results (example), start inspection. Refer toLAN-9, "

CHECK SHEET

RESULTS (EXAMPLE)"

Page 2386 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual LAN-10

[CAN]

CANSYSTEM(FORA/TMODELS)

3.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector F43 terminals

33(B/W), 34 (L/R) and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair h NISSAN X-TRAIL 2003 Electronic Repair Manual LAN-10

[CAN]

CANSYSTEM(FORA/TMODELS)

3.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector F43 terminals

33(B/W), 34 (L/R) and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair h](/img/5/57402/w960_57402-2385.png)

LAN-10

[CAN]

CANSYSTEM(FORA/TMODELS)

3.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector F43 terminals

33(B/W), 34 (L/R) and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness between ECM and TCM.

4.ECM/TCM INTERNAL CIRCUIT INSPECTION

Check components inspection. Refer toLAN-10, "

ECM/TCM INTERNAL CIRCUIT INSPECTION"

OK or NG

OK >> Reconnect all connectors to perform “SELF-DIAG RESULTS” and “DATA MONITOR” for

“ENGINE” and “A/T”. Refer toEC-114, "

DTC U1000 CAN COMMUNICATION LINE"(WITH

EURO-OBD) orEC-460, "

DTC U1000 CAN COMMUNICATION LINE"(WITHOUT EURO-OBD)

for “ENGINE” and Refer toAT-213, "

DTC U1000 CAN COMMUNICATION LINE"(EURO-OBD) or

AT-443, "

CAN CAMMUNICATION LINE"(EXC.F/EURO-OBD) for “A/T”.

NG >> Replace ECM and/or TCM.

Component InspectionEKS002AI

ECM/TCM INTERNAL CIRCUIT INSPECTION

lRemove ECM and TCM from vehicle.

lCheck resistance between ECM terminals 33 and 34.

lCheck resistance between TCM terminals 5 and 6.33(B/W) – ground : Continuity should not exist.

34(L/R) – ground : Continuity should not exist.

SKIA0889E

Unit Terminal Resistance value (W)

ECM 33–34

Approx. 108 - 132

TCM 5 – 6

PKIA0298E

Page 2389 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CAN SYSTEM (FOR M/T MODELS)

LAN-13

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Work FlowEKS002FN

1. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE”, “ALL MODE 4WD”,

and NISSAN X-TRAIL 2003 Electronic Repair Manual CAN SYSTEM (FOR M/T MODELS)

LAN-13

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Work FlowEKS002FN

1. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE”, “ALL MODE 4WD”,

and](/img/5/57402/w960_57402-2388.png)

CAN SYSTEM (FOR M/T MODELS)

LAN-13

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Work FlowEKS002FN

1. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE”, “ALL MODE 4WD”,

and “ABS” displayed on CONSULT-II. Refer toEC-114, "

DTC U1000 CAN COMMUNICATION LINE"

(WITH EURO-OBD) orEC-460, "DTC U1000 CAN COMMUNICATION LINE"(WITHOUT EURO-OBD)

for“ENGINE”andRefertoTF-53, "

CAN COMMUNICATION SYSTEM"for “ALL MODE 4WD”. Refer to

BRC-108, "

Inspection 15 CAN Communication Circuit, ESP/TCS/ABS Control Unit and Steering Angle

Sensor"for “ABS”.

2. Attach the printed sheet of “SELF-DIAG RESULTS” and “DATA MONITOR” onto the check sheet. Refer to

LAN-14, "

CHECK SHEET"

3. Based on the data monitor results, put “v” marks onto the items with “UNKWN” or “NG” in the check sheet

table. Refer toLAN-14, "

CHECK SHEET"

NOTE:

If “NG” is displayed on “CAN COMM” for the diagnosed control unit, replace the control unit.

4. According to the check sheet results (example), start inspection. Refer toLAN-15, "

CHECK SHEET

RESULTS (EXAMPLE)"

Page 2393 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CAN SYSTEM (FOR M/T MODELS)

LAN-17

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect steering wheel angle sensor connector and harness connector M75.

2. Check continuity NISSAN X-TRAIL 2003 Electronic Repair Manual CAN SYSTEM (FOR M/T MODELS)

LAN-17

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect steering wheel angle sensor connector and harness connector M75.

2. Check continuity](/img/5/57402/w960_57402-2392.png)

CAN SYSTEM (FOR M/T MODELS)

LAN-17

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect steering wheel angle sensor connector and harness connector M75.

2. Check continuity between steering wheel angle sensor harness

connector M81 terminals 4 (W), 5 (R) and harness connector

M75 terminals 8 (W), 19 (R).

OK or NG

OK >> GO TO 3.

NG >> Repair harness.

3.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect 4WD control unit connector.

2. Check continuity between harness connector E116 terminals

8(W), 19 (R) and 4WD control unit harness connector E122 ter-

minals 48 (W), 39 (R).

OK or NG

OK >> Reconnect all connectors to perform “SELF-DIAG

RESULTS” and “DATA MONITOR” for “ENGINE”, “ALL

MODE 4WD”, and “ABS” displayed on CONSULT-II.

Refer toEC-114, "

DTC U1000 CAN COMMUNICATION

LINE"(WITH EURO-OBD) orEC-460, "DTC U1000

CAN COMMUNICATION LINE"(WITHOUT EURO-OBD) for “ENGINE” and Refer toTF-53,

"CAN COMMUNICATION SYSTEM"for “ALL MODE 4WD”. Refer toBRC-108, "Inspection 15

CAN Communication Circuit, ESP/TCS/ABS Control Unit and Steering Angle Sensor"for “ABS”.

NG >> Repair harness.

ECM Circuit CheckEKS002FQ

1.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check following terminals and connector for damage, bend and loose connection. (control module-side

and harness-side)

lECM.

lHarness connector F41.

lHarness connector M61.

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.4(W) – 8(W) : Continuity should exist.

5(R) – 19(R) : Continuity should exist.

SKIA0928E

8(W) – 48(W) : Continuity should exist.

19(R) – 39(R) : Continuity should exist.

SKIA0929E

Page 2398 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual LAN-22

[CAN]

CAN SYSTEM (FOR M/T MODELS)

8.CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect ECM connector.

2. Check continuity between ECM harness connector F43 termi-

nals 33 (W) and 34(R).

OK or NG

OK NISSAN X-TRAIL 2003 Electronic Repair Manual LAN-22

[CAN]

CAN SYSTEM (FOR M/T MODELS)

8.CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect ECM connector.

2. Check continuity between ECM harness connector F43 termi-

nals 33 (W) and 34(R).

OK or NG

OK](/img/5/57402/w960_57402-2397.png)

LAN-22

[CAN]

CAN SYSTEM (FOR M/T MODELS)

8.CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect ECM connector.

2. Check continuity between ECM harness connector F43 termi-

nals 33 (W) and 34(R).

OK or NG

OK >> GO TO 9.

NG >> Repair harness between ECM and harness connector

F41.

9.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector F43 terminals 33

(W), 34 (R) and ground.

OK or NG

OK >> GO TO 10.

NG >> Repair harness between ECM and harness connector

F41.

10.ECM / ESP/TCS/ABS CONTROL UNIT INTERNAL CIRCUIT INSPECTION

Check components inspection. Refer toLAN-22, "

ECM / ESP/TCS/ABS CONTROL UNIT INTERNAL CIR-

CUIT INSPECTION"

OK or NG

OK >> Reconnect all connectors to perform “SELF-DIAG RESULTS” and “DATA MONITOR” for

“ENGINE”, “ALL MODE 4WD”, and “ABS” displayed on CONSULT-II. Refer toEC-114, "

DTC

U1000 CAN COMMUNICATION LINE"(WITH EURO-OBD) orEC-460, "DTC U1000 CAN COM-

MUNICATION LINE"(WITHOUT EURO-OBD) for “ENGINE” and Refer toTF-53, "CAN COMMU-

NICATION SYSTEM"for “ALL MODE 4WD”. Refer toBRC-108, "Inspection 15 CAN

Communication Circuit, ESP/TCS/ABS Control Unit and Steering Angle Sensor"for “ABS”.

NG >> Replace ECM and/or ESP/TCS/ABS control unit.

Component InspectionEKS002FW

ECM / ESP/TCS/ABS CONTROL UNIT INTERNAL CIRCUIT INSPECTION

lRemove ECM and ESP/TCS/ABS control unit from vehicle.

lCheck resistance between ECM terminals 33 and 34.

lCheck resistance between ESP/TCS/ABS control unit terminals

61 and 63.33(W) – 34(R) : Continuity should not exist.

SKIA0888E

33(W) – ground : Continuity should not exist.

34(R) – ground : Continuity should not exist.

SKIA0889E

Unit Terminal Resistance value (W)

ECM 33 – 34

Approx. 108 - 132

ESP/TCS/ABS control unit 61 – 63

SKIA0933E

Page 2404 of 3066

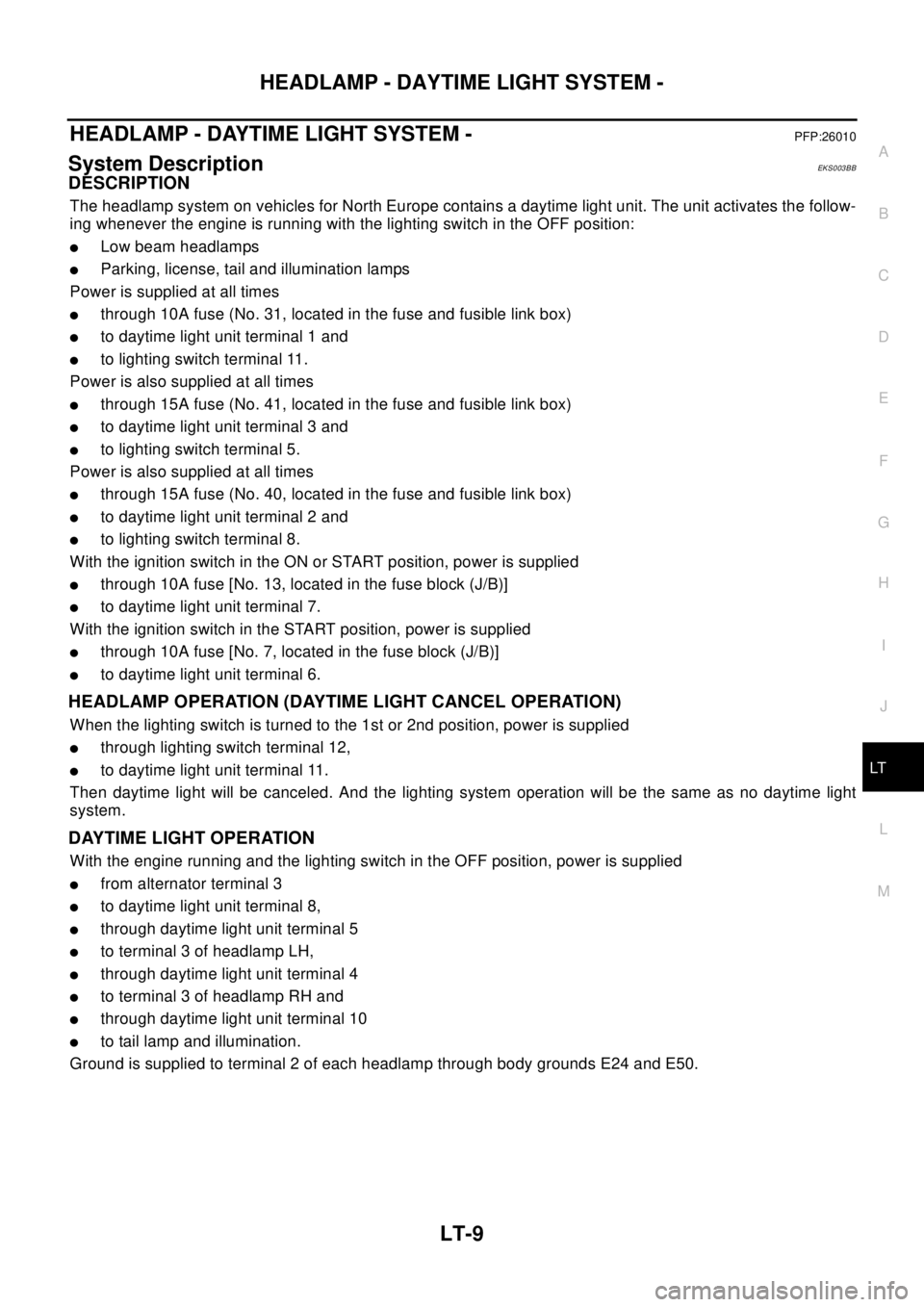

LT-6

HEADLAMP

Trouble Diagnoses

EKS003CF

Aiming AdjustmentEKS003CG

When performing headlamp aiming adjustment, use an aiming machine, aiming wall screen or headlamp

tester. Aimers should be in good repair, calibrated and operated in accordance with respective operation man-

uals.

If any aimer is not available, aiming adjustment can be done as follows:

For details, refer to the regulations in your own country.

lKeep all tires inflated to correct pressures.

lPlace vehicle and tester on one and same flat surface.

lSee that there is no-load in vehicle (coolant, engine oil filled up to correct level and full fuel tank) other

than the driver (or equivalent weight placed in driver's position).

Symptom Possible cause Repair order

Headlamp LH do not operate.1. Bulb

2. Grounds E24 and E50

3. 15A fuse

4. Lighting switch1. Check bulb.

2. Check grounds E24 and E50.

3. Check 15A fuse (No. 40, located in fuse

and fusible link box). Verify battery posi-

tive voltage is present at terminal 8 of

lighting switch.

4. Check lighting switch.

Headlamp RH do not operate.1. Bulb

2. Grounds E24 and E50

3. 15A fuse

4. Lighting switch1. Check bulb.

2. Check grounds E24 and E50.

3. Check 15A fuse (No. 41, located in fuse

and fusible link box). Verify battery posi-

tive voltage is present at terminal 5 of

lighting switch.

4. Check lighting switch.

High beam LH do not operate, but low

beam LH operates.1. Bulb

2. Open in high beam LH circuit

3. Lighting switch1. Check bulbs.

2. Check the wire between lighting switch

terminal 9 and headlamp LH terminal 1

for an open circuit.

3. Check lighting switch.

Low beam LH does not operate, but high

beam LH operates.1. Bulb

2. Open in low beam LH circuit

3. Lighting switch1. Check bulb.

2. Check the wire between lighting switch

terminal 10 and headlamp LH terminal 3

for an open circuit.

3. Check lighting switch.

High beam RH do not operate, but low

beam RH operates.1. Bulb

2. Open in high beam RH circuit

3. Lighting switch1. Check bulbs.

2. Check the wire between lighting switch

terminal 6 and headlamp RH terminal 1

for an open circuit.

3. Check lighting switch.

Low beam RH does not operate, but high

beam RH operates.1. Bulb

2. Open in low beam RH circuit

3. Lighting switch1. Check bulb.

2. Check the wire between lighting switch

terminal 7 and headlamp RH terminal 3

for an open circuit.

3. Check lighting switch.

High beam indicator does not work.1. Bulb

2. Grounds M27 and M70

3. Open in high beam circuit1. Check bulb in combination meter.

2. Check grounds M27 and M70.

3. Check the wire between lighting switch

terminal 9 and combination meter termi-

nal 61(LHD models) or 50(RHD models)

for an open circuit.

Page 2407 of 3066

HEADLAMP - DAYTIME LIGHT SYSTEM -

LT-9

C

D

E

F

G

H

I

J

L

MA

B

LT

HEADLAMP - DAYTIME LIGHT SYSTEM -PFP:26010

System DescriptionEKS003BB

DESCRIPTION

The headlamp system on vehicles for North Europe contains a daytime light unit. The unit activates the follow-

ing whenever the engine is running with the lighting switch in the OFF position:

lLow beam headlamps

lParking, license, tail and illumination lamps

Power is supplied at all times

lthrough 10A fuse (No. 31, located in the fuse and fusible link box)

lto daytime light unit terminal 1 and

lto lighting switch terminal 11.

Power is also supplied at all times

lthrough 15A fuse (No. 41, located in the fuse and fusible link box)

lto daytime light unit terminal 3 and

lto lighting switch terminal 5.

Power is also supplied at all times

lthrough 15A fuse (No. 40, located in the fuse and fusible link box)

lto daytime light unit terminal 2 and

lto lighting switch terminal 8.

With the ignition switch in the ON or START position, power is supplied

lthrough 10A fuse [No. 13, located in the fuse block (J/B)]

lto daytime light unit terminal 7.

With the ignition switch in the START position, power is supplied

lthrough 10A fuse [No. 7, located in the fuse block (J/B)]

lto daytime light unit terminal 6.

HEADLAMP OPERATION (DAYTIME LIGHT CANCEL OPERATION)

When the lighting switch is turned to the 1st or 2nd position, power is supplied

lthrough lighting switch terminal 12,

lto daytime light unit terminal 11.

Then daytime light will be canceled. And the lighting system operation will be the same as no daytime light

system.

DAYTIME LIGHT OPERATION

With the engine running and the lighting switch in the OFF position, power is supplied

lfrom alternator terminal 3

lto daytime light unit terminal 8,

lthrough daytime light unit terminal 5

lto terminal 3 of headlamp LH,

lthrough daytime light unit terminal 4

lto terminal 3 of headlamp RH and

lthrough daytime light unit terminal 10

lto tail lamp and illumination.

Ground is supplied to terminal 2 of each headlamp through body grounds E24 and E50.

Page 2412 of 3066

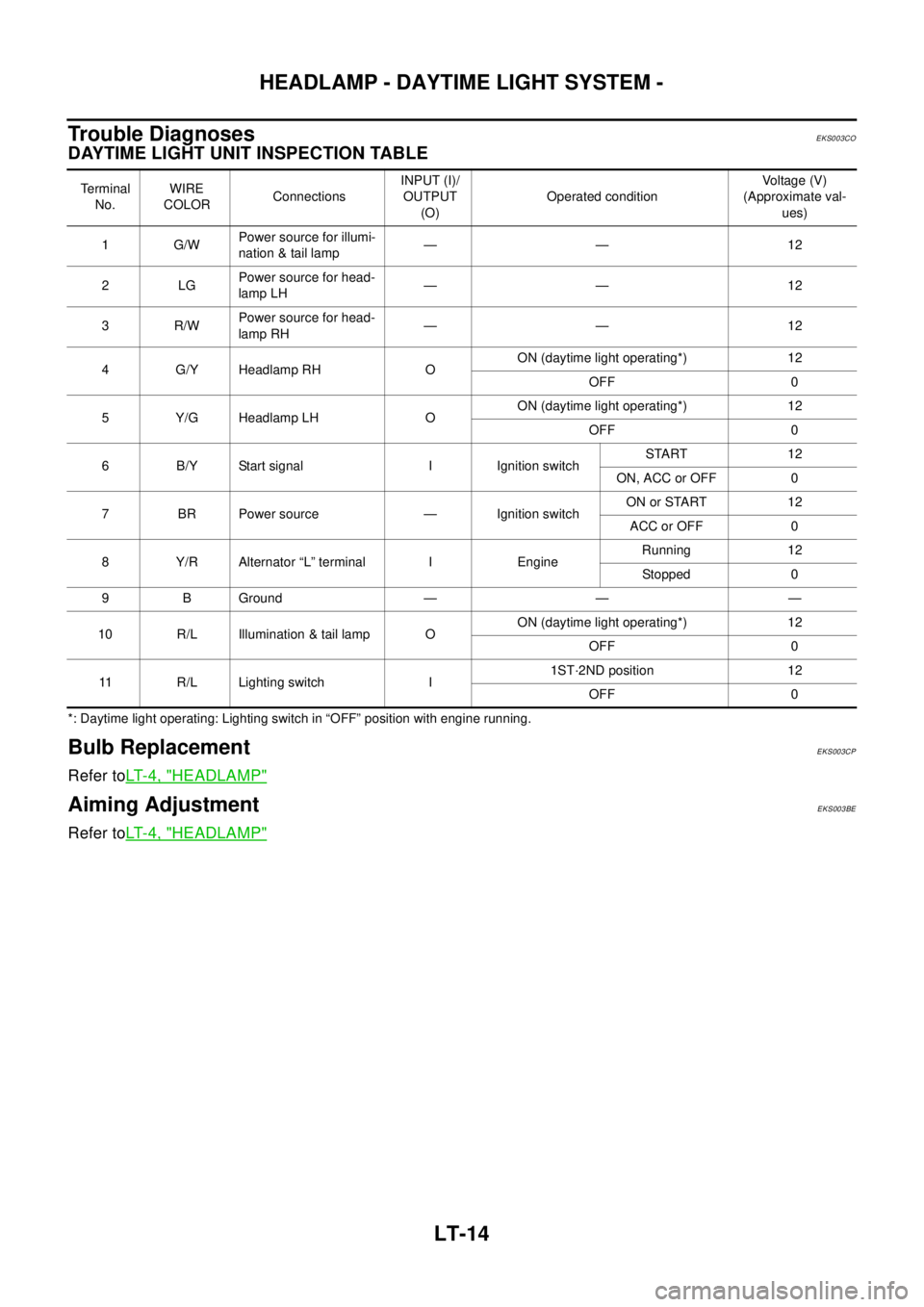

LT-14

HEADLAMP - DAYTIME LIGHT SYSTEM -

Trouble Diagnoses

EKS003CO

DAYTIME LIGHT UNIT INSPECTION TABLE

*: Daytime light operating: Lighting switch in “OFF” position with engine running.

Bulb ReplacementEKS003CP

Refer toLT- 4 , "HEADLAMP"

Aiming AdjustmentEKS003BE

Refer toLT- 4 , "HEADLAMP"

Te r m i n a l

No.WIRE

COLORConnectionsINPUT (I)/

OUTPUT

(O)Operated conditionVo l ta g e (V )

(Approximate val-

ues)

1G/WPower source for illumi-

nation & tail lamp—— 12

2LGPower source for head-

lamp LH—— 12

3R/WPower source for head-

lamp RH—— 12

4G/YHeadlampRH OON (daytime light operating*) 12

OFF 0

5Y/GHeadlampLH OON (daytime light operating*) 12

OFF 0

6 B/Y Start signal I Ignition switchSTART 12

ON, ACC or OFF 0

7 BR Power source — Ignition switchON or START 12

ACC or OFF 0

8 Y/R Alternator “L” terminal I EngineRunning 12

Stopped 0

9 B Ground — — —

10 R/L Illumination & tail lamp OON (daytime light operating*) 12

OFF 0

11 R/L Lighting switch I1ST·2ND position 12

OFF 0

Page 2467 of 3066

LU-1

ENGINE LUBRICATION SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

LU

ENGINE LUBRICATION SYSTEM

QR20DE

PRECAUTIONS .......................................................... 3

Precautions For Liquid Gasket ................................. 3

REMOVAL OF LIQUID GASKET SEALING .......... 3

LIQUID GASKET APPLICATION PROCEDURE..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

LUBRICATION SYSTEM ............................................ 5

Lubrication Circuit .................................................... 5

System Drawing ....................................................... 6

ENGINE OIL ............................................................... 7

Inspection ................................................................. 7

OIL LEVEL AND MUDDINESS ............................. 7

OIL LEAKAGE ....................................................... 7

OIL PRESSURE CHECK ...................................... 7

Changing Engine Oil ................................................ 8

OIL FILTER ................................................................. 9

Removal and Installation .......................................... 9

REMOVAL ............................................................. 9

INSTALLATION ..................................................... 9

OIL PUMP ................................................................. 10

Removal and Installation ........................................ 10

Disassembly and Assembly ................................... 10

DISASSEMBLY ................................................... 10

INSPECTION AFTER DISASSEMBLY ............... 10

ASSEMBLY ......................................................... 12

OIL COOLER ............................................................ 13

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSPECTION ...................................................... 13

INSTALLATION ................................................... 13

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 14

Standard and Limit ................................................. 14

OIL PRESSURE .................................................. 14

OIL PUMP ........................................................... 14

REGULATOR VALVE .......................................... 14

OIL CAPACITY .................................................... 14

TIGHTENING TORQUE ...................................... 14

YD22DDTi

PRECAUTIONS ........................................................ 15

Precautions For Liquid Gasket ............................... 15

REMOVAL OF LIQUID GASKET SEALING ........ 15

LIQUID GASKET APPLICATION PROCEDURE... 15

PREPARATION ......................................................... 16

Special Service Tools ............................................. 16

LUBRICATION SYSTEM .......................................... 17

Lubrication Circuit ................................................... 17

ENGINE OIL .............................................................. 18

Inspection ............................................................... 18

OIL LEVEL AND MUDDINESS ........................... 18

OIL LEAKAGE ..................................................... 18

OIL PRESSURE CHECK .................................... 18

Changing Engine Oil ............................................... 19

OIL FILTER ............................................................... 20

Removal and Installation ........................................ 20

REMOVAL ........................................................... 20

INSTALLATION ................................................... 21

OIL FILTER BRACKET ............................................. 22

Removal and Installation ........................................ 22

REMOVAL ........................................................... 22

INSTALLATION ................................................... 22

OIL PUMP ................................................................. 23

Removal and Installation ........................................ 23

Disassembly and Assembly .................................... 23

DISASSEMBLY ................................................... 23

INSPECTION AFTER DISASSEMBLY ................ 23

ASSEMBLY ......................................................... 24

OIL COOLER ............................................................ 25

Removal and Installation ........................................ 25

REMOVAL ........................................................... 25

INSPECTION ...................................................... 25

INSTALLATION ................................................... 25

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 26

Standard and Limit .................................................. 26

OIL PRESSURE .................................................. 26

OIL PUMP ........................................................... 26

REGULATOR VALVE .......................................... 26

Page 2469 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual PRECAUTIONS

LU-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009SQ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, dis NISSAN X-TRAIL 2003 Electronic Repair Manual PRECAUTIONS

LU-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009SQ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, dis](/img/5/57402/w960_57402-2468.png)

PRECAUTIONS

LU-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009SQ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

lIn areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the areas where the liquid gasket is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

lRemove the liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lighting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

lIf there is a groove for the liquid gasket application, apply the

gasket to the groove.

lAs for the bolt holes, normally apply the gasket inside the holes.

Occasionally, it should be applied outside the holes. Make sure

to read the text of service manual.

lWithin five minutes of gasket application, install the mating com-

ponent.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten after the installation.

lAfter 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe

them.

PBIC0275E

PBIC0003E

EMA0622D

SEM164F