dimensions NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 463 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ON-VEHICLE SERVICE

AT-457

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

Differential Side Oil Seal ReplacementECS0040F

1. Remove left side drive shaft assemblies. Refer toFAX-11,

"FRONT DRIVE SHAFT".

2. Remove tran NISSAN X-TRAIL 2003 Electronic Repair Manual ON-VEHICLE SERVICE

AT-457

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

Differential Side Oil Seal ReplacementECS0040F

1. Remove left side drive shaft assemblies. Refer toFAX-11,

"FRONT DRIVE SHAFT".

2. Remove tran](/img/5/57402/w960_57402-462.png)

ON-VEHICLE SERVICE

AT-457

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

Differential Side Oil Seal ReplacementECS0040F

1. Remove left side drive shaft assemblies. Refer toFAX-11,

"FRONT DRIVE SHAFT".

2. Remove transfer from right side of transaxle.

Refer toTF-12, "

TRANSFER ASSEMBLY", then remove

oilseals with tool.

3. Install oil seals.

lApply ATF to oil seal surface before installing.

lDrift for installing

lInstall oil seals so that dimensions “A” and “B” are within

specifications.

Unit: mm (in)

4. Reinstall any part removed.

Revolution Sensor ReplacementECS0040G

1. Disconnect revolution sensor harness connector.

2. Remove harness bracket from A/T.

3. Remove revolution sensor from A/T.

4. Reinstall any part removed.

Always use new sealing parts.

SCIA0790E

Transaxle case side :ST3340 0001

converter housing side :KV4010 0621

SCIA0788E

AB

-0.5 to 0.5 (-0.020 to 0.020)-0.5to0.5(-0.020 to 0.020)

SCIA0791E

SCIA0792E

Page 548 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-542

[ALL]

ASSEMBLY

9. Remove converter housing from transmission case.

10. Remove final drive assembly from transmission case.

11. Remove differential side bearing outer race from transmission

case NISSAN X-TRAIL 2003 Electronic Repair Manual AT-542

[ALL]

ASSEMBLY

9. Remove converter housing from transmission case.

10. Remove final drive assembly from transmission case.

11. Remove differential side bearing outer race from transmission

case](/img/5/57402/w960_57402-547.png)

AT-542

[ALL]

ASSEMBLY

9. Remove converter housing from transmission case.

10. Remove final drive assembly from transmission case.

11. Remove differential side bearing outer race from transmission

case.

12. Reinstall differential side bearing outer race and shim(s)

selected from SDS table on transmission case.

13. Reinstall converter housing on transmission case and tighten

transmission case fixing bolts to the specified torque. Refer to

AT-461, "

OVERHAUL".

14. Insert Tool and measure turning torque of final drive assembly.

lTurn final drive assembly in both directions several times

to seat bearing rollers correctly.

lWhen old bearing is used again, turning torque will be

slightly less than the above.

lMake sure torque is close to the specified range.

REDUCTION PINION GEAR BEARING PRELOAD

1. Remove transmission case and final drive assembly from con-

verter housing.

2. Select proper thickness of reduction pinion gear bearing adjust-

ing shim using the following procedures.

a. Place reduction pinion gear on transmission case as shown.

b. Place idler gear bearing on transmission case.

c. Measure dimensions “B” “C” and “D” and calculate dimension

“A”.

SAT010FC

Turning torque of final drive assembly (New bearing) :

0.78 - 1.37 N-m (8.0 - 14.0 kg-cm, 6.9 - 12.2 in-lb)

Preload adapter : KV38105210

SAT188FA

SAT332DA

A=D-(B + C)

“A” : Distance between the surface of idler gear bear-

ing inner race and the adjusting shim mating

surface of reduction pinion gear.

SAT333DA

Page 552 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-546

[ALL]

ASSEMBLY

4. Measure dimensions “1” and “2” at side cover and then cal-

culate dimension “A”.

lMeasure dimension “1”and“2” in at least two places.

5. Measure dimensions NISSAN X-TRAIL 2003 Electronic Repair Manual AT-546

[ALL]

ASSEMBLY

4. Measure dimensions “1” and “2” at side cover and then cal-

culate dimension “A”.

lMeasure dimension “1”and“2” in at least two places.

5. Measure dimensions](/img/5/57402/w960_57402-551.png)

AT-546

[ALL]

ASSEMBLY

4. Measure dimensions “1” and “2” at side cover and then cal-

culate dimension “A”.

lMeasure dimension “1”and“2” in at least two places.

5. Measure dimensions “

2”and“3” and then calculate dimen-

sion “B”.

lMeasure “2”and“3” in at least two places.

6. Select proper thickness of adjusting shim so that output shaft

end play (clearance between side cover and output shaft bear-

ing) is within specifications.

7. Install adjusting shim on output shaft bearing.

Assembly (2)ECS004MF

1. Apply locking sealant (Loctite #518) to transmission case as

shown in illustration.“A” : Distance between transmission case fitting

surface and adjusting shim mating surface.

A=

1-2

2

:Height of gauge

SAT374F

“B” : Distance between the end of output shaft bear-

ing outer race and the side cover fitting surface

of transmission case.

B=

2-3

2

:Height of gauge

SAT375F

Output shaft end play (A-B) :

0 - 0.15 mm (0 - 0.0059 in)

Output shaft end play adjusting shims :

Refer toAT-563, "

SERVICE DATA AND SPECIFICA-

TIONS (SDS)".

SAT440D

SAT441D

Page 559 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ASSEMBLY

AT-553

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

Adjustment (2)ECS0 04 MG

When any parts listed below are replaced, adjust total end play and reverse clutch end play.

TOTAL END PLAY

lMeasure clearance NISSAN X-TRAIL 2003 Electronic Repair Manual ASSEMBLY

AT-553

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

Adjustment (2)ECS0 04 MG

When any parts listed below are replaced, adjust total end play and reverse clutch end play.

TOTAL END PLAY

lMeasure clearance](/img/5/57402/w960_57402-558.png)

ASSEMBLY

AT-553

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

Adjustment (2)ECS0 04 MG

When any parts listed below are replaced, adjust total end play and reverse clutch end play.

TOTAL END PLAY

lMeasure clearance between reverse clutch drum and needle

bearing for oil pump cover.

lSelect proper thickness of bearing race so that end play is within

specifications.

1. Measure dimensions "K" and "L" and then calculate dimension

"J".

a. Measure dimension "K".

Part name Total end playReverseclutchend

play

Transmission casell

Overrun clutch hubll

Rear internal gearll

Rear planetary carrierll

Rear sun gearll

Front planetary carrierll

Front sun gearll

High clutch hubll

High clutch drumll

Oil pump coverll

Reverseclutchdrum —l

SAT374DA

SAT375D

SAT376D

Page 561 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ASSEMBLY

AT-555

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

REVERSE CLUTCH END PLAY

lMeasure clearance between oil pump cover and thrust washer

for reverse clutch drum.

lSelect proper thickness of thrust washer s NISSAN X-TRAIL 2003 Electronic Repair Manual ASSEMBLY

AT-555

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

REVERSE CLUTCH END PLAY

lMeasure clearance between oil pump cover and thrust washer

for reverse clutch drum.

lSelect proper thickness of thrust washer s](/img/5/57402/w960_57402-560.png)

ASSEMBLY

AT-555

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

REVERSE CLUTCH END PLAY

lMeasure clearance between oil pump cover and thrust washer

for reverse clutch drum.

lSelect proper thickness of thrust washer so that end play is

within specification.

1. Measure dimensions "O" and "P" and then calculate dimension

"N".

a. Place thrust washer on reverse clutch drum.

b. Measure dimension "O".

c. Measure dimension "P".

d. Calculate dimension "N".

SAT380DA

SAT381D

SAT382D

"N": Distance between oil pump fitting surface of trans-

mission case and thrust washer on reverse clutch drum.

N=O–P

SAT383D

Page 562 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-556

[ALL]

ASSEMBLY

2. Measure dimensions "R" and "S" and then calculate dimension

"Q".

a. Measure dimension "R".

b. Measure dimension "S".

c. Calculate dimension "Q".

3. Adjust reverse clutch end p NISSAN X-TRAIL 2003 Electronic Repair Manual AT-556

[ALL]

ASSEMBLY

2. Measure dimensions "R" and "S" and then calculate dimension

"Q".

a. Measure dimension "R".

b. Measure dimension "S".

c. Calculate dimension "Q".

3. Adjust reverse clutch end p](/img/5/57402/w960_57402-561.png)

AT-556

[ALL]

ASSEMBLY

2. Measure dimensions "R" and "S" and then calculate dimension

"Q".

a. Measure dimension "R".

b. Measure dimension "S".

c. Calculate dimension "Q".

3. Adjust reverse clutch end play "T

2".

lSelect proper thickness of thrust washer so that reverse clutch end play is within specifications.

Assembly (3)ECS0 04 MH

1. Install anchor end pin and lock nut on transmission case.

2. Place brake band on outside of reverse clutch drum. Tighten

anchor end pin just enough so that brake band is evenly fitted on

reverse clutch drum.

SAT384D

SAT385D

"Q": Distance between transmission case fitting sur-

face and thrust washer mating surface.

Q=R–S

SAT386D

T2=N–Q

Reverse clutch end play :

0.55 - 0.90 mm ( 0.0217 - 0.0354 in )

Thrust washer :Refer toAT-563, "

SERVICE DATA AND SPECIFICATIONS (SDS)"

.

SAT196F

Page 838 of 3066

BR-4

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsEFS000C0

Description Application

Output rod gauge

KV9910 02000 Adjusting brake booster output rod

dimensions

ZZA0756D

Page 840 of 3066

BR-6

BRAKE PEDAL

BRAKE PEDAL

PFP:46501

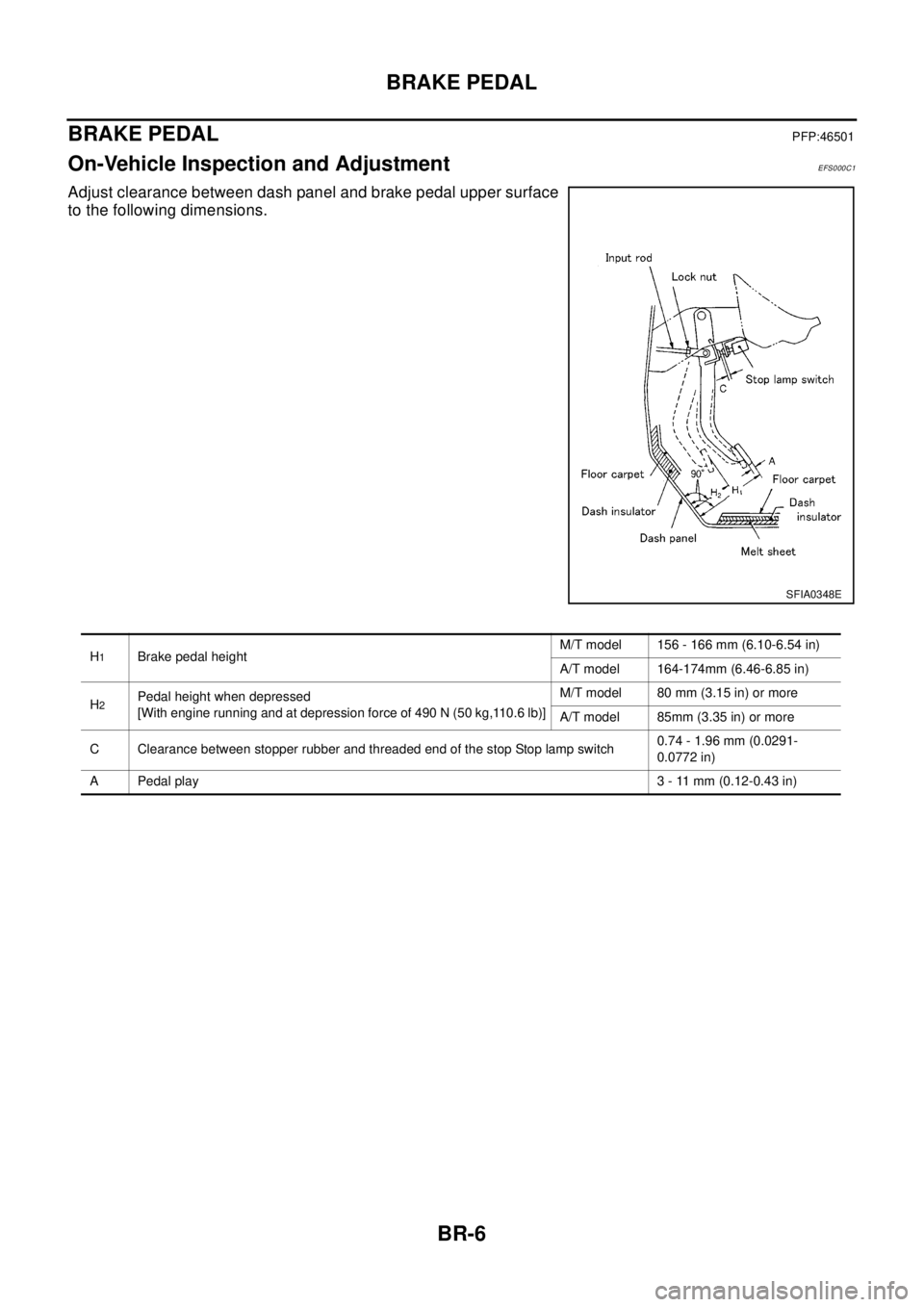

On-Vehicle Inspection and AdjustmentEFS000C1

Adjust clearance between dash panel and brake pedal upper surface

to the following dimensions.

SFIA0348E

H1Brake pedal heightM/T model 156 - 166 mm (6.10-6.54 in)

A/T model 164-174mm (6.46-6.85 in)

H

2Pedal height when depressed

[With engine running and at depression force of 490 N (50 kg,110.6 lb)]M/T model 80 mm (3.15 in) or more

A/T model 85mm (3.35 in) or more

C Clearance between stopper rubber and threaded end of the stop Stop lamp switch0.74 - 1.96 mm (0.0291-

0.0772 in)

A Pedal play3 - 11 mm (0.12-0.43 in)

Page 1013 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual PRECAUTIONS

CO-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009S9

REMOVAL OF LIQUID GASKET

lAfter removing the mounting bolts and nuts, disconnect NISSAN X-TRAIL 2003 Electronic Repair Manual PRECAUTIONS

CO-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009S9

REMOVAL OF LIQUID GASKET

lAfter removing the mounting bolts and nuts, disconnect](/img/5/57402/w960_57402-1012.png)

PRECAUTIONS

CO-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009S9

REMOVAL OF LIQUID GASKET

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

lIn areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the gasket applied area.

CAUTION:

Ifforsomeunavoidablereasonatoolsuchasaflat-blade

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

lRemove the liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lighting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

lIf there is a groove for the liquid gasket application, apply the

gasket to the groove.

lAs for the bolt holes, normally apply the gasket inside the holes.

Occasionally, it should be applied outside the holes. Make sure

to read the instruction in this manual.

lWithin five minutes of gasket application, install the mating com-

ponent.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten after the installation.

lAfter 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are instructions in this manual, observe them.

PBIC0275E

PBIC0003E

EMA0622D

SEM164F

Page 1034 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-24

[YD22DDTi]

PRECAUTIONS

[YD22DDTi]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS00BAU

REMOVAL AND LIQUID GASKET

lAfter removing the mounting bolts and nuts, disconnect and

remove the liqui NISSAN X-TRAIL 2003 Electronic Repair Manual CO-24

[YD22DDTi]

PRECAUTIONS

[YD22DDTi]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS00BAU

REMOVAL AND LIQUID GASKET

lAfter removing the mounting bolts and nuts, disconnect and

remove the liqui](/img/5/57402/w960_57402-1033.png)

CO-24

[YD22DDTi]

PRECAUTIONS

[YD22DDTi]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS00BAU

REMOVAL AND LIQUID GASKET

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

lIn areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the gasket applied area.

CAUTION:

If for some unavoidable reason a tool such as a flat-blade

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

lRemove the liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lighting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

lIf there is a groove for the liquid gasket application, apply the

gasket to the groove.

lAs for the bolt holes, normally apply the gasket inside the holes.

Occasionally, it should be applied outside the holes. Make sure

to read the service manual.

lWithin five minutes of gasket application, install the mating com-

ponent.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten after the installation.

lAfter 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe

them.

PBIC0275E

PBIC0003E

EMA0622D

SEM164F