heating NISSAN X-TRAIL 2003 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1880 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide EC-766

[YD]

DTC P1217 OVERHEAT (COOLING SYSTEM)

6.CHECK THERMOSTAT

1. Remove thermostat.

2. Check valve seating condition at normal room temperatures.

It should seat tightly.

3. Check valve opening te NISSAN X-TRAIL 2003 Electronic Owners Guide EC-766

[YD]

DTC P1217 OVERHEAT (COOLING SYSTEM)

6.CHECK THERMOSTAT

1. Remove thermostat.

2. Check valve seating condition at normal room temperatures.

It should seat tightly.

3. Check valve opening te](/img/5/57402/w960_57402-1879.png)

EC-766

[YD]

DTC P1217 OVERHEAT (COOLING SYSTEM)

6.CHECK THERMOSTAT

1. Remove thermostat.

2. Check valve seating condition at normal room temperatures.

It should seat tightly.

3. Check valve opening temperature and valve lift.

4. Check if valve is closed at 5°C(9°F) below valve opening tem-

perature. For details, refer toCO-42, "

THERMOSTAT AND

WATER PIPING".

OK or NG

OK >> GO TO 7.

NG >> Replace thermostat.

7.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer toEC-714, "

Component Inspection".

OK or NG

OK >> GO TO 8.

NG >> Replace engine coolant temperature sensor.

8.CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go toEC-770, "

Main 12 Causes of Overheating".

>>INSPECTION END

PROCEDURE A

1.CHECK COOLING FAN POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan relay-1.

3. Turn ignition switch “ON”.

4. Check voltage between cooling fan relay-1 terminals 1, 5, 7 and

ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.Valve opening temperature:

80 - 84°C (176 - 183°F) [standard]

Valve lift:

More than 10 mm/95°C (0.339 in/203°F)

SLC343

Voltage: Battery voltage

PBIB0422E

Page 1884 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide EC-770

[YD]

DTC P1217 OVERHEAT (COOLING SYSTEM)

5.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E64, F5

lHarness for open or short between cooling fan relays-2 and -3 and ECM

>> NISSAN X-TRAIL 2003 Electronic Owners Guide EC-770

[YD]

DTC P1217 OVERHEAT (COOLING SYSTEM)

5.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E64, F5

lHarness for open or short between cooling fan relays-2 and -3 and ECM

>>](/img/5/57402/w960_57402-1883.png)

EC-770

[YD]

DTC P1217 OVERHEAT (COOLING SYSTEM)

5.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E64, F5

lHarness for open or short between cooling fan relays-2 and -3 and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK COOLING FAN RELAYS-2 AND -3

Refer toEC-771, "

Component Inspection".

OK or NG

OK >> GO TO 7.

NG >> Replace cooling fan relays.

7.CHECK COOLING FAN MOTORS

Refer toEC-771, "

Component Inspection".

OK or NG

OK >> GO TO 8.

NG >> Replace cooling fan motors.

8.CHECK INTERMITTENT INCIDENT

PerformEC-699, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Main 12 Causes of OverheatingEBS004QY

Engine Step Inspection item Equipment Condition Reference page

OFF 1

lBlocked radiator

lBlocked radiator grille

lBlocked bumper

lVisual No blocking —

2

lCoolant mixturelCoolant tester 50 - 50% coolant mixture SeeMA-17, "RECOM-

MENDED FLUIDS AND

LUBRICANTS".

3

lCoolant levellVisual Coolant up to MAX level

in reservoir tank and radi-

ator filler neckSeeMA-27, "Changing

Engine Coolant".

4

lRadiator caplPressure tester 78 - 98 kPa (0.78 - 0.98

bar, 0.8 - 1.0 kg/cm2,11-

14 psi)SeeCO-34, "

Checking

Radiator Cap".

ON*

25lCoolant leakslVisual No leaks SeeCO-30, "LEAK

CHECK".

ON*

26lThermostatlTouch the upper and

lower radiator hosesBoth hoses should be hot SeeCO-42, "THERMO-

STAT AND WATER PIP-

ING".

ON*

17lCooling fanlCONSULT-II Operating See Trouble Diagnosis for

DTC P1217,EC-713

.

OFF 8

lCombustion gas leaklColor checker chemi-

cal tester 4 Gas ana-

lyzerNegative —

Page 1885 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide DTC P1217 OVERHEAT (COOLING SYSTEM)

EC-771

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes NISSAN X-TRAIL 2003 Electronic Owners Guide DTC P1217 OVERHEAT (COOLING SYSTEM)

EC-771

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes](/img/5/57402/w960_57402-1884.png)

DTC P1217 OVERHEAT (COOLING SYSTEM)

EC-771

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer toCO-26, "

OVERHEATING CAUSE ANALYSIS".

Component InspectionEBS004QZ

COOLING FAN RELAY-1, -2 AND -3

Check continuity between terminals 3 and 5, 6 and 7 under the fol-

lowing conditions.

COOLING FAN MOTOR-1 AND -2

Supply battery voltage between the following terminals and check

operation.

ON*39lCoolant temperature

gaugelVisual Gauge less than 3/4

when driving—

lCoolant overflow to

reservoir tanklVisual No overflow during driv-

ing and idlingSeeMA-27, "Changing

Engine Coolant".

OFF*

410lCoolant return from

reservoir tank to radia-

torlVisual Should be initial level in

reservoir tankSeeMA-28, "REFILLING

ENGINE COOLANT".

OFF 11

lCylinder headlStraight gauge feeler

gauge0.1mm (0.004 in) Maxi-

mum distortion (warping)SeeEM-173, "CYLIN-

DER HEAD".

12

lCylinder block and pis-

tonslVisual No scuffing on cylinder

walls or pistonSeeEM-188, "CYLIN-

DER BLOCK". Engine Step Inspection item Equipment Condition Reference page

Conditions Continuity

12V direct current supply between ter-

minals 1 and 2Ye s

No current supply No

SEF745U

SpeedTe r m i n a l s

(+) (–)

Cooling fan motor-1Low 1 4

High 1, 2 3, 4

Cooling fan motor-2Low 1 4

High 1, 2 3, 4

PBIB0423E

Page 1910 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide EC-796

[YD]

GLOW CONTROL SYSTEM

GLOW CONTROL SYSTEM

PFP:25230

DescriptionEBS0035J

SYSTEM DESCRIPTION

When engine coolant temperature is more than approximately 80°C (176°F), the glow relay turns off NISSAN X-TRAIL 2003 Electronic Owners Guide EC-796

[YD]

GLOW CONTROL SYSTEM

GLOW CONTROL SYSTEM

PFP:25230

DescriptionEBS0035J

SYSTEM DESCRIPTION

When engine coolant temperature is more than approximately 80°C (176°F), the glow relay turns off](/img/5/57402/w960_57402-1909.png)

EC-796

[YD]

GLOW CONTROL SYSTEM

GLOW CONTROL SYSTEM

PFP:25230

DescriptionEBS0035J

SYSTEM DESCRIPTION

When engine coolant temperature is more than approximately 80°C (176°F), the glow relay turns off.

When coolant temperature is lower than approximately 80°C (176°F):

lIgnition switch ON

After ignition switch has turned to ON, the glow relay turns ON for a certain period of time in relation to

engine coolant temperature, allowing current to flow through glow plug.

lCranking

The glow relay turns ON, allowing current to flow through glow plug.

lSta rting

After engine has started, current continues to flow through glow plug (after-glow mode) for a certain period

in relation to engine coolant temperature.

The glow indicator lamp turns ON for a certain period of time in relation to engine coolant temperature at the

time glow relay is turned ON.

COMPONENT DESCRIPTION

Glow Plug

The glow plug is provided with a ceramic heating element to obtain a

high-temperature resistance. It glows in response to a signal sent

from the ECM, allowing current to flow through the glow plug via the

glow relay.

ECM Terminals and Reference ValueEBS0035K

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (TDC) Engine speed

Glow controlGlow lamp

Glow relay

Glow plugs Engine coolant temperature sensor Engine coolant temperature

SEF376Y

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

D2 OR Glow lamp[Ignition switch “ON”]

lGlow lamp is "ON"Approximately 1.0V

[Ignition switch “ON”]

lGlow lamp is "OFF"BATTERY VOLTAGE

(11 - 14V)

E9 W/R Glow relay Refer toEC-796, "

SYSTEM DESCRIPTION"

Page 1916 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide EC-802

[YD]

GLOW CONTROL SYSTEM

17.CHECK INTERMITTENT INCIDENT

Refer toEC-699, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Component InspectionEBS003PM

GLOW RELAY

Check continuity NISSAN X-TRAIL 2003 Electronic Owners Guide EC-802

[YD]

GLOW CONTROL SYSTEM

17.CHECK INTERMITTENT INCIDENT

Refer toEC-699, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Component InspectionEBS003PM

GLOW RELAY

Check continuity](/img/5/57402/w960_57402-1915.png)

EC-802

[YD]

GLOW CONTROL SYSTEM

17.CHECK INTERMITTENT INCIDENT

Refer toEC-699, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Component InspectionEBS003PM

GLOW RELAY

Check continuity between glow relay terminals 3 and 5 under the fol-

lowing conditions.

Operation takes less than 1 second.

GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

NOTE:

lDo not bump glow plug heating element. If it is bumped,

replace glow plug with a new one.

lIf glow plug is dropped from a height of 10 cm (3.94 in) or

higher, replace with a new one.

lIf glow plug installation hole is contaminated with car-

bon, remove it with a reamer or suitable tool.

lHand-tighten glow plug by turning it two or three times,

then tighten using a tool to specified torque.

Removal and InstallationEBS008ZE

GLOW PLUG

Refer toEM-130, "GLOW PLUG".

Conditions Continuity

12V direct current supply between ter-

minals 1 and 2Ye s

No current supply No

PBIB0428E

Resistance: Approximately 0.8W[at 25°C(77°F)]

: 17.7 - 22.5 N-m (1.8 - 2.3 kg-m, 13 - 16 ft-lb)

PBIB0429E

Page 1976 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide EM-6

[QR20DE]

PRECAUTIONS

Precautions for Liquid Gasket

EBS009QJ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a s NISSAN X-TRAIL 2003 Electronic Owners Guide EM-6

[QR20DE]

PRECAUTIONS

Precautions for Liquid Gasket

EBS009QJ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a s](/img/5/57402/w960_57402-1975.png)

EM-6

[QR20DE]

PRECAUTIONS

Precautions for Liquid Gasket

EBS009QJ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

lIn areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the areas where the liquid gasket is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

lRemove the liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lighting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

lIf there is a groove for the liquid gasket application, apply the

gasket to the groove.

lAs for the bolt holes, normally apply the gasket inside the holes.

If specified, it should be applied outside the holes. Make sure to

read the text of service manual.

lWithin five minutes of gasket application, install the mating com-

ponent.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten after the installation.

lAfter 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe

them.

PBIC0275E

PBIC0003E

EMA0622D

SEM164F

Page 2073 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide PRECAUTIONS

EM-103

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Precautions for Liquid GasketEBS00BNU

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the li NISSAN X-TRAIL 2003 Electronic Owners Guide PRECAUTIONS

EM-103

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Precautions for Liquid GasketEBS00BNU

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the li](/img/5/57402/w960_57402-2072.png)

PRECAUTIONS

EM-103

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Precautions for Liquid GasketEBS00BNU

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

lIn areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the areas where the liquid gasket is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

lRemove the liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lighting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

lIf there is a groove for the liquid gasket application, apply the

gasket to the groove.

lAs for the bolt holes, normally apply the gasket inside the holes.

Occasionally, it should be applied outside the holes. Make sure

to read the text of service manual.

lWithin five minutes of gasket application, install the mating com-

ponent.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten after the installation.

lAfter 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe

them.

PBIC0275E

PBIC0003E

EMA0622D

SEM159F

Page 2279 of 3066

GI-26

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

UNDER SEATING AREAS

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under seating areas, inspect wire routing for possible damage or

pinching.

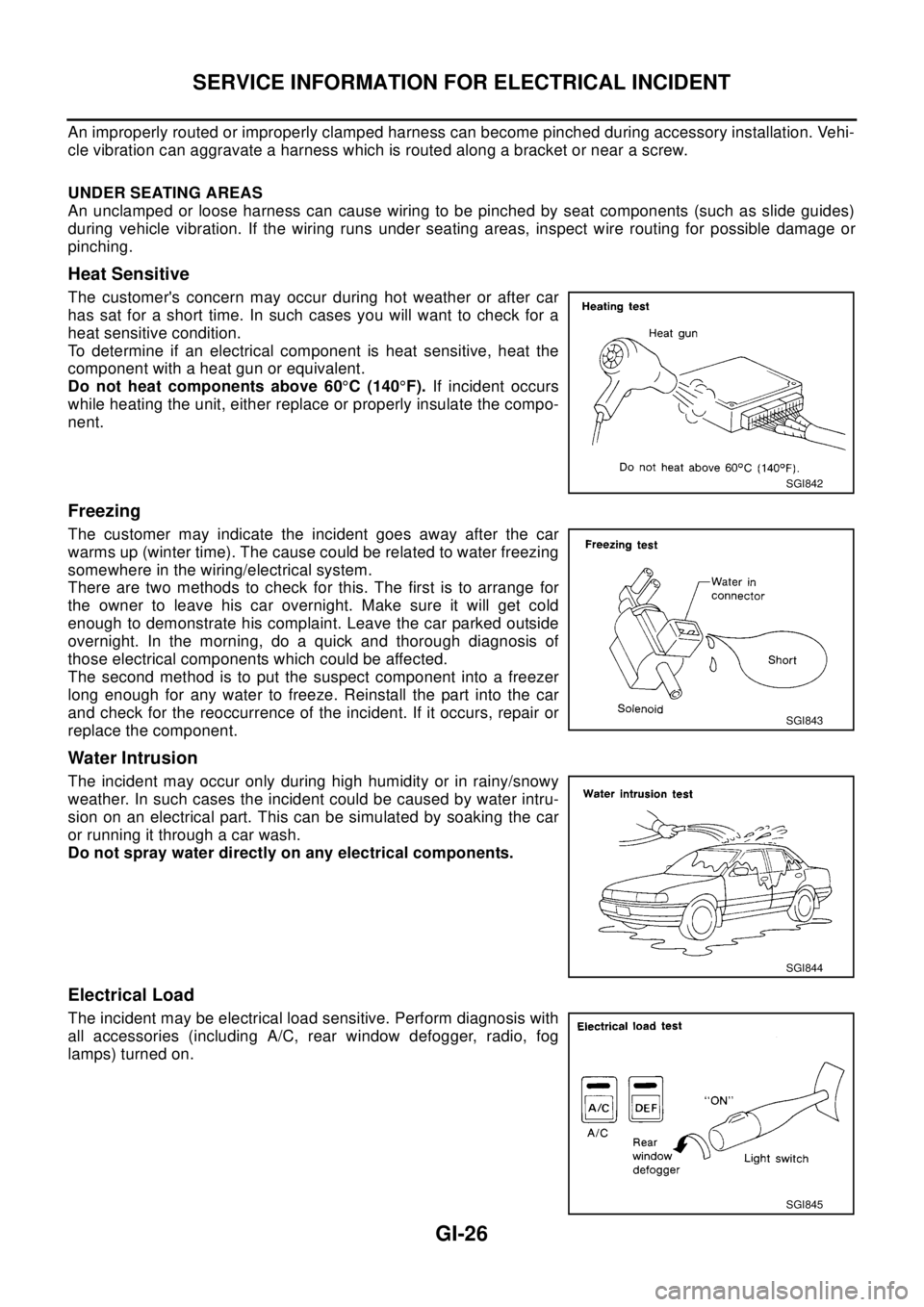

Heat Sensitive

The customer's concern may occur during hot weather or after car

has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60°C (140°F).If incident occurs

while heating the unit, either replace or properly insulate the compo-

nent.

Freezing

The customer may indicate the incident goes away after the car

warms up (winter time). The cause could be related to water freezing

somewhere in the wiring/electrical system.

There are two methods to check for this. The first is to arrange for

the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked outside

overnight. In the morning, do a quick and thorough diagnosis of

those electrical components which could be affected.

The second method is to put the suspect component into a freezer

long enough for any water to freeze. Reinstall the part into the car

and check for the reoccurrence of the incident. If it occurs, repair or

replace the component.

Water Intrusion

The incident may occur only during high humidity or in rainy/snowy

weather. In such cases the incident could be caused by water intru-

sion on an electrical part. This can be simulated by soaking the car

or running it through a car wash.

Do not spray water directly on any electrical components.

Electrical Load

The incident may be electrical load sensitive. Perform diagnosis with

all accessories (including A/C, rear window defogger, radio, fog

lamps) turned on.

SGI842

SGI843

SGI844

SGI845

Page 2349 of 3066

GW-46

DOOR MIRROR

DOOR MIRROR

PFP:96301

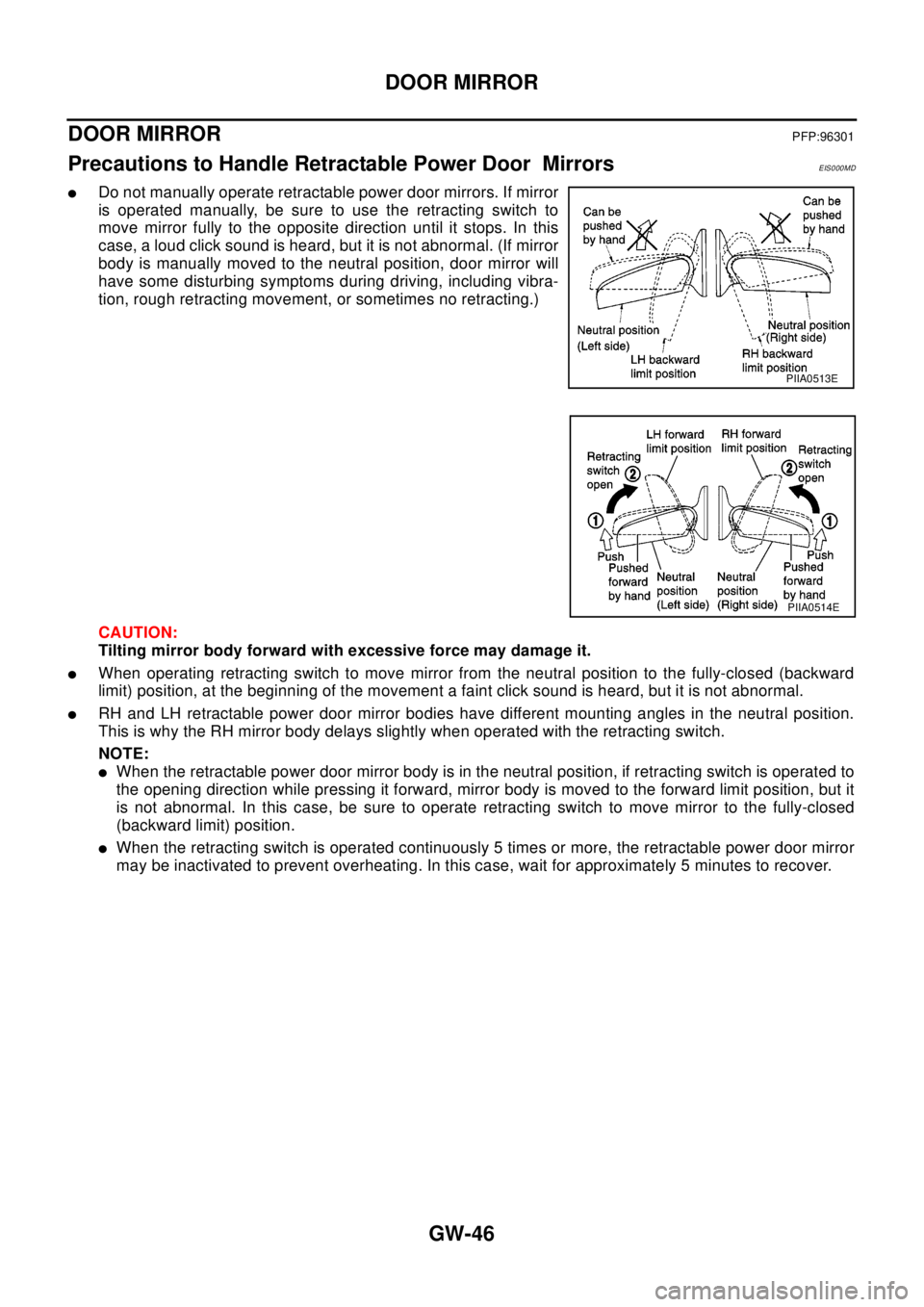

Precautions to Handle Retractable Power Door MirrorsEIS000MD

lDo not manually operate retractable power door mirrors. If mirror

is operated manually, be sure to use the retracting switch to

move mirror fully to the opposite direction until it stops. In this

case, a loud click sound is heard, but it is not abnormal. (If mirror

body is manually moved to the neutral position, door mirror will

have some disturbing symptoms during driving, including vibra-

tion, rough retracting movement, or sometimes no retracting.)

CAUTION:

Tilting mirror body forward with excessive force may damage it.

lWhen operating retracting switch to move mirror from the neutral position to the fully-closed (backward

limit) position, at the beginning of the movement a faint click sound is heard, but it is not abnormal.

lRH and LH retractable power door mirror bodies have different mounting angles in the neutral position.

This is why the RH mirror body delays slightly when operated with the retracting switch.

NOTE:

lWhen the retractable power door mirror body is in the neutral position, if retracting switch is operated to

the opening direction while pressing it forward, mirror body is moved to the forward limit position, but it

is not abnormal. In this case, be sure to operate retracting switch to move mirror to the fully-closed

(backward limit) position.

lWhen the retracting switch is operated continuously 5 times or more, the retractable power door mirror

may be inactivated to prevent overheating. In this case, wait for approximately 5 minutes to recover.

PIIA0513E

PIIA0514E

Page 2469 of 3066

![NISSAN X-TRAIL 2003 Electronic Owners Guide PRECAUTIONS

LU-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009SQ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, dis NISSAN X-TRAIL 2003 Electronic Owners Guide PRECAUTIONS

LU-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009SQ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, dis](/img/5/57402/w960_57402-2468.png)

PRECAUTIONS

LU-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009SQ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

lIn areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the areas where the liquid gasket is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

lRemove the liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lighting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

lIf there is a groove for the liquid gasket application, apply the

gasket to the groove.

lAs for the bolt holes, normally apply the gasket inside the holes.

Occasionally, it should be applied outside the holes. Make sure

to read the text of service manual.

lWithin five minutes of gasket application, install the mating com-

ponent.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten after the installation.

lAfter 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe

them.

PBIC0275E

PBIC0003E

EMA0622D

SEM164F