dimensions NISSAN X-TRAIL 2003 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1972 of 3066

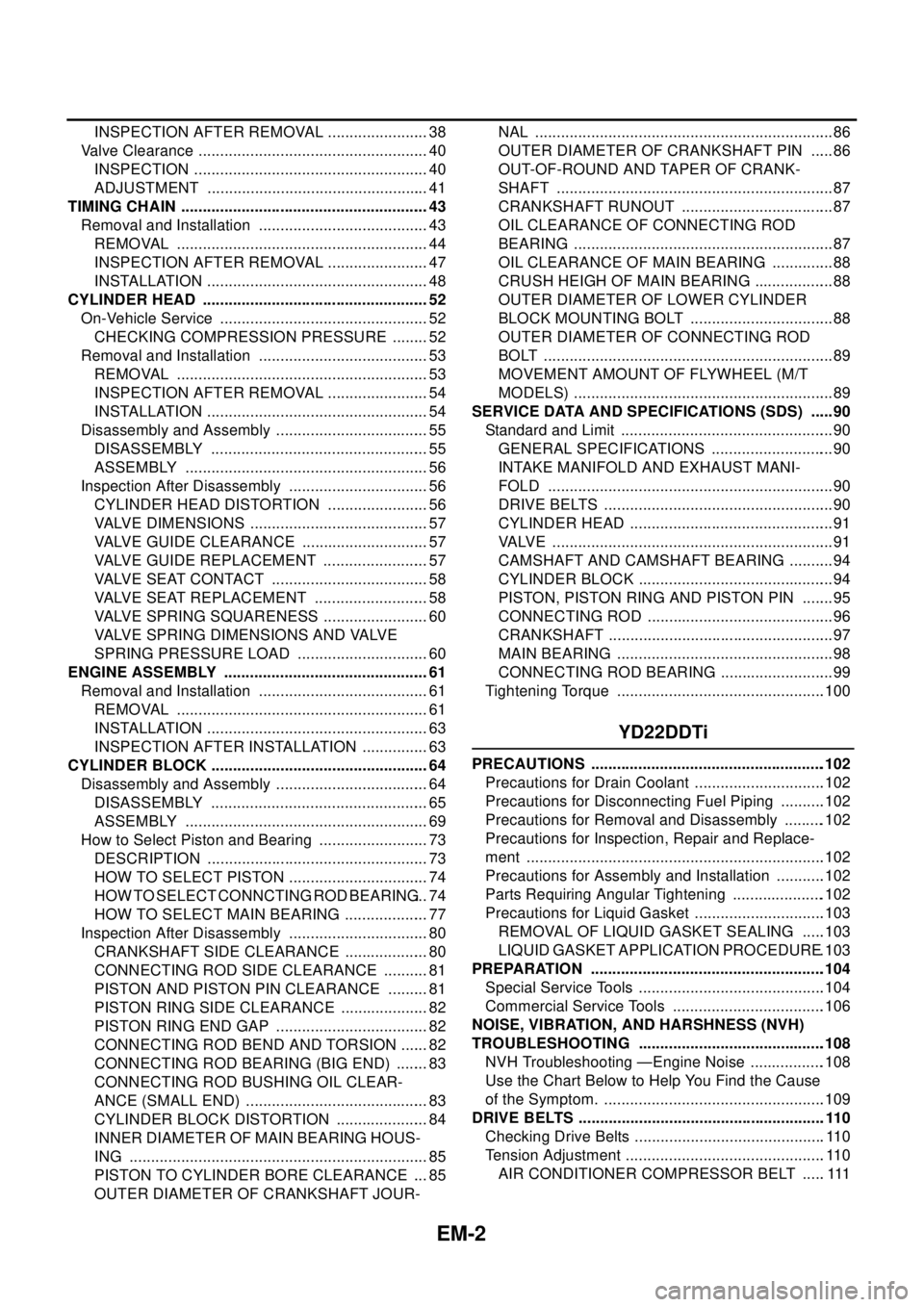

EM-2

INSPECTION AFTER REMOVAL ........................ 38

Valve Clearance ...................................................... 40

INSPECTION ....................................................... 40

ADJUSTMENT .................................................... 41

TIMING CHAIN .......................................................... 43

Removal and Installation ........................................ 43

REMOVAL ........................................................... 44

INSPECTION AFTER REMOVAL ........................ 47

INSTALLATION .................................................... 48

CYLINDER HEAD ..................................................... 52

On-Vehicle Service ................................................. 52

CHECKING COMPRESSION PRESSURE ......... 52

Removal and Installation ........................................ 53

REMOVAL ........................................................... 53

INSPECTION AFTER REMOVAL ........................ 54

INSTALLATION .................................................... 54

Disassembly and Assembly .................................... 55

DISASSEMBLY ................................................... 55

ASSEMBLY ......................................................... 56

Inspection After Disassembly ................................. 56

CYLINDER HEAD DISTORTION ........................ 56

VALVE DIMENSIONS .......................................... 57

VALVE GUIDE CLEARANCE .............................. 57

VALVE GUIDE REPLACEMENT ......................... 57

VALVE SEAT CONTACT ..................................... 58

VALVE SEAT REPLACEMENT ........................... 58

VALVE SPRING SQUARENESS ......................... 60

VALVE SPRING DIMENSIONS AND VALVE

SPRING PRESSURE LOAD ............................... 60

ENGINE ASSEMBLY ................................................ 61

Removal and Installation ........................................ 61

REMOVAL ........................................................... 61

INSTALLATION .................................................... 63

INSPECTION AFTER INSTALLATION ................ 63

CYLINDER BLOCK ................................................... 64

Disassembly and Assembly .................................... 64

DISASSEMBLY ................................................... 65

ASSEMBLY ......................................................... 69

How to Select Piston and Bearing .......................... 73

DESCRIPTION .................................................... 73

HOW TO SELECT PISTON ................................. 74

HOW TO SELECT CONNCTING ROD BEARING... 74

HOW TO SELECT MAIN BEARING .................... 77

Inspection After Disassembly ................................. 80

CRANKSHAFT SIDE CLEARANCE .................... 80

CONNECTING ROD SIDE CLEARANCE ........... 81

PISTON AND PISTON PIN CLEARANCE .......... 81

PISTON RING SIDE CLEARANCE ..................... 82

PISTON RING END GAP .................................... 82

CONNECTING ROD BEND AND TORSION ....... 82

CONNECTING ROD BEARING (BIG END) ........ 83

CONNECTING ROD BUSHING OIL CLEAR-

ANCE (SMALL END) ........................................... 83

CYLINDER BLOCK DISTORTION ...................... 84

INNER DIAMETER OF MAIN BEARING HOUS-

ING ...................................................................... 85

PISTON TO CYLINDER BORE CLEARANCE .... 85

OUTER DIAMETER OF CRANKSHAFT JOUR-NAL ......................................................................86

OUTER DIAMETER OF CRANKSHAFT PIN ......86

OUT-OF-ROUND AND TAPER OF CRANK-

SHAFT .................................................................87

CRANKSHAFT RUNOUT ....................................87

OIL CLEARANCE OF CONNECTING ROD

BEARING .............................................................87

OIL CLEARANCE OF MAIN BEARING ...............88

CRUSH HEIGH OF MAIN BEARING ...................88

OUTER DIAMETER OF LOWER CYLINDER

BLOCK MOUNTING BOLT ..................................88

OUTER DIAMETER OF CONNECTING ROD

BOLT ....................................................................89

MOVEMENT AMOUNT OF FLYWHEEL (M/T

MODELS) .............................................................89

SERVICE DATA AND SPECIFICATIONS (SDS) ......90

Standard and Limit ..................................................90

GENERAL SPECIFICATIONS .............................90

INTAKE MANIFOLD AND EXHAUST MANI-

FOLD ...................................................................90

DRIVE BELTS ......................................................90

CYLINDER HEAD ................................................91

VALVE ..................................................................91

CAMSHAFT AND CAMSHAFT BEARING ...........94

CYLINDER BLOCK ..............................................94

PISTON, PISTON RING AND PISTON PIN ........95

CONNECTING ROD ............................................96

CRANKSHAFT .....................................................97

MAIN BEARING ...................................................98

CONNECTING ROD BEARING ...........................99

Tightening Torque ................................................. 100

YD22DDTi

PRECAUTIONS ....................................................... 102

Precautions for Drain Coolant ............................... 102

Precautions for Disconnecting Fuel Piping ........... 102

Precautions for Removal and Disassembly .......... 102

Precautions for Inspection, Repair and Replace-

ment ...................................................................... 102

Precautions for Assembly and Installation ............ 102

Parts Requiring Angular Tightening ...................... 102

Precautions for Liquid Gasket ............................... 103

REMOVAL OF LIQUID GASKET SEALING ...... 103

LIQUID GASKET APPLICATION PROCEDURE. 103

PREPARATION ....................................................... 104

Special Service Tools ............................................ 104

Commercial Service Tools .................................... 106

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ............................................ 108

NVH Troubleshooting —Engine Noise .................. 108

Use the Chart Below to Help You Find the Cause

of the Symptom. .................................................... 109

DRIVE BELTS ..........................................................110

Checking Drive Belts .............................................110

Tension Adjustment ...............................................110

AIR CONDITIONER COMPRESSOR BELT ...... 111

Page 1976 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide EM-6

[QR20DE]

PRECAUTIONS

Precautions for Liquid Gasket

EBS009QJ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a s NISSAN X-TRAIL 2003 Electronic User Guide EM-6

[QR20DE]

PRECAUTIONS

Precautions for Liquid Gasket

EBS009QJ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a s](/img/5/57402/w960_57402-1975.png)

EM-6

[QR20DE]

PRECAUTIONS

Precautions for Liquid Gasket

EBS009QJ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

lIn areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the areas where the liquid gasket is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

lRemove the liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lighting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

lIf there is a groove for the liquid gasket application, apply the

gasket to the groove.

lAs for the bolt holes, normally apply the gasket inside the holes.

If specified, it should be applied outside the holes. Make sure to

read the text of service manual.

lWithin five minutes of gasket application, install the mating com-

ponent.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten after the installation.

lAfter 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe

them.

PBIC0275E

PBIC0003E

EMA0622D

SEM164F

Page 1979 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide PREPARATION

EM-9

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Tool number

Tool name Description

Quick connector release Removing fuel tube quick connectors in

engine room

(Available in SEC. 164 of PARTS

CATALOG NISSAN X-TRAIL 2003 Electronic User Guide PREPARATION

EM-9

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Tool number

Tool name Description

Quick connector release Removing fuel tube quick connectors in

engine room

(Available in SEC. 164 of PARTS

CATALOG](/img/5/57402/w960_57402-1978.png)

PREPARATION

EM-9

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Tool number

Tool name Description

Quick connector release Removing fuel tube quick connectors in

engine room

(Available in SEC. 164 of PARTS

CATALOG: Part No. 16441 6N210)

Pulley holderCrankshaft pulley removing and installing

a: 68 mm (2.68 in)

b: 8 mm (0.31 in)

Crank pullerCrankshaft pulley removing

Spark plug wrench Removing and installing spark plug

Valve seat cutter set Finishing valve seat dimensions

Piston ring expander Removing and installing piston ring

PBIC0198E

NT628

ZZA0010D

S-NT047

S-NT048

S-NT030

Page 2027 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide CYLINDER HEAD

EM-57

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

VA LV E D I M EN S IO N S

Check dimensions of each valve. For dimensions, refer to SDSEM-

91, "VA LV E"

VALVE GUIDE CLEARANCE

Perform this inspec NISSAN X-TRAIL 2003 Electronic User Guide CYLINDER HEAD

EM-57

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

VA LV E D I M EN S IO N S

Check dimensions of each valve. For dimensions, refer to SDSEM-

91, "VA LV E"

VALVE GUIDE CLEARANCE

Perform this inspec](/img/5/57402/w960_57402-2026.png)

CYLINDER HEAD

EM-57

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

VA LV E D I M EN S IO N S

Check dimensions of each valve. For dimensions, refer to SDSEM-

91, "VA LV E"

VALVE GUIDE CLEARANCE

Perform this inspection before removing valve guide.

1. Make sure that the valve stem diameter is within the specification.

2. Push the valve out by approx. 15 mm (0.59 in) toward the combustion chamber side to measure the

valve's run-out volume (in the direction of dial gauge) with dial gauge.

3. The half of the run-out volume accounts for the valve guide clearance.

VALVE GUIDE REPLACEMENT

When valve guide is removed, replace with oversized (0.2 mm, 0.008 in) valve guide.

1. To remove valve guide, heat cylinder head to 110 to 130°C(230

to 266°F) by soaking in heated oil.

2. Driveoutvalveguidewithapress[undera20kN(2ton,2.2US

ton, 2.0 lmp ton) pressure] or hammer and suitable tool.

SEM188A

Standard

Intake : 0.020 - 0.053 mm (0.0008 - 0.0021 in)

Exhaust : 0.030 - 0.063 mm (0.0012 - 0.0025 in)

PBIC0077E

SEM008A

SEM931C

Page 2028 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide EM-58

[QR20DE]

CYLINDER HEAD

3. Ream cylinder head valve guide hole.

4. Heat cylinder head to 110 to 130°C (230 to 266°F) by soaking in

heated oil.

5. Press valve guide from camshaft side to dimensi NISSAN X-TRAIL 2003 Electronic User Guide EM-58

[QR20DE]

CYLINDER HEAD

3. Ream cylinder head valve guide hole.

4. Heat cylinder head to 110 to 130°C (230 to 266°F) by soaking in

heated oil.

5. Press valve guide from camshaft side to dimensi](/img/5/57402/w960_57402-2027.png)

EM-58

[QR20DE]

CYLINDER HEAD

3. Ream cylinder head valve guide hole.

4. Heat cylinder head to 110 to 130°C (230 to 266°F) by soaking in

heated oil.

5. Press valve guide from camshaft side to dimensions as in illus-

tration.

6. Using valve guide reamer, apply reamer finish to valve guide.

VA LV E S E AT C O N TA C T

lAfter confirming that the dimensions of valve guides and valves

are within specifications, perform this procedure.

lApply prussian blue (or white lead) onto contacting surface of

valve seat to check the condition of the valve contact on the sur-

face.

lCheck if the contact area band is continuous all around the cir-

cumference.

lIf not, grind to adjust valve fitting and check again. If the contact-

ing surface still has N.G conditions even after the re-check,

replace valve seat.

VALVE SEAT REPLACEMENT

When valve seat is removed, replace with oversized (0.5 mm, 0.020 in) valve seat.

1. Bore out old seat until it collapses. Boring should not continue beyond the bottom face of the seat recess

in cylinder head. Set the machine depth stop to ensure this.Valve guide hole diameter (for service parts)

Intake and exhaust

: 10.175 - 10.196 mm (0.4006 - 0.4014 in)

SEM932C

PBIC0078E

Standard

Intake and exhaust : 6.000- 6.018 mm (0.2362- 0.2369

in)

SEM932C

EMA0487D

Page 2029 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide CYLINDER HEAD

EM-59

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

2. Ream cylinder head recess diameter for service valve seat.

lBe sure to ream in circles concentric to the valve guide center.

lThis will enable NISSAN X-TRAIL 2003 Electronic User Guide CYLINDER HEAD

EM-59

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

2. Ream cylinder head recess diameter for service valve seat.

lBe sure to ream in circles concentric to the valve guide center.

lThis will enable](/img/5/57402/w960_57402-2028.png)

CYLINDER HEAD

EM-59

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

2. Ream cylinder head recess diameter for service valve seat.

lBe sure to ream in circles concentric to the valve guide center.

lThis will enable valve seat to fit correctly.

3. Heat cylinder head to 110 to 130°C (230 to 266°F) by soaking in

heated oil.

4. Provide valve seats cooled well with dry ice. Force fit valve seat

into cylinder head.

CAUTION:

Avoid directly to touching cold valve seats.

5. Using valve seat cutter set or valve seat grinder, finish the seat

to the specified dimensions.

CAUTION:

When using valve seat cutter, firmly grip the cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cut in a single drive. Improper

pressure on with the cutter or cutting many different times

may result in stage valve seat.

Grind to obtain the dimensions indicated in figure.

6. Using compound, grind to adjust valve fitting.

7. Check again for normal contact.Oversize [0.5 mm (0.020 in)]

Intake : 37.000 - 37.016 mm (1.4567 - 1.4573 in)

Exhaust : 32.000 - 32.016 mm (1.2598 - 1.2605 in)

SEM795A

SEM008A

SEM934C

Standard

D1 dia. : 33.5 mm (1.3189 in)

D2 dia. : 35.1 - 35.3 mm (1.382 - 1.390 in)

D3 dia. : 39.0 - 39.2 mm (1.535 - 1.543 in)

D4 dia. : 28 mm (1.10 in)

D5 dia. : 29.9 - 30.1 mm (1.177- 1.185 in)

D6 dia. : 33.5 - 33.7mm (1.319 - 1.327 in)

SBIA0226E

Page 2030 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide EM-60

[QR20DE]

CYLINDER HEAD

VALVE SPRING SQUARENESS

Set try square along the side of valve spring and rotate the spring.

Measure the maximum clearance between the top face of spring and

try square.

V NISSAN X-TRAIL 2003 Electronic User Guide EM-60

[QR20DE]

CYLINDER HEAD

VALVE SPRING SQUARENESS

Set try square along the side of valve spring and rotate the spring.

Measure the maximum clearance between the top face of spring and

try square.

V](/img/5/57402/w960_57402-2029.png)

EM-60

[QR20DE]

CYLINDER HEAD

VALVE SPRING SQUARENESS

Set try square along the side of valve spring and rotate the spring.

Measure the maximum clearance between the top face of spring and

try square.

VALVE SPRING DIMENSIONS AND VALVE SPRING PRESSURE LOAD

Check valve spring pressure with valve spring seat installed at spec-

ified spring height.

CAUTION:

Do not remove valve spring seat.Limit : More than 1.9 mm (0.0748 in)

PBIC0080E

Standard: INTAKE EXHAUST

Free height 44.84-45.34 mm

(1.7654-1.7850

in)45.28-45.78 mm

(1.7827-1.8024 in)

Installation

height35.30 mm (1.390

in)35.30 mm (1.390

in)

Installation

load151-175 N (15.4-

17.8 kg, 34-39 lb)151-175 N (15.4-

17.8 kg, 34-39 lb)

Height during

valve open24.94 mm

(0.9819 in)26.39 mm (1.0390

in)

Load with

valve open358-408 N (36.5-

41.6 kg, 80-92 lb)325-371 N (33.1-

37.8 kg, 73-83 lb)

Identification

colorBlue Yellow

SEM113

Page 2045 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide CYLINDER BLOCK

EM-75

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

2. Apply pin diameter grade stamped on crankshaft front side to

the column in the “Connecting Rod Bearing Selection Table”.

3. Read the symb NISSAN X-TRAIL 2003 Electronic User Guide CYLINDER BLOCK

EM-75

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

2. Apply pin diameter grade stamped on crankshaft front side to

the column in the “Connecting Rod Bearing Selection Table”.

3. Read the symb](/img/5/57402/w960_57402-2044.png)

CYLINDER BLOCK

EM-75

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

2. Apply pin diameter grade stamped on crankshaft front side to

the column in the “Connecting Rod Bearing Selection Table”.

3. Read the symbol at the cross point of selected row and column

in the “Connecting Rod Bearing Selection Table”. selective-fit

service parts table.

4. Apply the symbol obtained to connecting rod bearing grade table

to select.

When Crankshaft and Connecting Rod are Reused:

1. Measure dimensions of the big end inner diameter of connecting rod and outer diameter of crankshaft pin

individually.

2. Apply the measured dimension to the “Connecting Rod Bearing Selection Table” selective-fit service

parts table.

3. The following steps are same as in Step 3 or later in “When New Connecting Rod and Crankshaft are

Used”.

KBIA0073E

Page 2057 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide CYLINDER BLOCK

EM-87

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

lUsing a micrometer, measure the dimensions at 4 different

points shown in the figure on each journal and p NISSAN X-TRAIL 2003 Electronic User Guide CYLINDER BLOCK

EM-87

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

lUsing a micrometer, measure the dimensions at 4 different

points shown in the figure on each journal and p](/img/5/57402/w960_57402-2056.png)

CYLINDER BLOCK

EM-87

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

lUsing a micrometer, measure the dimensions at 4 different

points shown in the figure on each journal and pin.

lOut-of-round is indicated by the difference in dimensions

between X and Y at A and B.

lTaper is indicated by the difference in dimension between A and

BatXandY.

CRANKSHAFT RUNOUT

lPlace a V-block on a precise flat table to support the journals on

the both end of the crankshaft.

lPlace a dial gauge straight up on the No. 3 journal.

lWhile rotating the crankshaft, read the movement of the pointer

on the dial gauge. (Total indicator reading)

OIL CLEARANCE OF CONNECTING ROD BEARING

Method of Measurement

lInstall the connecting rod bearings to the connecting rod and the

cap, and tighten the connecting rod bolts to the specified torque.

Using a inside micrometer measure the inner diameter of con-

necting rod bearing.

(Oil clearance) = (Inner diameter of connecting rod bearing) – (Outer

diameter of crankshaft pin)

lIf clearance cannot be adjusted within the standard, grind crank-

shaft pin and use undersized bearing. Refer toEM-74, "

HOW

TO SELECT CONNCTING ROD BEARING".

Method of Using Plastigauge

lRemove oil and dust on the crankshaft pin and the surfaces of

each bearing completely.

lCut a plastigauge slightly shorter than the bearing width, and

place it in crankshaft axial direction, avoiding oil holes.

lInstall the connecting rod bearings to the connecting rod cap,

and tighten the connecting rod bolts to the specified torque.

CAUTION:

Never rotate the crankshaft.

lRemove the connecting rod cap and bearings, and using the

scale on the plastigauge bag, measure the plastigauge width.

NOTE:

The procedure when the measured value exceeds the limit is same as that described in the method by

calculation.Limit:

Out-of-round (X– Y) : 0.005 mm (0.0002in)

Taper (A – B) : 0.005 mm (0.0002in)

PBIC0128E

Limit: : 0.10 mm (0.004 in)

PBIC0271E

Standard : 0.028 - 0.045 mm (0.0011 - 0.0018 in)

Limit : 0.10 mm (0.0039in)

PBIC0119E

EM142

Page 2058 of 3066

![NISSAN X-TRAIL 2003 Electronic User Guide EM-88

[QR20DE]

CYLINDER BLOCK

OIL CLEARANCE OF MAIN BEARING

Method of Measurement

lInstall the main bearings to the cylinder block and bearing cap. Measure the main bearing inner diameter

with the bea NISSAN X-TRAIL 2003 Electronic User Guide EM-88

[QR20DE]

CYLINDER BLOCK

OIL CLEARANCE OF MAIN BEARING

Method of Measurement

lInstall the main bearings to the cylinder block and bearing cap. Measure the main bearing inner diameter

with the bea](/img/5/57402/w960_57402-2057.png)

EM-88

[QR20DE]

CYLINDER BLOCK

OIL CLEARANCE OF MAIN BEARING

Method of Measurement

lInstall the main bearings to the cylinder block and bearing cap. Measure the main bearing inner diameter

with the bearing cap bolt tightened to the specified torque.

(Oil clearance) = (Inner diameter of main bearing) – (Outer diameter of crankshaft journal)

lIf the measured value exceeds the limit, select main bearings referring to the main bearing inner diameter

and crankshaft journal outer diameter, so that the oil clearance satisfies the standard. Refer toEM-77,

"HOW TO SELECT MAIN BEARING".

Method of Using Plastigauge

lRemove oil and dust on the crankshaft journal and the surfaces

of each bearing completely.

lCut a plastigauge slightly shorter than the bearing width, and

place it in crankshaft axial direction, avoiding oil holes.

lTighten the main bearing bolts to the specified torque.

CAUTION:

Never rotate the crankshaft.

lRemove the bearing cap and bearings, and using the scale on

the plastigauge bag, measure the plastigauge width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in “the method by calculation.”

CRUSH HEIGH OF MAIN BEARING

lWhen the bearing cap is removed after being tightened to the

specified torque with main bearings installed, the tip end of bear-

ing must protrude.

lIf the standard is not met, replace main bearings.

OUTER DIAMETER OF LOWER CYLINDER BLOCK MOUNTING BOLT

lPerform only with M10 (0.39 in) bolts.

lMeasure outer diameters (d1, d2) at two positions shown in the figure.

lMeasure d2 at a point within block A.

lWhen the value of d1- d2 exceeds the limit (a large difference in

dimensions), replace the bolt with a new one.Standard:

No. 1, 3 and 5 journals : 0.012 - 0.022 mm (0.0005 - 0.0009 in)

No. 2 and 4 journals : 0.018 - 0.028 mm (0.0007 - 0.0011 in)

Limit :0.1mm (0.004in)

EM142

Standard : There must be crush height

SEM502G

Limit : 0.13 mm (0.0051 in) or more.

PBIC0272E