heating NISSAN X-TRAIL 2003 Electronic Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2481 of 3066

![NISSAN X-TRAIL 2003 Electronic Service Manual PRECAUTIONS

LU-15

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

LU

[YD22DDTi]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS00B00

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts NISSAN X-TRAIL 2003 Electronic Service Manual PRECAUTIONS

LU-15

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

LU

[YD22DDTi]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS00B00

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts](/img/5/57402/w960_57402-2480.png)

PRECAUTIONS

LU-15

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

LU

[YD22DDTi]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS00B00

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

lIn areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the areas where the liquid gasket is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

lRemove the liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lighting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

lIf there is a groove for the liquid gasket application, apply the

gasket to the groove.

lAs for the bolt holes, normally apply the gasket inside the holes.

Occasionally, it should be applied outside the holes. Make sure

to read the text of service manual.

lWithin five minutes of gasket application, install the mating com-

ponent.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten after the installation.

lAfter 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe

them.

PBIC0275E

PBIC0003E

EMA0622D

SEM159F

Page 2637 of 3066

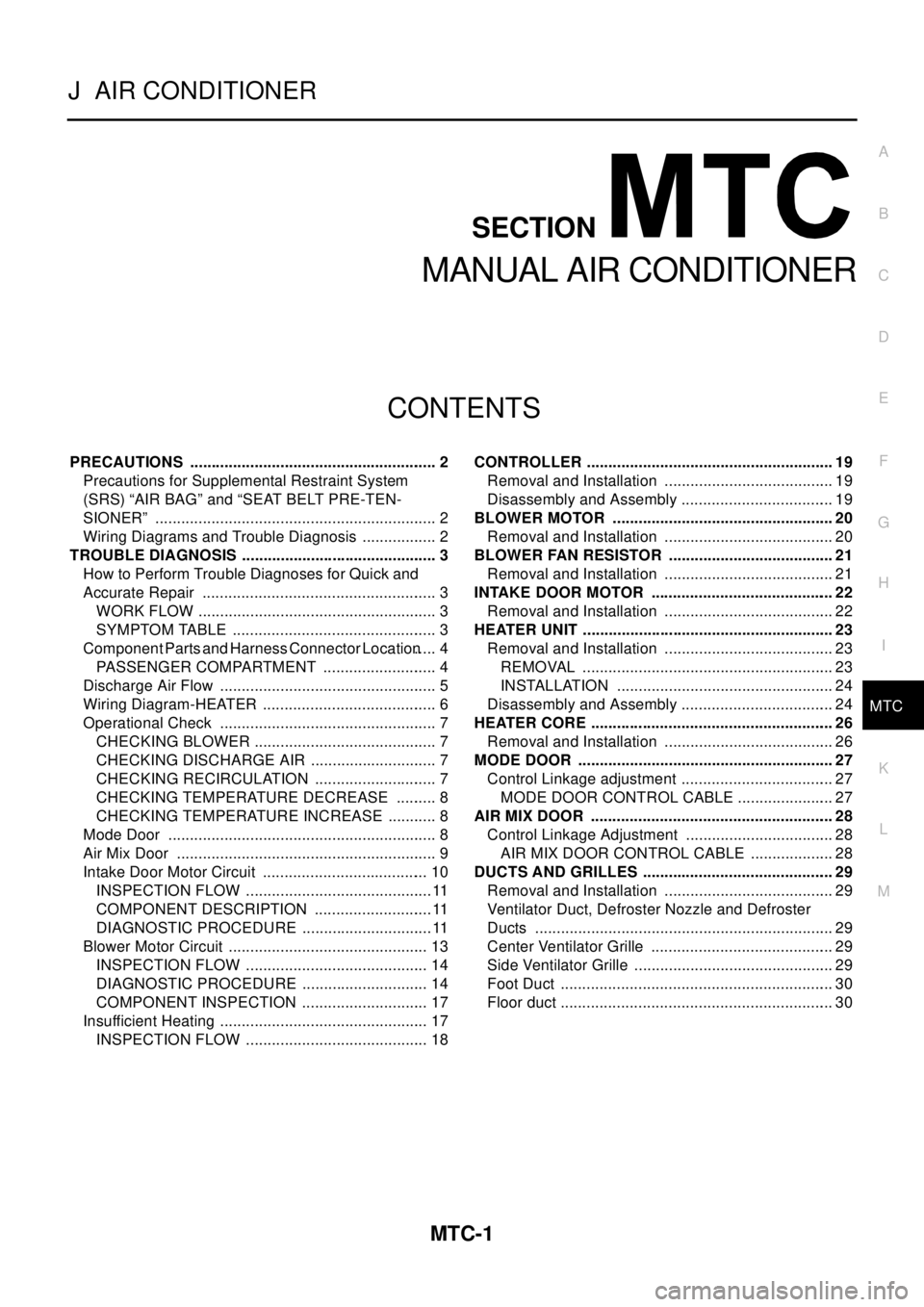

MTC-1

MANUAL AIR CONDITIONER

J AIR CONDITIONER

CONTENTS

C

D

E

F

G

H

I

K

L

M

SECTION

A

B

MTC

MANUAL AIR CONDITIONER

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

Wiring Diagrams and Trouble Diagnosis .................. 2

TROUBLE DIAGNOSIS .............................................. 3

How to Perform Trouble Diagnoses for Quick and

Accurate Repair ....................................................... 3

WORK FLOW ........................................................ 3

SYMPTOM TABLE ................................................ 3

Component Parts and Harness Connector Location..... 4

PASSENGER COMPARTMENT ........................... 4

Discharge Air Flow ................................................... 5

Wiring Diagram-HEATER ......................................... 6

Operational Check ................................................... 7

CHECKING BLOWER ........................................... 7

CHECKING DISCHARGE AIR .............................. 7

CHECKING RECIRCULATION ............................. 7

CHECKING TEMPERATURE DECREASE .......... 8

CHECKING TEMPERATURE INCREASE ............ 8

Mode Door ............................................................... 8

Air Mix Door ............................................................. 9

Intake Door Motor Circuit ....................................... 10

INSPECTION FLOW ............................................11

COMPONENT DESCRIPTION ............................11

DIAGNOSTIC PROCEDURE ...............................11

Blower Motor Circuit ............................................... 13

INSPECTION FLOW ........................................... 14

DIAGNOSTIC PROCEDURE .............................. 14

COMPONENT INSPECTION .............................. 17

Insufficient Heating ................................................. 17

INSPECTION FLOW ........................................... 18CONTROLLER .......................................................... 19

Removal and Installation ........................................ 19

Disassembly and Assembly .................................... 19

BLOWER MOTOR .................................................... 20

Removal and Installation ........................................ 20

BLOWER FAN RESISTOR ....................................... 21

Removal and Installation ........................................ 21

INTAKE DOOR MOTOR ........................................... 22

Removal and Installation ........................................ 22

HEATER UNIT ........................................................... 23

Removal and Installation ........................................ 23

REMOVAL ........................................................... 23

INSTALLATION ................................................... 24

Disassembly and Assembly .................................... 24

HEATER CORE ......................................................... 26

Removal and Installation ........................................ 26

MODE DOOR ............................................................ 27

Control Linkage adjustment .................................... 27

MODE DOOR CONTROL CABLE ....................... 27

AIR MIX DOOR ......................................................... 28

Control Linkage Adjustment ................................... 28

AIR MIX DOOR CONTROL CABLE .................... 28

DUCTS AND GRILLES ............................................. 29

Removal and Installation ........................................ 29

Ventilator Duct, Defroster Nozzle and Defroster

Ducts ...................................................................... 29

Center Ventilator Grille ........................................... 29

Side Ventilator Grille ............................................... 29

Foot Duct ................................................................ 30

Floor duct ................................................................ 30

Page 2639 of 3066

TROUBLE DIAGNOSIS

MTC-3

C

D

E

F

G

H

I

K

L

MA

B

MTC

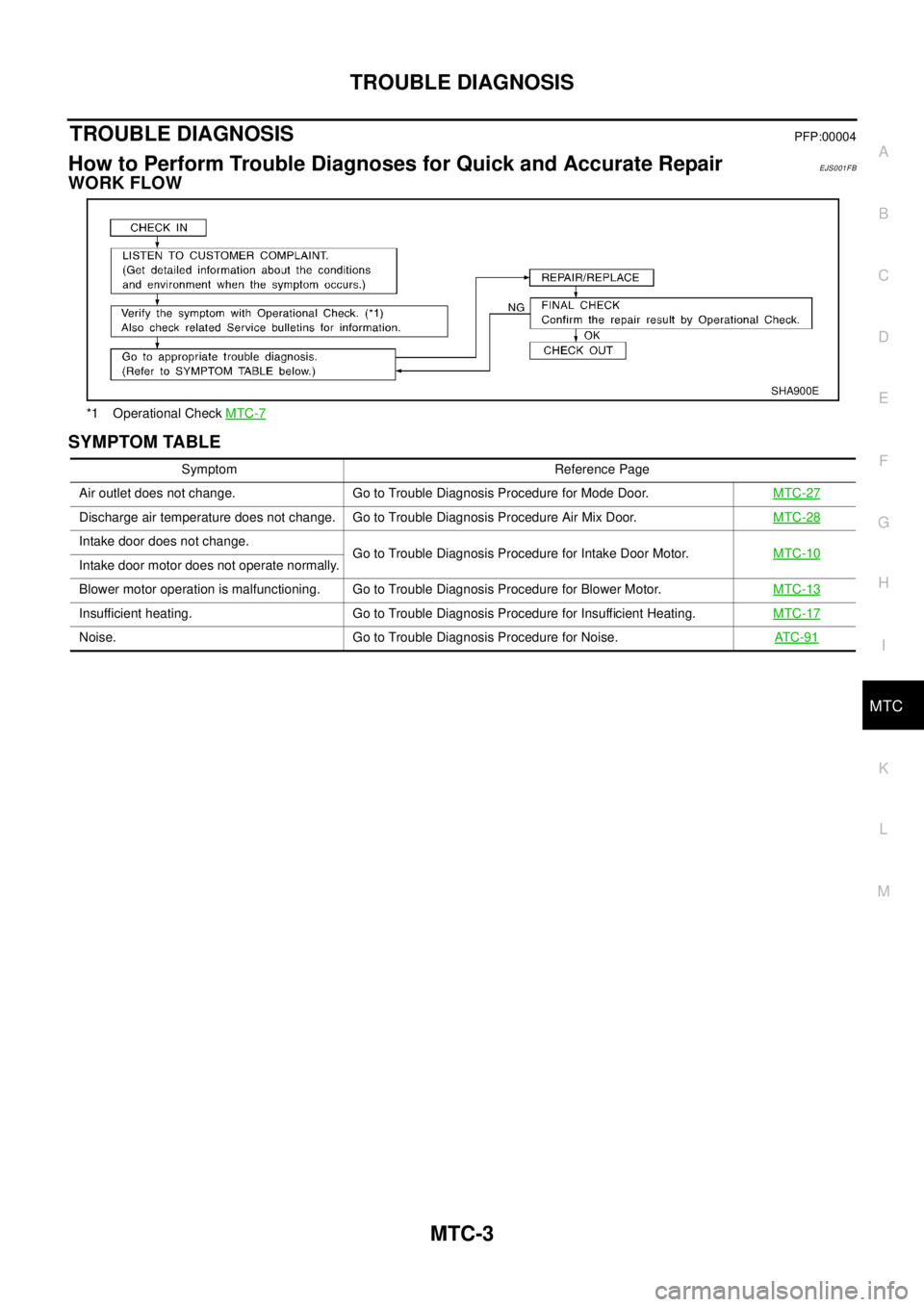

TROUBLE DIAGNOSISPFP:00004

How to Perform Trouble Diagnoses for Quick and Accurate RepairEJS001FB

WORK FLOW

SYMPTOM TABLE

*1 Operational CheckMTC-7

SHA900E

Symptom Reference Page

Air outlet does not change. Go to Trouble Diagnosis Procedure for Mode Door.MTC-27

Discharge air temperature does not change. Go to Trouble Diagnosis Procedure Air Mix Door.MTC-28

Intake door does not change.

Go to Trouble Diagnosis Procedure for Intake Door Motor.MTC-10

Intake door motor does not operate normally.

Blower motor operation is malfunctioning. Go to Trouble Diagnosis Procedure for Blower Motor.MTC-13

Insufficient heating. Go to Trouble Diagnosis Procedure for Insufficient Heating.MTC-17

Noise. Go to Trouble Diagnosis Procedure for Noise.AT C -9 1

Page 2644 of 3066

MTC-8

TROUBLE DIAGNOSIS

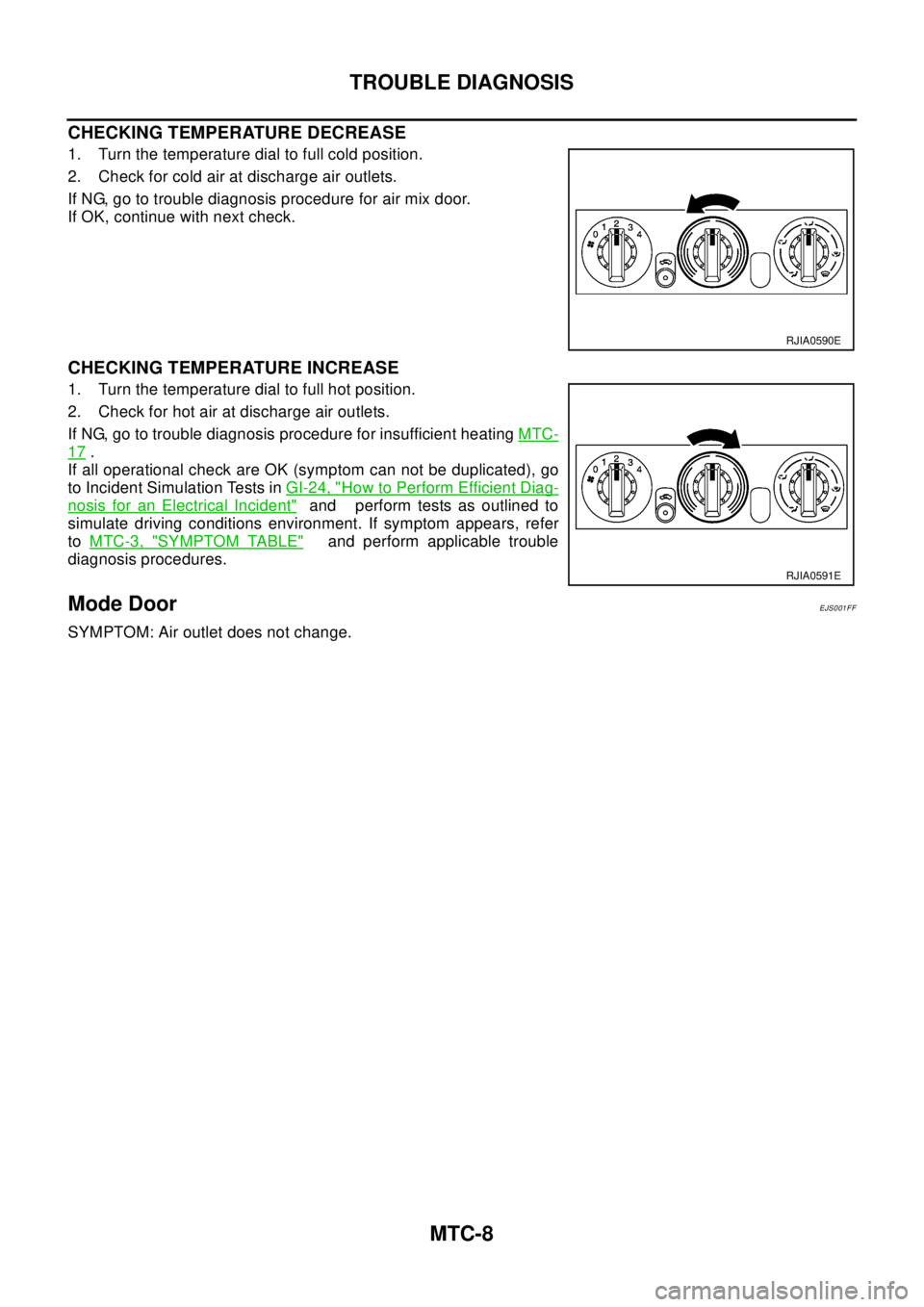

CHECKING TEMPERATURE DECREASE

1. Turn the temperature dial to full cold position.

2. Check for cold air at discharge air outlets.

If NG, go to trouble diagnosis procedure for air mix door.

If OK, continue with next check.

CHECKING TEMPERATURE INCREASE

1. Turn the temperature dial to full hot position.

2. Check for hot air at discharge air outlets.

If NG, go to trouble diagnosis procedure for insufficient heatingMTC-

17.

If all operational check are OK (symptom can not be duplicated), go

to Incident Simulation Tests inGI-24, "

How to Perform Efficient Diag-

nosis for an Electrical Incident"and perform tests as outlined to

simulate driving conditions environment. If symptom appears, refer

toMTC-3, "

SYMPTOM TABLE"and perform applicable trouble

diagnosis procedures.

Mode DoorEJS001FF

SYMPTOM: Air outlet does not change.

RJIA0590E

RJIA0591E

Page 2653 of 3066

TROUBLE DIAGNOSIS

MTC-17

C

D

E

F

G

H

I

K

L

MA

B

MTC

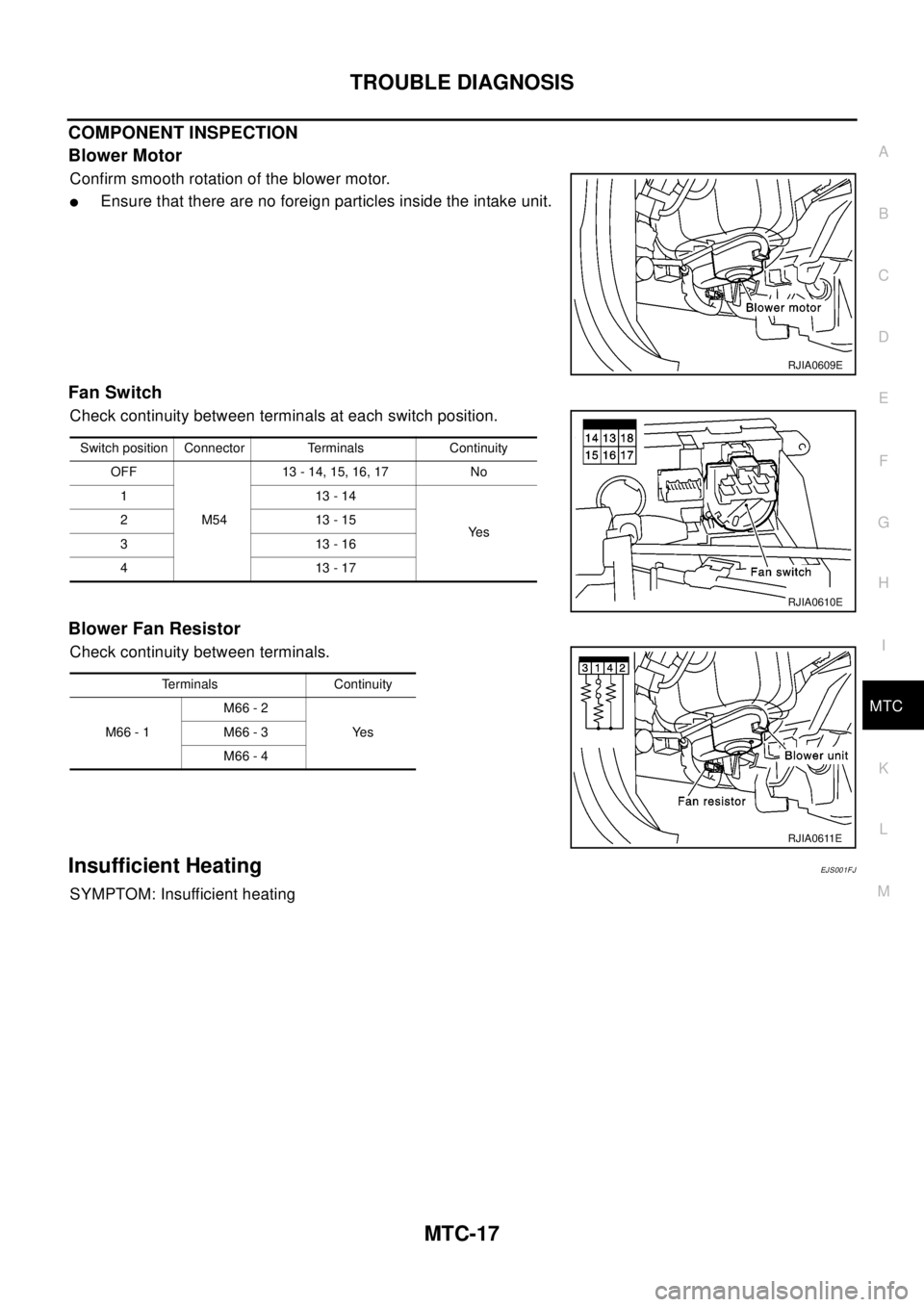

COMPONENT INSPECTION

Blower Motor

Confirm smooth rotation of the blower motor.

lEnsure that there are no foreign particles inside the intake unit.

Fan Switch

Check continuity between terminals at each switch position.

Blower Fan Resistor

Check continuity between terminals.

Insufficient HeatingEJ S00 1F J

SYMPTOM: Insufficient heating

RJIA0609E

Switch position Connector Terminals Continuity

OFF

M5413 - 14, 15, 16, 17 No

113-14

Ye s 213-15

313-16

413-17

RJIA0610E

Terminals Continuity

M66 - 1M66 - 2

Ye s M66 - 3

M66 - 4

RJIA0611E