engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2904 of 3066

SC-32

STARTING SYSTEM

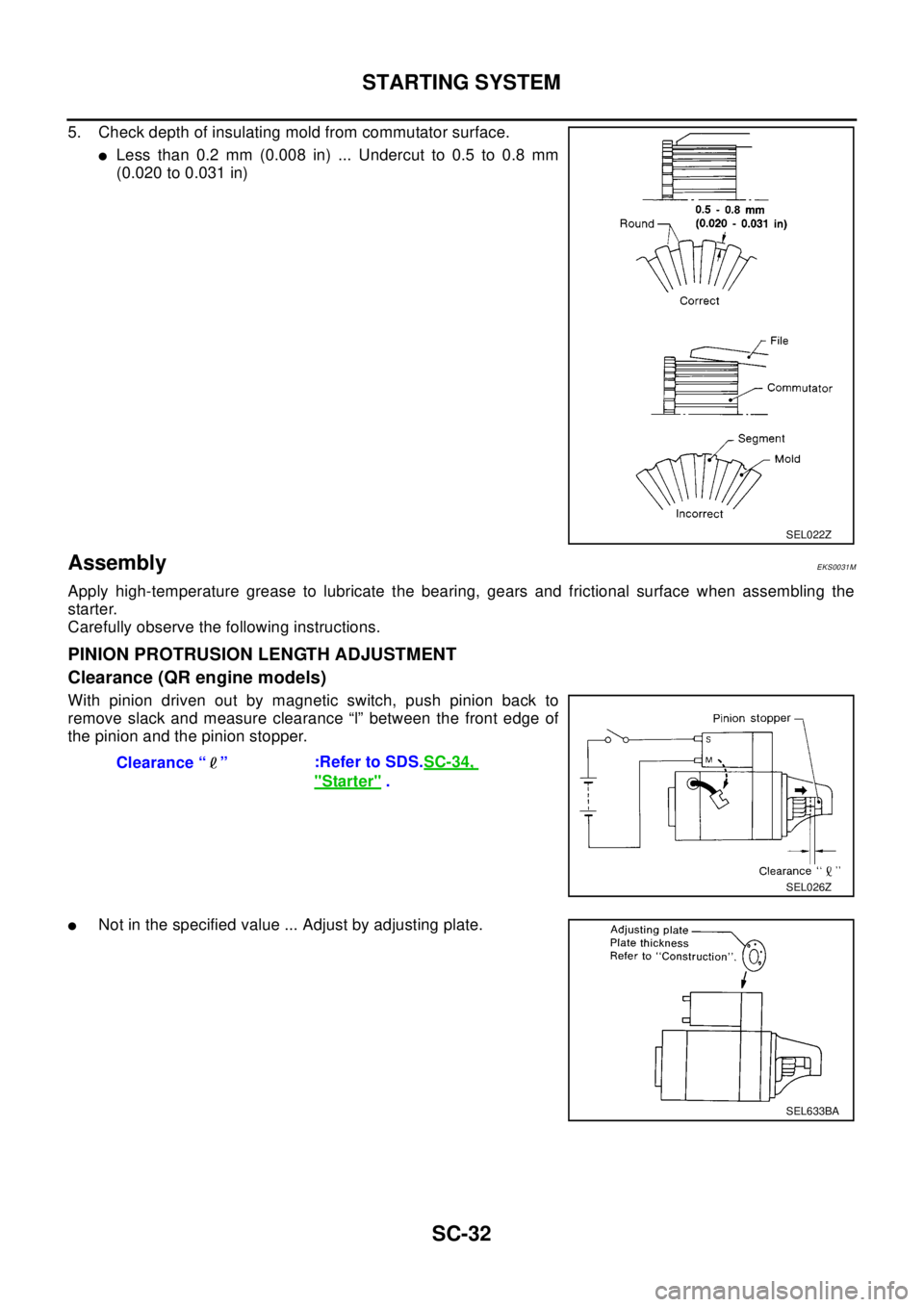

5. Check depth of insulating mold from commutator surface.

lLess than 0.2 mm (0.008 in) ... Undercut to 0.5 to 0.8 mm

(0.020 to 0.031 in)

AssemblyEKS0031M

Apply high-temperature grease to lubricate the bearing, gears and frictional surface when assembling the

starter.

Carefully observe the following instructions.

PINION PROTRUSION LENGTH ADJUSTMENT

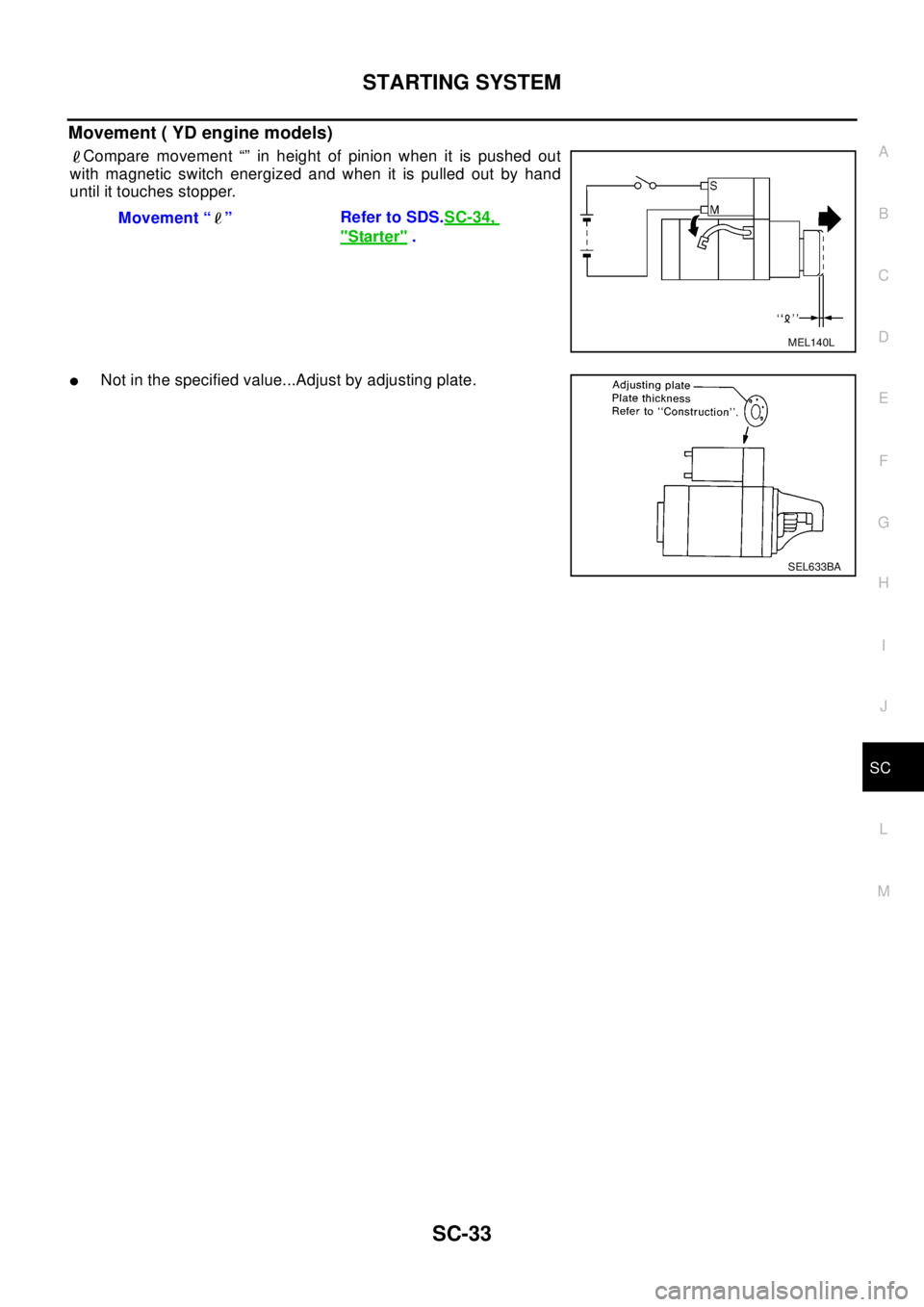

Clearance (QR engine models)

With pinion driven out by magnetic switch, push pinion back to

remove slack and measure clearance “l” between the front edge of

the pinion and the pinion stopper.

lNot in the specified value ... Adjust by adjusting plate.

SEL022Z

Clearance “ ”:Refer to SDS.SC-34,

"Starter".

SEL026Z

SEL633BA

Page 2905 of 3066

STARTING SYSTEM

SC-33

C

D

E

F

G

H

I

J

L

MA

B

SC

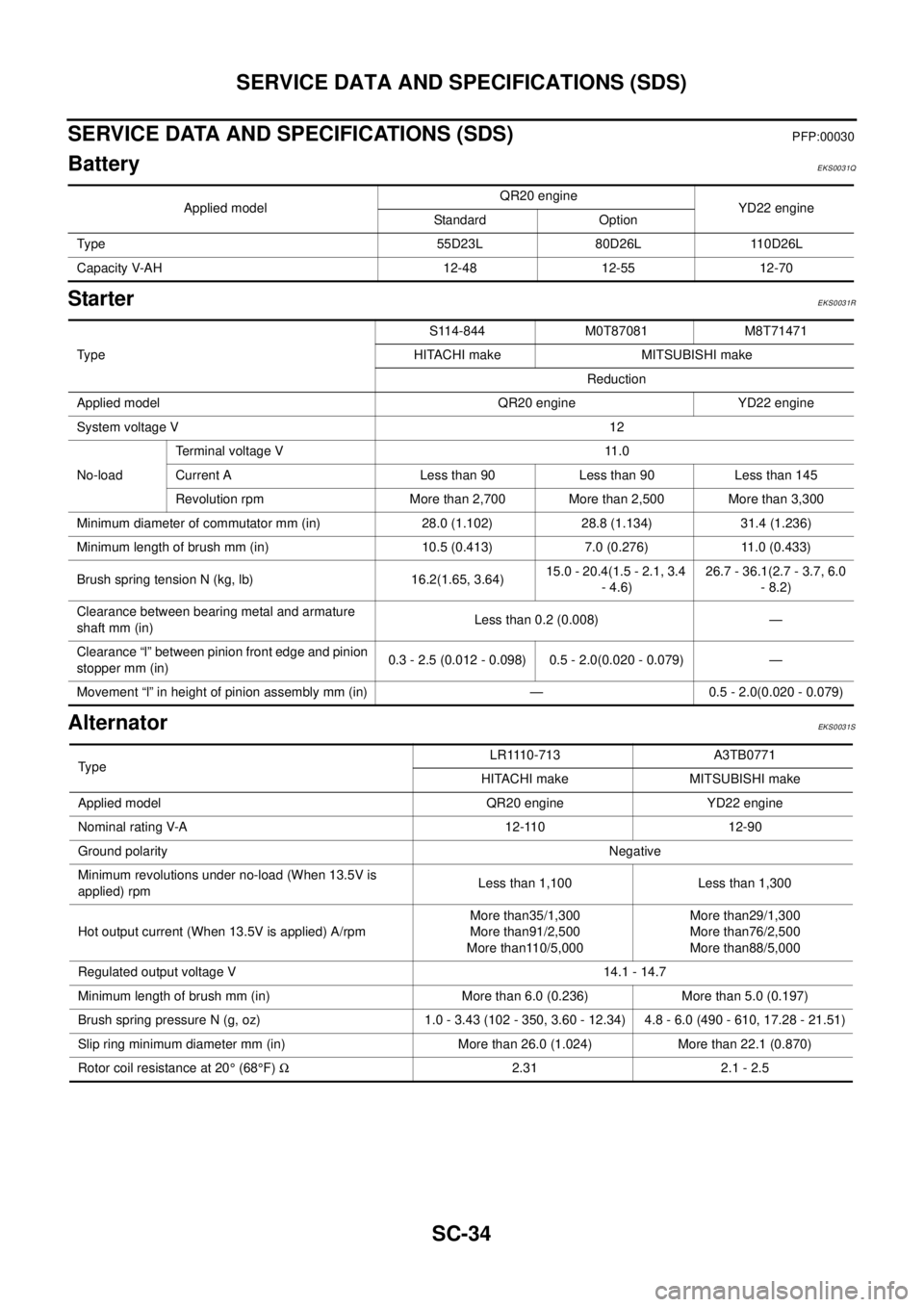

Movement ( YD engine models)

Compare movement “” in height of pinion when it is pushed out

with magnetic switch energized and when it is pulled out by hand

until it touches stopper.

lNot in the specified value...Adjust by adjusting plate.Movement “ ”Refer to SDS.SC-34,

"Starter".

MEL140L

SEL633BA

Page 2906 of 3066

SC-34

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

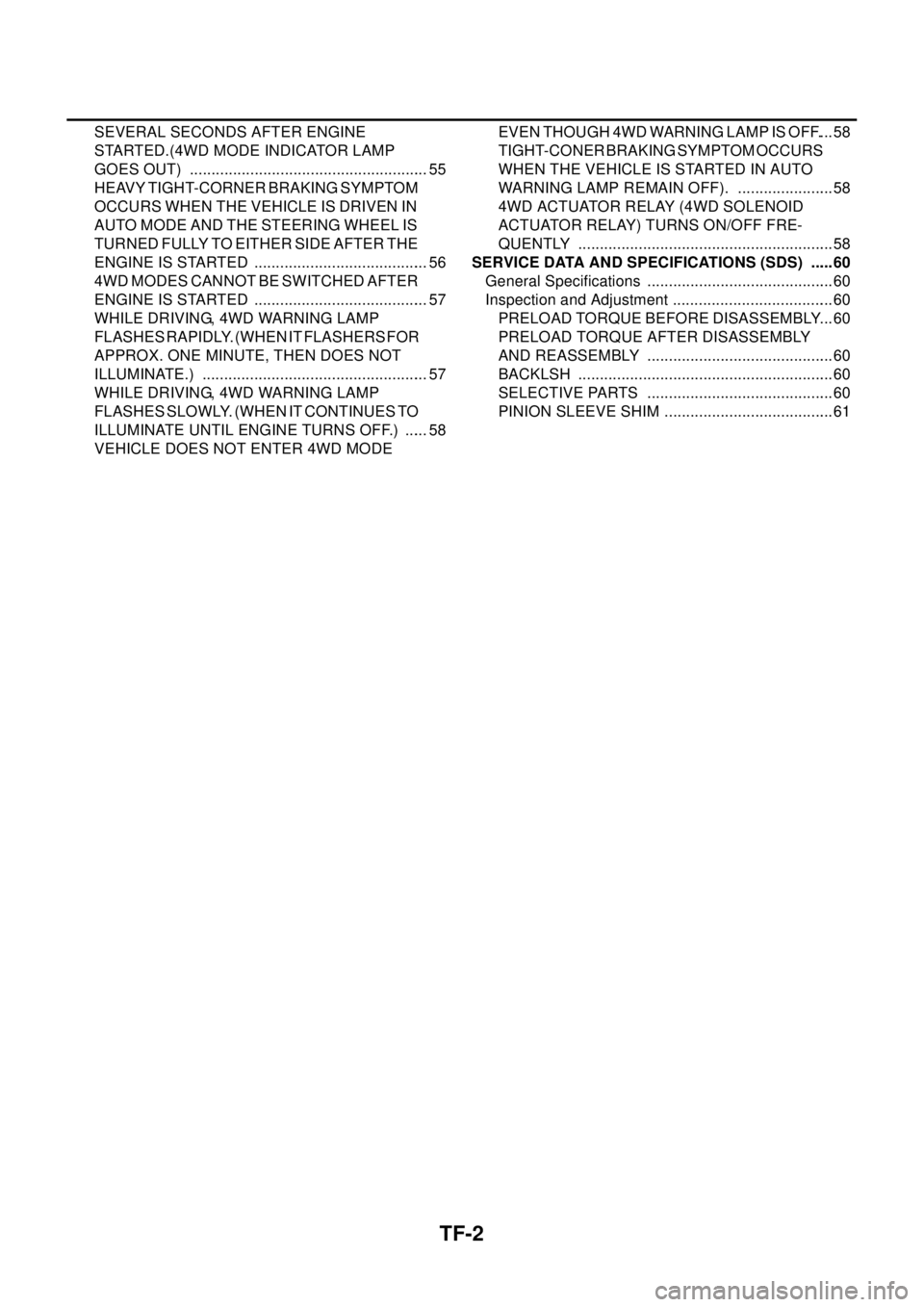

BatteryEKS0031Q

StarterEKS0031R

AlternatorEKS0031S

Applied modelQR20 engine

YD22 engine

Standard Option

Type 55D23L 80D26L 110D26L

Capacity V-AH 12-48 12-55 12-70

Ty p eS114-844 M0T87081 M8T71471

HITACHI make MITSUBISHI make

Reduction

Applied model QR20 engine YD22 engine

System voltage V12

No-loadTerminal voltage V 11.0

Current A Less than 90 Less than 90 Less than 145

Revolution rpm More than 2,700 More than 2,500 More than 3,300

Minimum diameter of commutator mm (in) 28.0 (1.102) 28.8 (1.134) 31.4 (1.236)

Minimum length of brush mm (in) 10.5 (0.413) 7.0 (0.276) 11.0 (0.433)

Brush spring tension N (kg, lb) 16.2(1.65, 3.64)15.0 - 20.4(1.5 - 2.1, 3.4

-4.6)26.7 - 36.1(2.7 - 3.7, 6.0

-8.2)

Clearance between bearing metal and armature

shaft mm (in)Less than 0.2 (0.008) —

Clearance “l” between pinion front edge and pinion

stopper mm (in)0.3 - 2.5 (0.012 - 0.098) 0.5 - 2.0(0.020 - 0.079) —

Movement “l” in height of pinion assembly mm (in) — 0.5 - 2.0(0.020 - 0.079)

Ty p eLR1110-713 A3TB0771

HITACHI make MITSUBISHI make

Applied model QR20 engine YD22 engine

Nominal rating V-A 12-110 12-90

Ground polarityNegative

Minimum revolutions under no-load (When 13.5V is

applied) rpmLess than 1,100 Less than 1,300

Hot output current (When 13.5V is applied) A/rpmMore than35/1,300

More than91/2,500

More than110/5,000More than29/1,300

More than76/2,500

More than88/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) More than 6.0 (0.236) More than 5.0 (0.197)

Brush spring pressure N (g, oz) 1.0 - 3.43 (102 - 350, 3.60 - 12.34) 4.8 - 6.0 (490 - 610, 17.28 - 21.51)

Slip ring minimum diameter mm (in) More than 26.0 (1.024) More than 22.1 (0.870)

Rotor coil resistance at 20°(68°F)W2.31 2.1 - 2.5

Page 2972 of 3066

TF-2

SEVERAL SECONDS AFTER ENGINE

STARTED.(4WD MODE INDICATOR LAMP

GOES OUT) ........................................................ 55

HEAVY TIGHT-CORNER BRAKING SYMPTOM

OCCURS WHEN THE VEHICLE IS DRIVEN IN

AUTO MODE AND THE STEERING WHEEL IS

TURNED FULLY TO EITHER SIDE AFTER THE

ENGINE IS STARTED ......................................... 56

4WD MODES CANNOT BE SWITCHED AFTER

ENGINE IS STARTED ......................................... 57

WHILE DRIVING, 4WD WARNING LAMP

FLASHES RAPIDLY.(WHEN IT FLASHERSFOR

APPROX. ONE MINUTE, THEN DOES NOT

ILLUMINATE.) ..................................................... 57

WHILE DRIVING, 4WD WARNING LAMP

FLASHES SLOWLY. (WHEN IT CONTINUES TO

ILLUMINATE UNTIL ENGINE TURNS OFF.) ...... 58

VEHICLE DOES NOT ENTER 4WD MODEEVEN THOUGH 4WD WARNING LAMP IS OFF.... 58

TIGHT-CONER BRAKING SYMPTOM OCCURS

WHEN THE VEHICLE IS STARTED IN AUTO

WARNING LAMP REMAIN OFF). .......................58

4WD ACTUATOR RELAY (4WD SOLENOID

ACTUATOR RELAY) TURNS ON/OFF FRE-

QUENTLY ............................................................58

SERVICE DATA AND SPECIFICATIONS (SDS) ......60

General Specifications ............................................60

Inspection and Adjustment ......................................60

PRELOAD TORQUE BEFORE DISASSEMBLY...60

PRELOAD TORQUE AFTER DISASSEMBLY

AND REASSEMBLY ............................................60

BACKLSH ............................................................60

SELECTIVE PARTS ............................................60

PINION SLEEVE SHIM ........................................61

Page 2978 of 3066

TF-8

TRANSFER FLUID

TRANSFER FLUID

PFP:KLD30

ReplacementEDS0004Q

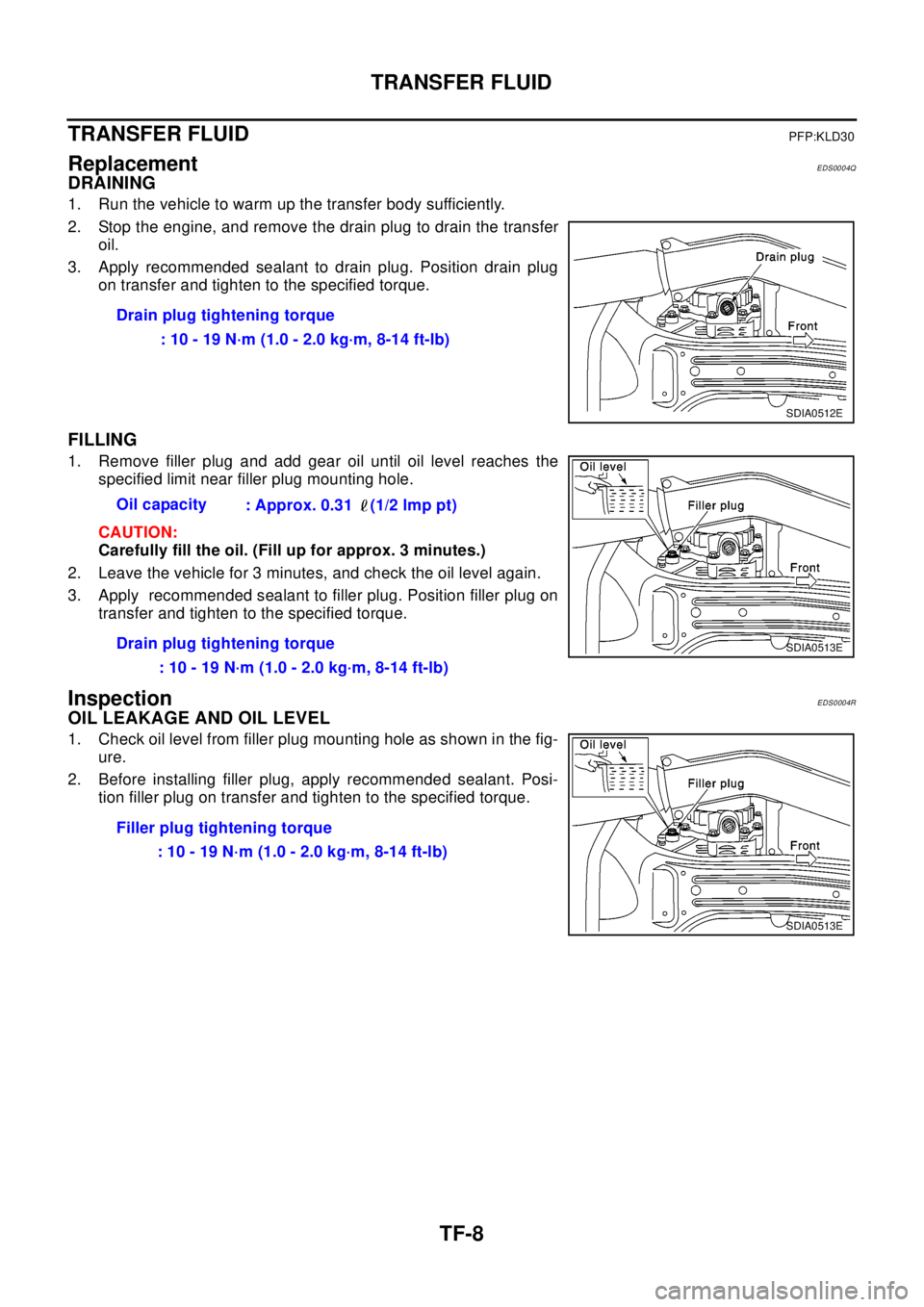

DRAINING

1. Run the vehicle to warm up the transfer body sufficiently.

2. Stop the engine, and remove the drain plug to drain the transfer

oil.

3. Apply recommended sealant to drain plug. Position drain plug

on transfer and tighten to the specified torque.

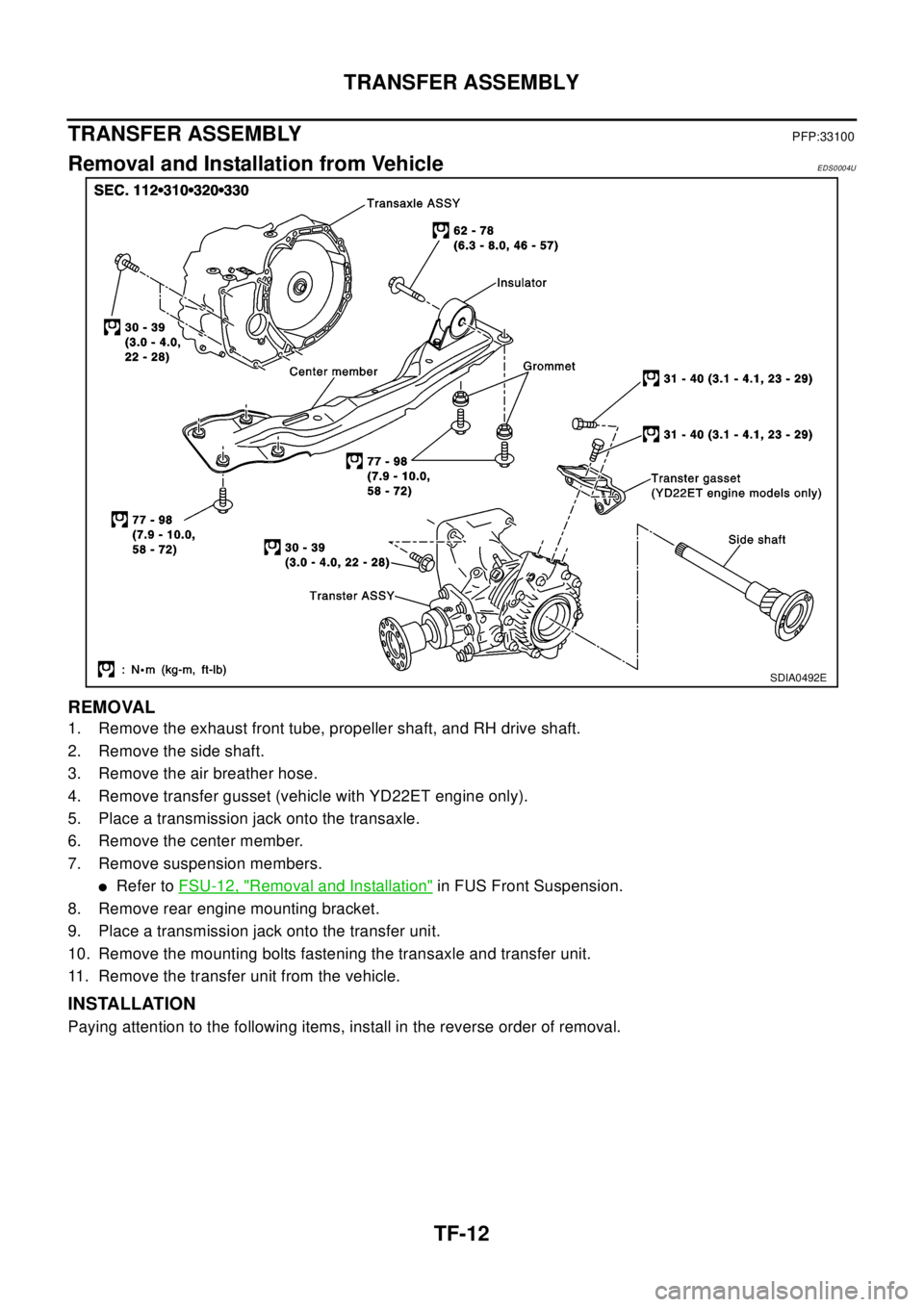

FILLING

1. Remove filler plug and add gear oil until oil level reaches the

specified limit near filler plug mounting hole.

CAUTION:

Carefully fill the oil. (Fill up for approx. 3 minutes.)

2. Leave the vehicle for 3 minutes, and check the oil level again.

3. Apply recommended sealant to filler plug. Position filler plug on

transfer and tighten to the specified torque.

InspectionEDS0004R

OIL LEAKAGE AND OIL LEVEL

1. Check oil level from filler plug mounting hole as shown in the fig-

ure.

2. Before installing filler plug, apply recommended sealant. Posi-

tion filler plug on transfer and tighten to the specified torque.Drain plug tightening torque

: 10 - 19 N·m (1.0 - 2.0 kg·m, 8-14 ft-lb)

SDIA0512E

Oil capacity

: Approx. 0.31 (1/2 lmp pt)

Drain plug tightening torque

: 10 - 19 N·m (1.0 - 2.0 kg·m, 8-14 ft-lb)

SDIA0513E

Filler plug tightening torque

:10-19N·m(1.0-2.0kg·m,8-14ft-lb)

SDIA0513E

Page 2982 of 3066

TF-12

TRANSFER ASSEMBLY

TRANSFER ASSEMBLY

PFP:33100

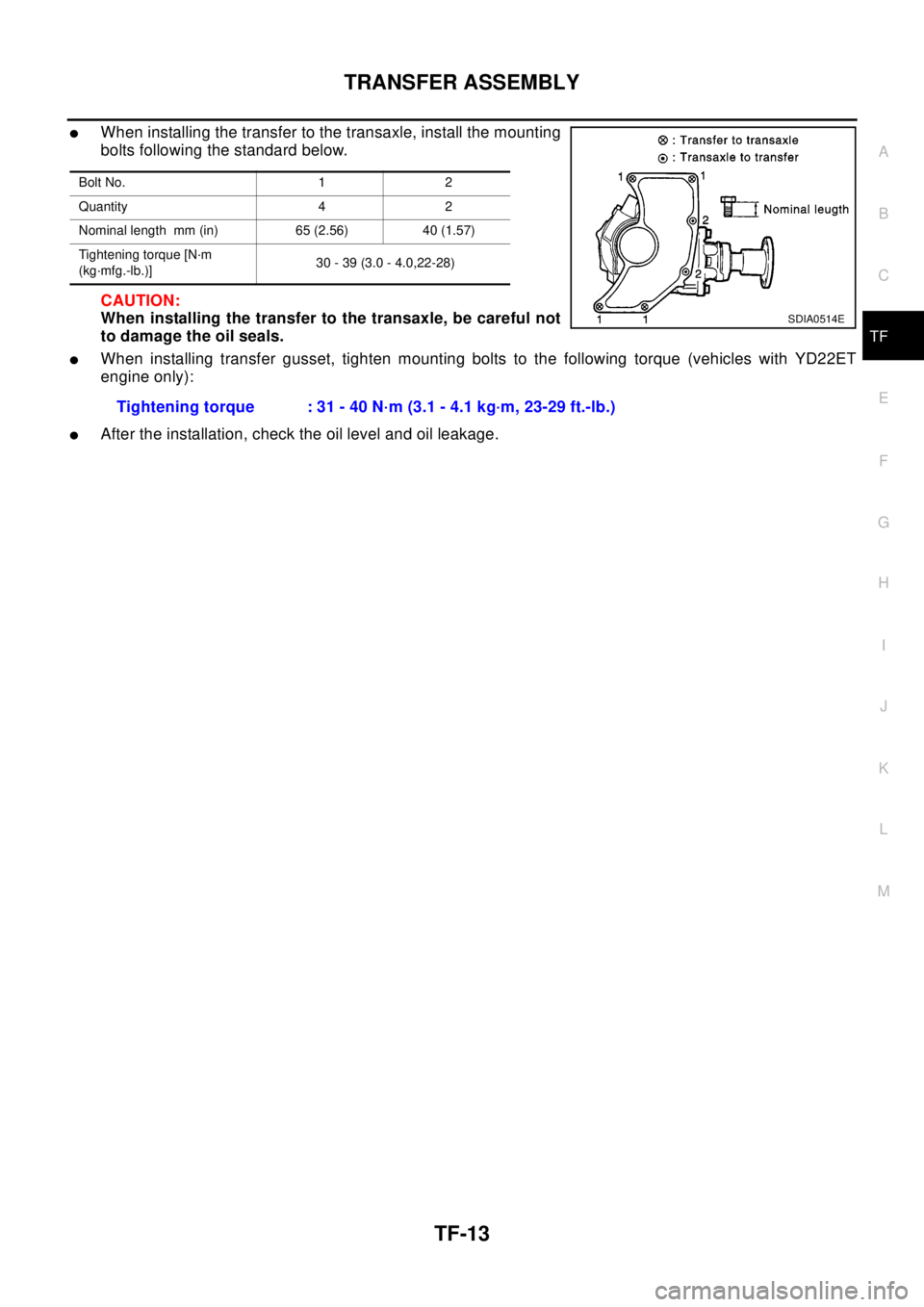

Removal and Installation from VehicleEDS0004U

REMOVAL

1. Remove the exhaust front tube, propeller shaft, and RH drive shaft.

2. Remove the side shaft.

3. Remove the air breather hose.

4. Remove transfer gusset (vehicle with YD22ET engine only).

5. Place a transmission jack onto the transaxle.

6. Remove the center member.

7. Remove suspension members.

lRefer toFSU-12, "Removal and Installation"in FUS Front Suspension.

8. Remove rear engine mounting bracket.

9. Place a transmission jack onto the transfer unit.

10. Remove the mounting bolts fastening the transaxle and transfer unit.

11. Remove the transfer unit from the vehicle.

INSTALLATION

Paying attention to the following items, install in the reverse order of removal.

SDIA0492E

Page 2983 of 3066

TRANSFER ASSEMBLY

TF-13

C

E

F

G

H

I

J

K

L

MA

B

TF

lWhen installing the transfer to the transaxle, install the mounting

bolts following the standard below.

CAUTION:

When installing the transfer to the transaxle, be careful not

to damage the oil seals.

lWhen installing transfer gusset, tighten mounting bolts to the following torque (vehicles with YD22ET

engine only):

lAfter the installation, check the oil level and oil leakage.

Bolt No. 1 2

Quantity 4 2

Nominal length mm (in) 65 (2.56) 40 (1.57)

Tightening torque [N·m

(kg·mfg.-lb.)]30 - 39 (3.0 - 4.0,22-28)

SDIA0514E

Tightening torque : 31 - 40 N·m (3.1 - 4.1 kg·m, 23-29 ft.-lb.)

Page 3002 of 3066

TF-32

ALL MODE 4X4 SYSTEM

4WD MODE SWITCT

AUTO mode (AUTO indicator lamp ON)

lElectronic control allows optimal distribution of torque to front/rear wheels to match road conditions.

lMakes possible stable driving, with no wheel spin, on snowy roads or other slippery surfaces.

lOn roads which do not require 4WD, it contributes to improved fuel economy by driving in conditions close

to front-wheel drive.

lSensors determine the vehicle's turning condition, and in response tight cornering/braking are controlled

by distributing optimum torque to rear wheels.

NOTE:

lWhen driving in AUTO mode or LOCK mode, if there is a large difference between front and rear wheel

speed which continues for a long time, oil temperature of drive system parts becomes too high and 4WD

warning lamp flashes rapidly. (When 4WD warning lamp flashes, vehicle changes to front-wheel drive

conditions.)

lWhen driving in AUTO mode, 4WD warning lamp may flash slowly if there is a significant difference in

pressure or wear between tires. At this time, vehicle performance is not fully available and cautious driving

is required. (Continues until engine is turned OFF.)

lIf 4WD warning lamp is flashing rapidly, stop vehicle and allow it to idle for some time. Flashing will stop

and AUTO mode will be restored.

lIf the warning lamp flashes slowly during driving but remains OFF after engine is restarted, the system is

normal. If it again flashes slowly after driving for some time, vehicle must be inspected.

lWhen the difference of revolution speed between the front and rear wheel with AUTO mode the shift

switch occasionally changes to LOCK mode automatically. This is not malfunction.

LOCK mode (LOCK indicator lamp and AUTO indicator lamp ON)

lFront/rear wheel torque distribution is fixed, ensuring stable driving when climbing slopes.

lWhen LOCK mode is selected, vehicle will switch automatically to AUTO mode if vehicle speed increases.

If vehicle speed then decreases, the vehicle automatically returns to direct 4-wheel driving conditions.

NOTE:

If there is a significant difference in pressure or wear between tires, full vehicle performance is not available.

Tire conditions are detected, and LOCK mode may be prohibited, or else speeds at which LOCK mode is

enabled may be restricted.

2WD mode (indicator lamps OFF)

Vehicle is in front-wheel drive.

NOTE:

lIf front wheels are slipping in 2WD mode, do not switch to AUTO or LOCK. This can cause difficulties for

the system.

lThe shift switch even if the shift switch is in 2WD mode, the sift switch occasionally automatically change

to 4WD mode depending on the driving condition (For example; Depressing the acceleration firmly). this is

not malfunction. How ever, 4WD mode indicator lamp dose not illuminate.

4WD WARNING LAMP

Turns ON when there is a malfunction in 4WD system. It indicates that fail-safe mode is engaged and vehicle

is in 2WD.

Also turns ON when ignition switch is turned ON, for purpose of bulb check. Turns OFF approximately for 3

seconds after the engine starts if system is normal.

4WD waning lamp indiction

Condition Display 4WD warning lamp

Self-diagnosisWhen self-diagnosis is performed, indicates location of

malfunction by number of flashes.-

Lamp checkTurns ON when engine is started to check for burned-out

lamps.Turns ON when ignition switch

is turned ON. Turns OFF

approximately 3 seconds after

engine start.

4WD system malfunction Turns ON if there is malfunction in 4WD system. ON

Page 3004 of 3066

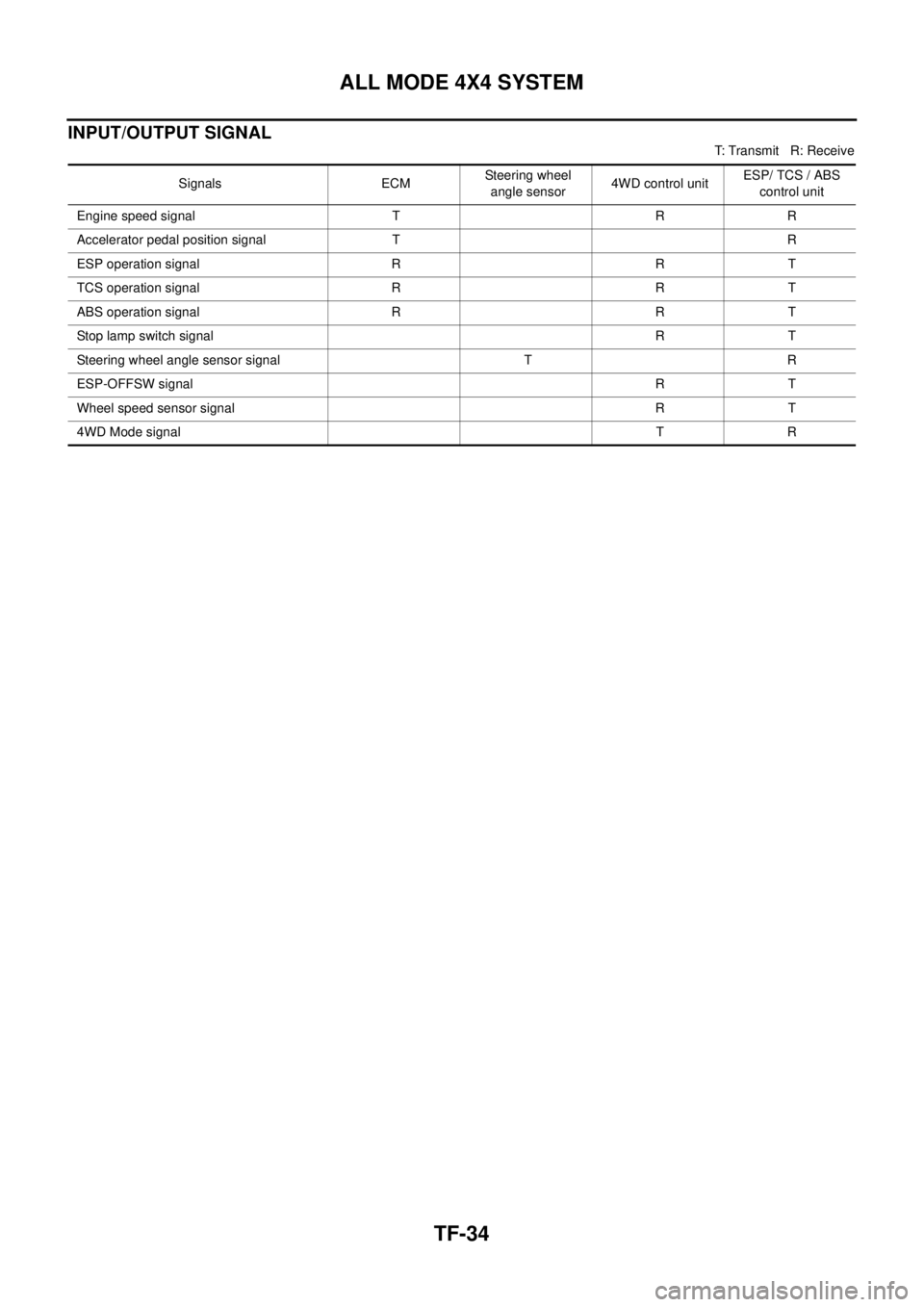

TF-34

ALL MODE 4X4 SYSTEM

INPUT/OUTPUT SIGNAL

T: Transmit R: Receive

Signals ECMSteering wheel

angle sensor4WD control unitESP/ TCS / ABS

control unit

Engine speed signal T R R

Accelerator pedal position signal T R

ESP operation signal R R T

TCS operation signal R R T

ABS operation signal R R T

Stop lamp switch signalRT

Steering wheel angle sensor signal T R

ESP-OFFSW signalRT

Wheel speed sensor signalRT

4WD Mode signalTR

Page 3011 of 3066

TROUBLE DIAGNOSIS

TF-41

C

E

F

G

H

I

J

K

L

MA

B

TF

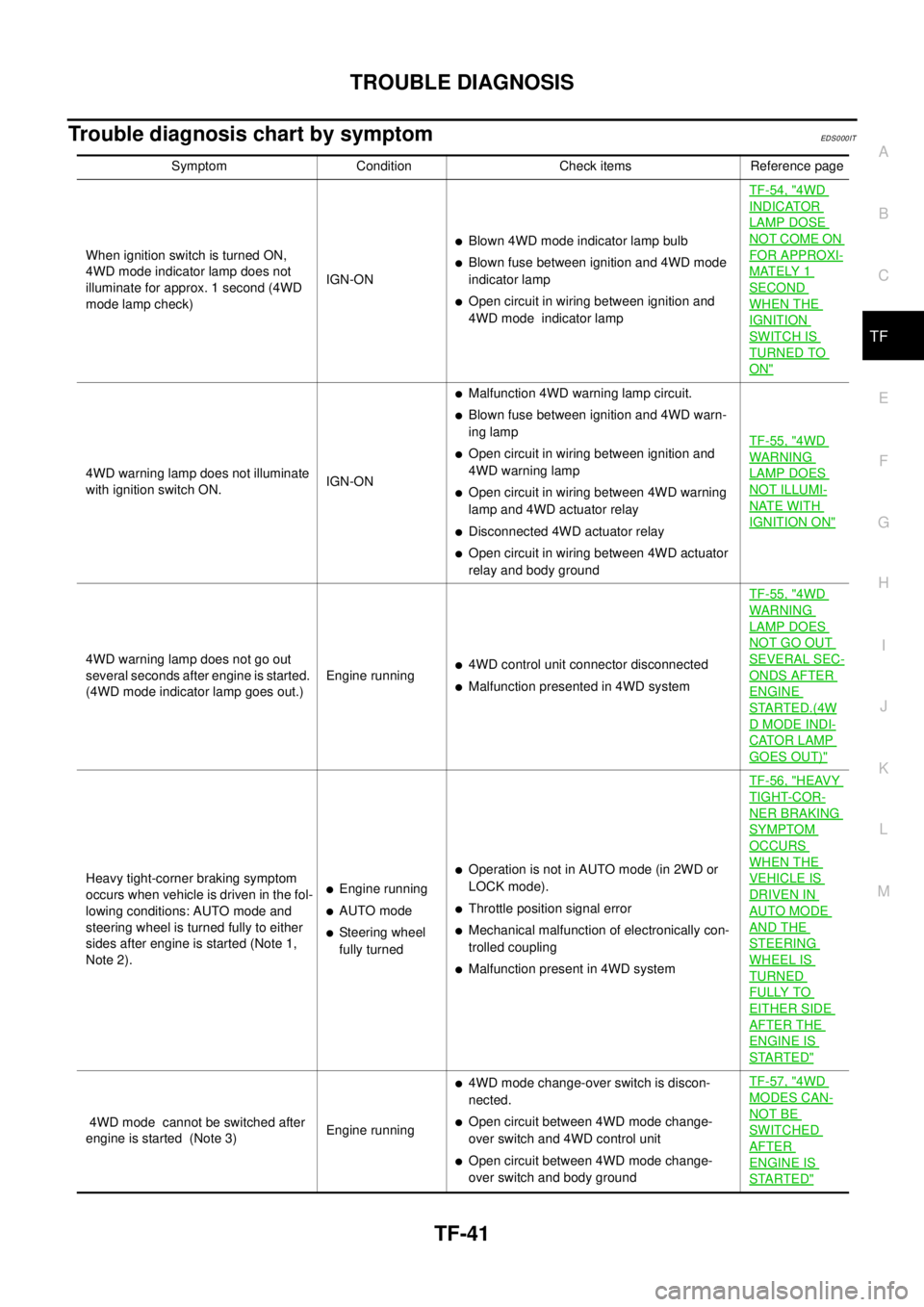

Trouble diagnosis chart by symptomEDS0 00 IT

Symptom Condition Check items Reference page

When ignition switch is turned ON,

4WD mode indicator lamp does not

illuminate for approx. 1 second (4WD

mode lamp check)IGN-ON

lBlown 4WD mode indicator lamp bulb

lBlown fuse between ignition and 4WD mode

indicator lamp

lOpen circuit in wiring between ignition and

4WD mode indicator lampTF-54, "

4WD

INDICATOR

LAMP DOSE

NOT COME ON

FOR APPROXI-

MATELY 1

SECOND

WHEN THE

IGNITION

SWITCH IS

TURNED TO

ON"

4WD warning lamp does not illuminate

with ignition switch ON.IGN-ON

lMalfunction 4WD warning lamp circuit.

lBlown fuse between ignition and 4WD warn-

ing lamp

lOpen circuit in wiring between ignition and

4WD warning lamp

lOpen circuit in wiring between 4WD warning

lamp and 4WD actuator relay

lDisconnected 4WD actuator relay

lOpen circuit in wiring between 4WD actuator

relay and body groundTF-55, "

4WD

WAR NIN G

LAMP DOES

NOT ILLUMI-

NATE WITH

IGNITION ON"

4WD warning lamp does not go out

several seconds after engine is started.

(4WD mode indicator lamp goes out.)Engine runningl4WD control unit connector disconnected

lMalfunction presented in 4WD systemTF-55, "

4WD

WAR NIN G

LAMP DOES

NOT GO OUT

SEVERAL SEC-

ONDS AFTER

ENGINE

STARTED.(4W

DMODEINDI-

CATOR LAMP

GOES OUT)"

Heavy tight-corner braking symptom

occurs when vehicle is driven in the fol-

lowing conditions: AUTO mode and

steering wheel is turned fully to either

sides after engine is started (Note 1,

Note 2).lEngine running

lAUTO mode

lSteering wheel

fully turned

lOperation is not in AUTO mode (in 2WD or

LOCK mode).

lThrottle position signal error

lMechanical malfunction of electronically con-

trolled coupling

lMalfunction present in 4WD systemTF-56, "

HEAVY

TIGHT-COR-

NER BRAKING

SYMPTOM

OCCURS

WHEN THE

VEHICLE IS

DRIVEN IN

AUTO MODE

AND THE

STEERING

WHEEL IS

TURNED

FULLY TO

EITHER SIDE

AFTER THE

ENGINE IS

STARTED"

4WD mode cannot be switched after

engine is started (Note 3)Engine running

l4WD mode change-over switch is discon-

nected.

lOpen circuit between 4WD mode change-

over switch and 4WD control unit

lOpen circuit between 4WD mode change-

over switch and body groundTF-57, "

4WD

MODES CAN-

NOT BE

SWITCHED

AFTER

ENGINE IS

STARTED"