engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2643 of 3066

TROUBLE DIAGNOSIS

MTC-7

C

D

E

F

G

H

I

K

L

MA

B

MTC

Operational CheckEJS001FE

The purpose of the operational check is to confirm that the system operates properly.

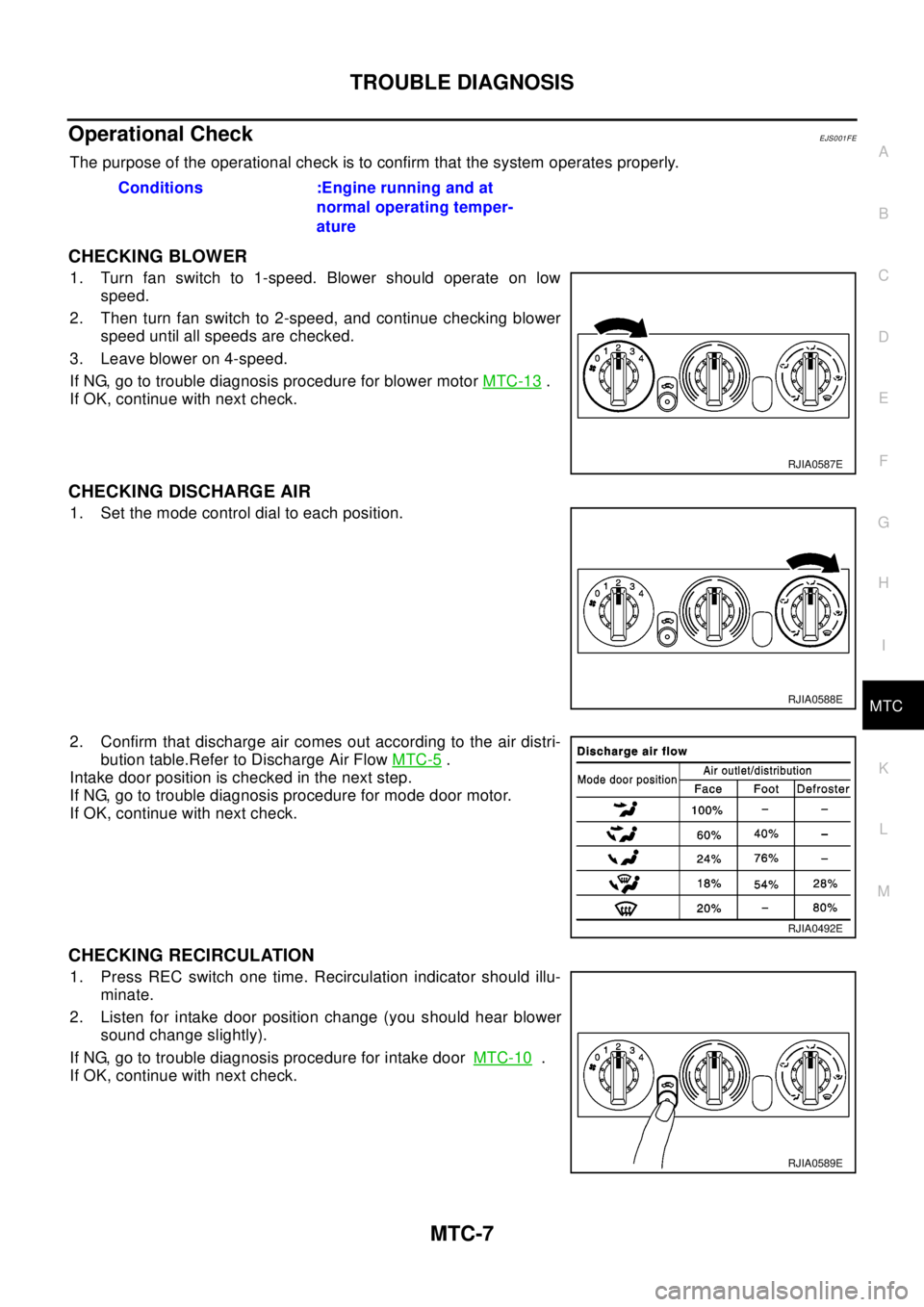

CHECKING BLOWER

1. Turn fan switch to 1-speed. Blower should operate on low

speed.

2. Then turn fan switch to 2-speed, and continue checking blower

speed until all speeds are checked.

3. Leave blower on 4-speed.

If NG, go to trouble diagnosis procedure for blower motorMTC-13

.

If OK, continue with next check.

CHECKING DISCHARGE AIR

1. Set the mode control dial to each position.

2. Confirm that discharge air comes out according to the air distri-

bution table.Refer to Discharge Air FlowMTC-5

.

Intake door position is checked in the next step.

If NG, go to trouble diagnosis procedure for mode door motor.

If OK, continue with next check.

CHECKING RECIRCULATION

1. Press REC switch one time. Recirculation indicator should illu-

minate.

2. Listen for intake door position change (you should hear blower

sound change slightly).

If NG, go to trouble diagnosis procedure for intake doorMTC-10

.

If OK, continue with next check.Conditions :Engine running and at

normal operating temper-

ature

RJIA0587E

RJIA0588E

RJIA0492E

RJIA0589E

Page 2654 of 3066

MTC-18

TROUBLE DIAGNOSIS

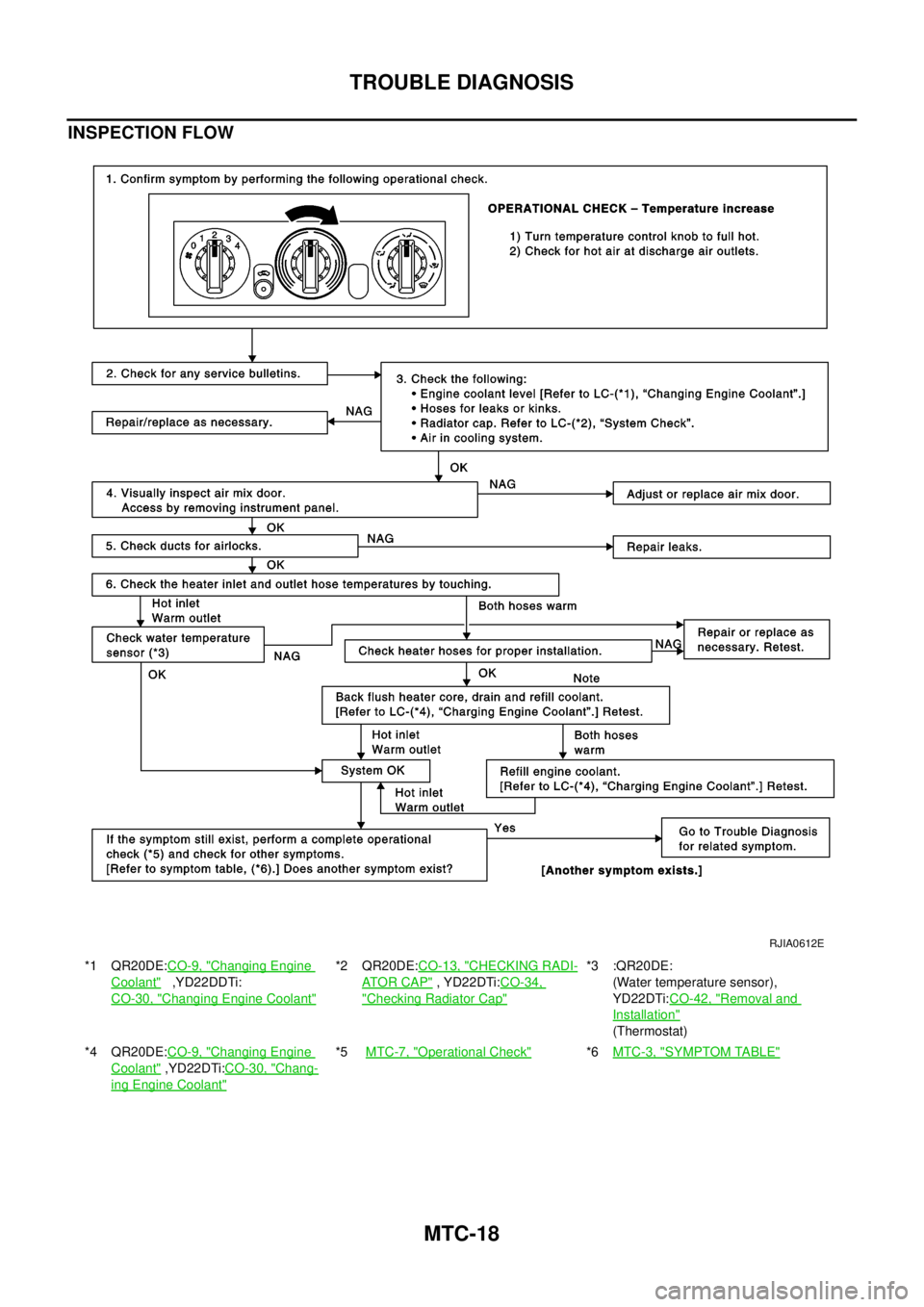

INSPECTION FLOW

*1 QR20DE:CO-9, "Changing Engine

Coolant",YD22DDTi:

CO-30, "

Changing Engine Coolant"

*2 QR20DE:CO-13, "CHECKING RADI-

AT O R C A P", YD22DTi:CO-34,

"Checking Radiator Cap"

*3 :QR20DE:

(Water temperature sensor),

YD22DTi:CO-42, "

Removal and

Installation"

(Thermostat)

*4 QR20DE:CO-9, "

Changing Engine

Coolant",YD22DTi:CO-30, "Chang-

ing Engine Coolant"

*5MTC-7, "Operational Check"*6MTC-3, "SYMPTOM TABLE"

RJIA0612E

Page 2660 of 3066

MTC-24

HEATER UNIT

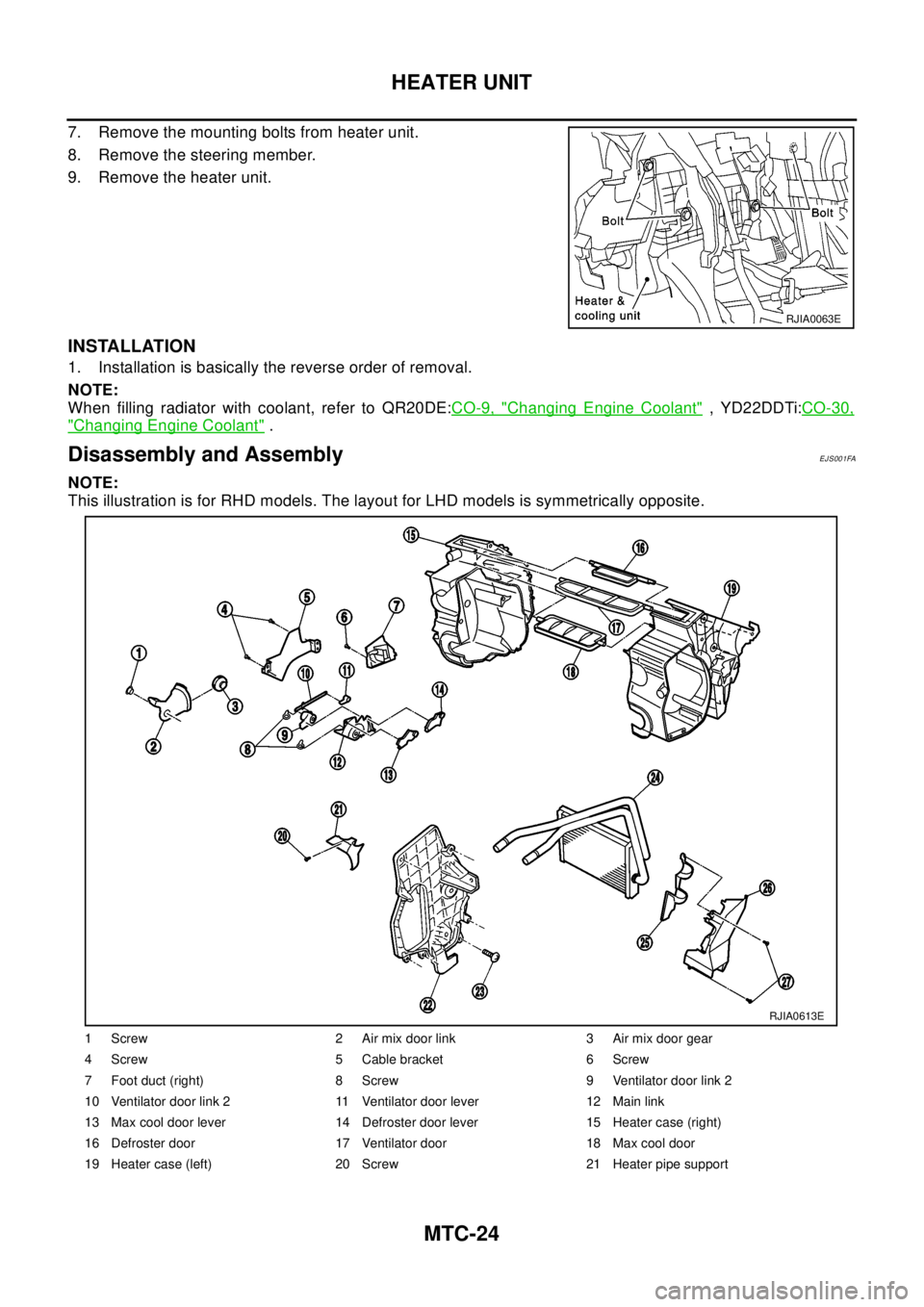

7. Remove the mounting bolts from heater unit.

8. Remove the steering member.

9. Remove the heater unit.

INSTALLATION

1. Installation is basically the reverse order of removal.

NOTE:

When filling radiator with coolant, refer to QR20DE:CO-9, "

Changing Engine Coolant",YD22DDTi:CO-30,

"Changing Engine Coolant".

Disassembly and AssemblyEJS001FA

NOTE:

This illustration is for RHD models. The layout for LHD models is symmetrically opposite.

RJIA0063E

1 Screw 2 Air mix door link 3 Air mix door gear

4Screw 5Cablebracket 6Screw

7 Foot duct (right) 8 Screw 9 Ventilator door link 2

10 Ventilator door link 2 11 Ventilator door lever 12 Main link

13 Max cool door lever 14 Defroster door lever 15 Heater case (right)

16 Defroster door 17 Ventilator door 18 Max cool door

19 Heater case (left) 20 Screw 21 Heater pipe support

RJIA0613E

Page 2677 of 3066

PG-1

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION

A

B

PG

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

POWER SUPPLY ROUTING ...................................... 2

Schematic ................................................................ 2

Wiring Diagram — POWER — ................................. 3

BATTERY POWER SUPPLY — IGNITION SW.

IN ANY POSITION ................................................ 3

ACCESSORY POWER SUPPLY — IGNITION

SW. IN “ACC” OR “ON” ......................................... 7

IGNITION POWER SUPPLY — IGNITION SW.

IN “ON” AND/OR “START” .................................... 8

Fuse ....................................................................... 12

Fusible Link ............................................................ 12

Circuit Breaker ....................................................... 12

GROUND .................................................................. 13

Ground Distribution ................................................ 13

MAIN HARNESS/LHD MODELS ........................ 14

MAIN HARNESS/RHD MODELS ........................ 16

ENGINE ROOM HARNESS/LHD MODELS ....... 18

ENGINE ROOM HARNESS/RHD MODELS ....... 19

ENGINE ROOM HARNESS ................................ 20

ENGINE CONTROL HARNESS/GASOLINE

ENGINE MODELS .............................................. 21

ENGINE CONTROL HARNESS/DIESEL

ENGINE MODELS .............................................. 22

BODY HARNESS/LHD MODELS ....................... 23

BODY HARNESS/RHD MODELS ....................... 24

BODY NO.2 HARNESS/LHD MODELS .............. 25

BODY NO.2 HARNESS/RHD MODELS ............. 26

BODY NO.2 HARNESS ...................................... 27

BACK DOOR SUB HARNESS/REAR WINDOW

DEFOGGER HARNESS ..................................... 28

HARNESS ................................................................. 29

Harness Layout ...................................................... 29

HOW TO READ HARNESS LAYOUTS ............... 29

OUTLINE/LHD MODELS .................................... 30

OUTLINE/RHD MODELS .................................... 31

MAIN HARNESS/LHD MODELS ........................ 32

MAIN HARNESS/RHD MODELS ........................ 34ENGINE ROOM HARNESS/LHD MODELS ........ 36

ENGINE ROOM HARNESS/RHD MODELS ....... 41

ENGINE CONTROL HARNESS .......................... 46

BODY HARNESS/LHD MODELS ....................... 49

BODY HARNESS/RHD MODELS ....................... 50

BODY NO.2 HARNESS/LHD MODELS .............. 51

BODY NO.2 HARNESS/RHD MODELS .............. 52

ROOM LAMP HARNESS .................................... 53

FRONT DOOR HARNESS/LHD MODELS .......... 54

FRONT DOOR HARNESS/RHD MODELS ......... 56

REAR DOOR HARNESS .................................... 58

BACK DOOR HARNESS .................................... 60

Wiring Diagram Codes (Cell Codes) ...................... 61

ELECTRICAL UNITS LOCATION ............................ 64

Electrical Units Location ......................................... 64

ENGINE COMPARTMENT .................................. 65

PASSENGER COMPARTMENT/LHD MODELS... 66

PASSENGER COMPARTMENT/RHD MODELS... 68

HARNESS CONNECTOR ......................................... 70

Description .............................................................. 70

HARNESS CONNECTOR (TAB-LOCKING

TYPE) .................................................................. 70

HARNESS CONNECTOR (SLIDE-LOCKING

TYPE) .................................................................. 71

JOINT CONNECTOR (J/C) ....................................... 72

Terminal Arrangement ............................................ 72

ELECTRICAL UNITS ................................................ 73

Terminal Arrangement ............................................ 73

STANDARDIZED RELAY .......................................... 74

Description .............................................................. 74

NORMAL OPEN, NORMAL CLOSED AND

MIXED TYPE RELAYS ........................................ 74

TYPE OF STANDARDIZED RELAYS ................. 74

FUSE BLOCK-JUNCTION BOX(J/B) ....................... 76

Terminal Arrangement ............................................ 76

FUSE AND FUSIBLE LINK BOX .............................. 77

Terminal Arrangement ............................................ 77

Page 2694 of 3066

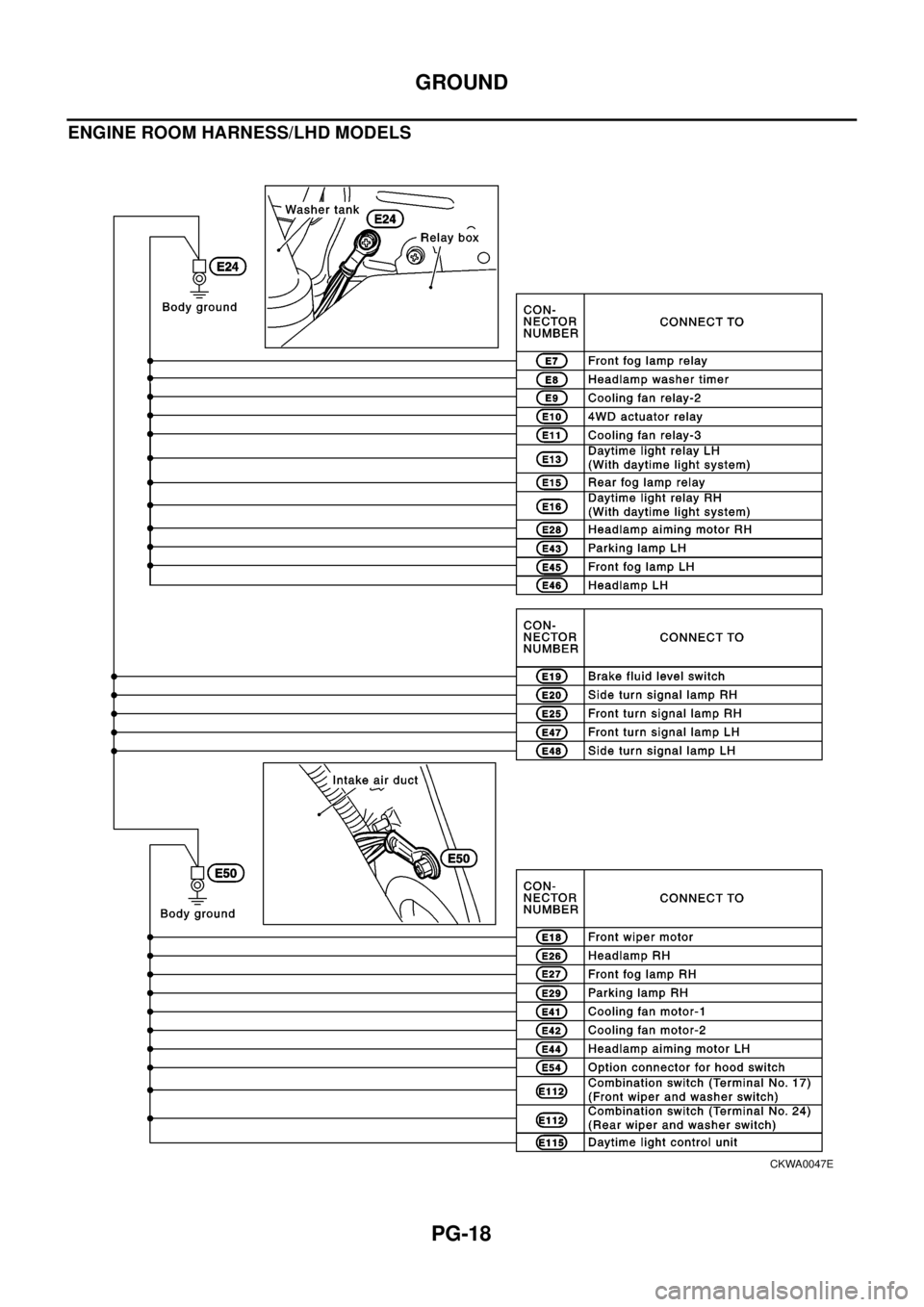

PG-18

GROUND

ENGINE ROOM HARNESS/LHD MODELS

CKWA0047E

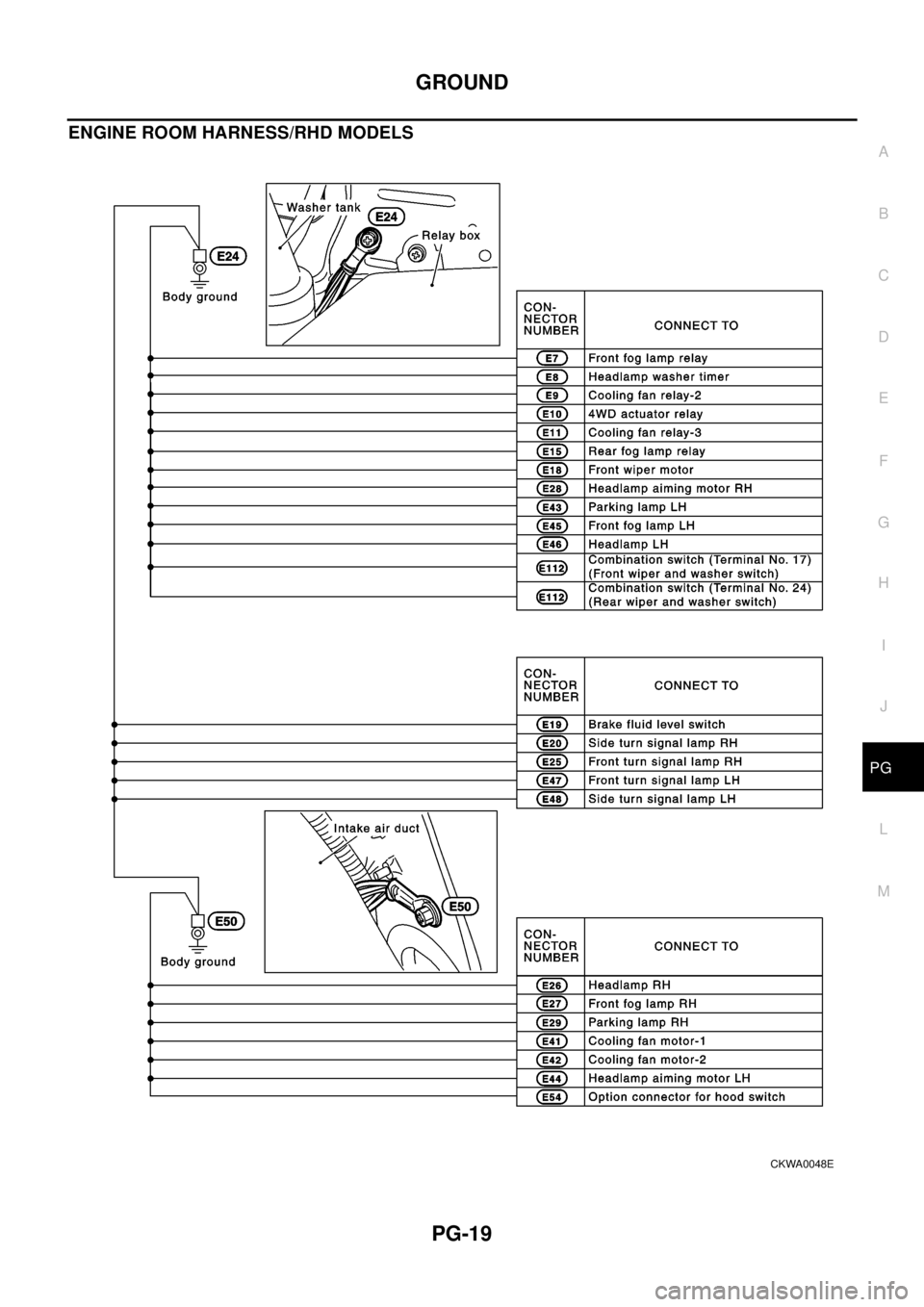

Page 2695 of 3066

GROUND

PG-19

C

D

E

F

G

H

I

J

L

MA

B

PG

ENGINE ROOM HARNESS/RHD MODELS

CKWA0048E

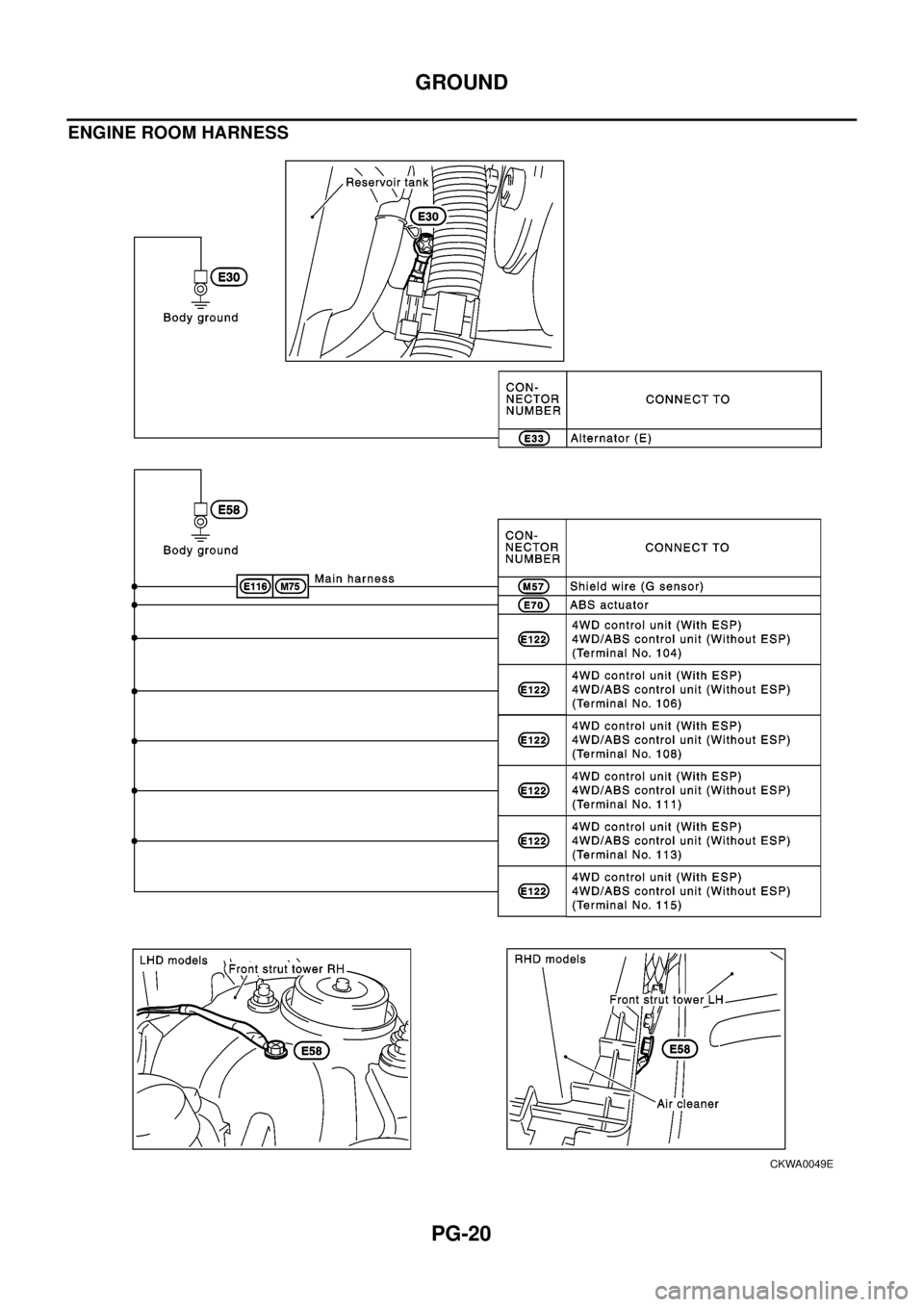

Page 2696 of 3066

PG-20

GROUND

ENGINE ROOM HARNESS

CKWA0049E

Page 2697 of 3066

GROUND

PG-21

C

D

E

F

G

H

I

J

L

MA

B

PG

ENGINE CONTROL HARNESS/GASOLINE ENGINE MODELS

CKWA0050E

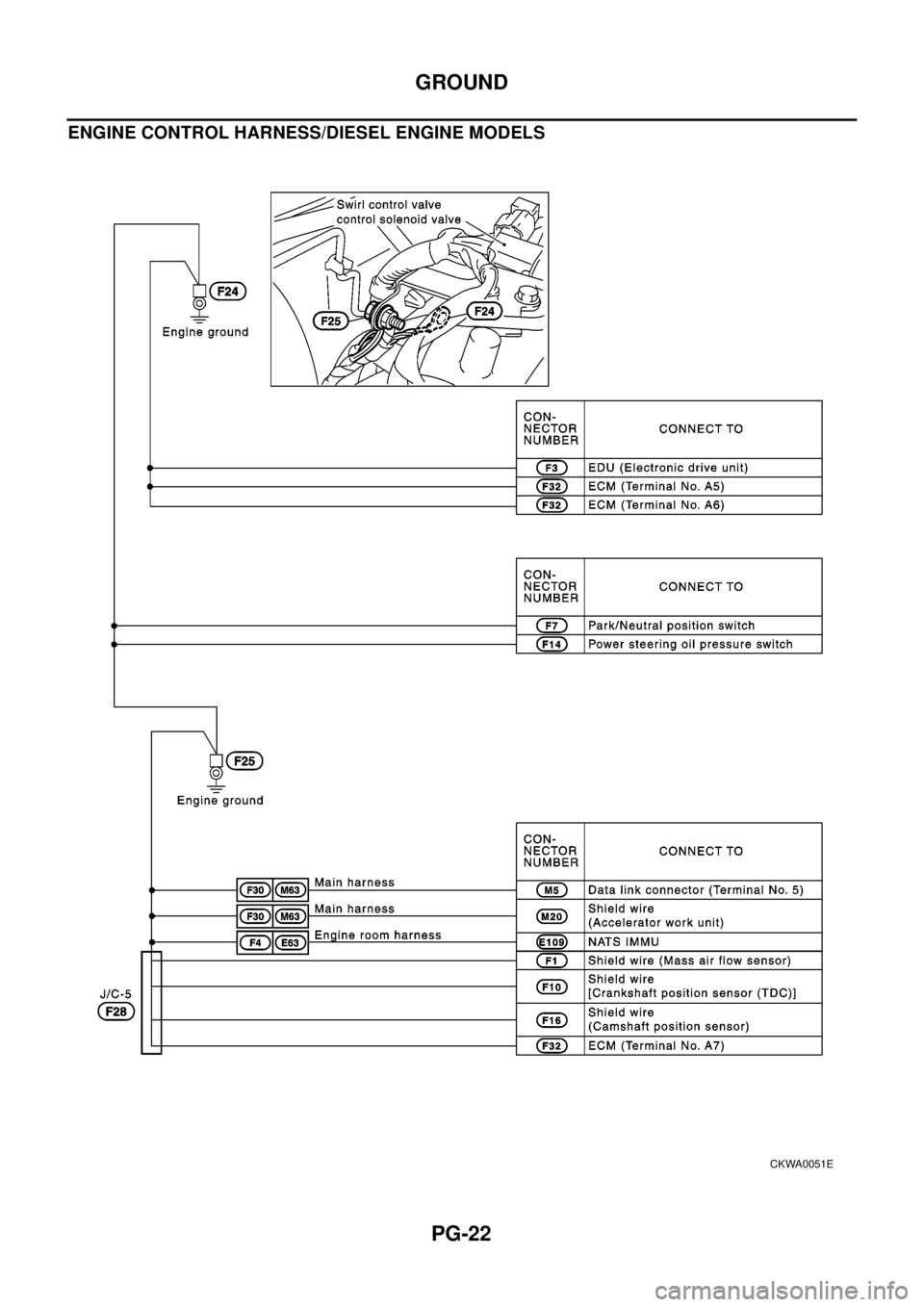

Page 2698 of 3066

PG-22

GROUND

ENGINE CONTROL HARNESS/DIESEL ENGINE MODELS

CKWA0051E

Page 2705 of 3066

HARNESS

PG-29

C

D

E

F

G

H

I

J

L

MA

B

PG

HARNESSPFP:00011

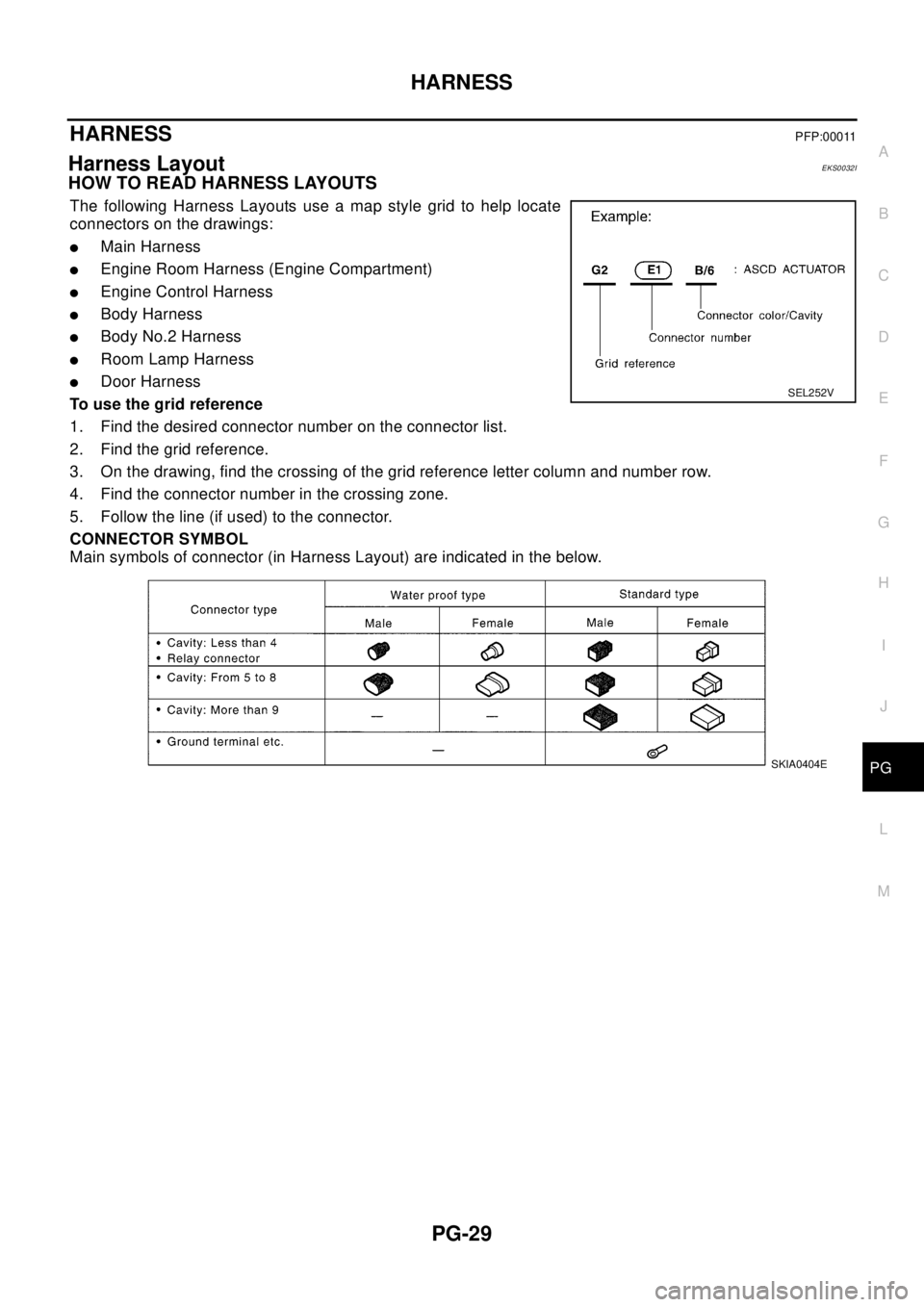

Harness LayoutEKS0032I

HOW TO READ HARNESS LAYOUTS

The following Harness Layouts use a map style grid to help locate

connectors on the drawings:

lMain Harness

lEngine Room Harness (Engine Compartment)

lEngine Control Harness

lBody Harness

lBody No.2 Harness

lRoom Lamp Harness

lDoor Harness

To use the grid reference

1. Find the desired connector number on the connector list.

2. Find the grid reference.

3. On the drawing, find the crossing of the grid reference letter column and number row.

4. Find the connector number in the crossing zone.

5. Follow the line (if used) to the connector.

CONNECTOR SYMBOL

Main symbols of connector (in Harness Layout) are indicated in the below.SEL252V

SKIA0404E