open gas tank NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 594 of 3066

ATC-16

REFRIGERATION SYSTEM

REFRIGERATION SYSTEM

PFP:KA990

Refrigerant CycleEJS000TD

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is, through the compressor, the condenser with liquid tank,

through the evaporator, and back to the compressor. The refrigerant evaporation through the evaporator coil is

controlled by an externally equalized expansion valve, located inside the evaporator case.

FREEZE PROTECTION (WITH GASOLINE ENGINE: CWV-615M COMPRESSOR)

Under normal operating conditions, when the A/C is switched on, the compressor runs continuously, and the

evaporator pressure, and therefore, temperature is controlled by the V-6 variable displacement compressor to

prevent freeze up.

Refrigerant System ProtectionEJS000TE

REFRIGERANT PRESSURE SENSOR (WITH GASOLINE ENGINE: CWV-615M COMPRESSOR)

The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure sen-

sor, located on the liquid tank. If the system pressure rises above, or falls below the specifications, the refriger-

ant pressure sensor detects the pressure inside the refrigerant line and sends the voltage signal to the ECM.

ECM makes the A/C relay go OFF and stops the compressor when pressure on the high pressure side

detected by refrigerant pressure sensor is over about 2,746 kPa (28 kg/cm

2, 398 psi), or below about 134 kPa

(1.4 kg/cm

2,20psi).

DUAL-PRESSURE SWITCH (WITH DIESEL ENGINE: DKV-11G COMPRESSOR)

The refrigerant system is protected against excessively high or low pressures by the dual-pressure switch,

located on the liquid tank. If the system pressure rises above or falls below the specifications, the dual-pres-

sure switch opens to interrupt the compressor operation.

PRESSURE RELIEF VALVE (WITH GASOLINE ENGINE: CWV-615M COMPRESSOR)

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system increases to an abnormal level [more than 3,727 kPa (38 kg/

Page 1020 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-10

[QR20DE]

ENGINE COOLANT

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If NISSAN X-TRAIL 2003 Electronic Repair Manual CO-10

[QR20DE]

ENGINE COOLANT

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If](/img/5/57402/w960_57402-1019.png)

CO-10

[QR20DE]

ENGINE COOLANT

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If contaminated, flush engine cooling system. Refer toCO-10,

"FLUSHING COOLING SYSTEM".

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

Apply sealant to the thread of cylinder block drain plug.

lUse Genuine Liquid Gasket or equivalent.

2. Fill radiator and reservoir tank to specified level.

lUse genuine Nissan anti-freeze coolant or equivalent mixed

with water (distilled or demineralized).

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS".

lPour coolant slowly of less than 2 (2-1/8US qt,1-3/4 lmp

qt) a minute to allow air in system to escape.

3. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hole, install filler cap.

4. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

lRepeat two or three times.

Watch coolant temperature gauge so as not to overheat the engine.

5. Stop engine and cool down to less than approximately 50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with coolant.

6. Refill reservoir tank to MAX level line with coolant.

7. Repeat steps 5 through 7 two or more times with radiator cap installed until coolant level no longer drops.

8. Check cooling system for leaks with engine running.

9. Warm up engine, and check for sound of coolant flow while running engine from idle up to 3,000 rpm with

heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

10. If sound is heard, bleed air from cooling system by repeating steps 5 through 7 until coolant level no

longer drops.

lClean excess coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator and reservoir tank with water and reinstall radiator cap.

KBIA0163E

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Engine coolant capacity (With reservoir tank):

Approx. 7.1 (6-1/4 Imp qt)

SMA182B

Reservoir tank:

0.6 (1/2 lmp qt )

SMA412B

Page 1041 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE COOLANT

CO-31

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

3. Open drain plugs on cylinder block and air relief plug.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration. NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE COOLANT

CO-31

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

3. Open drain plugs on cylinder block and air relief plug.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.](/img/5/57402/w960_57402-1040.png)

ENGINE COOLANT

CO-31

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

3. Open drain plugs on cylinder block and air relief plug.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If contaminated, flush engine cooling system. Refer toCO-32,

"FLUSHING COOLING SYSTEM".

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

Apply sealant to the thread of cylinder block drain plug.

lUse Genuine Liquid Gasket or equivalent.

2. Fill radiator slowly with coolant until coolant spills from the air

relief plugs, then install air relief plugs.

CAUTION:

If the filling rate is too fast, this could lead to air being

mixed in the coolant. Be sure to fill the coolant slowly

according to the rate indicated above.

lReplace the copper washer of the air bleeding plug.

lUse genuine Nissan anti-freeze coolant or equivalent mixed with water (distilled or demineralized).

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRICANTS".

lPour coolant through coolant filler neck slowly of less than 2 (1-3/4 lmp qt) a minute to allow air

in system to escape.

SBIA0129E

SBIA0130E

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Air relief plug :

: 6.7 - 7.9 N·m (0.68 - 0.81 kg-m, 59 - 70 in-lb)

Engine coolant capacity (With reservoir tank):

9.5 ( 8-3/8 Imp qt)

SMA182B

Reservoir tank : 0.6 (1/2 lmp qt )

Page 1884 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-770

[YD]

DTC P1217 OVERHEAT (COOLING SYSTEM)

5.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E64, F5

lHarness for open or short between cooling fan relays-2 and -3 and ECM

>> NISSAN X-TRAIL 2003 Electronic Repair Manual EC-770

[YD]

DTC P1217 OVERHEAT (COOLING SYSTEM)

5.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E64, F5

lHarness for open or short between cooling fan relays-2 and -3 and ECM

>>](/img/5/57402/w960_57402-1883.png)

EC-770

[YD]

DTC P1217 OVERHEAT (COOLING SYSTEM)

5.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E64, F5

lHarness for open or short between cooling fan relays-2 and -3 and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK COOLING FAN RELAYS-2 AND -3

Refer toEC-771, "

Component Inspection".

OK or NG

OK >> GO TO 7.

NG >> Replace cooling fan relays.

7.CHECK COOLING FAN MOTORS

Refer toEC-771, "

Component Inspection".

OK or NG

OK >> GO TO 8.

NG >> Replace cooling fan motors.

8.CHECK INTERMITTENT INCIDENT

PerformEC-699, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Main 12 Causes of OverheatingEBS004QY

Engine Step Inspection item Equipment Condition Reference page

OFF 1

lBlocked radiator

lBlocked radiator grille

lBlocked bumper

lVisual No blocking —

2

lCoolant mixturelCoolant tester 50 - 50% coolant mixture SeeMA-17, "RECOM-

MENDED FLUIDS AND

LUBRICANTS".

3

lCoolant levellVisual Coolant up to MAX level

in reservoir tank and radi-

ator filler neckSeeMA-27, "Changing

Engine Coolant".

4

lRadiator caplPressure tester 78 - 98 kPa (0.78 - 0.98

bar, 0.8 - 1.0 kg/cm2,11-

14 psi)SeeCO-34, "

Checking

Radiator Cap".

ON*

25lCoolant leakslVisual No leaks SeeCO-30, "LEAK

CHECK".

ON*

26lThermostatlTouch the upper and

lower radiator hosesBoth hoses should be hot SeeCO-42, "THERMO-

STAT AND WATER PIP-

ING".

ON*

17lCooling fanlCONSULT-II Operating See Trouble Diagnosis for

DTC P1217,EC-713

.

OFF 8

lCombustion gas leaklColor checker chemi-

cal tester 4 Gas ana-

lyzerNegative —

Page 2513 of 3066

ENGINE MAINTENANCE (QR20DE)

MA-21

C

D

E

F

G

H

I

J

K

MA

B

MA

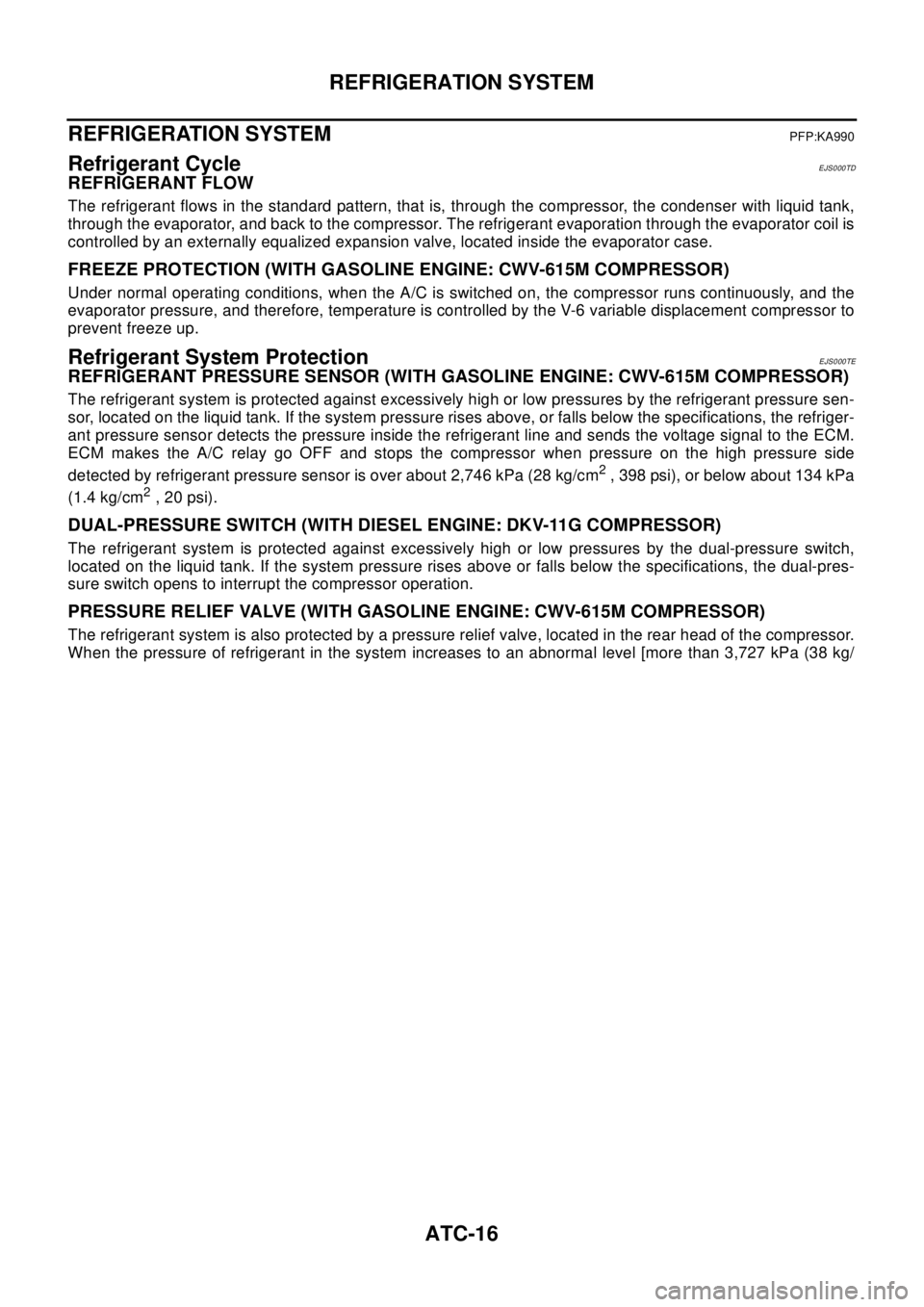

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If contaminated, flush engine cooling system. Refer toMA-21,

"FLUSHING COOLING SYSTEM".

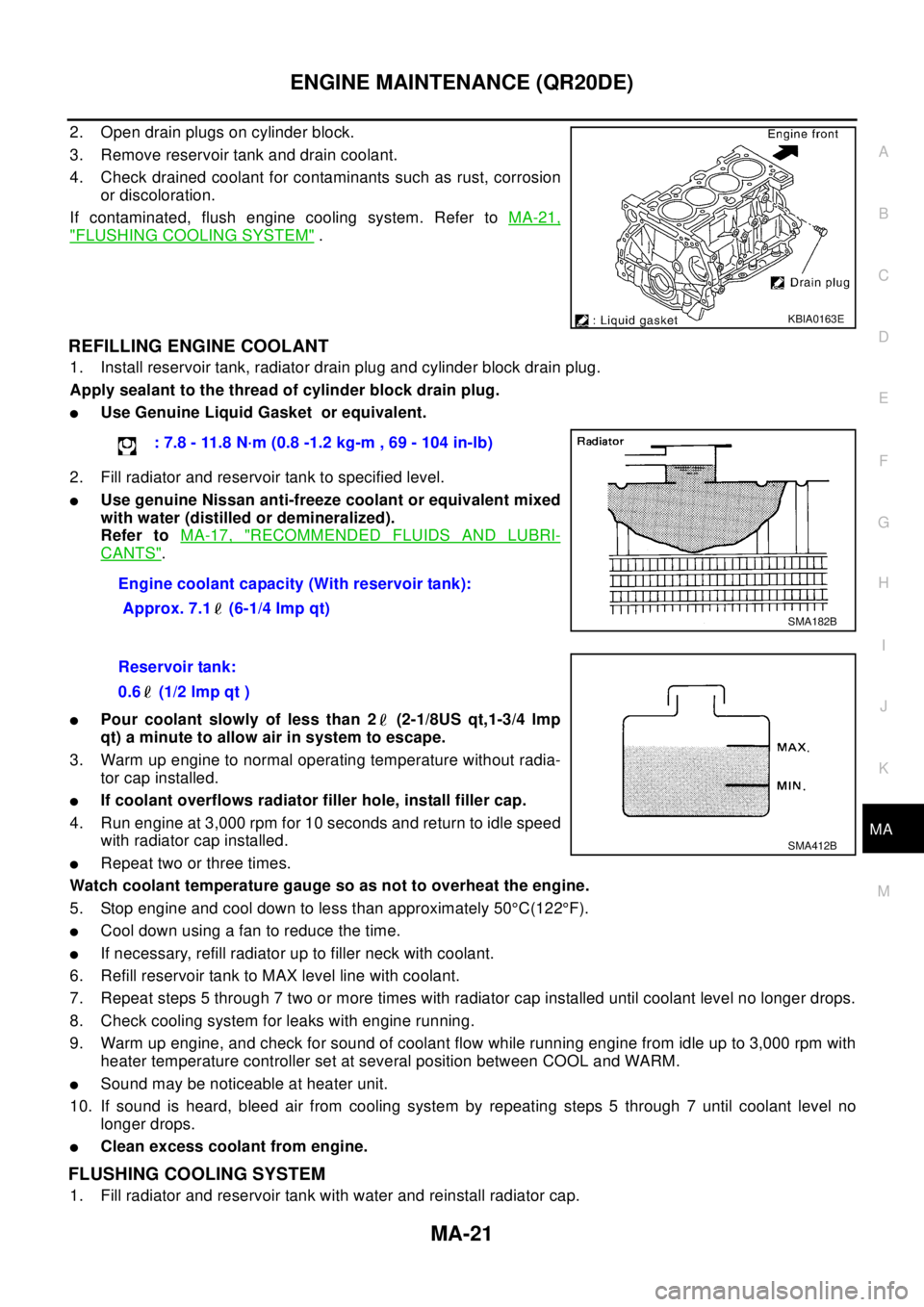

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

Apply sealant to the thread of cylinder block drain plug.

lUse Genuine Liquid Gasket or equivalent.

2. Fill radiator and reservoir tank to specified level.

lUse genuine Nissan anti-freeze coolant or equivalent mixed

with water (distilled or demineralized).

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS".

lPour coolant slowly of less than 2 (2-1/8US qt,1-3/4 lmp

qt) a minute to allow air in system to escape.

3. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hole, install filler cap.

4. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

lRepeat two or three times.

Watch coolant temperature gauge so as not to overheat the engine.

5. Stop engine and cool down to less than approximately 50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with coolant.

6. Refill reservoir tank to MAX level line with coolant.

7. Repeat steps 5 through 7 two or more times with radiator cap installed until coolant level no longer drops.

8. Check cooling system for leaks with engine running.

9. Warm up engine, and check for sound of coolant flow while running engine from idle up to 3,000 rpm with

heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

10. If sound is heard, bleed air from cooling system by repeating steps 5 through 7 until coolant level no

longer drops.

lClean excess coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator and reservoir tank with water and reinstall radiator cap.

KBIA0163E

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Engine coolant capacity (With reservoir tank):

Approx. 7.1 (6-1/4 Imp qt)

SMA182B

Reservoir tank:

0.6 (1/2 lmp qt )

SMA412B