dimensions NISSAN X-TRAIL 2003 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2255 of 3066

GI-2

MANUAL TRANSAXLE NUMBER ....................... 46

Dimensions ............................................................. 46

Wheels & Tires ....................................................... 46TERMINOLOGY ........................................................47

SAE J1930 Terminology List ...................................47

Page 2299 of 3066

GI-46

IDENTIFICATION INFORMATION

MANUAL TRANSAXLE NUMBER

DimensionsEAS000GF

Unit: mm(in)

Wheels & TiresEAS000GG

PAIA0010E

Overall length 4,510

Overall width 1,765

Overall height 1,675 (Standard), 1,750 (With Rear spoiler)

Front tread 1,530

Rear tread 1,530

Wheelbase 2,625

Conventional Spare

Road wheel/offset mm (in)15´6JJ Steel/40 (1.57)

16´6.5JJ Steel/Aluminum/40 (1.57)Conventional

Tire size215/70 R15

215/65 R16Conventional

Page 2469 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide PRECAUTIONS

LU-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009SQ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, dis NISSAN X-TRAIL 2003 Electronic Owners Guide PRECAUTIONS

LU-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009SQ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, dis](/img/5/57402/w960_57402-2468.png)

PRECAUTIONS

LU-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009SQ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

lIn areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the areas where the liquid gasket is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

lRemove the liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lighting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

lIf there is a groove for the liquid gasket application, apply the

gasket to the groove.

lAs for the bolt holes, normally apply the gasket inside the holes.

Occasionally, it should be applied outside the holes. Make sure

to read the text of service manual.

lWithin five minutes of gasket application, install the mating com-

ponent.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten after the installation.

lAfter 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe

them.

PBIC0275E

PBIC0003E

EMA0622D

SEM164F

Page 2481 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide PRECAUTIONS

LU-15

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

LU

[YD22DDTi]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS00B00

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts NISSAN X-TRAIL 2003 Electronic Owners Guide PRECAUTIONS

LU-15

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

LU

[YD22DDTi]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS00B00

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts](/img/5/57402/w960_57402-2480.png)

PRECAUTIONS

LU-15

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

LU

[YD22DDTi]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS00B00

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

lIn areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the areas where the liquid gasket is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

lRemove the liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lighting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

lIf there is a groove for the liquid gasket application, apply the

gasket to the groove.

lAs for the bolt holes, normally apply the gasket inside the holes.

Occasionally, it should be applied outside the holes. Make sure

to read the text of service manual.

lWithin five minutes of gasket application, install the mating com-

ponent.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten after the installation.

lAfter 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe

them.

PBIC0275E

PBIC0003E

EMA0622D

SEM159F

Page 2994 of 3066

TF-24

TRANSFER ASSEMBLY

CAUTION:

If a malfunction is detected on the drive gear or drive pinion gear, replace the drive gear and drive pin-

ion gear as a set.

Bearings

lCheck for seizure, peeling, wear, corrosion, sticking/abnormal noise/roughness in hand turning, and other

damage.

CAUTION:

When replacing the bearing, always replace the inner race and outer race as a pair.

Washers and shims

lCheck for seizure, damage, and abnormal wear.

Oil seals

lDiscard old oil seals; replace with new ones.

lIf wear, deterioration of adherence (sealing force of lips), or damage is detected on the lips, replace them.

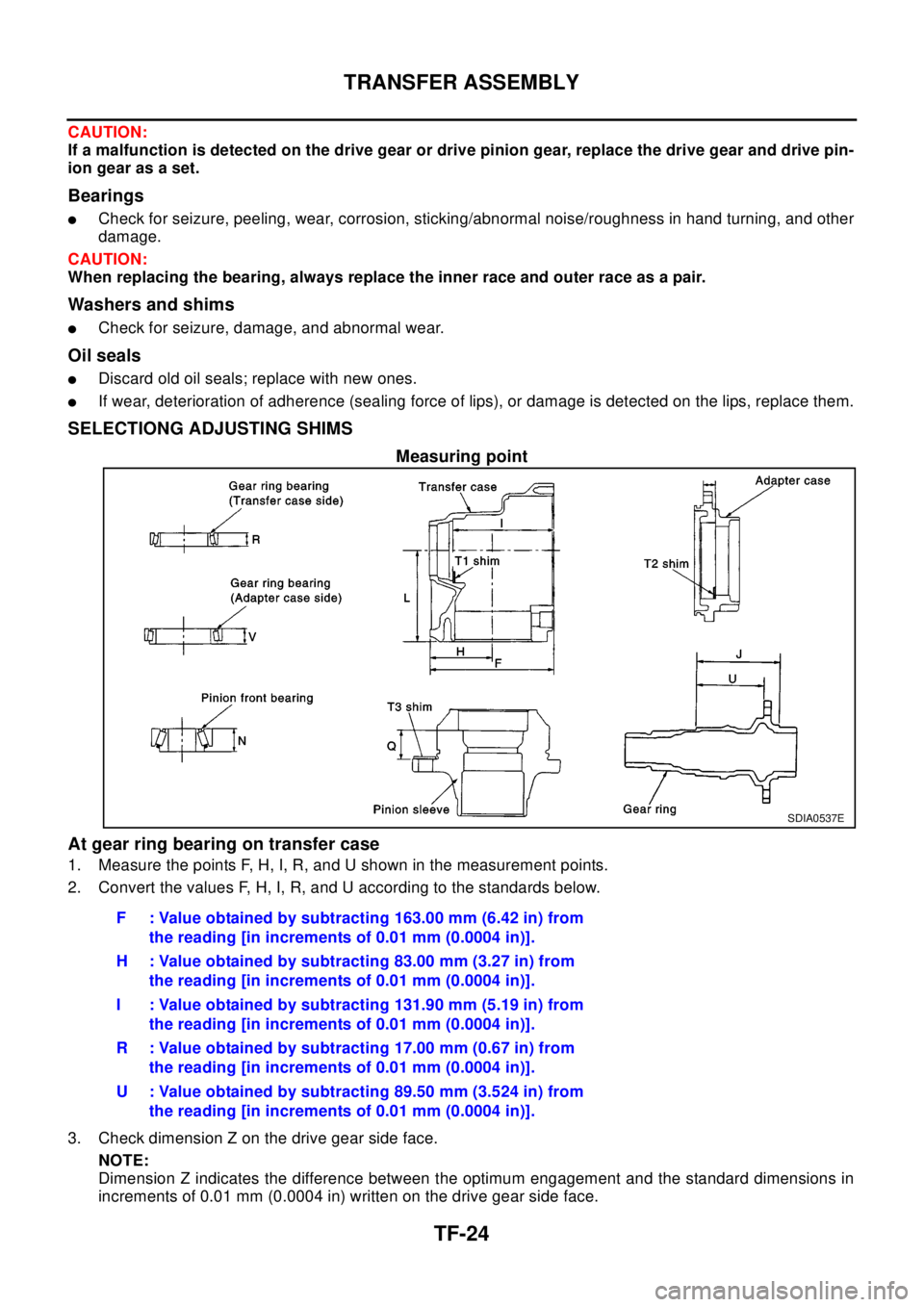

SELECTIONG ADJUSTING SHIMS

Measuring point

At gear ring bearing on transfer case

1. Measure the points F, H, I, R, and U shown in the measurement points.

2. Convert the values F, H, I, R, and U according to the standards below.

3. Check dimension Z on the drive gear side face.

NOTE:

Dimension Z indicates the difference between the optimum engagement and the standard dimensions in

increments of 0.01 mm (0.0004 in) written on the drive gear side face.

SDIA0537E

F : Value obtained by subtracting 163.00 mm (6.42 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

H : Value obtained by subtracting 83.00 mm (3.27 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

I : Value obtained by subtracting 131.90 mm (5.19 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

R : Value obtained by subtracting 17.00 mm (0.67 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

U : Value obtained by subtracting 89.50 mm (3.524 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

Page 2995 of 3066

TRANSFER ASSEMBLY

TF-25

C

E

F

G

H

I

J

K

L

MA

B

TF

4. Use the formula below to calculate adjusting shim thickness T1at the ring gear bearing on the transfer

case.

5. Select the adjusting shim.

lFor information on selecting an adjusting shim, refer toTF-60, "SELECTIVE PARTS".

CAUTION:

lOnly one adjusting shim can be selected.

lIf no adjusting shim with the calculated value is available, select the thicker and closest one.

At the gear bearing on the adapter case

1. Measure the points F, H, J, K, U, and V shown in the measurement points.

2. Convert the values F, H, J, K, U, and V according to the standards below.

3. Check dimension Z on the drive gear side face.

NOTE:

Dimension Z indicates the difference between the optimum engagement and the standard dimensions in

increments of 0.01mm (0.0004 in) written on the drive gear side face.

4. Use the formula below to calculate the thickness of adjusting shim T

2attheringgearbearingonthe

adapter case.

5. Select the adjusting shim.

lFor information on selecting an adjusting shim, refer toTF-60, "SELECTIVE PARTS".

CAUTION:

lOnly one adjusting shim can be selected.

lIf no adjusting shim with the calculated value is available, select the thicker and closest one.

Pinion sleeve shim

1. Measure the points L, N and Q shown in the measurement points.

2. Check the dimension S written on the gear end of the drive pinion gear.

NOTE:

The dimension S indicates the difference between the optimum engagement and the standard dimensions

in increments of 0.01 mm (0.0004 in) written on the gear end of the drive pinion gear.

3. Use the formula below to calculate pinion sleeve shim thickness T

3.

4. Select the pinion sleeve shim.

lFor information on selecting a pinion sleeve shim, refer toTF-60, "SELECTIVE PARTS".

CAUTION:

Only one pinion sleeve shim can be selected.T

1=(I-F+H+Z-U-R)´0.01 mm (0.0004 in) + 1.49 mm (0.0587 in)

F : Value obtained by subtracting 163.00 mm (6.42 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

H : Value obtained by subtracting 83.00 mm (3.27 in) from the

reading [in increments of 0.01 mm (0.0004 in)].

J : Value obtained by subtracting 109.50 mm (4.31 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

K : Value obtained by subtracting 14.40 mm (0.5669 in) from

the reading ([n increments of 0.01 mm (0.0004 in)].

U : Value obtained by subtracting 89.50 mm (3.524 in) from

the reading [in increments of 0.01 mm (0.0004 in)].

V : Value obtained by subtracting 17.00 mm (0.67 in) from the

reading [in increments of 0.01 mm (0.0004 in)].

T

2= (K+F-H-Z+U-J-V)´0.01 mm (0.0004 in) + 1.49 mm (0.0587 in)

T

3= (74.6 mm (2.937 in) + S) +N+Q-L