fuel filter NISSAN X-TRAIL 2003 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1747 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide FUEL PUMP CIRCUIT

EC-633

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

FUEL PUMP

1. Disconnect fuel level sensor unit and fuel pump harness connector.

2. Check resistance between fuel level sensor NISSAN X-TRAIL 2003 Electronic User Guide FUEL PUMP CIRCUIT

EC-633

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

FUEL PUMP

1. Disconnect fuel level sensor unit and fuel pump harness connector.

2. Check resistance between fuel level sensor](/img/5/57402/w960_57402-1746.png)

FUEL PUMP CIRCUIT

EC-633

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

FUEL PUMP

1. Disconnect fuel level sensor unit and fuel pump harness connector.

2. Check resistance between fuel level sensor unit and fuel pump

terminals 3 and 5.

CONDENSER

1. Turn ignition switch "OFF".

2. Disconnect condenser harness connector.

3. Check resistance between condenser terminals as 1 and 2.

Removal and InstallationEBS00BA2

FUEL PUMP

Refer toFL-4, "FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY". Resistance: Approximately 1.0W[at 25°C(77°F)]

PBIB0658E

Resistance: Above 1 MWat 25°C(77°F)

SEF124Y

Page 1778 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide EC-664

[YD]

BASIC SERVICE PROCEDURE

BASIC SERVICE PROCEDURE

PFP:00018

Fuel FilterEBS0036N

DESCRIPTION

A water draining cock is on the lower side and a priming pump for bleeding air is on the upper sid NISSAN X-TRAIL 2003 Electronic User Guide EC-664

[YD]

BASIC SERVICE PROCEDURE

BASIC SERVICE PROCEDURE

PFP:00018

Fuel FilterEBS0036N

DESCRIPTION

A water draining cock is on the lower side and a priming pump for bleeding air is on the upper sid](/img/5/57402/w960_57402-1777.png)

EC-664

[YD]

BASIC SERVICE PROCEDURE

BASIC SERVICE PROCEDURE

PFP:00018

Fuel FilterEBS0036N

DESCRIPTION

A water draining cock is on the lower side and a priming pump for bleeding air is on the upper side.

AIR BLEEDING

Pump the priming pump to bleed air.

lWhen air is bled completely, the pumping of the priming pump

suddenly becomes heavy. Stop the operation at that time.

lIf it is difficult to bleed air by the pumping of the priming pump

(the pumping of the priming pump does not become heavy), dis-

connect the fuel supply hose between the fuel filter and the fuel

gallery. Then, perform the operation described above, and make

sure that fuel comes out. (Use a pan, etc. so as not to spill fuel.

Do not let fuel get on engine and other parts.) After that, connect

the hose, then bleed air again.

lStart engine and let it idle for at least one minute after perform-

ing air bleeding.

WATER DRAINING

1. Remove the fuel filter, filter bracket, protector assembly from the dash panel as follows.

a. Remove the air cleaner case (upper), air duct assembly, and vacuum hose for brake booster (between the

vacuum pump and vacuum pipe).

CAUTION:

After the duct is removed, cover the opening with gum tape, etc. to prevent foreign object from

getting into the engine during the operation.

b. Remove the mounting nuts on the dash panel, then remove the fuel filter, filter bracket, and protector

assembly from the dash panel.

lIt is not necessary to disconnect the fuel hose.

2. Using a tool such as a pliers, loosen the water draining cock at the bottom of the fuel filter.

Accelerator Pedal Released Position LearningEBS009NW

DESCRIPTION

"Accelerator Pedal Released Position Learning" is an operating to learn the fully released position of the

accelerator pedal by monitoring the accelerator pedal position sensor output signal. It must be performed

when accelerator work unit or ECM is replaced.

OPERATION PROCEDURE

1. Turn ignition switch "ON".

2. Select "OFF ACCEL PO SIG" in "ACTIVE TEST" mode with

CONSULT-II

3. Make sure that accelerator pedal is released.

SEF375Y

PBIB0411E

Page 1787 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide TROUBLE DIAGNOSIS

EC-673

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem.

2. Check the current need for scheduled NISSAN X-TRAIL 2003 Electronic User Guide TROUBLE DIAGNOSIS

EC-673

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem.

2. Check the current need for scheduled](/img/5/57402/w960_57402-1786.png)

TROUBLE DIAGNOSIS

EC-673

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem.

2. Check the current need for scheduled maintenance, especially for fuel filter and air cleaner filter. Refer to

MA-7, "

PERIODIC MAINTENANCE".

3. Open engine hood and check the following:

–Harness connectors for improper connections

–Vacuum hoses for splits, kinks, or improper connections

–Wiring for improper connections, pinches, or cuts

4. Start engine and warm it up to the normal operating tempera-

ture.

>> GO TO 2.

2.PREPARATION FOR CHECKING IDLE SPEED

With CONSULT-II

Connect CONSULT-II to the data link connector.

>> GO TO 3.

3.CHECK IDLE SPEED

With CONSULT-II

1. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

2. Read idle speed.

OK or NG

OK >>INSPECTION END

NG >> GO TO 4.

4.CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace.

SEF142I

725±25 rpm

SEF817Y

Page 1788 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide EC-674

[YD]

TROUBLE DIAGNOSIS

5.BLEED AIR FROM FUEL SYSTEM

1. Stop engine.

2. Use priming pump to bleed air from fuel system. Refer toEC-664, "

AIR BLEEDING".

>> GO TO 6.

6.CHECK IDLE SPEED AGAIN

With NISSAN X-TRAIL 2003 Electronic User Guide EC-674

[YD]

TROUBLE DIAGNOSIS

5.BLEED AIR FROM FUEL SYSTEM

1. Stop engine.

2. Use priming pump to bleed air from fuel system. Refer toEC-664, "

AIR BLEEDING".

>> GO TO 6.

6.CHECK IDLE SPEED AGAIN

With](/img/5/57402/w960_57402-1787.png)

EC-674

[YD]

TROUBLE DIAGNOSIS

5.BLEED AIR FROM FUEL SYSTEM

1. Stop engine.

2. Use priming pump to bleed air from fuel system. Refer toEC-664, "

AIR BLEEDING".

>> GO TO 6.

6.CHECK IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and let it idle.

2. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

3. Read idle speed.

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

7.DRAIN WATER FROM FUEL FILTER

Drain water from fuel filter. Refer toEC-664, "

WATER DRAINING".

>> GO TO 8.

8.CHECK IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and let it idle.

2. Select “CKPS·RPM (TDC)” in “DATA MONITOR” mode with CONSULT-II.

3. Read idle speed.

OK or NG

OK >>INSPECTION END

NG >> GO TO 9.

9.CHECK AIR CLEANER FILTER

Check air cleaner filter for clogging or breaks.

OK or NG

OK >> GO TO 10.

NG >> Replace air cleaner filter.725±25 rpm

SEF817Y

725±25 rpm

SEF817Y

Page 2135 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide PRIMARY TIMING CHAIN

EM-165

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

REMOVAL

1. Remove coolant reservior tank.

2. Remove charge air cooler. Refer toEM-114, "

Removal and Installation".

3. Remove oil clean NISSAN X-TRAIL 2003 Electronic User Guide PRIMARY TIMING CHAIN

EM-165

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

REMOVAL

1. Remove coolant reservior tank.

2. Remove charge air cooler. Refer toEM-114, "

Removal and Installation".

3. Remove oil clean](/img/5/57402/w960_57402-2134.png)

PRIMARY TIMING CHAIN

EM-165

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

REMOVAL

1. Remove coolant reservior tank.

2. Remove charge air cooler. Refer toEM-114, "

Removal and Installation".

3. Remove oil cleaner and air duct. Refer toEM-112, "

Removal and Installation".

4. Remove rocker cover. Refer toEM-147, "

Removal and Installation".

5. Remove RH engine mount insulator and bracket. Refer toEM-184, "

Removal and Installation".

6. Pull power steering reservoir tank out of brackets to move power steering piping.

CAUTION:

To avoid removing power steering reservoir tank out of brackets move it with power steering pip-

ing aside.

7. Remove oil pan. Refer toEM-125, "

Removal and Installation".

8. Remove oil filter bracket. Refer toLU-22, "

Removal and Installation".

9. Remove injection tube and fuel injector. Refer toEM-135, "

Removal and Installation".

10. Remove secondary timing chain and associated parts. Refer toEM-158, "

Removal and Installation".

11. When removing rear chain case, remove camshaft sprockets. Refer toEM-149, "

Removal and Installa-

tion".

12. Remove crankshaft pulley.

a. Hold crankshaft pulley with the pulley holder (SST).

b. Loosen crankshaft pulley fixing bolt and pull out the bolt approx-

imately 10 mm (0.39 in).

c. Using pulley puller (SST), remove crankshaft pulley.

lUse two M6 bolts with approx. 60 mm (2.36 in) shank length

for securing crankshaft pulley.

7. Chain guide 8. Spacer 9. Front chain case

10. Crankshaft pully 11. Front oil seal 12. Oil pump

13. Primary timing chain 14. Oil pump drive sprocket 15. Crankshaft sprocket

16. Secondary timing chain 17. Rear chain case 18. Power steering pump

JEM131G

JEM132G

Page 2216 of 3066

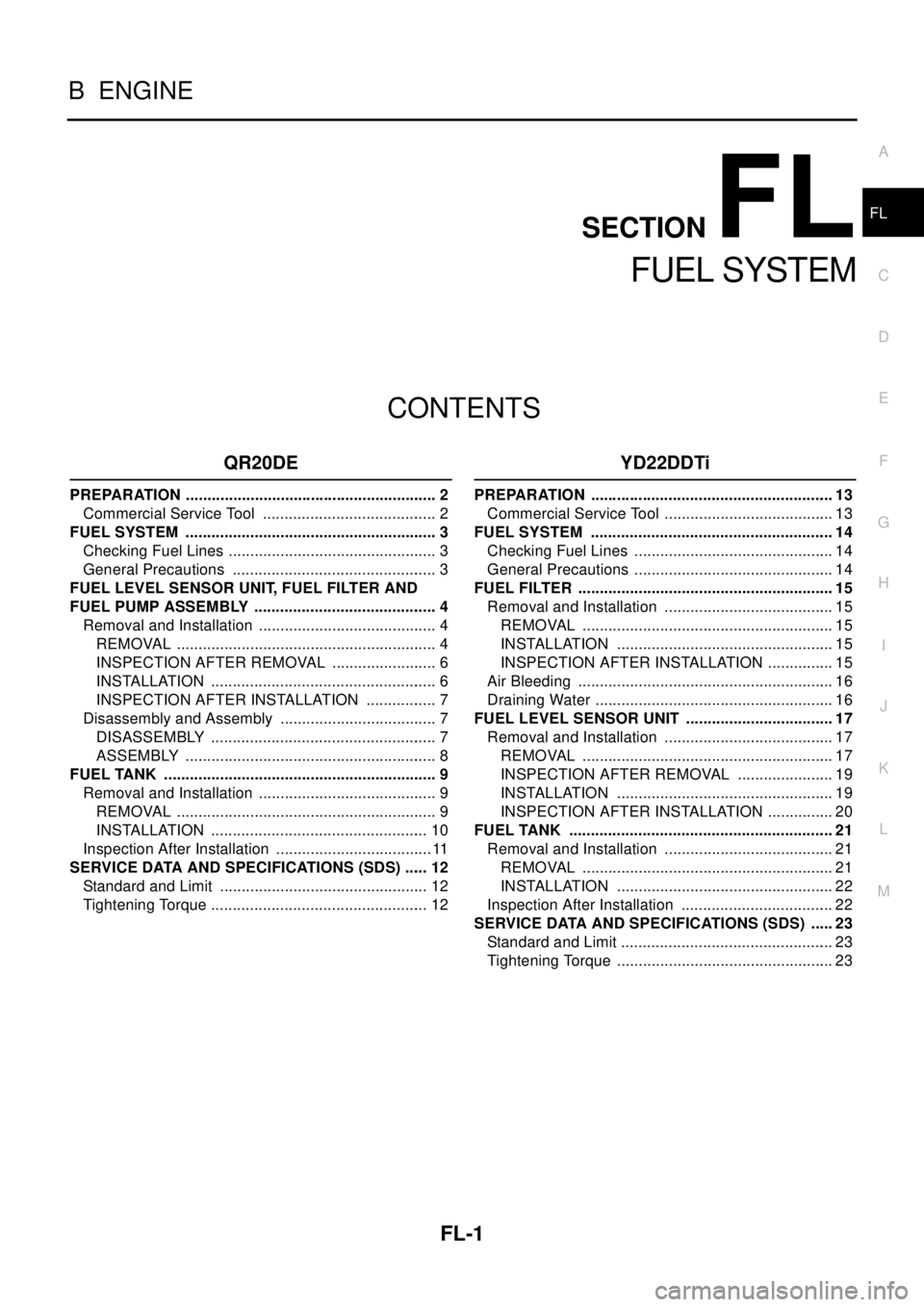

FL-1

FUEL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

FL

FUEL SYSTEM

QR20DE

PREPARATION ........................................................... 2

Commercial Service Tool ......................................... 2

FUEL SYSTEM ........................................................... 3

Checking Fuel Lines ................................................. 3

General Precautions ................................................ 3

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND

FUEL PUMP ASSEMBLY ........................................... 4

Removal and Installation .......................................... 4

REMOVAL ............................................................. 4

INSPECTION AFTER REMOVAL ......................... 6

INSTALLATION ..................................................... 6

INSPECTION AFTER INSTALLATION ................. 7

Disassembly and Assembly ..................................... 7

DISASSEMBLY ..................................................... 7

ASSEMBLY ........................................................... 8

FUEL TANK ................................................................ 9

Removal and Installation .......................................... 9

REMOVAL ............................................................. 9

INSTALLATION ................................................... 10

Inspection After Installation .....................................11

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 12

Standard and Limit ................................................. 12

Tightening Torque ................................................... 12

YD22DDTi

PREPARATION ......................................................... 13

Commercial Service Tool ........................................ 13

FUEL SYSTEM ......................................................... 14

Checking Fuel Lines ............................................... 14

General Precautions ............................................... 14

FUEL FILTER ............................................................ 15

Removal and Installation ........................................ 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 15

INSPECTION AFTER INSTALLATION ................ 15

Air Bleeding ............................................................ 16

Draining Water ........................................................ 16

FUEL LEVEL SENSOR UNIT ................................... 17

Removal and Installation ........................................ 17

REMOVAL ........................................................... 17

INSPECTION AFTER REMOVAL ....................... 19

INSTALLATION ................................................... 19

INSPECTION AFTER INSTALLATION ................ 20

FUEL TANK .............................................................. 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSTALLATION ................................................... 22

Inspection After Installation .................................... 22

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 23

Standard and Limit .................................................. 23

Tightening Torque ................................................... 23

Page 2219 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide FL-4

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

PFP:17042

Removal and InstallationEBS00BKR

REMOVAL

WAR NIN G:

Be sur NISSAN X-TRAIL 2003 Electronic User Guide FL-4

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

PFP:17042

Removal and InstallationEBS00BKR

REMOVAL

WAR NIN G:

Be sur](/img/5/57402/w960_57402-2218.png)

FL-4

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

PFP:17042

Removal and InstallationEBS00BKR

REMOVAL

WAR NIN G:

Be sure to read “General Precautions” when working on fuel system. Refer toFL-3, "

General Precau-

tions"

1. Release fuel pressure from fuel line.

Refer toEC-34, "

FUEL PRESSURE RELEASE"(WITH EURO-

OBD),EC-399, "

FUEL PRESSURE RELEASE"(WITHOUT

EURO-OBD).

2. Open fuel filer lid.

3. Open the filler cap and release the pressure inside the fuel tank.

4. Check fuel level on level place. If gauge indicates more than the

level shown in figure (full or almost full), drain fuel from fuel tank

until gauge indicates level shown in figure or below.

In case of fuel pump does not operate, take following procedure.

a. Insert fuel tube of less than 25 mm (0.98 in) in diameter into fuel

filler tube through fuel filler opening to draw fuel from fuel filler

tube.

b. Disconnect fuel filler hose from fuel filler tube.

c. Insert fuel tube into fuel tank through fuel filler hose to draw fuel

from fuel tank.

lAs a guide, fuel level becomes the position shown in figure or

below when approximately 15 liter (13-1/4 lmp qt) of fuel are drained from fuel position.

KBIA0278E

1Lockring 2Main fuel level sensor unit, fuel filter

and fuel pump assembly3Jet pump, fuel hose and jet pump inlet

assembly

4 Chamber 5 Seal packing 6 Sub fuel level sensor unit

KBIA0280E

FEL0403D

Page 2220 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-5

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

FL

NOTE:

Adjusting fuel level is to prevent fuel from spilling, when fuel level sensor unit, fuel filter NISSAN X-TRAIL 2003 Electronic User Guide FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-5

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

FL

NOTE:

Adjusting fuel level is to prevent fuel from spilling, when fuel level sensor unit, fuel filter](/img/5/57402/w960_57402-2219.png)

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-5

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

FL

NOTE:

Adjusting fuel level is to prevent fuel from spilling, when fuel level sensor unit, fuel filter and fuel pump

assembly is removed.

5. Remove rear seat bottom.

6. Remove inspection hole cover, harness connector and fuel feed hose.

lRemove the quick connector as follows.

NOTE:

lHold the sides of the connector, push in tubs and pull out the

tube.

lIf the connector and the tube are stuck together, push and pull

several times until they start to move. Then disconnect them by

pulling.

CAUTION:

lThe tube can be removed when the tabs are completely

depressed. Do not twist it more than necessary.

lDo not use any tools to remove the quick connector.

lKeep the resin tube away from heat. Be especially careful

when welding near the tube.

lPrevent acid liquid such as battery electrolyte etc. from get-

ting on the resin tube.

lDo not bend or twist the tube during installation and

removal.

lDo not remove the remaining retainer on tube or fuel level

sensor unit.

lWhen the tube or fuel level sensor unit is replaced, also

replace the retainer with a new one.

Retainer color: Green.

lTo keep clean the connecting portion and to avoid damage

and foreign materials, cover them completely with plastic

bags or something similar.

SFE562A

PBIC0199E

PBIC0163E

Page 2221 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide FL-6

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

7. Using a lock ring wrench, remove the lock ring.

8. Remove main fuel level sensor unit, fuel filter and fuel pump

assembly, a NISSAN X-TRAIL 2003 Electronic User Guide FL-6

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

7. Using a lock ring wrench, remove the lock ring.

8. Remove main fuel level sensor unit, fuel filter and fuel pump

assembly, a](/img/5/57402/w960_57402-2220.png)

FL-6

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

7. Using a lock ring wrench, remove the lock ring.

8. Remove main fuel level sensor unit, fuel filter and fuel pump

assembly, and sub fuel level sensor unit.

CAUTION:

lDo not bend the float arm during removal.

lAvoid impacts such as falling when handling compo-

nents.

lRemoval of main fuel level sensor unit, fuel filter, fuel pump

assembly.

lRaise the sender unit, and remove the jet pump to remove the

sender unit.

lLeave the jet pump on the fuel tank with the fuel hose.

lIf necessary, remove the chamber from the bottom of the fuel tank.

lRemove the chamber by sliding toward the rear of the vehicle.

Removal of sub fuel level sensor unit.

lRaise and release the sub fuel level sensor unit to remove.

lIf necessary, remove the jet pump inlet from the bottom of the fuel tank.

To remove it, pinch the tabs (2 places).

INSPECTION AFTER REMOVAL

Make sure the fuel pump strainer is free from foreign materials, If any are found, remove them.

INSTALLATION

Install in the reverse order of removal paying attention to the follow-

ing.

lWhen installing the chamber and jet pump, insert them fully until

a click sound of full stopper engagement is heard (Ditto for jet

pump inlet).

lConnect the quick connector as follows.

1. Check the connection for damage and foreign materials.

2. Align the connector with the tube, then insert the connector straight into the tube until a click is heard.

3. After connecting, make sure that the connection is secure by following the steps below.

lVisually confirm that the two retainer tabs are connected to the connector.

lPull the tube and the connector to make sure they are securely connected.

PBIC0240E

KBIA0281E

KBIA0302E

Page 2222 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-7

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

FL

lInstall fuel level sensor unit with mating mark (triangular protru-

sion) facing between two carved NISSAN X-TRAIL 2003 Electronic User Guide FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-7

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

FL

lInstall fuel level sensor unit with mating mark (triangular protru-

sion) facing between two carved](/img/5/57402/w960_57402-2221.png)

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-7

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

FL

lInstall fuel level sensor unit with mating mark (triangular protru-

sion) facing between two carved lines on fuel tank.(Figure

shows left side of fuel tank.)

NOTE:

On right side of fuel tank, there are three carved lines on fuel

tank. Set mating mark between two outer carved lines.

lInstall the inspection hole cover with the front mark (arrow) fac-

ing front of the vehicle (Both for RH and LH).

INSPECTION AFTER INSTALLATION

Start the engine and rev it up and make sure there is no fuel leakage at connections.

Disassembly and AssemblyEBS00BKS

NOTE:

Sub fuel level sensor unit cannot be disassembled and should be replaced as a unit.

DISASSEMBLY

1. Remove fuel pump removing bracket.

lUsing a screwdriver, remove the snap fit portion of bracket in the

order of (1), (2), (3) and (4) as shown in the figure.

KBIA0282E

PBIC0241E

1 Pressure regulator 2 Fuel pump 3 Packing

4 Fuel filter 5 Rubber 6 Fuel level sensor unit

7 Bracket

PBIC0242E