Filter NISSAN X-TRAIL 2003 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 500 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual AT-494

[ALL]

REPAIR FOR COMPONENT PARTS

ASSEMBLY

1. Install upper, inter and lower body.

a. Place oil circuit of upper body face up. Install steel balls in their

proper positions.

b. Install upper sep NISSAN X-TRAIL 2003 Electronic Owners Manual AT-494

[ALL]

REPAIR FOR COMPONENT PARTS

ASSEMBLY

1. Install upper, inter and lower body.

a. Place oil circuit of upper body face up. Install steel balls in their

proper positions.

b. Install upper sep](/img/5/57402/w960_57402-499.png)

AT-494

[ALL]

REPAIR FOR COMPONENT PARTS

ASSEMBLY

1. Install upper, inter and lower body.

a. Place oil circuit of upper body face up. Install steel balls in their

proper positions.

b. Install upper separating gasket, upper inter separating gasket

and upper separating plate in order shown in illustration.

c. Install reamer boltsffrom bottom of upper body. Using reamer

bolts as guides, install separating plate and gaskets as a set.

d. Install pilot filter.

SAT771J

SAT072F

SAT073FA

SAT074F

Page 581 of 3066

ATC-3

C

D

E

F

G

H

I

K

L

MA

B

AT C INTAKE SENSOR CIRCUIT ................................... 108

Removal and Installation ...................................... 108

BLOWER UNIT ....................................................... 109

Removal and Installation ...................................... 109

REMOVAL ......................................................... 109

INSTALLATION ................................................. 109

Disassembly and Assembly ................................. 109

BLOWER MOTOR ................................................... 111

Removal and Installation ...................................... . 111

INTAKE DOOR MOTOR .......................................... 112

Removal and Installation ....................................... 112

FAN CONTROL AMPLIFIER ................................... 113

Removal and Installation ....................................... 113

VENTILATION AIR FILTER ..................................... 114

Removal and Installation ....................................... 114

Function ................................................................ 114

Replacement Timing ............................................. 114

Replacement Procedures ...................................... 114

HEATER & COOLING UNIT ASSEMBLY ............... 115

Removal and Installation ....................................... 115

REMOVAL .......................................................... 115

INSTALLATION .................................................. 116

Disassembly and Assembly .................................. 116

MODE DOOR MOTOR ............................................ 118

Removal and Installation ....................................... 118

AIR MIX DOOR MOTOR .......................................... 119

Removal and Installation ....................................... 119

HEATER CORE ...................................................... 120

Removal and Installation ...................................... 120

DUCTS AND GRILLES .......................................... 121

Removal and Installation ...................................... 121

Ventilator Duct, Defroster Nozzle and Defroster

Ducts .................................................................... 121

Center Ventilator Grille ......................................... 121

Side Ventilator Grille ............................................. 121

Foot Duct .............................................................. 122

Floor duct ............................................................. 122

REFRIGERANT LINES ........................................... 123

HFC-134a (R-134a) Service Procedure ............... 123

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ................................................................ 123

Components ......................................................... 125

Removal and Installation for Compressor ............ 126REMOVAL .........................................................126

INSTALLATION .................................................128

Removal and Installation for Compressor Clutch . 129

REMOVAL .........................................................129

INSTALLATION .................................................132

Removal and Installation for Low-pressure flexible

hose ......................................................................135

REMOVAL .........................................................135

INSTALLATION .................................................136

Removal and Installation for High-pressure flexible

hose ......................................................................136

REMOVAL .........................................................136

INSTALLATION .................................................136

Removal and Installation for High-pressure pipe ..137

REMOVAL .........................................................137

INSTALLATION .................................................137

Removal and Installation for Refrigerant Pressure

Sensor ..................................................................137

Removal and Installation for Dual-pressure Switch.138

Removal and Installation for Condenser ..............138

REMOVAL .........................................................138

INSTALLATION .................................................138

Removal and Installation for Evaporator ..............139

REMOVAL .........................................................139

INSTALLATION .................................................139

Removal and Installation for Expansion Valve ......140

Removal and Installation for Desiccant Assembly. 140

REMOVAL .........................................................140

INSTALLATION .................................................140

Checking for Refrigerant Leaks ............................140

Checking System for Leaks Using the Fluorescent

Leak Detector .......................................................141

Dye Injection .........................................................141

Electronic Refrigerant Leak Detector ....................141

PRECAUTIONS FOR HANDLING LEAK

DETECTOR .......................................................141

CHECKING PROCEDURE ...............................142

Service Data and Specifications (SDS) ................143

COMPRESSOR ................................................143

LUBRICANT ......................................................144

REFRIGERANT .................................................144

ENGINE IDLING SPEED ..................................144

BELT TENSION .................................................144

Page 688 of 3066

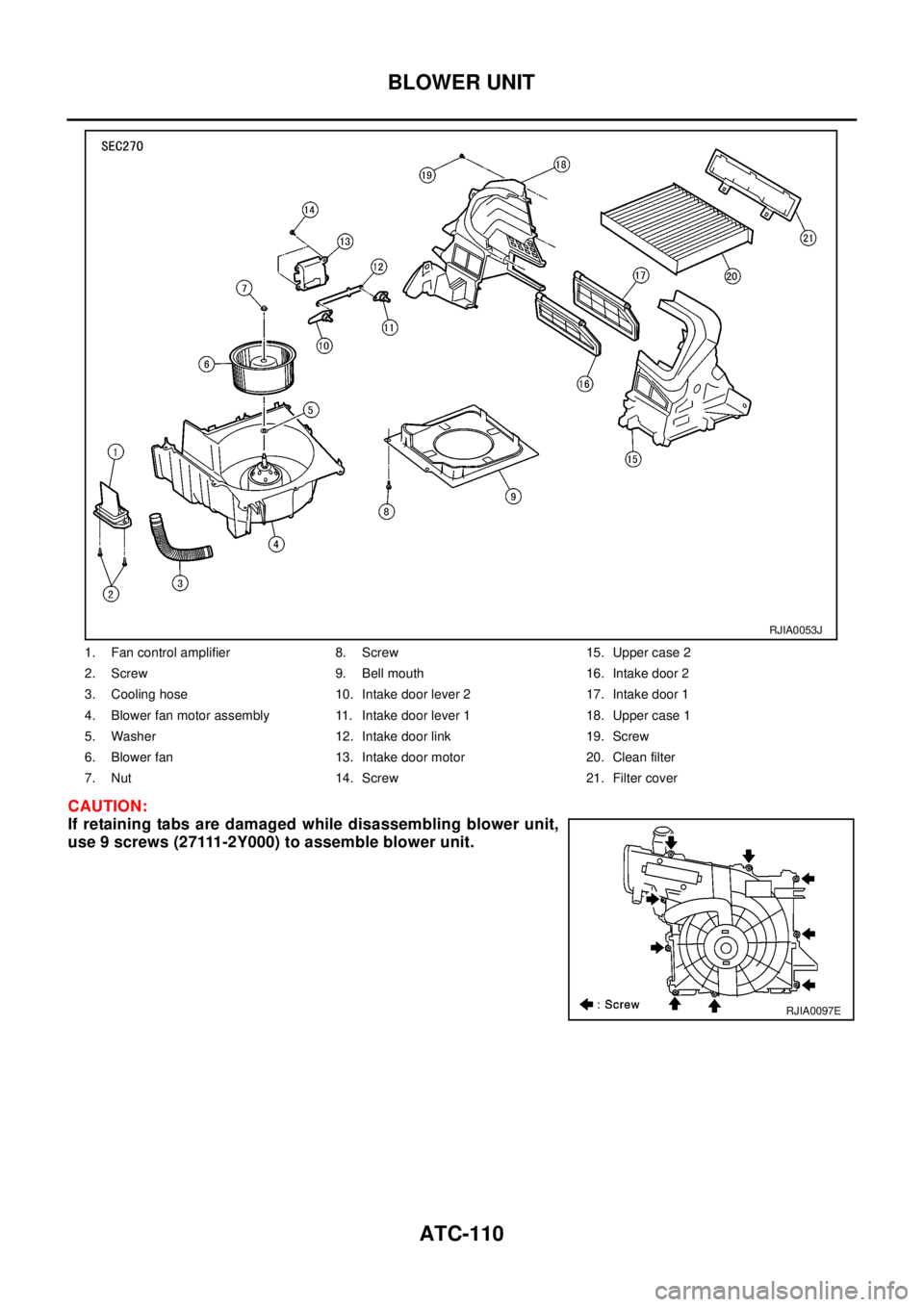

ATC-110

BLOWER UNIT

CAUTION:

If retaining tabs are damaged while disassembling blower unit,

use 9 screws (27111-2Y000) to assemble blower unit.

1. Fan control amplifier 8. Screw 15. Upper case 2

2. Screw 9. Bell mouth 16. Intake door 2

3. Cooling hose 10. Intake door lever 2 17. Intake door 1

4. Blower fan motor assembly 11. Intake door lever 1 18. Upper case 1

5. Washer 12. Intake door link 19. Screw

6. Blower fan 13. Intake door motor 20. Clean filter

7. Nut 14. Screw 21. Filter cover

RJIA0053J

RJIA0097E

Page 692 of 3066

ATC-114

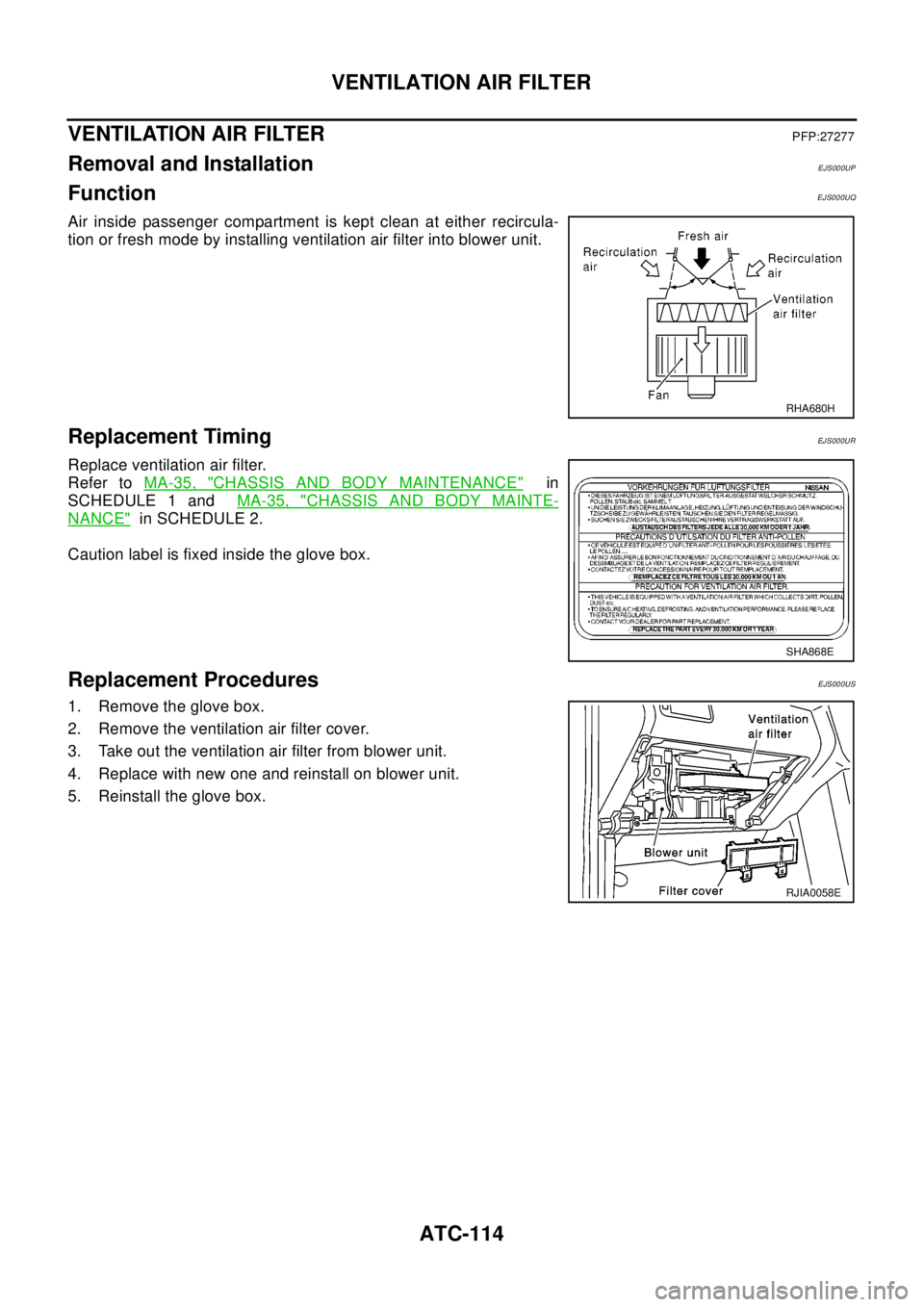

VENTILATION AIR FILTER

VENTILATION AIR FILTER

PFP:27277

Removal and InstallationEJS000UP

FunctionEJS000UQ

Air inside passenger compartment is kept clean at either recircula-

tion or fresh mode by installing ventilation air filter into blower unit.

Replacement TimingEJ S00 0UR

Replace ventilation air filter.

Refer toMA-35, "

CHASSIS AND BODY MAINTENANCE"in

SCHEDULE 1 andMA-35, "

CHASSIS AND BODY MAINTE-

NANCE"in SCHEDULE 2.

Caution label is fixed inside the glove box.

Replacement ProceduresEJS000US

1. Remove the glove box.

2. Remove the ventilation air filter cover.

3. Take out the ventilation air filter from blower unit.

4. Replace with new one and reinstall on blower unit.

5. Reinstall the glove box.

RHA680H

SHA868E

RJIA0058E

Page 718 of 3066

ATC-140

REFRIGERANT LINES

Removal and Installation for Expansion Valve

EJS000VH

1. Using the recycling and recovery equipment (for HFC-134a),

discharge the refrigerant.

2. Disconnect the low-pressure flexible hose and high-pressure

pipe from the evaporator.

CAUTION:

Cap or wrap the joint of the low-pressure flexible hose and

the high-pressure pipe with a suitable tool such as a vinyl

tape to avoid the entry of air.

3. Remove the expansion valve cover.

4. Remove the expansion valve.

Removal and Installation for Desiccant AssemblyEJS000VI

REMOVAL

1. Remove the condenser.

2. Clean the area around the snap ring. Remove any dirt or rust.

CAUTION:

Be sure to clean carefully.

3. Remove the snap ring from the lower side of liquid tank.

4. Remove the cap, filter and desiccant assembly.

INSTALLATION

1. Install the new desiccant, filter, cap, O-ring, and snap ring.

2. The work must be performed with clean hands. (Gloves may

not be worn.)

3. The desiccant, filter, cap, O-ring, and snap ring cannot be

reused.

4. When inserting the desiccant, be sure to insert it all the way in,

taking care not to allow any dirt to contact the surrounding area.

5. Do not install the filter backwards.

6. When inserting the cap, be certain to avoid having the O-ring

catch on something, fall out, or contact dirt

7. Apply lubricating oil to the cap O-ring, then insert all the way to

the end.

8. Check that there is no dust or dirt adhering to the snap ring installation groove.

9. The snap ring must be installed securely into the groove.

Checking for Refrigerant LeaksEJS000VJ

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage may indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electronic refrigerant leak detector or fluorescent

dye leak detector.

If dye is observed, confirm the leak with an electronic refrigerant leak detector. It is possible a prior leak was

repaired and not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.Expansion valve mounting bolts

Tightening torque :2.9 - 5.0 N-m (0.30 - 0.50 kg-m)

RJIA0083E

RJIA0086E

RJIA0087E

Page 1072 of 3066

DI-18

COMBINATION METERS (LHD MODELS)

The Fuel Gauge Does Not Move to F-position.

EKS002ZK

1.QUESTIONNAIRE 1

Does it take a long time for the pointer to move to F-position?

YES?

YES >> GO TO 2.

NO >> GO TO 3.

2.QUESTIONNAIRE 2

Was the vehicle fueled with the ignition switch ON?

YES?

YES >> Be sure to fuel the vehicle with the ignition switch OFF. Otherwise it will take a long time to move

to F-position because of the characteristic of the fuel gauge.

NO >> GO TO 3.

3.QUESTIONNAIRE 3

Is the floor or the vehicle inclined?

YES?

YES >> It may not be filled fully.

NO >> GO TO 4.

4.QUESTIONNAIRE 4

During driving, does the fuel gauge pointer move gradually toward E-position?

YES?

YES >> Check the components. Refer toDI-19, "Electrical Components Inspection".

NO >> The float arm may interfere or bind with any of the components in the fuel tank.

The Fuel Gauge Does Not Work.EKS002ZL

1.HARNESS CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Check combination meter, fuel level sensor unit, sub fuel level sensor unit and terminals (meter-side,

module-side, and harness-side) for poor connection and bend.

OK or NG

OK >> GO TO 2.

NG >> Repair connector.

2.CHECK INSTALLATION CONDITION

Check fuel level sensor unit or sub fuel level sensor unit installation (refer toFL-4, "

FUEL LEVEL SENSOR

UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY"for QR engine models orFL-17, "FUEL LEVEL SEN-

SOR UNIT"for YD engine models, and check whether the float arm interferes or binds with any components

inside the arm.

OK or NG

OK >> Fuel level sensor unit is OK.

NG >> Check fuel level sensor unit or sub fuel level sensor unit. Refer toDI-19, "

Electrical Components

Inspection".

Page 1073 of 3066

COMBINATION METERS (LHD MODELS)

DI-19

C

D

E

F

G

H

I

J

L

MA

B

DI

Low Fuel Warning Lamp Illuminate or Not IlluminateEKS002ZM

1.DIAGNOSIS MODE INSPECTION

Preform combination meter diagnosis mode. Refer toDI-10, "

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode".

OK or NG

OK >> Check fuel level sensor unit or sub fuel level sensor unit. Refer toDI-19, "Electrical Components

Inspection".

NG >> Replace combination meter.

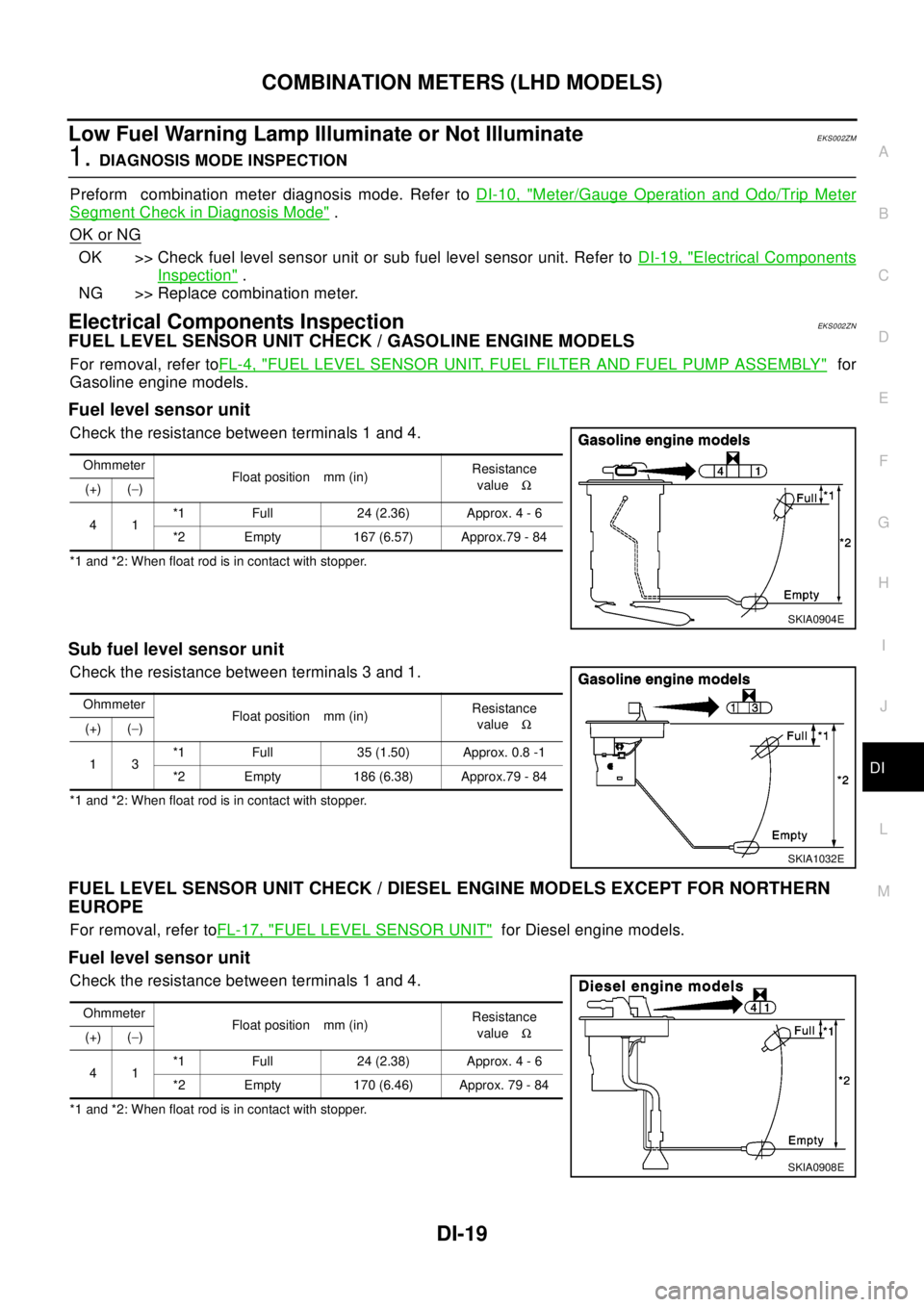

Electrical Components InspectionEKS002ZN

FUEL LEVEL SENSOR UNIT CHECK / GASOLINE ENGINE MODELS

For removal, refer toFL-4, "FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY"for

Gasoline engine models.

Fuel level sensor unit

Check the resistance between terminals 1 and 4.

*1 and *2: When float rod is in contact with stopper.

Sub fuel level sensor unit

Check the resistance between terminals 3 and 1.

*1 and *2: When float rod is in contact with stopper.

FUEL LEVEL SENSOR UNIT CHECK / DIESEL ENGINE MODELS EXCEPT FOR NORTHERN

EUROPE

For removal, refer toFL-17, "FUEL LEVEL SENSOR UNIT"for Diesel engine models.

Fuel level sensor unit

Check the resistance between terminals 1 and 4.

*1 and *2: When float rod is in contact with stopper.Ohmmeter

Float position mm (in)Resistance

valueW

(+) (-)

41*1 Full 24 (2.36) Approx. 4 - 6

*2 Empty 167 (6.57) Approx.79 - 84

SKIA0904E

Ohmmeter

Float position mm (in)Resistance

valueW

(+) (-)

13*1 Full 35 (1.50) Approx. 0.8 -1

*2 Empty 186 (6.38) Approx.79 - 84

SKIA1032E

Ohmmeter

Float position mm (in)Resistance

valueW

(+) (-)

41*1 Full 24 (2.38) Approx. 4 - 6

*2 Empty 170 (6.46) Approx. 79 - 84

SKIA0908E

Page 1090 of 3066

DI-36

COMBINATION METERS (RHD MODELS)

The Fuel Gauge Does Not Move to F-position.

EKS0030V

1.QUESTIONNAIRE 1

Does it take a long time for the pointer to move to F-position?

YES?

YES >> GO TO 2.

NO >> GO TO 3.

2.QUESTIONNAIRE 2

Was the vehicle fueled with the ignition switch ON?

YES ?

YES >> Be sure to fuel the vehicle with the ignition switch OFF. Otherwise it will take a long time to move

to F-position because of the characteristic of the fuel gauge.

NO >> GO TO 3.

3.QUESTIONNAIRE 3

Is the floor or the vehicle inclined?

YES?

YES >> It may not be filled fully.

NO >> GO TO 4.

4.QUESTIONNAIRE 4

During driving, does the fuel gauge pointer move gradually toward E-position?

YES ?

YES >> Check the components. Refer toDI-37, "Electrical Components Inspection".

NO >> The float arm may interfere or bind with any of the components in the fuel tank.

The Fuel Gauge Does Not Work.EKS0030W

1.HARNESS CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Check combination meter, fuel level sensor unit, sub fuel level sensor unit and terminals (meter-side,

module-side, and harness-side) for poor connection and bend.

OK or NG

OK >> GO TO 2.

NG >> Repair connector.

2.CHECK INSTALLATION CONDITION

Check fuel level sensor unit or sub fuel level sensor unit installation (refer toFL-4, "

FUEL LEVEL SENSOR

UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY"for QR engine models orFL-17, "FUEL LEVEL SEN-

SOR UNIT"for YD engine models, and check whether the float arm interferes or binds with any components

inside the arm.

OK or NG

OK >> Fuel level sensor unit is OK.

NG >> Check fuel level sensor unit or sub fuel level sensor unit. Refer toDI-37, "

Electrical Components

Inspection".

Page 1091 of 3066

COMBINATION METERS (RHD MODELS)

DI-37

C

D

E

F

G

H

I

J

L

MA

B

DI

Low Fuel Warning Lamp Illuminate or Not IlluminateEKS0030X

1.DIAGNOSIS MODE INSPECTION

Preform combination meter diagnosis mode. Refer toDI-28, "

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode".

OK or NG

OK >> Check fuel level sensor unit or sub fuel level sensor unit. Refer toDI-37, "Electrical Components

Inspection".

NG >> Replace combination meter.

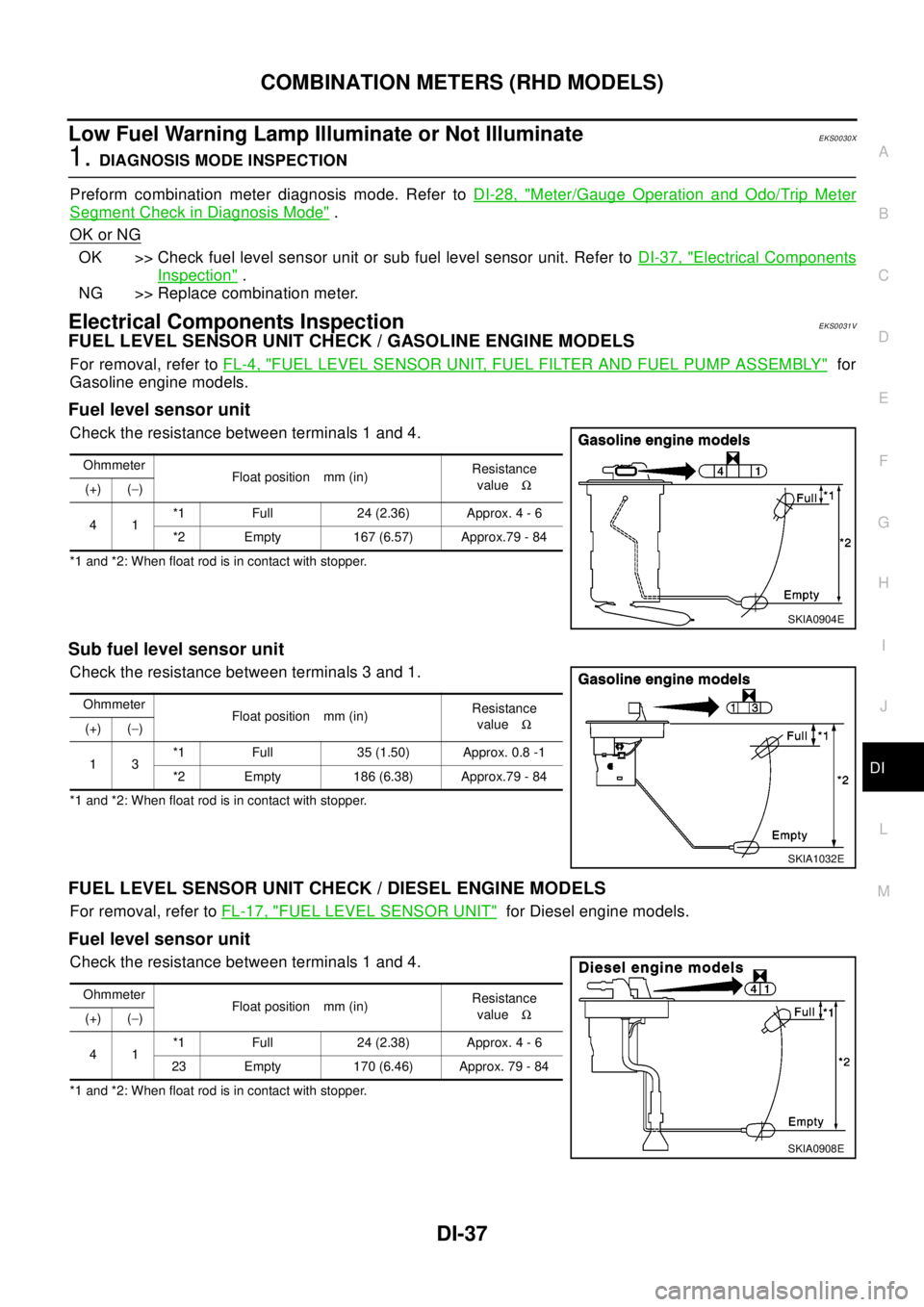

Electrical Components InspectionEKS0031V

FUEL LEVEL SENSOR UNIT CHECK / GASOLINE ENGINE MODELS

For removal, refer toFL-4, "FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY"for

Gasoline engine models.

Fuel level sensor unit

Check the resistance between terminals 1 and 4.

*1 and *2: When float rod is in contact with stopper.

Sub fuel level sensor unit

Check the resistance between terminals 3 and 1.

*1 and *2: When float rod is in contact with stopper.

FUEL LEVEL SENSOR UNIT CHECK / DIESEL ENGINE MODELS

For removal, refer toFL-17, "FUEL LEVEL SENSOR UNIT"for Diesel engine models.

Fuel level sensor unit

Check the resistance between terminals 1 and 4.

*1 and *2: When float rod is in contact with stopper.Ohmmeter

Float position mm (in)Resistance

valueW

(+) (-)

41*1 Full 24 (2.36) Approx. 4 - 6

*2 Empty 167 (6.57) Approx.79 - 84

SKIA0904E

Ohmmeter

Float position mm (in)Resistance

valueW

(+) (-)

13*1 Full 35 (1.50) Approx. 0.8 -1

*2 Empty 186 (6.38) Approx.79 - 84

SKIA1032E

Ohmmeter

Float position mm (in)Resistance

valueW

(+) (-)

41*1 Full 24 (2.38) Approx. 4 - 6

23 Empty 170 (6.46) Approx. 79 - 84

SKIA0908E

Page 1123 of 3066

EC-9

C

D

E

F

G

H

I

J

K

L

M

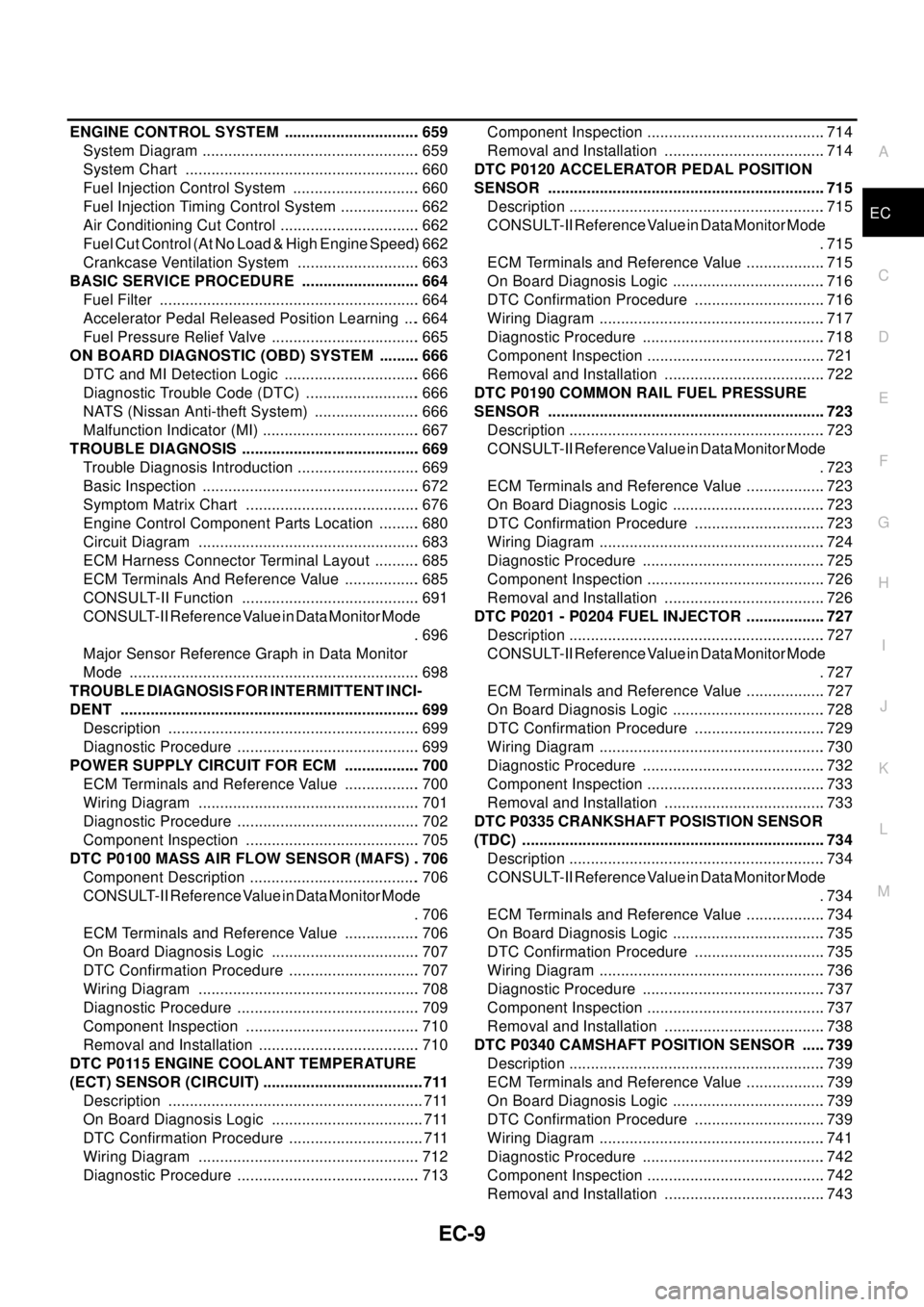

ECA ENGINE CONTROL SYSTEM ................................ 659

System Diagram ................................................... 659

System Chart ....................................................... 660

Fuel Injection Control System .............................. 660

Fuel Injection Timing Control System ................... 662

Air Conditioning Cut Control ................................. 662

Fuel Cut Control (At No Load & High Engine Speed). 662

Crankcase Ventilation System ............................. 663

BASIC SERVICE PROCEDURE ............................ 664

Fuel Filter ............................................................. 664

Accelerator Pedal Released Position Learning .... 664

Fuel Pressure Relief Valve ................................... 665

ON BOARD DIAGNOSTIC (OBD) SYSTEM .......... 666

DTC and MI Detection Logic ................................ 666

Diagnostic Trouble Code (DTC) ........................... 666

NATS (Nissan Anti-theft System) ......................... 666

Malfunction Indicator (MI) ..................................... 667

TROUBLE DIAGNOSIS .......................................... 669

Trouble Diagnosis Introduction ............................. 669

Basic Inspection ................................................... 672

Symptom Matrix Chart ......................................... 676

Engine Control Component Parts Location .......... 680

Circuit Diagram .................................................... 683

ECM Harness Connector Terminal Layout ........... 685

ECM Terminals And Reference Value .................. 685

CONSULT-II Function .......................................... 691

CONSULT-II Reference Value in Data Monitor Mode

. 696

Major Sensor Reference Graph in Data Monitor

Mode .................................................................... 698

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT ...................................................................... 699

Description ........................................................... 699

Diagnostic Procedure ........................................... 699

POWER SUPPLY CIRCUIT FOR ECM .................. 700

ECM Terminals and Reference Value .................. 700

Wiring Diagram .................................................... 701

Diagnostic Procedure ........................................... 702

Component Inspection ......................................... 705

DTCP0100MASSAIRFLOWSENSOR(MAFS).. 706

Component Description ........................................ 706

CONSULT-II Reference Value in Data Monitor Mode

. 706

ECM Terminals and Reference Value .................. 706

On Board Diagnosis Logic ................................... 707

DTC Confirmation Procedure ............................... 707

Wiring Diagram .................................................... 708

Diagnostic Procedure ........................................... 709

Component Inspection ......................................... 710

Removal and Installation ...................................... 710

DTC P0115 ENGINE COOLANT TEMPERATURE

(ECT) SENSOR (CIRCUIT) ...................................... 711

Description ............................................................ 711

On Board Diagnosis Logic .................................... 711

DTC Confirmation Procedure ................................ 711

Wiring Diagram .................................................... 712

Diagnostic Procedure ........................................... 713Component Inspection ..........................................714

Removal and Installation ......................................714

DTC P0120 ACCELERATOR PEDAL POSITION

SENSOR .................................................................715

Description ............................................................715

CONSULT-II Reference Value in Data Monitor Mode

.715

ECM Terminals and Reference Value ...................715

On Board Diagnosis Logic ....................................716

DTC Confirmation Procedure ...............................716

Wiring Diagram .....................................................717

Diagnostic Procedure ...........................................718

Component Inspection ..........................................721

Removal and Installation ......................................722

DTC P0190 COMMON RAIL FUEL PRESSURE

SENSOR .................................................................723

Description ............................................................723

CONSULT-II Reference Value in Data Monitor Mode

.723

ECM Terminals and Reference Value ...................723

On Board Diagnosis Logic ....................................723

DTC Confirmation Procedure ...............................723

Wiring Diagram .....................................................724

Diagnostic Procedure ...........................................725

Component Inspection ..........................................726

Removal and Installation ......................................726

DTC P0201 - P0204 FUEL INJECTOR ...................727

Description ............................................................727

CONSULT-II Reference Value in Data Monitor Mode

.727

ECM Terminals and Reference Value ...................727

On Board Diagnosis Logic ....................................728

DTC Confirmation Procedure ...............................729

Wiring Diagram .....................................................730

Diagnostic Procedure ...........................................732

Component Inspection ..........................................733

Removal and Installation ......................................733

DTC P0335 CRANKSHAFT POSISTION SENSOR

(TDC) .......................................................................734

Description ............................................................734

CONSULT-II Reference Value in Data Monitor Mode

.734

ECM Terminals and Reference Value ...................734

On Board Diagnosis Logic ....................................735

DTC Confirmation Procedure ...............................735

Wiring Diagram .....................................................736

Diagnostic Procedure ...........................................737

Component Inspection ..........................................737

Removal and Installation ......................................738

DTC P0340 CAMSHAFT POSITION SENSOR ......739

Description ............................................................739

ECM Terminals and Reference Value ...................739

On Board Diagnosis Logic ....................................739

DTC Confirmation Procedure ...............................739

Wiring Diagram .....................................................741

Diagnostic Procedure ...........................................742

Component Inspection ..........................................742

Removal and Installation ......................................743