check engine light NISSAN X-TRAIL 2003 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 874 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual BRC-6

[4WD/ABS]

ALL MODE 4X4 SYSTEM

ALL MODE 4X4 SYSTEM

PFP:47850

System DescriptionEFS001CJ

ABS FUNCTION

lDuring ABS operation, brake pedal lightly vibrates and its mechanical noise may be heard. Thi NISSAN X-TRAIL 2003 Electronic Owners Manual BRC-6

[4WD/ABS]

ALL MODE 4X4 SYSTEM

ALL MODE 4X4 SYSTEM

PFP:47850

System DescriptionEFS001CJ

ABS FUNCTION

lDuring ABS operation, brake pedal lightly vibrates and its mechanical noise may be heard. Thi](/img/5/57402/w960_57402-873.png)

BRC-6

[4WD/ABS]

ALL MODE 4X4 SYSTEM

ALL MODE 4X4 SYSTEM

PFP:47850

System DescriptionEFS001CJ

ABS FUNCTION

lDuring ABS operation, brake pedal lightly vibrates and its mechanical noise may be heard. This is a nor-

mal condition.

lWhen starting engine, or just after starting vehicle, brake pedal may vibrate. Also motor operating noise

may be heard from engine compartment. This is a normal status of operation check.

lWhen vehicle drives on rough, gravel, or snowy (fresh deep snow) road, the following conditions occur.

Stopping distance may be longer than that of vehicles without ABS.

4WD FUNCTION

lElectronically controlled 4WD is controlled by the same control module as that for ABS (4WD/ABS control

unit). 4WD/ABS control unit controls both electronically-controlled 4WD and ABS, based on input signals

from several sensors.

lIf electrical system-related malfunction occurred in 4WD/ABS system, control unit illuminates the following

lamps: 4WD warning lamp and/or ABS warning lamp on meter control unit assembly. This notifies driver of

malfunction. At the same time, control unit indicates malfunctioning part detected by self-diagnosis with

flashing pattern of LED. Indication on electronic system diagnosis tester (CONSULT) corresponds to this

flashing pattern as shown below.

Control System DiagramEFS001CK

Self-diagnostic test mode Remarks

Result of self-diagnosis Conformable to 4WD/ABS

Data monitor Conformable to 4WD/ABS

Active testChecks ABS solenoid valve ON/OFF, ABS motor ON/OFF, 4WD sole-

noid

Control unit part No. 4WD/ABS control unit

SFIA0350E

Page 887 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual TROUBLE DIAGNOSIS

BRC-19

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode.

This is not malfunction.

2. Heavy t NISSAN X-TRAIL 2003 Electronic Owners Manual TROUBLE DIAGNOSIS

BRC-19

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode.

This is not malfunction.

2. Heavy t](/img/5/57402/w960_57402-886.png)

TROUBLE DIAGNOSIS

BRC-19

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

CAUTION:

1. Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode.

This is not malfunction.

2. Heavy tight-corner braking symptom occurs when vehicle is driven in the following conditions:

LOCK mode, steering wheel is turned fully to either sides, and accelerator pedal was depressed.

4WD/ABS Control Unit Input/Output Signal StandardEFS001BG

4WD/ABS CONTROL UINT CONNECTOR TERMINAL ARRANGEMENT

CAUTION:

When ignition switch is turned to ON with connectors of 4WD/ABS control unit and actuator con-

nected.

REFERENCE STANDARD TABLE

Specifications defined by circuit tester

Vehicle running, 4WD warning lamp

flashes slowly. (When it flashes for

Approx. One minute, then does not illu-

minate.)Slow flashing: One flashing

per 2 secondslEngine run-

ning

lDriving at

vehicle speed

30km/hTire size is different for front and rear of vehicle.BRC-45

Vehicle does not enter 4WD mode

even though 4WD warning lamp is off.Engine runningMechanical malfunction of electronically con-

trolled coupling (Mechanical engagement of

clutch is not possible.)BRC-46

Symptom Condition Check items Reference page

SFIA0351E

Terminal No.

Location Standard (note 1)(Note) Check

points when result

was malfunctioning +-

3.

109Power supply Ignition switch ONBattery voltage (Approx.

12V)Control unit power

supply circuit

Page 898 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual BRC-30

[4WD/ABS]

TROUBLE DIAGNOSIS

NOTE:

lIf active test is performed with brake pedal depressed, pedal

stroke may be changed. This is a normal condition.

l“TEST STOP” is displayed 10 seconds late NISSAN X-TRAIL 2003 Electronic Owners Manual BRC-30

[4WD/ABS]

TROUBLE DIAGNOSIS

NOTE:

lIf active test is performed with brake pedal depressed, pedal

stroke may be changed. This is a normal condition.

l“TEST STOP” is displayed 10 seconds late](/img/5/57402/w960_57402-897.png)

BRC-30

[4WD/ABS]

TROUBLE DIAGNOSIS

NOTE:

lIf active test is performed with brake pedal depressed, pedal

stroke may be changed. This is a normal condition.

l“TEST STOP” is displayed 10 seconds later from the operation

start.

lTo perform test again after “TEST STOP” is displayed, repeat

step 6 of operation procedure.

ABS motor

Touch “ON” and “OFF” on screen. Check ABS motor relay operates

as shown in the following chart.

NOTE:

lIf active test is performed with brake pedal depressed, pedal

stroke may be changed. This is a normal condition.

l“TEST STOP” is displayed 10 seconds later from the operation

start.

Active test

4WD solenoid valve

Under the vehicle stopped with engine running, touch UP, DOWN on

screen. Adjust 4WD solenoid command current.

Check the monitor current at that time. If monitor current is within

Approx.±10%, light switch is normal.

CAUTION:

Do not continuously energize solenoid for long period of time.

Component InspectionEFS001BJ

ABS ACTUATOR

lDisconnect each ABS actuator E69, E70, E71 connector. Con-

firm continuity and resistance value between each pair of ABS

actuator-side terminal.

CAUTION:

Be sure ABS motor is securely grounded.

SFIA0396E

Operation ON OFF

ABS actuator ON ON

ABS motor ON OFF

SFIA0397E

SDIA0626E

SFIA0352E

Page 913 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual TROUBLE DIAGNOSIS

BRC-45

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.INSPECTION USING DRIVE MODE CHANGE-OVER SWITCH

lOn data monitor screen of the CONSULT, check 4WD mode switch.

lCheck if the display chan NISSAN X-TRAIL 2003 Electronic Owners Manual TROUBLE DIAGNOSIS

BRC-45

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.INSPECTION USING DRIVE MODE CHANGE-OVER SWITCH

lOn data monitor screen of the CONSULT, check 4WD mode switch.

lCheck if the display chan](/img/5/57402/w960_57402-912.png)

TROUBLE DIAGNOSIS

BRC-45

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.INSPECTION USING DRIVE MODE CHANGE-OVER SWITCH

lOn data monitor screen of the CONSULT, check 4WD mode switch.

lCheck if the display changes from ## to 2WD mode when the 2WD switch is pressed.

lCheck if the display changes from ## to AUTO mode when the AUTO switch is pressed.

lCheck if the display changes from ## to LOCK mode when the LOCK switch is pressed.

Is inspection result OK?

YES >> No malfunction detected.

NO >>

lNot in AUTO mode. (In 2WD or LOCK mode)

Countermeasure: Slightly depress the accelerator pedal and check that the operation mode

changes to LOCK mode.

lCheck path between drive mode switch and 4WD/ABS control unit E122 terminal No.27 (BR).

(AUTO mode is not available because a malfunction is present in the 2WD mode harness.)

NOTICE:

Mechanism of drive mode change-over

l2WD mode: Operation changes to 2WD mode when 4WD/ABS control unit connector terminal

No. 27 is shorted to ground.

lAUTO mode: Operation changes to AUTO mode when 4WD/ABS control unit connector termi-

nals No. 27 and No. 26 were shorted to ground.

lLOCK mode: Operation changes to LOCK mode when 4WD/ABS control unit connector E122

terminal No. 26 (L) is shorted to ground.

Drive modes cannot be switched after engine is started.EFS001BU

1.INSPECTION USING DRIVE MODE CHANGE-OVER SWITCH

lDrive modes cannot be switched after the engine is started.

lOn data monitor screen of the CONSULT, check 4WD mode switch.

lCheck if the display changes from ## to 2WD mode when the 2WD switch is pressed.

lCheck if the display changes from ## to AUTO mode when the AUTO switch is pressed.

lCheck if the display changes from ## to LOCK mode when the LOCK switch is pressed.

Is inspection result OK?

YES >> No malfunction detected.

NO >>

lCONSULT-II display does not change from ## when the 2WD switch is pressed. Check harness

of the 2WD switch.

lCONSULT-II display does not change from ## when the AUTO switch is pressed. Check har-

ness of the 2WD switch and LOCK switch.

lCONSULT-II display does not change from ## when the LOCK switch is pressed. Check har-

ness of the LOCK switch.

lPerform drive mode change-over switch inspection.

Wheel driving, 4WD warning lamp flashes rapidly. (When it flashes for Approx.

one minute, then does not illuminate.)

EFS001BV

lWheel driving, 4WD warning lamp flashes rapidly. (When it flashes for Approx. 1 minute, then does not

illuminate.)

Rapid flashing: 2 times/second

This phenomenon protects drivetrain parts when a heavy load is applied to the electronically controlled

coupling and multiple disc clutch temperature increases. It is not a malfunction.

Wheel driving, 4WD warning lamp flashes slowly. (When it continues to illumi-

nate until engine turns OFF.)

EFS001BW

1. Check using the data monitor function of the CONSULT.

lPerform inspection with the data monitor function of the CONSULT.

lCheck if the value of IMPROPER SIZE TIRE MONITOR is 8 mm or more.

Page 920 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual BRC-52

[ESP/TCS/ABS]

PRECAUTIONS

[ESP/TCS/ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS0019N

The Supplemental Restrai NISSAN X-TRAIL 2003 Electronic Owners Manual BRC-52

[ESP/TCS/ABS]

PRECAUTIONS

[ESP/TCS/ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS0019N

The Supplemental Restrai](/img/5/57402/w960_57402-919.png)

BRC-52

[ESP/TCS/ABS]

PRECAUTIONS

[ESP/TCS/ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS0019N

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WAR NIN G:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

Precautions for Brake SystemEFS0019O

lRecommended fluid is brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed

on painted areas, wash it away with water immediately.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of hydraulic system.

lUse flare nut wrench when removing and installing brake tubes.

lAlways torque brake lines when installing.

lBefore working, turn the ignition switch OFF and disconnect the

connectors for the ESP/TCS/ABS actuator and control unit or

the battery terminals.

lBurnish the brake contact surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer toBR-10, "

Brake Burnishing

Procedure".

WAR NIN G:

Clean brakes with a vacuum dust collector to minimize risk

of health hazard from powder caused by friction.

Precautions for Brake ControlEFS0019P

lDuring the EPS/TCS/ABS operation, the brake pedal vibrates lightly and its mechanical noise may be

heard. This is a normal condition.

lJust after starting the vehicle after ignition switch ON, the brake pedal may vibrate or the motor operating

noise may be heard from the engine compartment. This is a normal status of the operation check.

lThe stopping distance may be longer than that of vehicles without ABS when the vehicle drives on rough,

gravel, or snowy (fresh deep snow) road.

lIf a malfunction is indicated by the ABS warning lamp, or other warning lamps, collect the necessary infor-

mation from the customer (what symptoms are present under what conditions) and find out the possible

causes before starting the service. Besides the electrical system inspection, check the booster operation,

brake fluid level, and oil leaks.

lIf the tire size and type are used in a improper combination, or the brake pads are not NISSAN genuine

parts, the stopping distance or steering stability may deteriorate.

lIf there is a radio, antenna, or antenna lead-in wire (including wiring) near the control unit, the ESP/TCS/

ABS function may have a malfunction or error.

lIf aftermarket parts (e.g. Car stereo equipment, CD player) have been installed, check the electrical har-

nesses for pinches, open, and improper wiring.

SBR686C

Page 925 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual GENERAL INFORMATION

BRC-57

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

lWhen starting the engine, or just after starting the vehicle, the brake pedal may vibrate or the

motor operating noise may be heard NISSAN X-TRAIL 2003 Electronic Owners Manual GENERAL INFORMATION

BRC-57

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

lWhen starting the engine, or just after starting the vehicle, the brake pedal may vibrate or the

motor operating noise may be heard](/img/5/57402/w960_57402-924.png)

GENERAL INFORMATION

BRC-57

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

lWhen starting the engine, or just after starting the vehicle, the brake pedal may vibrate or the

motor operating noise may be heard from the engine compartment. This is a normal status of the

operation check.

lThe stopping distance may be longer than that of vehicles without ABS when the vehicle drives on

rough, gravel, or snowy (fresh deep snow) road.

TCS FunctionsEFS0019V

1. With the wheel speed sensor signals from 4 wheels, the ESP/TCS/ABS control unit detects a wheel spin.

If a wheel spins, the control unit controls brake fluid pressure to the spinning wheel, and cuts the fuel to

the engine. It also closes the throttle valve to reduce the engine torque. Furthermore, throttle position is

controlled to the appropriate engine torque.

2. If a wheel spins, the TCS system works same as LSD (Limited Slip Differential) function applying brake

fluid pressure to the spinning wheel.

3. During TCS operation, it informs a driver of system operation by flashing SLIP indicator lamp.

CAUTION:

lDuring TCS operation, the body and the brake pedal lightly vibrate and the mechanical noise may

be heard. This is a normal condition.

lDepending on road circumstances, the driver may have a sluggish feel. This is not abnormal,

because the optimum traction has the highest priority by TCS operation.

lWhen the vehicle is passing through a road where the surface friction coefficient varies, down-

shifting or depressing the accelerator pedal fully may activate TCS temporarily.

ESP FunctionsEFS0019W

1. The Electronic Stability Program is called the ESP for short.

The ESP is indicated as the VDC (the Vehicle Dynamics Control) on the CONSULT-II screen.

2. In addition to the ABS/TCS function, ESP detects the driver's steering operation amount and brake opera-

tion amount from the steering angle sensor and pressure sensor. Using the information from the yaw rate/

side G sensor and wheel speed sensors, ESP judges the driving condition (conditions of understeer and

oversteer) to improve the stability by controlling the brake on 4 wheels and engine output.

3. During ESP operation, the SLIP indicator lamp flashes to inform the driver of the operation.

CAUTION:

lDuring ESP operation, the body and the brake pedal lightly vibrate and their mechanical noise

may be heard. This is a normal condition.

lIf the vehicle is rotated on a turn table, or rolled and rocked on a ship, the ABS warning lamp,

ESP OFF indicator lamp, and SLIP indicator lamp may turn ON. In this case, start the engine on a

normal road again. If the ABS warning lamp, ESP OFF indicator lamp, and SLIP indicator lamp

turn OFF after the restart, it is normal.

lWhen driving in a steep slope such as a bank, the ABS warning lamp, ESP OFF indicator lamp,

and SLIP indicator lamp may turn ON. In this case, start the engine on a normal road again. If the

ABS warning lamp, ESP OFF indicator lamp, and SLIP indicator lamp turn OFF after the restart, it

is normal.

Page 956 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual BRC-88

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

For Correct and Quick Diagnosis

EFS001A8

PRECAUTIONS FOR TROUBLE DIAGNOSIS

lBefore performing the trouble diagnosis, always read theGI-3, "PRECAUTIONS"to confirm NISSAN X-TRAIL 2003 Electronic Owners Manual BRC-88

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

For Correct and Quick Diagnosis

EFS001A8

PRECAUTIONS FOR TROUBLE DIAGNOSIS

lBefore performing the trouble diagnosis, always read theGI-3, "PRECAUTIONS"to confirm](/img/5/57402/w960_57402-955.png)

BRC-88

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

For Correct and Quick Diagnosis

EFS001A8

PRECAUTIONS FOR TROUBLE DIAGNOSIS

lBefore performing the trouble diagnosis, always read theGI-3, "PRECAUTIONS"to confirm the general

precautions.

lAfter replacement of ESP/TCS/ABS control unit, steering angle sensor, steering parts, suspension parts,

or tires, and adjustment of alignment, always adjust the neutral position of steering angle sensor before

driving.

lWhen the ESP/TCS/ABS control unit is replaced, check that the label on the computer unit is identical

color.

lAfter completing the trouble diagnosis, always erase the malfunctioning memory.BRC-77, "Functions of

CONSULT-II"

lWhen inspection of the continuity or voltage between units is performed, check the connector terminals for

disconnection, looseness, bend, or collapse. If any malfunction is detected, repair or replace the applica-

ble part.

lIntermittent problems may be caused by a malfunction on harness, connector, or terminal. Move the har-

nesses, harness connectors, or terminals by hand to make sure that there is no contact malfunction.

lIf a circuit tester is used for the check, be careful not to forcibly extend any connector terminal.

lFor self-diagnosis, active test, and work support of ESP/TCS/ABS control unit with CONSULT-II, stop and

connect CONSULT-II and select²ABS².

lCONSULT-II self-diagnosis results are displayed without regard to occurrence timing. In some case, the

later ones (timing value is small) appear on the next screen.

lWhile the self-diagnosis results of CONSULT-II shows a malfunction, if CONSULT-II active test is per-

formed, an engine system malfunction may be indicated. In this case, start the engine to resume the nor-

mal screen.

lESP/TCS/ABS system electronically controls the brake operation and engine output. The following symp-

toms may be caused by the normal operations.

Symptom Symptom description Result

Motor operation noiseDuring ESP, TCS, or ABS operation, sometimes a faint noise can be

heard. This is a motor operation noise in the ESP/TCS/ABS actuator.

Normal

Just after the engine starts, the motor operating noise may be heard.

This is a normal status of the system operation check.

System operation check

noiseWhen the engine starts, a²click²noise may be heard from the engine

compartment. This is a normal status of the system operation check.Normal

ESP/TCS operation

(SLIP lamp ON)When the vehicle is passing through a road where the surface friction

coefficient varies or the wheel speed changes suddenly by downshifting

or depressing of the accelerator pedal fully, TCS may be activated tem-

porarily.

Normal

Cancel the ESP/TCS

function for the

inspection on a chas-

sis dynamometer. Before the speedometer inspection, turn ESP OFF switch off to cancel

the ESP/TCS function.

When the accelerator pedal is depressed on a chassis dynamometer,

the vehicle speed will not increase. This is not malfunction, because

TCS is activated by the wheel speed difference between front and rear.

The warning lamp may also illuminate to show²sensor system failure²in

this case. This is not malfunction either, because the stationary front

wheels are detected. Restart the engine, and drive the vehicle at 30 km/

h or higher to check that the warning lamp no longer illuminates.

ABS operation (Longer stop-

ping distance)The stopping distance may be longer for the vehicles with ABS when the

vehicle is driver on snowy and rough road. When driving on the road like

that, slow down the speed.Normal

Sluggish feelDepending on road circumstances, the driver may have a sluggish feel.

This is not abnormal, because the optimum traction has the highest pri-

ority (safety first) by TCS operation. Sometimes the driver has a slight

sluggish feel against the substantial accelerator pedal operation.Normal

Page 982 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Manual BRC-114

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

4.WHEEL SPEED SENSOR INSPECTION

Check the wheel speed sensor system.

lSensor mounting inspection

lSensor pick-up inspection for iron chips

lSensor rotor inspect NISSAN X-TRAIL 2003 Electronic Owners Manual BRC-114

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

4.WHEEL SPEED SENSOR INSPECTION

Check the wheel speed sensor system.

lSensor mounting inspection

lSensor pick-up inspection for iron chips

lSensor rotor inspect](/img/5/57402/w960_57402-981.png)

BRC-114

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

4.WHEEL SPEED SENSOR INSPECTION

Check the wheel speed sensor system.

lSensor mounting inspection

lSensor pick-up inspection for iron chips

lSensor rotor inspection (e.g. Number of teeth, damaged teeth)

lSensor connector engagement inspection

Is inspection result OK?

YES >> Normal

NO >> Wheel speed sensor and rotor lines repair

Symptom 4: ABS Does Not Work.EF S0 01 AV

Inspection procedure

1.ABS WARNING LAMP INDICATOR INSPECTION

Check that the ABS warning lamp illuminates.

Does the ABS warning lamp illuminate?

YES >> Perform the self-diagnosis.

NO >> GO TO 2.

2.WHEEL SPEED SENSOR INSPECTION

Check the wheel speed sensor system.

lSensor mounting inspection

lSensor pick-up inspection for iron chips

lSensor rotor inspection (e.g. Number of teeth, damaged teeth)

lSensor connector engagement inspection

Is inspection result OK?

YES >> Normal

NO >> Wheel speed sensor and rotor lines repair

Symptom 5: Pedal Vibration and NoiseEFS001AW

Inspection procedure

1.SYMPTOM CHECK

Check the brake system for pedal vibration or noise at the engine start.

Is inspection result OK?

YES >> Perform the self-diagnosis.

NO >> GO TO 2.

2.SYMPTOM CHECK 2

Check the brake system for pedal vibration or noise when the pedal depressed lightly (just put a foot on).

CAUTION:

Under the following driving conditions, the wheel speed will fluctuates, resulting in ABS activation.

lWhen shifting gears

lHigh speed cornering

lWhenagustofwind

Is inspection result OK?

YES >> GO TO 3.

NO >> Normal

Page 998 of 3066

CL-6

CLUTCH PEDAL

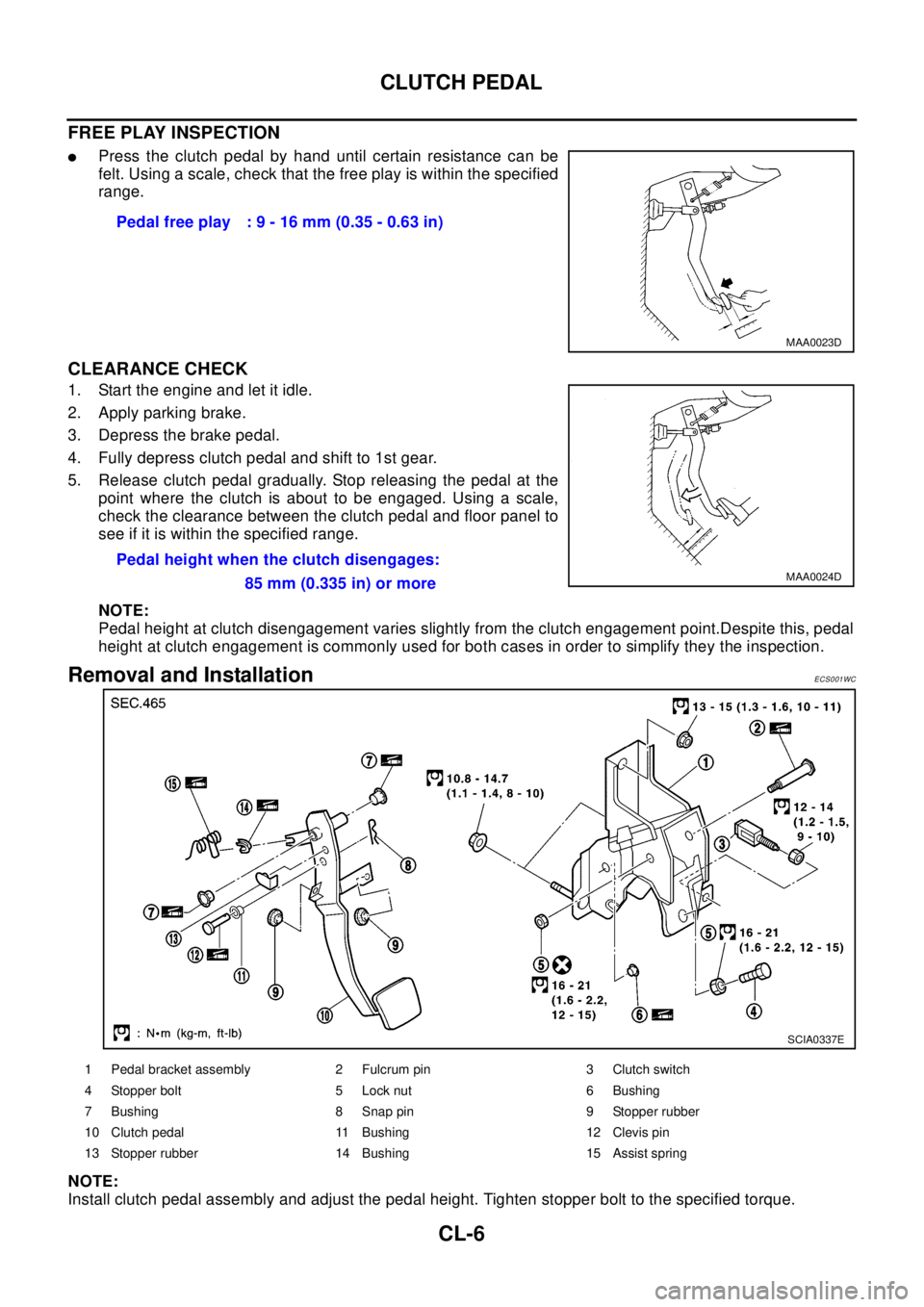

FREE PLAY INSPECTION

lPress the clutch pedal by hand until certain resistance can be

felt. Using a scale, check that the free play is within the specified

range.

CLEARANCE CHECK

1. Start the engine and let it idle.

2. Apply parking brake.

3. Depress the brake pedal.

4. Fully depress clutch pedal and shift to 1st gear.

5. Release clutch pedal gradually. Stop releasing the pedal at the

point where the clutch is about to be engaged. Using a scale,

check the clearance between the clutch pedal and floor panel to

see if it is within the specified range.

NOTE:

Pedal height at clutch disengagement varies slightly from the clutch engagement point.Despite this, pedal

height at clutch engagement is commonly used for both cases in order to simplify they the inspection.

Removal and InstallationECS001WC

NOTE:

Install clutch pedal assembly and adjust the pedal height. Tighten stopper bolt to the specified torque.Pedalfreeplay :9-16mm(0.35-0.63in)

MAA0023D

Pedal height when the clutch disengages:

85 mm (0.335 in) or more

MAA0024D

SCIA0337E

1 Pedal bracket assembly 2 Fulcrum pin 3 Clutch switch

4 Stopper bolt 5 Lock nut 6 Bushing

7 Bushing 8 Snap pin 9 Stopper rubber

10 Clutch pedal 11 Bushing 12 Clevis pin

13 Stopper rubber 14 Bushing 15 Assist spring

Page 1056 of 3066

DI-2

Engine Models) ....................................................... 31

Inspection/Vehicle speed signal ............................. 32

Inspection/Fuel Level Sensor Unit .......................... 33

FUEL LEVEL SENSOR UNIT .............................. 33

LOW-FUEL WARNING LAMP ............................. 33

The Fuel Gauge Pointer Fluctuates·Indicator

Wrong Value·or Varies. ........................................... 35

The Fuel Gauge Does Not Move to F-position. ...... 36

The Fuel Gauge Does Not Work. ........................... 36

Low Fuel Warning Lamp Illuminate or Not Illuminate... 37

Electrical Components Inspection .......................... 37

FUEL LEVEL SENSOR UNIT CHECK / GASO-

LINE ENGINE MODELS ...................................... 37

FUEL LEVEL SENSOR UNIT CHECK / DIESEL

ENGINE MODELS ............................................... 37

THERMAL TRANSMITTER CHECK ................... 38

Removal and Installation for Combination Meter .... 38

Disassembly and Assembly for Combination Meter... 38

WARNING LAMPS .................................................... 39

Schematic ............................................................... 39

Wiring Diagram — WARN —/ LHD Models ............ 40Wiring Diagram — WARN — / RHD Models ...........45

Electrical Components Inspection ...........................50

FUEL WARNING LAMP OPERATION CHECK ... 50

OIL PRESSURE SWITCH CHECK ......................50

DIODE CHECK ....................................................50

A/T INDICATOR .........................................................51

Wiring Diagram — AT/IND — .................................51

WARNING CHIME .....................................................52

System Description .................................................52

POWER SUPPLY AND GROUND CIRCUIT .......52

IGNITION KEY WARNING CHIME ......................52

LIGHT WARNING CHIME ...................................52

Component Parts and Harness Connector Location... 53

Wiring Diagram — CHIME — .................................54

Symptom Chart .......................................................56

Power Supply and Ground Circuit Check ...............56

Lighting Switch Input Signal Check .........................57

Key Switch Insert Signal Check ..............................57

Door Unlock Sensor Check .....................................58

Front Door Switch (driver side) Check ....................59

CLOCK ......................................................................60

Wiring Diagram — CLOCK — .................................60