check engine light NISSAN X-TRAIL 2003 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 292 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide AT-286

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS004VR

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for NISSAN X-TRAIL 2003 Electronic User Guide AT-286

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS004VR

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for](/img/5/57402/w960_57402-291.png)

AT-286

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

TROUBLE DIAGNOSIS — BASIC INSPECTION

PFP:00000

A/T Fluid CheckECS004VR

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for example, mating surface

of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in “D” posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

FLUID CONDITION CHECK

FLUID LEVEL CHECK

Refer to “Checking A/T Fluid”,AT-13, "A/T FLUID".

SAT767B

SAT288G

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination — Road water

entering through filler tube or breather

Varnished fluid, light to dark brown and

tackyOxidation — Over or under filling, —

Overheating

SAT638A

Page 308 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide AT-302

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

5.CHECK LOCK-UP (D4TO D4L/U)

Does A/T perform lock-up at the specified speed?

Read vehicle speed, throttle position when lock-up duty bec NISSAN X-TRAIL 2003 Electronic User Guide AT-302

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

5.CHECK LOCK-UP (D4TO D4L/U)

Does A/T perform lock-up at the specified speed?

Read vehicle speed, throttle position when lock-up duty bec](/img/5/57402/w960_57402-307.png)

AT-302

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

5.CHECK LOCK-UP (D4TO D4L/U)

Does A/T perform lock-up at the specified speed?

Read vehicle speed, throttle position when lock-up duty becomes 94%.

Ye s o r N o

Yes >>GOTO6

No >> Go To "12. A/T Does Not Perform Lock-up”,AT-374, "

12.

A/T Does Not Perform Lock-up".ContinueROAD

TEST.

6.CHECK HOLD LOCK-UP

Does A/T hold lock-up condition for more than 30 seconds?

Ye s o r N o

Yes >>GOTO7

No >> Go To "13. A/T Does Not Hold Lock-up Condition”,AT-375, "

13. A/T Does Not Hold Lock-up Con-

dition".

7.CHECK SHIFT DOWN (D4L/U TO D4)

1. Release accelerator pedal.

2. Is lock-up released when accelerator pedal is released?

Ye s o r N o

Yes >>GOTO8

No >> Go To "14. Lock-up Is Not Released”,AT-376, "

14. Lock-

up Is Not Released". Continue ROAD TEST.

8.CHECK SHIFT DOWN (D4TO D3)

1. Decelerate vehicle by applying foot brake lightly.

2. Does engine speed return to idle smoothly when A/T is shifted from D

4to D3?

Read gear position and engine speed.

Ye s o r N o

Ye s > > 1 . St o p v e h i c l e .

2. Go To “Cruise test — Part 2”,AT-303, "

Cruise Test—

Part 2".

No >> Go To "15. Engine Speed Does Not Return To Idle (Light

Braking D

4®D3)”,AT-377, "15. Engine Speed Does

Not Return To Idle (Light Braking D4®D3)". Continue

ROAD TEST. Specified speed when lock-up occurs:

Refer to Shift schedule, $$$$$.

SAT957I

SAT958I

SAT959I

Page 312 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide AT-306

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

2.CHECK ENGINE BRAKE

Does vehicle decelerate by engine brake?

Ye s o r N o

Yes >>GOTO3

No >> Go To "15. Engine Speed Does Not Return To I NISSAN X-TRAIL 2003 Electronic User Guide AT-306

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

2.CHECK ENGINE BRAKE

Does vehicle decelerate by engine brake?

Ye s o r N o

Yes >>GOTO3

No >> Go To "15. Engine Speed Does Not Return To I](/img/5/57402/w960_57402-311.png)

AT-306

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

2.CHECK ENGINE BRAKE

Does vehicle decelerate by engine brake?

Ye s o r N o

Yes >>GOTO3

No >> Go To "15. Engine Speed Does Not Return To Idle (Light

Braking D

4®D3)”,AT-377, "15. Engine Speed Does

Not Return To Idle (Light Braking D4®D3)". Continue

ROAD TEST.

3.CHECK SHIFT DOWN (D3TO D2)

1. Move selector lever from “D” to “2” position while driving in D

3(O/D OFF).

2. Does A/T shift from D

3(O/D OFF) to 22?

Read gear position.

Ye s o r N o

Yes >>GOTO4

No >> Go To "18. A/T Does Not Shift: D

3®D2, When Selec-

tor Lever “D”®“2” Position”,AT - 3 8 0 , "

18. A/T Does Not

Shift: D3®22, When Selector Lever“D”®“2”Position"

. Continue ROAD TEST.

4.CHECK ENGINE BRAKE

Does vehicle decelerate by engine brake?

Ye s o r N o

Yes >>GOTO5

No >> Go To "15. Engine Speed Does Not Return To Idle (Light

Braking D

4®D3)”,AT-377, "15. Engine Speed Does

Not Return To Idle (Light Braking D4®D3)". Continue

ROAD TEST.

SAT776BA

SAT791GA

SAT791GA

Page 383 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide TROUBLE DIAGNOSES FOR SYMPTOMS

AT-377

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Lock-up is not released when accelerator pedal is released.

1.CHECK THROTTLE POSITION SENSOR* CIRCUIT

*: This sensor me NISSAN X-TRAIL 2003 Electronic User Guide TROUBLE DIAGNOSES FOR SYMPTOMS

AT-377

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Lock-up is not released when accelerator pedal is released.

1.CHECK THROTTLE POSITION SENSOR* CIRCUIT

*: This sensor me](/img/5/57402/w960_57402-382.png)

TROUBLE DIAGNOSES FOR SYMPTOMS

AT-377

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Lock-up is not released when accelerator pedal is released.

1.CHECK THROTTLE POSITION SENSOR* CIRCUIT

*: This sensor means accelerator pedal position (app) senror.

With CONSULT-II

Does “TCM INPUT SIGNALS” in “DATA MONITOR” show damage throttle position sensor circuit?

Without CONSULT-II

Does self-diagnosis show damage to throttle position sensor circuit?

Ye s o r N o

Yes >> Check throttle position sensor circuit. Refer to “21. TCM

Self-diagnosis Does Not Activate (PNP & Overdrive

Control switches, and Throttle Position Sensor )”,AT-

382, "21. TCM Self-diagnosis Does Not Activate (PNP &

Overdrive Control Switches, and Throttle Position Sen-

sor Circuit Checks)".

No >> GOTO2

2.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> 1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

15. Engine Speed Does Not Return To Idle (Light Braking D4®D3)ECS004VG

SYMPTOM:

lEngine speed does not smoothly return to idle when A/T shifts from D4to D3.

lVehicle does not decelerate by engine brake when turning overdrive control switch OFF.

lVehicle does not decelerate by engine brake when shifting A/T from “D” to “2” position.

1.CHECK SELF-DIAGNOSTIC RESULTS

Does self-diagnosis show damage to overrun clutch solenoid valve

circuit after cruise test?

Ye s o r N O

Yes >> Check overrun clutch solenoid valve circuit. Refer toAT-

416, "OVERRUN CLUTCH SOLENOID VALVE"

(Except for Euro-OBD)/AT - 2 0 8 , "DTC P1760 OVERRUN

CLUTCH SOLENOID VALVE"(Euro-OBD).

No >> GOTO2

SAT367J

SCIA0774E

Page 387 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide TROUBLE DIAGNOSES FOR SYMPTOMS

AT-381

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

19.A/TDoesNotShift:22®11, When Selector Lever “2”®“1” PositionECS004VK

SYMPTOM:

A/T does not shift from 2

2to NISSAN X-TRAIL 2003 Electronic User Guide TROUBLE DIAGNOSES FOR SYMPTOMS

AT-381

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

19.A/TDoesNotShift:22®11, When Selector Lever “2”®“1” PositionECS004VK

SYMPTOM:

A/T does not shift from 2

2to](/img/5/57402/w960_57402-386.png)

TROUBLE DIAGNOSES FOR SYMPTOMS

AT-381

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

19.A/TDoesNotShift:22®11, When Selector Lever “2”®“1” PositionECS004VK

SYMPTOM:

A/T does not shift from 2

2to 11when changing selector lever from “2” to “1” position.

1.CHECK PNP SWITCH CIRCUIT

With CONSULT-II

Does “TCM INPUT SIGNALS” in “DATA MONITOR” show damage to PNP switch circuit?

Without CONSULT-II

Does self-diagnosis show damage to PNP switch circuit?

Ye s o r N o

Yes >> Check PNP switch circuit. Refer to “21. TCM Self-diag-

nosis Does Not Activate (PNP & Overdrive Control

switches, and Throttle Position Sensor Circuit Checks)”,

AT-382, "

21. TCM Self-diagnosis Does Not Activate

(PNP & Overdrive Control Switches, and Throttle Posi-

tion Sensor Circuit Checks)".

No >> GOTO2

2.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> 1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose

connection with harness connector.

20. Vehicle Does Not Decelerate By Engine BrakeECS004VL

SYMPTOM:

Vehicle does not decelerate by engine brake when shifting from 2

2(12)to11.

1.CHECK SYMPTOM

Is 6. Vehicle Does Not Creep Backward In “R” Position OK?

Ye s o r N o

Yes >> Go to 15. Engine Speed Does Not Return To Idle (Light Braking D4®D3),AT - 3 7 7 , "15. Engine

Speed Does Not Return To Idle (Light Braking D4®D3)".

No >> Go to 6. Vehicle Does Not Creep Backward In “R” Position,AT-359, "

6. Vehicle Does Not Creep

Backward In“R”Position".

SCIA0706E

SAT778B

Page 466 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide AT-460

[ALL]

REMOVAL AND INSTALLATION

3. Install torque converter to drive plate.

lWith converter installed, rotate crankshaft several turns

to check that transaxle rotates freely without binding.

4. NISSAN X-TRAIL 2003 Electronic User Guide AT-460

[ALL]

REMOVAL AND INSTALLATION

3. Install torque converter to drive plate.

lWith converter installed, rotate crankshaft several turns

to check that transaxle rotates freely without binding.

4.](/img/5/57402/w960_57402-465.png)

AT-460

[ALL]

REMOVAL AND INSTALLATION

3. Install torque converter to drive plate.

lWith converter installed, rotate crankshaft several turns

to check that transaxle rotates freely without binding.

4. Tighten belts fixing transaxle.

5. Reinstall any part removed.

6. Adjust control cable. Refer toAT-456, "

Control Cable Adjust-

ment".

7. Check continuity of PNP switch. Refer toAT-130, "

DTC P0705

PARK/NEUTRAL POSITION (PNP) SWITCH".

8. Refill transaxle with ATF and check fluid level.

9. Move selector lever through all positions to be sure that tran-

saxle operates correctly. With parking brake applied, idle

engine. Move selector lever through “N” to “D”, to “2”, to “1” and

“R” positions. A slight shock should be felt through the hand

gripping the selector each time the transaxle is shifted.

10. Perform road test. Refer toAT-69, "

Road Test".

AAT266A

Bolt No.Tightening torque

N-m (kg-m, ft-lb)Bolt length “ L ”

mm (in)

1

69.6 - 79.4 (7.1 - 8.1, 51.4 - 58.6)49 (1.93)

245(1.77)

3

39.2 - 46.1 (4.0 - 4.7, 29.0 - 34.0)40 (1.57)

430(1.18)

5

30.4 - 40.2 (3.1 - 4.1, 22.4 - 29.7)40 (1.57)

645(1.97)

SCIA0795E

SAT638A

Page 719 of 3066

REFRIGERANT LINES

ATC-141

C

D

E

F

G

H

I

K

L

MA

B

AT C

CAUTION:

Moving the electronic leak detector probe slower and closer to the suspected leak area will improve

the chances of finding a leak.

Checking System for Leaks Using the Fluorescent Leak DetectorEJS000VK

1. Check A/C system for leaks using the UV lamp and safety glasses (J-42220) in a low sunlight area (area

without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a bright

green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain opening indi-

cates an evaporator core assembly (tubes, core or TXV) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner (J-43872) to prevent future misdiag-

nosis.

4. Perform a system performance check and verify the leak repair with an approved electronic refrigerant

leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.

Dye InjectionEJS000VL

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (50 psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool (J-41459).

3. Connect the injector tool to the A/C LOW PRESSURE side service fitting.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool J-41459 (refer to the manufacture's operat-

ing instructions).

6. With the engine still running, disconnect the injector tool from the service fitting.

CAUTION:

Be careful the A/C system or replacing a component, pour the dye directly into the open system con-

nection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak, it may take from minutes to days for the dye to

penetrate a leak and become visible.

Electronic Refrigerant Leak DetectorEJS000VM

PRECAUTIONS FOR HANDLING LEAK DETECTOR

When performing a refrigerant leak check, use an A/C leak detector

or equivalent. Ensure that the instrument is calibrated and set prop-

erly per the operating instructions.

The leak detector is a delicate device. In order to use the leak detec-

tor properly, read the operating instructions and perform any speci-

fied maintenance.

SHA705EB

Page 822 of 3066

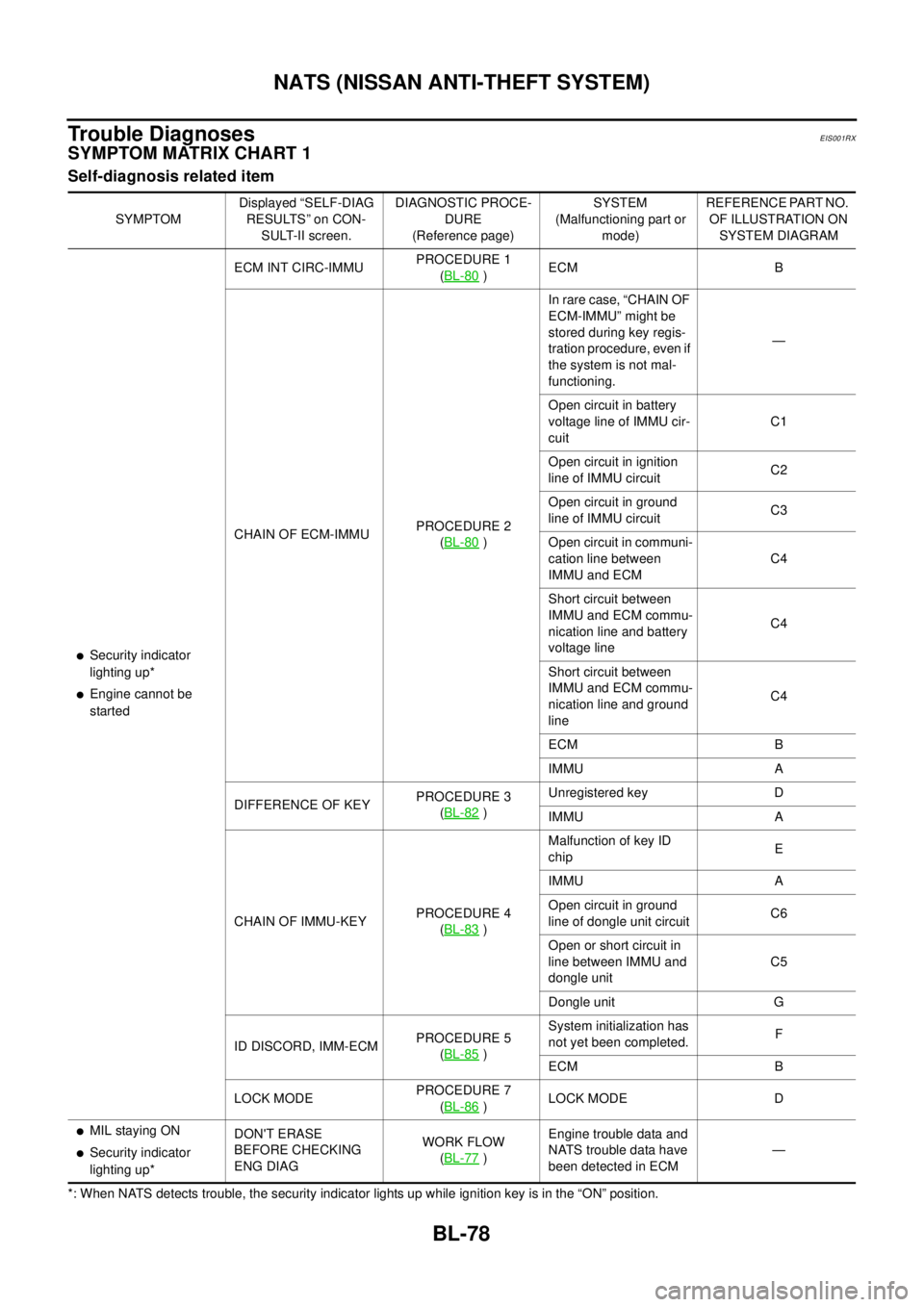

BL-78

NATS (NISSAN ANTI-THEFT SYSTEM)

Trouble Diagnoses

EIS001RX

SYMPTOM MATRIX CHART 1

Self-diagnosis related item

*: When NATS detects trouble, the security indicator lights up while ignition key is in the “ON” position.SYMPTOMDisplayed “SELF-DIAG

RESULTS ” on CON-

SULT-II screen.DIAGNOSTIC PROCE-

DURE

(Reference page)SYSTEM

(Malfunctioning part or

mode)REFERENCE PART NO.

OF ILLUSTRATION ON

SYSTEM DIAGRAM

lSecurity indicator

lighting up*

lEngine cannot be

startedECM INT CIRC-IMMUPROCEDURE 1

(BL-80

)ECM B

CHAIN OF ECM-IMMUPROCEDURE 2

(BL-80

)In rare case, “CHAIN OF

ECM-IMMU” might be

stored during key regis-

tration procedure, even if

the system is not mal-

functioning.—

Open circuit in battery

voltage line of IMMU cir-

cuitC1

Open circuit in ignition

line of IMMU circuitC2

Open circuit in ground

line of IMMU circuitC3

Open circuit in communi-

cation line between

IMMU and ECMC4

Short circuit between

IMMU and ECM commu-

nication line and battery

voltage lineC4

Short circuit between

IMMU and ECM commu-

nication line and ground

lineC4

ECM B

IMMU A

DIFFERENCE OF KEYPROCEDURE 3

(BL-82

)Unregistered key D

IMMU A

CHAIN OF IMMU-KEYPROCEDURE 4

(BL-83

)Malfunction of key ID

chipE

IMMU A

Open circuit in ground

line of dongle unit circuitC6

Open or short circuit in

line between IMMU and

dongle unitC5

Dongle unit G

ID DISCORD, IMM-ECMPROCEDURE 5

(BL-85

)System initialization has

not yet been completed.F

ECM B

LOCK MODEPROCEDURE 7

(BL-86

)LOCK MODE D

lMIL staying ON

lSecurity indicator

lighting up*DON'T ERASE

BEFORE CHECKING

ENG DIAGWORK FLOW

(BL-77)Engine trouble data and

NATS trouble data have

been detected in ECM—

Page 829 of 3066

NATS (NISSAN ANTI-THEFT SYSTEM)

BL-85

C

D

E

F

G

H

J

K

L

MA

B

BL

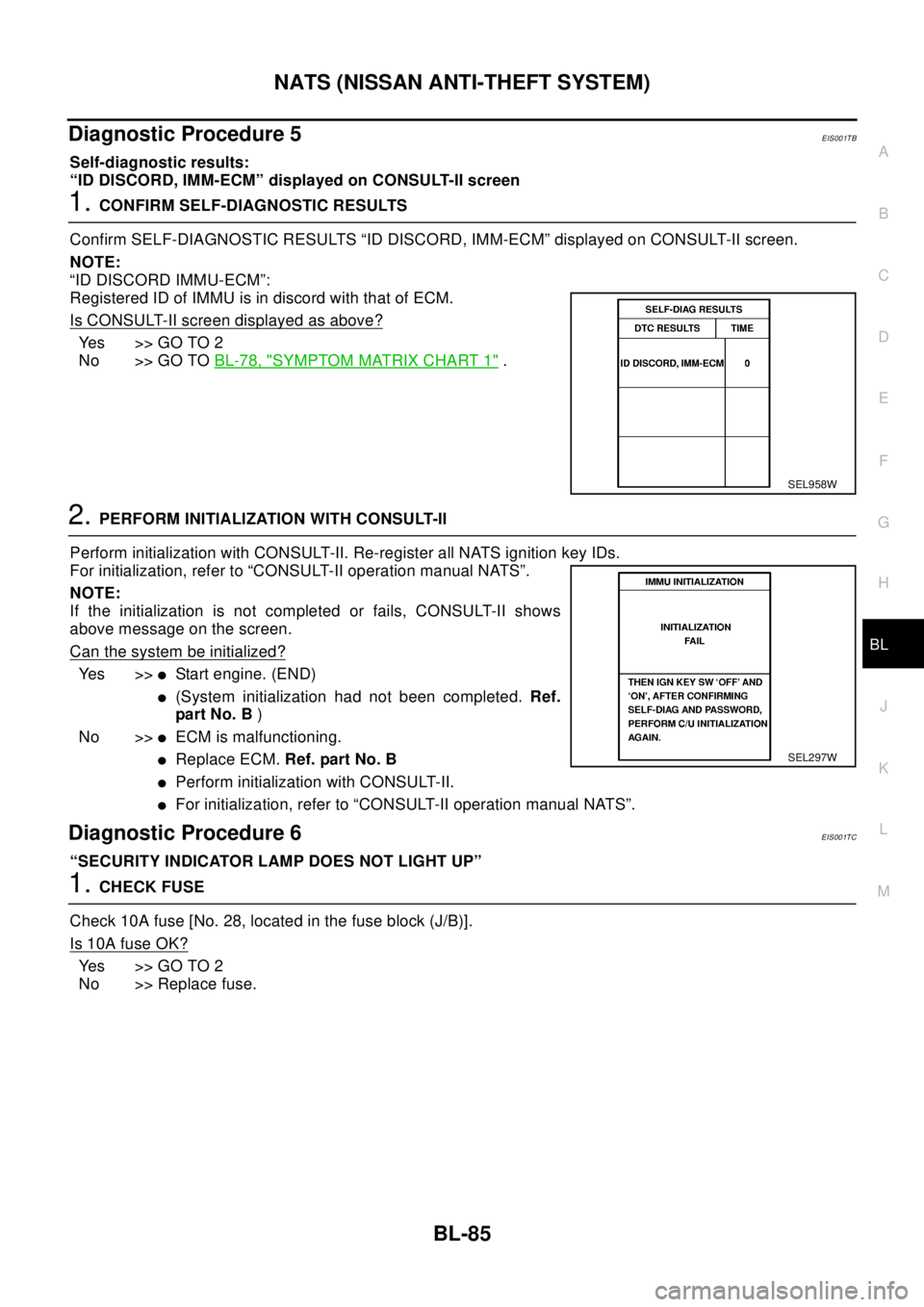

Diagnostic Procedure 5EIS001TB

Self-diagnostic results:

“ID DISCORD, IMM-ECM” displayed on CONSULT-II screen

1.CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS “ID DISCORD, IMM-ECM” displayed on CONSULT-II screen.

NOTE:

“ID DISCORD IMMU-ECM”:

Registered ID of IMMU is in discord with that of ECM.

Is CONSULT-II screen displayed as above?

Yes >>GOTO2

No >> GO TOBL-78, "

SYMPTOM MATRIX CHART 1".

2.PERFORM INITIALIZATION WITH CONSULT-II

Perform initialization with CONSULT-II. Re-register all NATS ignition key IDs.

For initialization, refer to “CONSULT-II operation manual NATS”.

NOTE:

If the initialization is not completed or fails, CONSULT-II shows

above message on the screen.

Can the system be initialized?

Ye s > >lStart engine. (END)

l(System initialization had not been completed.Ref.

pa rt N o. B)

No >>

lECM is malfunctioning.

lReplace ECM.Ref. part No. B

lPerform initialization with CONSULT-II.

lFor initialization, refer to “CONSULT-II operation manual NATS”.

Diagnostic Procedure 6EIS001TC

“SECURITY INDICATOR LAMP DOES NOT LIGHT UP”

1.CHECK FUSE

Check 10A fuse [No. 28, located in the fuse block (J/B)].

Is 10A fuse OK?

Yes >>GOTO2

No >> Replace fuse.

SEL958W

SEL297W

Page 830 of 3066

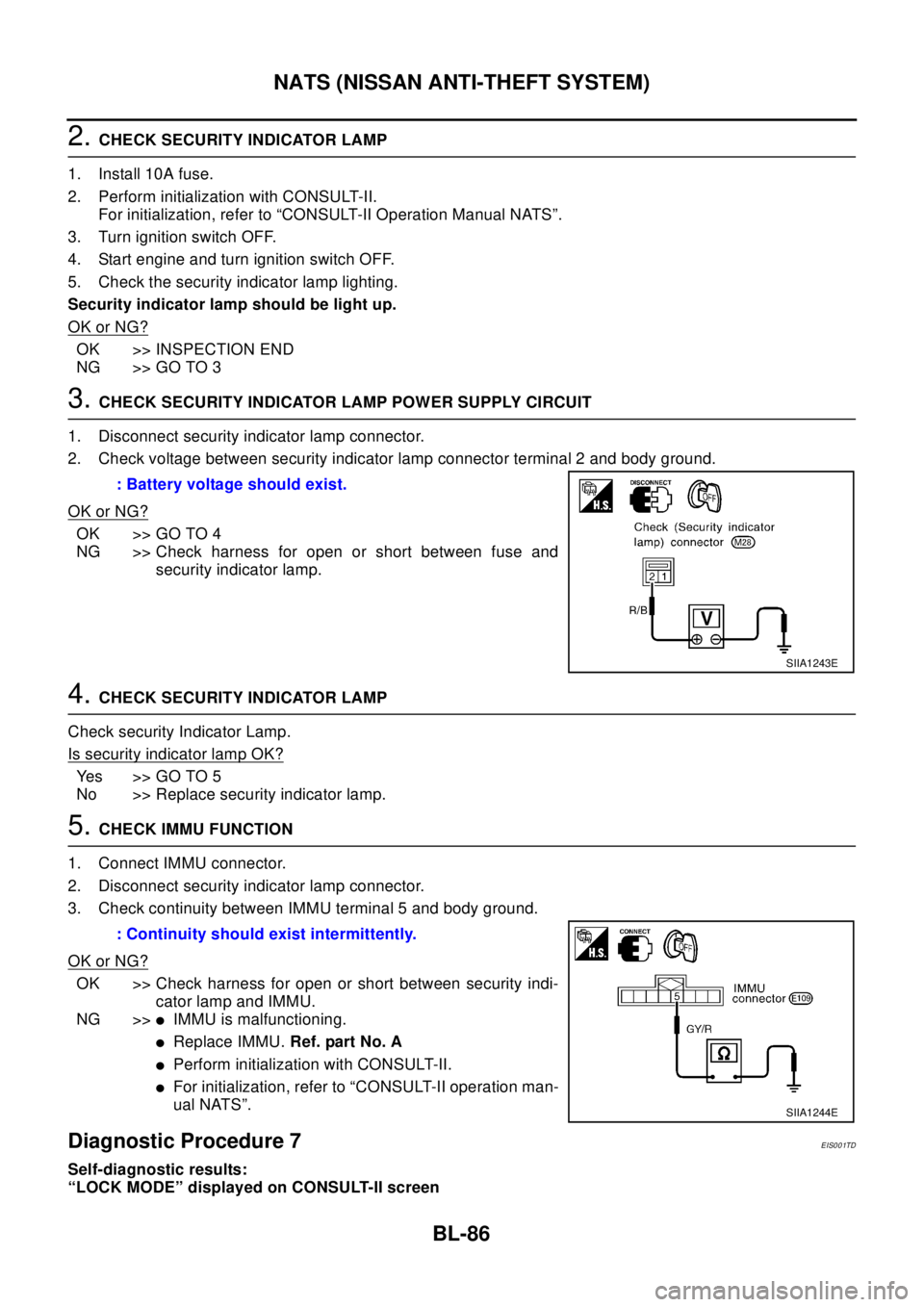

BL-86

NATS (NISSAN ANTI-THEFT SYSTEM)

2.CHECK SECURITY INDICATOR LAMP

1. Install 10A fuse.

2. Perform initialization with CONSULT-II.

For initialization, refer to “CONSULT-II Operation Manual NATS”.

3. Turn ignition switch OFF.

4. Start engine and turn ignition switch OFF.

5. Check the security indicator lamp lighting.

Security indicator lamp should be light up.

OK or NG?

OK >> INSPECTION END

NG >> GO TO 3

3.CHECK SECURITY INDICATOR LAMP POWER SUPPLY CIRCUIT

1. Disconnect security indicator lamp connector.

2. Check voltage between security indicator lamp connector terminal 2 and body ground.

OK or NG?

OK >> GO TO 4

NG >> Check harness for open or short between fuse and

security indicator lamp.

4.CHECK SECURITY INDICATOR LAMP

Check security Indicator Lamp.

Is security indicator lamp OK?

Yes >>GOTO5

No >> Replace security indicator lamp.

5.CHECK IMMU FUNCTION

1. Connect IMMU connector.

2. Disconnect security indicator lamp connector.

3. Check continuity between IMMU terminal 5 and body ground.

OK or NG?

OK >> Check harness for open or short between security indi-

cator lamp and IMMU.

NG >>

lIMMU is malfunctioning.

lReplace IMMU.Ref. part No. A

lPerform initialization with CONSULT-II.

lFor initialization, refer to “CONSULT-II operation man-

ual NATS”.

Diagnostic Procedure 7EIS001TD

Self-diagnostic results:

“LOCK MODE” displayed on CONSULT-II screen: Battery voltage should exist.

SIIA1243E

: Continuity should exist intermittently.

SIIA1244E