engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2824 of 3066

RFD-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

CautionEDS00056

lBefore starting diagnosis of the vehicle, understand symptoms well. Perform correct and systematic oper-

ations.

lCheck for the correct installation status prior to removal or disassembly. When mating marks are required,

be sure they do not interfere with the function of the parts they are applied to.

lCarry out an overhaul in a clean work place. Using a dust proof room is recommended.

lBefore disassembly, using steam or white gasoline, completely remove sand and mud from the exterior of

the unit, preventing them from entering into the unit during disassembly or assembly.

lCheck appearance of the disassembled parts for damage, deformation, and abnormal wear. If a malfunc-

tion is detected, replace it with a new one.

lNormally replace lock pins, oil seals, and bearings with new ones every time they are removed.

lIn principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, observe it.

lClean and flush the parts sufficiently and blow them dry.

lBe careful not to damage the sliding surfaces and mating surfaces.

lWhen applying sealant, remove the old sealant from the mounting surface; then remove any moisture, oil,

and foreign materials from the application and mounting surfaces.

lAlways use shop paper for cleaning the inside of components.

lAvoid using cotton gloves or a shop cloth to prevent entering of lint.

lDuring assembly, observe the specified tightening torque, and apply new differential oil, Vaseline, or Nis-

san MP Special Grease No. 2, as specified for each vehicle, when necessary.

lDo not reuse drained oil. Discard waste oil after oil changes or part treatment in accordance with local

laws and regulations.

Precautions for Brake SystemEDS000HX

lWhen installing rubber parts, final tightening must be carried out

under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

lAfter installing removed suspension parts, check wheel align-

ment and adjust if necessary.

lUse flare nut wrench when removing or installing brake tubes.

lAlways torque brake lines when installing.

SBR686C

Page 2854 of 3066

RSU-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

CautionEES0007C

lFinal tightening of bushings must be carried out under unladen condition with tires on the ground. Oil will

shorten life of bushings. Be sure to wipe off any spilled oil.

l“Unladen condition” means that fuel, coolant and lubricant are full and ready for drive. However, spare tire,

jack, and hand tools should be unloaded.

lAfter installing the removed suspension parts, always check wheel alignment and adjust if necessary.

lReplace the caulking nut with a new one. Install a new nut without wiping the oil off before tightening.

Precautions for Brake SystemEES000JB

lWhen installing rubber parts, final tightening must be carried out

under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

lUse flare nut wrench when removing or installing brake tubes.

lAfter installing removed suspension parts, check wheel align-

ment and adjust if necessary.

lAlways torque brake lines when installing.

SBR686C

Page 2866 of 3066

RSU-14

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

General SpecificationEES000J7

Wheel Alignment (Unladen)EES0007N

: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

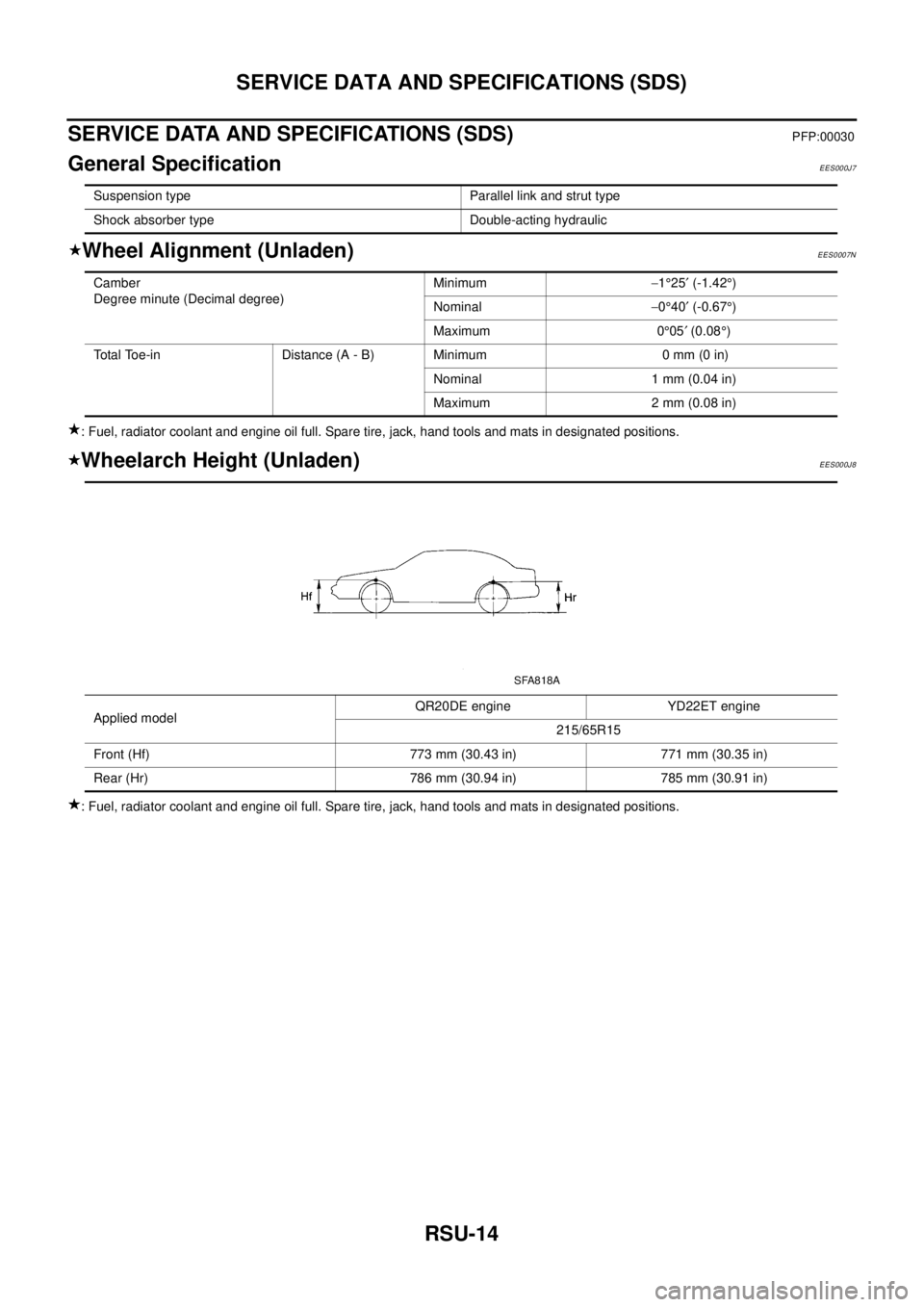

Wheelarch Height (Unladen)EES000J8

: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Suspension type Parallel link and strut type

Shock absorber type Double-acting hydraulic

Camber

Degree minute (Decimal degree)Minimum-1°25¢(-1.42°)

Nominal-0°40¢(-0.67°)

Maximum 0°05¢(0.08°)

Total Toe-in Distance (A - B) Minimum 0 mm (0 in)

Nominal 1 mm (0.04 in)

Maximum 2 mm (0.08 in)

Applied modelQR20DE engine YD22ET engine

215/65R15

Front (Hf) 773 mm (30.43 in) 771 mm (30.35 in)

Rear (Hr) 786 mm (30.94 in) 785 mm (30.91 in)

SFA818A

Page 2873 of 3066

SC-1

STARTING & CHARGING SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION

A

B

SC

STARTING & CHARGING SYSTEM

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

Wiring Diagrams and Trouble Diagnosis .................. 2

BATTERY .................................................................... 3

How to Handle Battery ............................................. 3

METHODS OF PREVENTING OVER-DIS-

CHARGE ............................................................... 3

CHECKING ELECTROLYTE LEVEL .................... 3

SPECIFIC GRAVITY CHECK ............................... 4

Battery Test and Charging Chart .............................. 5

CHART I ................................................................ 5

CHART II ............................................................... 6

A: SLOW CHARGE ............................................... 7

B: STANDARD CHARGE ...................................... 8

C: QUICK CHARGE ............................................ 10

Removal and Installation .........................................11

CHARGING SYSTEM ............................................... 12

System Description ................................................ 12

Wiring Diagram — CHARGE — ............................. 13

Trouble Diagnoses ................................................. 14

WITH IC REGULATOR ....................................... 14

MALFUNCTION INDICATOR .............................. 14

Removal and Installation ........................................ 14

REMOVAL (QR ENGINE MODELS) ................... 14

REMOVAL (YD ENGINE MODELS) ................... 15

INSTALLATION ................................................... 15

Disassembly and Assembly ................................... 16

............................................................................ 16

............................................................................ 17

Disassembly ........................................................... 17

REAR COVER .................................................... 17REAR BEARING ................................................. 18

Inspection ............................................................... 18

ROTOR CHECK .................................................. 18

BRUSH CHECK .................................................. 18

PULLEY CHECK(WITH CLUTCH TYPE) ............ 18

STATOR CHECK ................................................. 19

Assembly ................................................................ 19

RING FITTING IN REAR BEARING .................... 19

REAR COVER INSTALLATION ........................... 19

STARTING SYSTEM ................................................. 21

System Description ................................................. 21

M/T MODELS ...................................................... 21

A/T MODELS ....................................................... 21

Wiring Diagram — START —/M/T models ............. 22

Wiring Diagram — START —/A/T models .............. 23

Trouble Diagnoses ................................................. 24

Removal and Installation ........................................ 25

REMOVAL ........................................................... 25

INSTALLATION ................................................... 25

Disassembly and Assembly .................................... 26

Inspection ............................................................... 28

MAGNETIC SWITCH CHECK ............................. 28

PINION/CLUTCH CHECK ................................... 29

BRUSH CHECK .................................................. 29

YOKE CHECK ..................................................... 30

ARMATURE CHECK ........................................... 31

Assembly ................................................................ 32

PINION PROTRUSION LENGTH ADJUST-

MENT .................................................................. 32

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 34

Battery .................................................................... 34

Starter ..................................................................... 34

Alternator ................................................................ 34

Page 2875 of 3066

BATTERY

SC-3

C

D

E

F

G

H

I

J

L

MA

B

SC

BATTERYPFP:00011

How to Handle BatteryEKS00313

CAUTION:

lIf it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

lAfter connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

lNever add distilled water through the hole used to check specific gravity.

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging a battery.

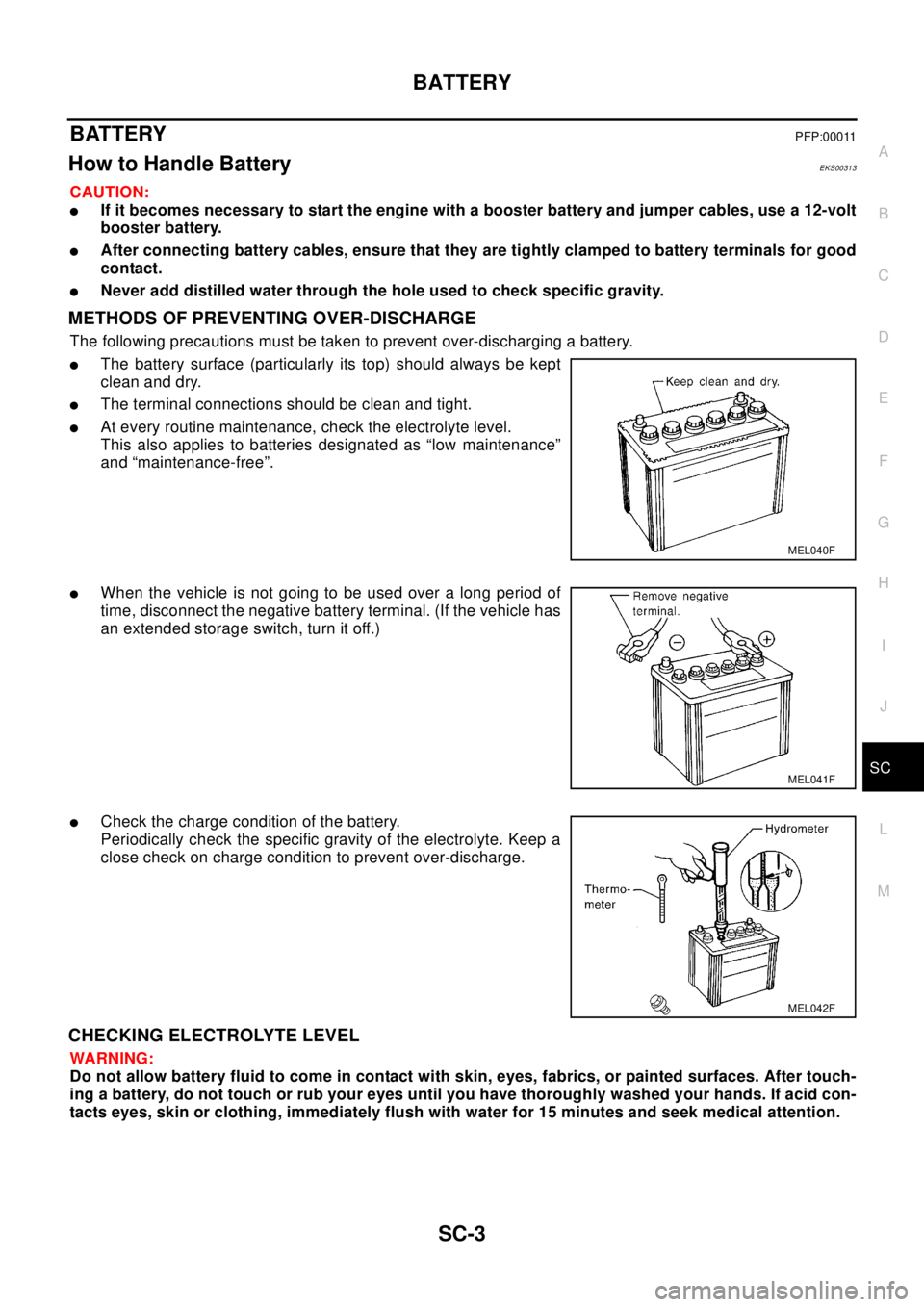

lThe battery surface (particularly its top) should always be kept

clean and dry.

lThe terminal connections should be clean and tight.

lAt every routine maintenance, check the electrolyte level.

This also applies to batteries designated as “low maintenance”

and “maintenance-free”.

lWhen the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal. (If the vehicle has

an extended storage switch, turn it off.)

lCheck the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep a

close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVEL

WA RN ING:

Do not allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, do not touch or rub your eyes until you have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

MEL040F

MEL041F

MEL042F

Page 2884 of 3066

SC-12

CHARGING SYSTEM

CHARGING SYSTEM

PFP:00011

System DescriptionEKS00316

The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

l120A (Gasoline engine models) or 100A (Diesel engine models) fusible link (letter A, located in the fuse

and fusible link box), and

l10A fuse (No.34, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle's electrical system. Output voltage is

controlled by the IC regulator at terminal 4 (S) detecting the input voltage. The charging circuit is protected by

the 120A (Gasoline engine models) or 100A (Diesel engine models) link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

l10A fuse [No. 11, located in the fuse block (J/B)]

lto combination meter terminal 46 (LHD models) or terminal 59 (RHD models) for the charge warning

lamp.

Ground is supplied With power and ground supplied

lto terminal 64 (LHD models) or terminal 54 ( RHD models) of the combination meter

lthrough terminal 3 (L) of the alternator.

the charge warning lamp will illuminate. When the alternator is providing sufficient voltage with the engine run-

ning, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

Page 2886 of 3066

SC-14

CHARGING SYSTEM

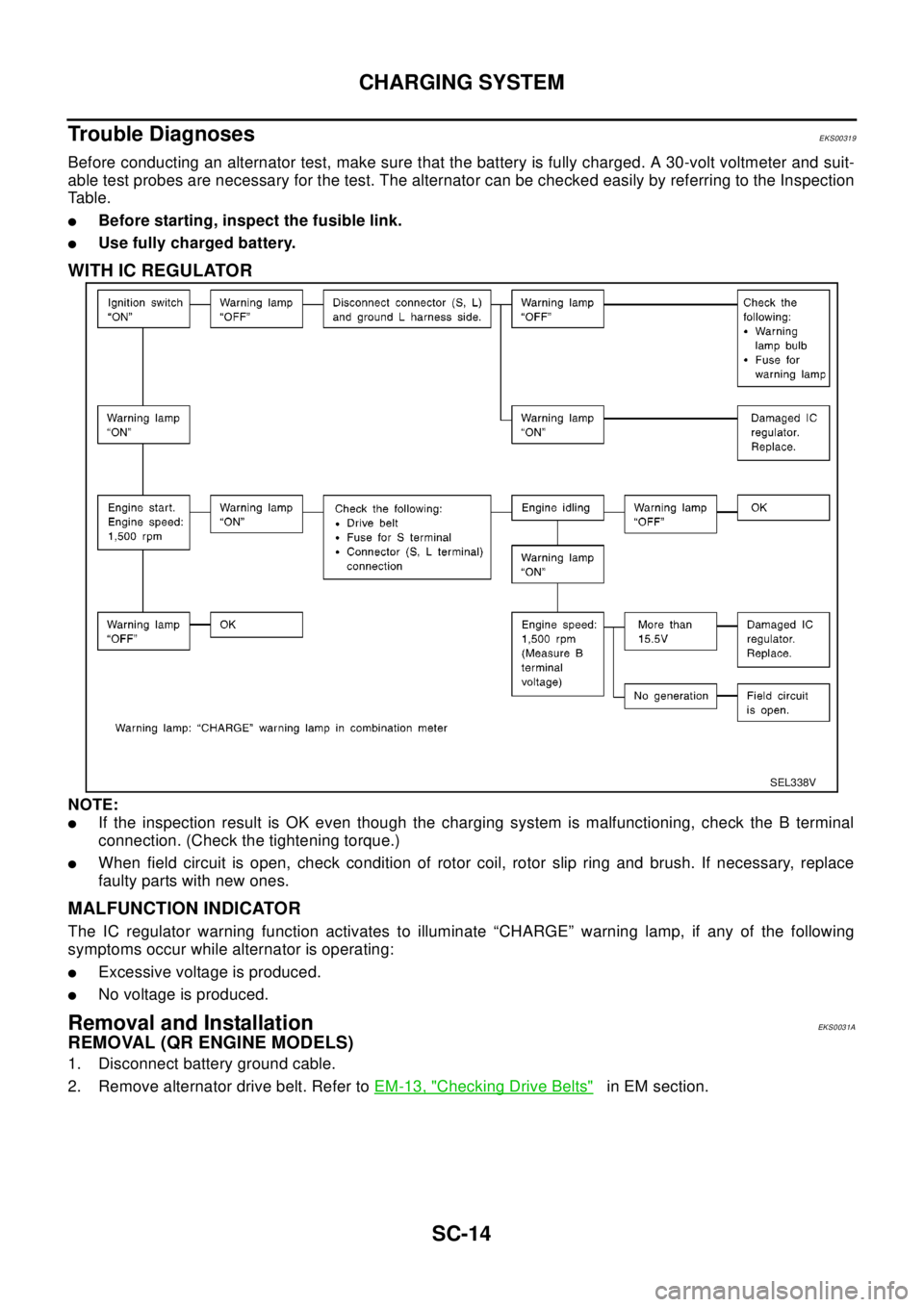

Trouble Diagnoses

EKS00319

Before conducting an alternator test, make sure that the battery is fully charged. A 30-volt voltmeter and suit-

able test probes are necessary for the test. The alternator can be checked easily by referring to the Inspection

Table.

lBefore starting, inspect the fusible link.

lUse fully charged battery.

WITH IC REGULATOR

NOTE:

lIf the inspection result is OK even though the charging system is malfunctioning, check the B terminal

connection. (Check the tightening torque.)

lWhen field circuit is open, check condition of rotor coil, rotor slip ring and brush. If necessary, replace

faulty parts with new ones.

MALFUNCTION INDICATOR

The IC regulator warning function activates to illuminate “CHARGE” warning lamp, if any of the following

symptoms occur while alternator is operating:

lExcessive voltage is produced.

lNo voltage is produced.

Removal and InstallationEKS0031A

REMOVAL (QR ENGINE MODELS)

1. Disconnect battery ground cable.

2. Remove alternator drive belt. Refer toEM-13, "

Checking Drive Belts"in EM section.

SEL338V

Page 2887 of 3066

CHARGING SYSTEM

SC-15

C

D

E

F

G

H

I

J

L

MA

B

SC

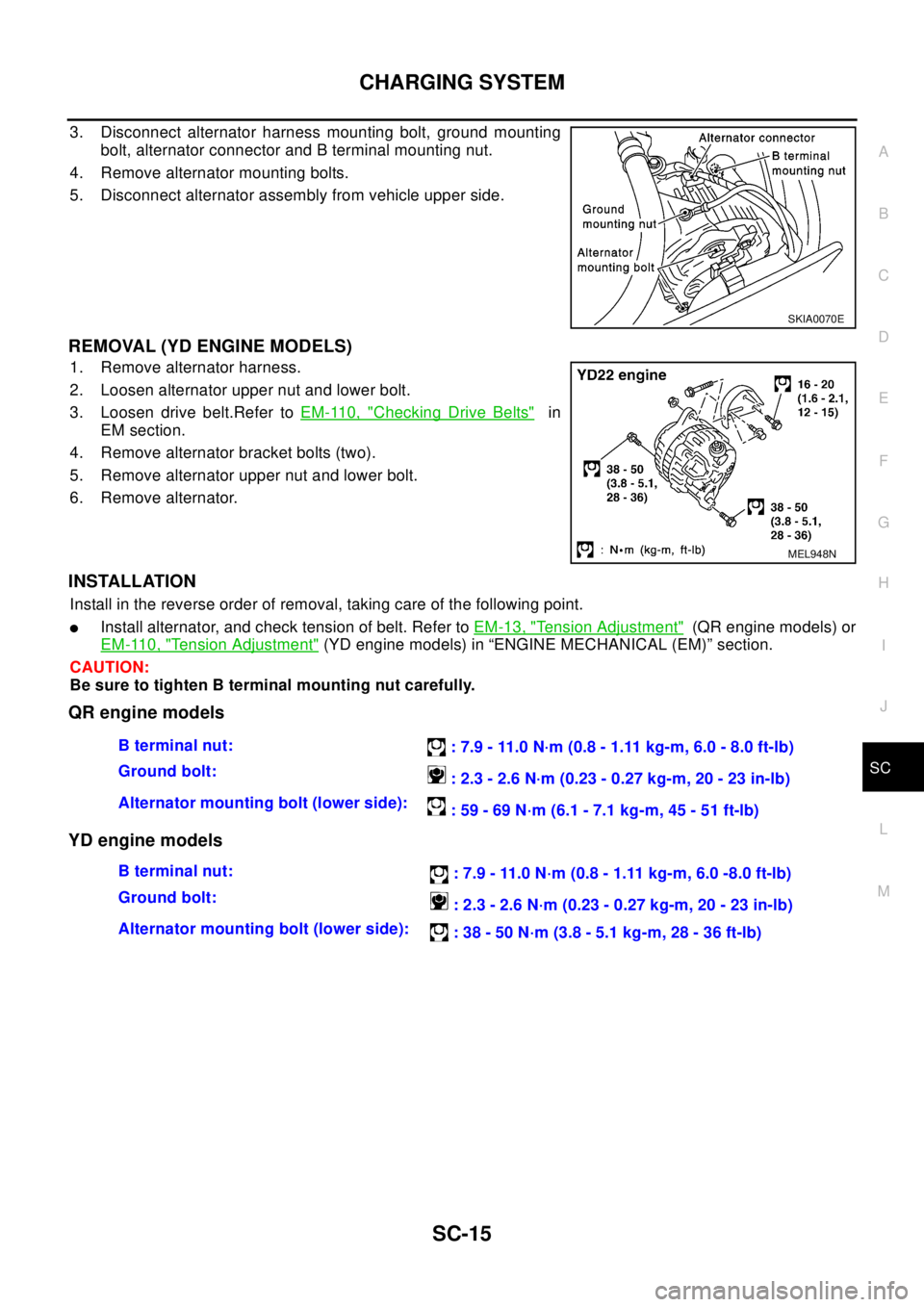

3. Disconnect alternator harness mounting bolt, ground mounting

bolt, alternator connector and B terminal mounting nut.

4. Remove alternator mounting bolts.

5. Disconnect alternator assembly from vehicle upper side.

REMOVAL (YD ENGINE MODELS)

1. Remove alternator harness.

2. Loosen alternator upper nut and lower bolt.

3. Loosen drive belt.Refer toEM-110, "

Checking Drive Belts"in

EM section.

4. Remove alternator bracket bolts (two).

5. Remove alternator upper nut and lower bolt.

6. Remove alternator.

INSTALLATION

Install in the reverse order of removal, taking care of the following point.

lInstall alternator, and check tension of belt. Refer toEM-13, "Tension Adjustment"(QR engine models) or

EM-110, "

Tension Adjustment"(YD engine models) in “ENGINE MECHANICAL (EM)” section.

CAUTION:

Be sure to tighten B terminal mounting nut carefully.

QR engine models

YD engine models

SKIA0070E

MEL948N

Bterminalnut:

: 7.9 - 11.0 N·m (0.8 - 1.11 kg-m, 6.0 - 8.0 ft-lb)

Ground bolt:

:2.3-2.6N·m(0.23-0.27kg-m,20-23in-lb)

Alternator mounting bolt (lower side):

: 59 - 69 N·m (6.1 - 7.1 kg-m, 45 - 51 ft-lb)

Bterminalnut:

: 7.9 - 11.0 N·m (0.8 - 1.11 kg-m, 6.0 -8.0 ft-lb)

Ground bolt:

: 2.3 - 2.6 N·m (0.23 - 0.27 kg-m, 20 - 23 in-lb)

Alternator mounting bolt (lower side):

: 38 - 50 N·m (3.8 - 5.1 kg-m, 28 - 36 ft-lb)

Page 2893 of 3066

STARTING SYSTEM

SC-21

C

D

E

F

G

H

I

J

L

MA

B

SC

STARTING SYSTEMPFP:00011

System DescriptionEKS0031F

M/T MODELS

Power is supplied at all times

lthrough 30A fusible link (letter J, located in the fuse and fusible link box)

lto ignition switch terminal 1.

With the ignition switch in the ON or START position, power is supplied

lfrom ignition switch terminal 5

lto starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the

engine starts.

A/T MODELS

Power is supplied at all times

lthrough 30A fusible link (letter J, located in the fuse and fusible link box)

lto ignition switch terminal 1.

With the ignition switch in the ON or START position, power is supplied

lthrough 10A fuse [No,13 located in the fuse block (J/B)]

lto park/neutral position relay terminal 1.

With the selector lever in the P or N position, ground is supplied

lto park/neutral position relay terminal 2

lthrough the park neutral position switch terminals 1 and 2,and

lthrough body grounds, F9 and F10.

Then park/neutral position relay is energized and power is supplied

lfrom park/neutral position relay terminal 3

lto starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the

engine starts.

Page 2897 of 3066

STARTING SYSTEM

SC-25

C

D

E

F

G

H

I

J

L

MA

B

SC

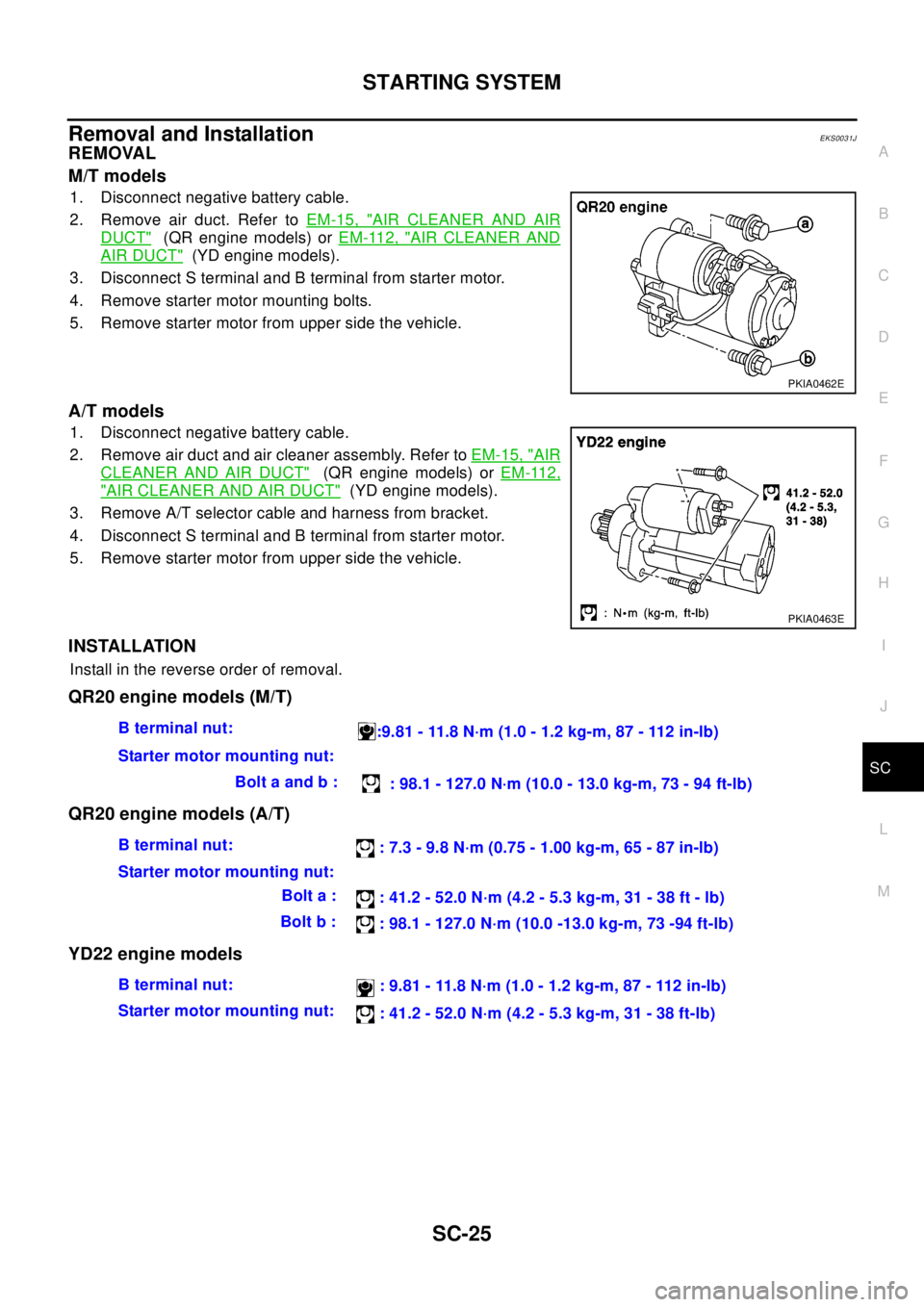

Removal and InstallationEKS0031J

REMOVAL

M/T models

1. Disconnect negative battery cable.

2. Remove air duct. Refer toEM-15, "

AIR CLEANER AND AIR

DUCT"(QR engine models) orEM-112, "AIR CLEANER AND

AIR DUCT"(YD engine models).

3. Disconnect S terminal and B terminal from starter motor.

4. Remove starter motor mounting bolts.

5. Remove starter motor from upper side the vehicle.

A/T models

1. Disconnect negative battery cable.

2. Remove air duct and air cleaner assembly. Refer toEM-15, "

AIR

CLEANER AND AIR DUCT"(QR engine models) orEM-112,

"AIR CLEANER AND AIR DUCT"(YD engine models).

3. Remove A/T selector cable and harness from bracket.

4. Disconnect S terminal and B terminal from starter motor.

5. Remove starter motor from upper side the vehicle.

INSTALLATION

Install in the reverse order of removal.

QR20 engine models (M/T)

QR20 engine models (A/T)

YD22 engine models

PKIA0462E

PKIA0463E

Bterminalnut:

:9.81 - 11.8 N·m (1.0 - 1.2 kg-m, 87 - 112 in-lb)

Starter motor mounting nut:

Bolt a and b :

: 98.1 - 127.0 N·m (10.0 - 13.0 kg-m, 73 - 94 ft-lb)

Bterminalnut:

: 7.3 - 9.8 N·m (0.75 - 1.00 kg-m, 65 - 87 in-lb)

Starter motor mounting nut:

Bolt a :

: 41.2 - 52.0 N·m (4.2 - 5.3 kg-m, 31 - 38 ft - lb)

Bolt b :

: 98.1 - 127.0 N·m (10.0 -13.0 kg-m, 73 -94 ft-lb)

Bterminalnut:

: 9.81 - 11.8 N·m (1.0 - 1.2 kg-m, 87 - 112 in-lb)

Starter motor mounting nut:

: 41.2 - 52.0 N·m (4.2 - 5.3 kg-m, 31 - 38 ft-lb)