Filter NISSAN X-TRAIL 2003 Electronic Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2506 of 3066

MA-14

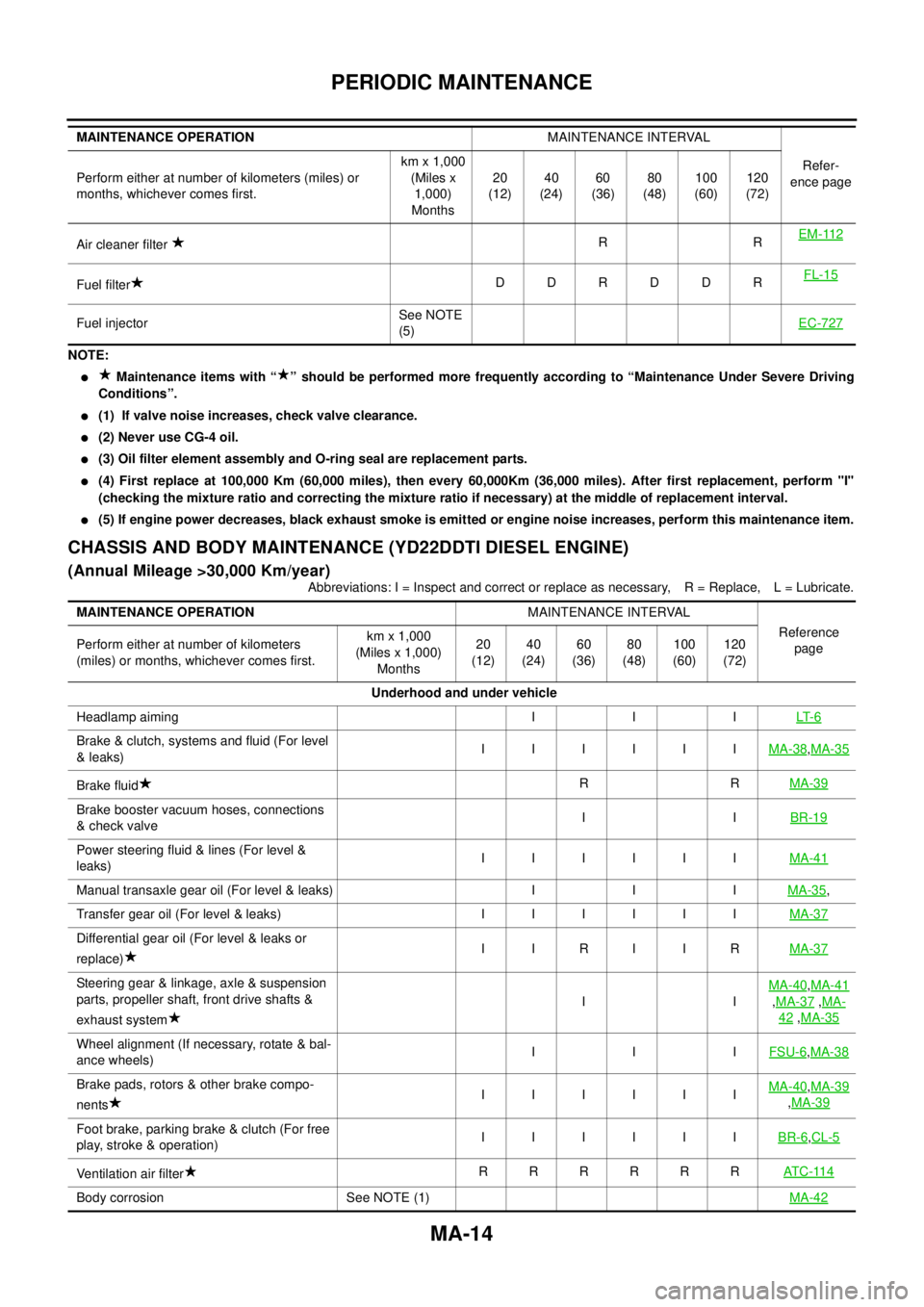

PERIODIC MAINTENANCE

NOTE:

lMaintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving

Conditions”.

l(1) If valve noise increases, check valve clearance.

l(2) Never use CG-4 oil.

l(3) Oil filter element assembly and O-ring seal are replacement parts.

l(4) First replace at 100,000 Km (60,000 miles), then every 60,000Km (36,000 miles). After first replacement, perform "I"

(checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

l(5) If engine power decreases, black exhaust smoke is emitted or engine noise increases, perform this maintenance item.

CHASSIS AND BODY MAINTENANCE (YD22DDTI DIESEL ENGINE)

(Annual Mileage >30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate. Air cleaner filterRREM-112

Fuel filterDDRDDRFL-15

Fuel injectorSee NOTE

(5)EC-727

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence page Perform either at number of kilometers (miles) or

months, whichever comes first.km x 1,000

(Miles x

1,000)

Months20

(12)40

(24)60

(36)80

(48)100

(60)120

(72)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform either at number of kilometers

(miles) or months, whichever comes first.km x 1,000

(Miles x 1,000)

Months20

(12)40

(24)60

(36)80

(48)100

(60)120

(72)

Underhood and under vehicle

Headlamp aiming I I ILT- 6

Brake & clutch, systems and fluid (For level

&leaks)IIIIIIMA-38,MA-35

Brake fluidRRMA-39

Brake booster vacuum hoses, connections

& check valveIIBR-19

Power steering fluid & lines (For level &

leaks)IIIIIIMA-41

Manual transaxle gear oil (For level & leaks) I I IMA-35,

Transfergearoil(Forlevel&leaks) IIIIIIMA-37

Differential gear oil (For level & leaks or

replace)IIRIIRMA-37

Steering gear & linkage, axle & suspension

parts, propeller shaft, front drive shafts &

exhaust systemIIMA-40,MA-41

,MA-37,MA-

42,MA-35

Wheel alignment (If necessary, rotate & bal-

ance wheels)IIIFSU-6,MA-38

Brake pads, rotors & other brake compo-

nentsIIIIIIMA-40,MA-39

,MA-39

Foot brake, parking brake & clutch (For free

play, stroke & operation)IIIIIIBR-6,CL-5

Ventilation air filterRRRRRRAT C -11 4

Body corrosion See NOTE (1)MA-42

Page 2507 of 3066

PERIODIC MAINTENANCE

MA-15

C

D

E

F

G

H

I

J

K

MA

B

MA

NOTE:

l(1) Inspect once per year.

lMaintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving

Conditions”.

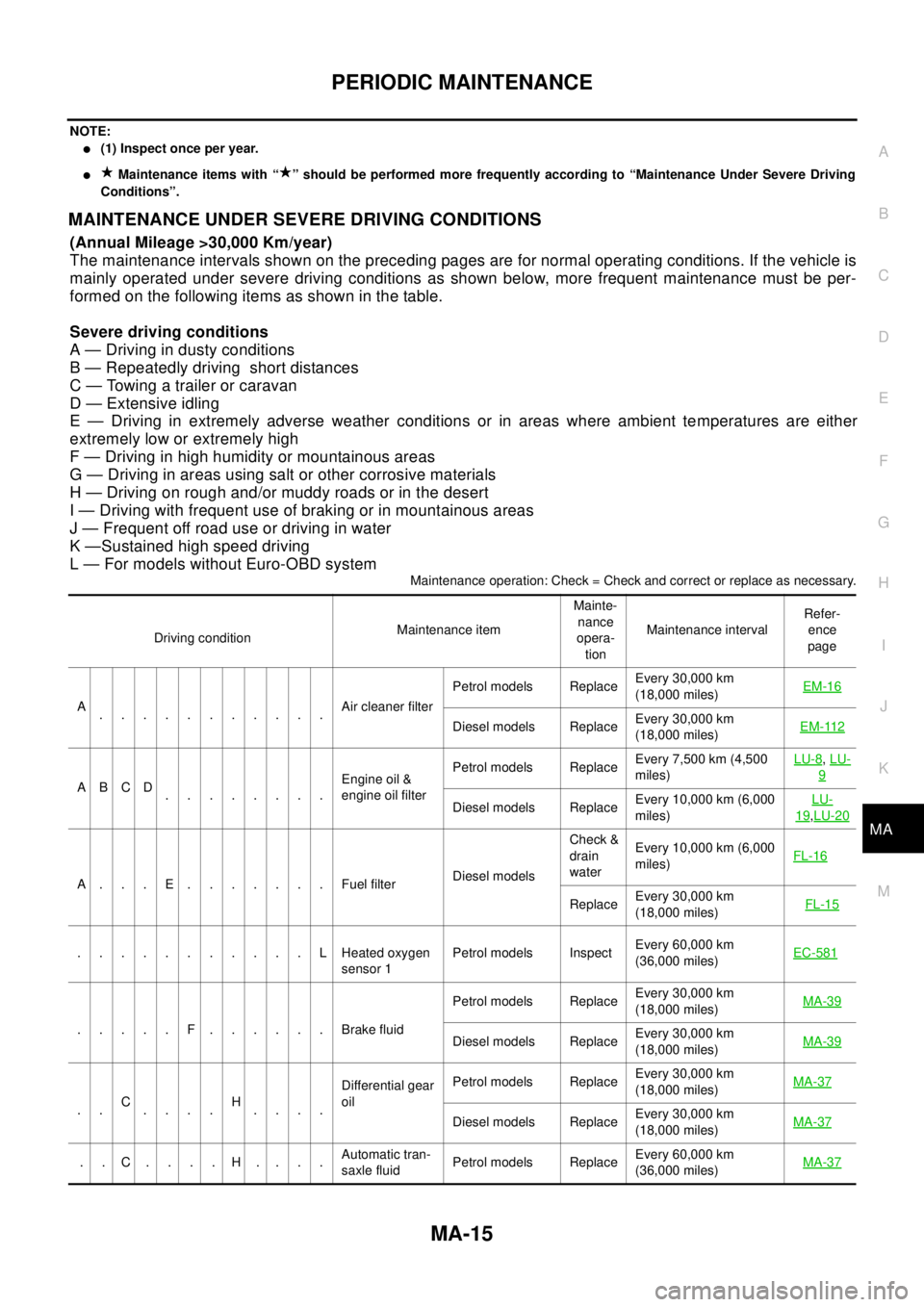

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

(Annual Mileage >30,000 Km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving in dusty conditions

B — Repeatedly driving short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity or mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

J — Frequent off road use or driving in water

K —Sustained high speed driving

L — For models without Euro-OBD system

Maintenance operation: Check = Check and correct or replace as necessary.

Driving conditionMaintenance itemMainte-

nance

opera-

tionMaintenance intervalRefer-

ence

page

A

...........Air cleaner filterPetrol models ReplaceEvery 30,000 km

(18,000 miles)EM-16

Diesel models ReplaceEvery 30,000 km

(18,000 miles)EM-112

ABCD

........Engine oil &

engine oil filterPetrol models ReplaceEvery 7,500 km (4,500

miles)LU-8

,LU-

9

Diesel models ReplaceEvery 10,000 km (6,000

miles)LU-19,LU-20

A...E.......FuelfilterDiesel modelsCheck &

drain

waterEvery 10,000 km (6,000

miles)FL-16

ReplaceEvery 30,000 km

(18,000 miles)FL-15

...........LHeatedoxygen

sensor 1Petrol models InspectEvery 60,000 km

(36,000 miles)EC-581

.....F......BrakefluidPetrol models ReplaceEvery 30,000 km

(18,000 miles)MA-39Diesel models ReplaceEvery 30,000 km

(18,000 miles)MA-39

..C

....H

....Differential gear

oilPetrol models ReplaceEvery 30,000 km

(18,000 miles)MA-37Diesel models ReplaceEvery 30,000 km

(18,000 miles)MA-37

..C....H....Automatic tran-

saxle fluidPetrol models ReplaceEvery 60,000 km

(36,000 miles)MA-37

Page 2509 of 3066

RECOMMENDED FLUIDS AND LUBRICANTS

MA-17

C

D

E

F

G

H

I

J

K

MA

B

MA

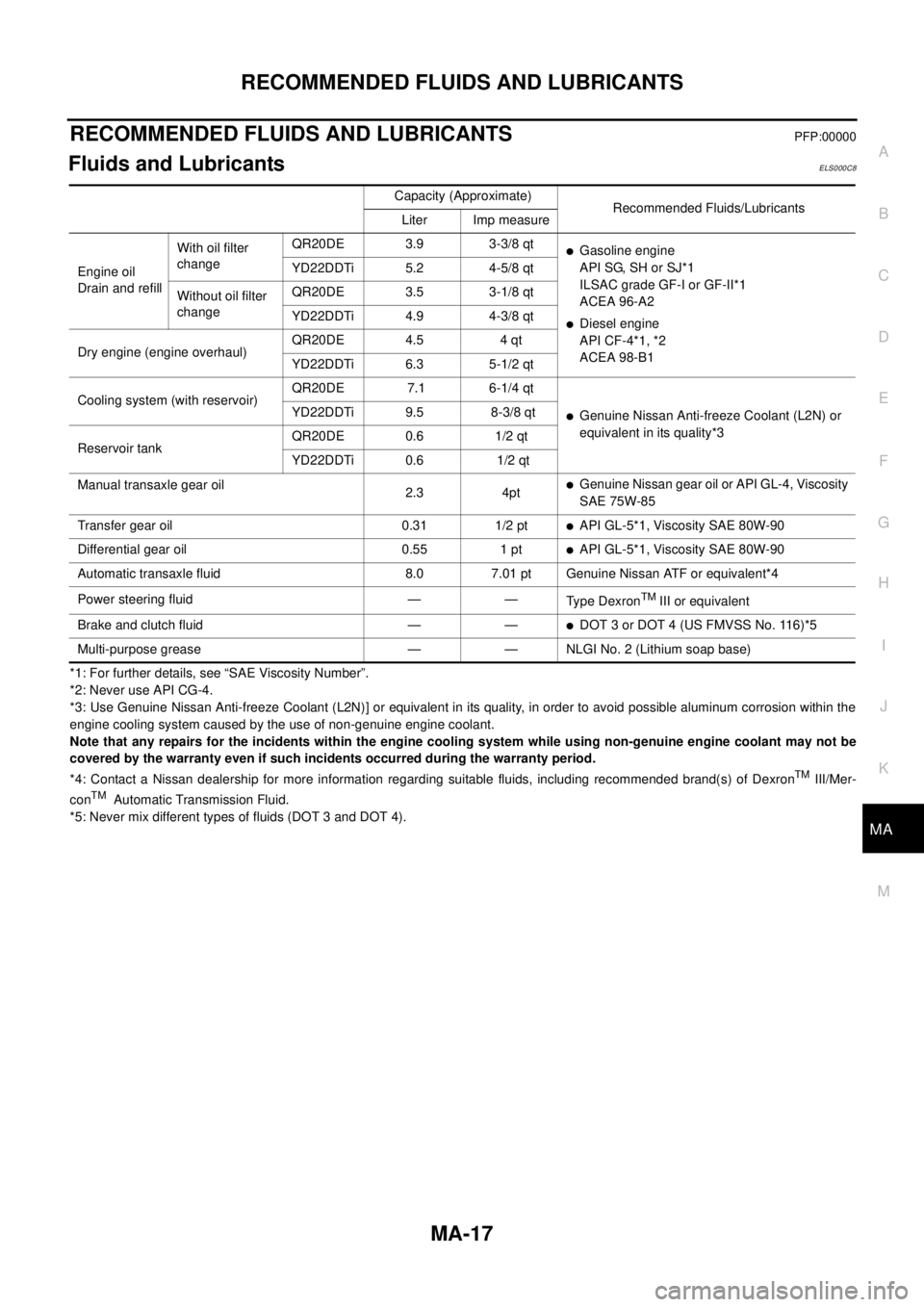

RECOMMENDED FLUIDS AND LUBRICANTSPFP:00000

Fluids and LubricantsELS000C8

*1: For further details, see “SAE Viscosity Number”.

*2: Never use API CG-4.

*3: Use Genuine Nissan Anti-freeze Coolant (L2N)] or equivalent in its quality, in order to avoid possible aluminum corrosion within the

engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*4: Contact a Nissan dealership for more information regarding suitable fluids, including recommended brand(s) of Dexron

TMIII/Mer-

conTMAutomatic Transmission Fluid.

*5: Never mix different types of fluids (DOT 3 and DOT 4).Capacity (Approximate)

Recommended Fluids/Lubricants

Liter Imp measure

Engine oil

Drain and refillWith oil filter

changeQR20DE 3.9 3-3/8 qt

lGasoline engine

API SG, SH or SJ*1

ILSAC grade GF-I or GF-II*1

ACEA 96-A2

lDiesel engine

API CF-4*1, *2

ACEA 98-B1 YD22DDTi 5.2 4-5/8 qt

Without oil filter

changeQR20DE 3.5 3-1/8 qt

YD22DDTi 4.9 4-3/8 qt

Dry engine (engine overhaul)QR20DE 4.5 4 qt

YD22DDTi 6.3 5-1/2 qt

Cooling system (with reservoir)QR20DE 7.1 6-1/4 qt

lGenuine Nissan Anti-freeze Coolant (L2N) or

equivalent in its quality*3 YD22DDTi 9.5 8-3/8 qt

Reservoir tankQR20DE 0.6 1/2 qt

YD22DDTi 0.6 1/2 qt

Manual transaxle gear oil

2.3 4pt

lGenuine Nissan gear oil or API GL-4, Viscosity

SAE 75W-85

Transfer gear oil 0.31 1/2 pt

lAPI GL-5*1, Viscosity SAE 80W-90

Differential gear oil 0.55 1 pt

lAPI GL-5*1, Viscosity SAE 80W-90

Automatic transaxle fluid 8.0 7.01 pt Genuine Nissan ATF or equivalent*4

Power steering fluid — —

Ty p e D e x r o n

TMIII or equivalent

Brake and clutch fluid — —

lDOT 3 or DOT 4 (US FMVSS No. 116)*5

Multi-purpose grease — — NLGI No. 2 (Lithium soap base)

Page 2515 of 3066

ENGINE MAINTENANCE (QR20DE)

MA-23

C

D

E

F

G

H

I

J

K

MA

B

MA

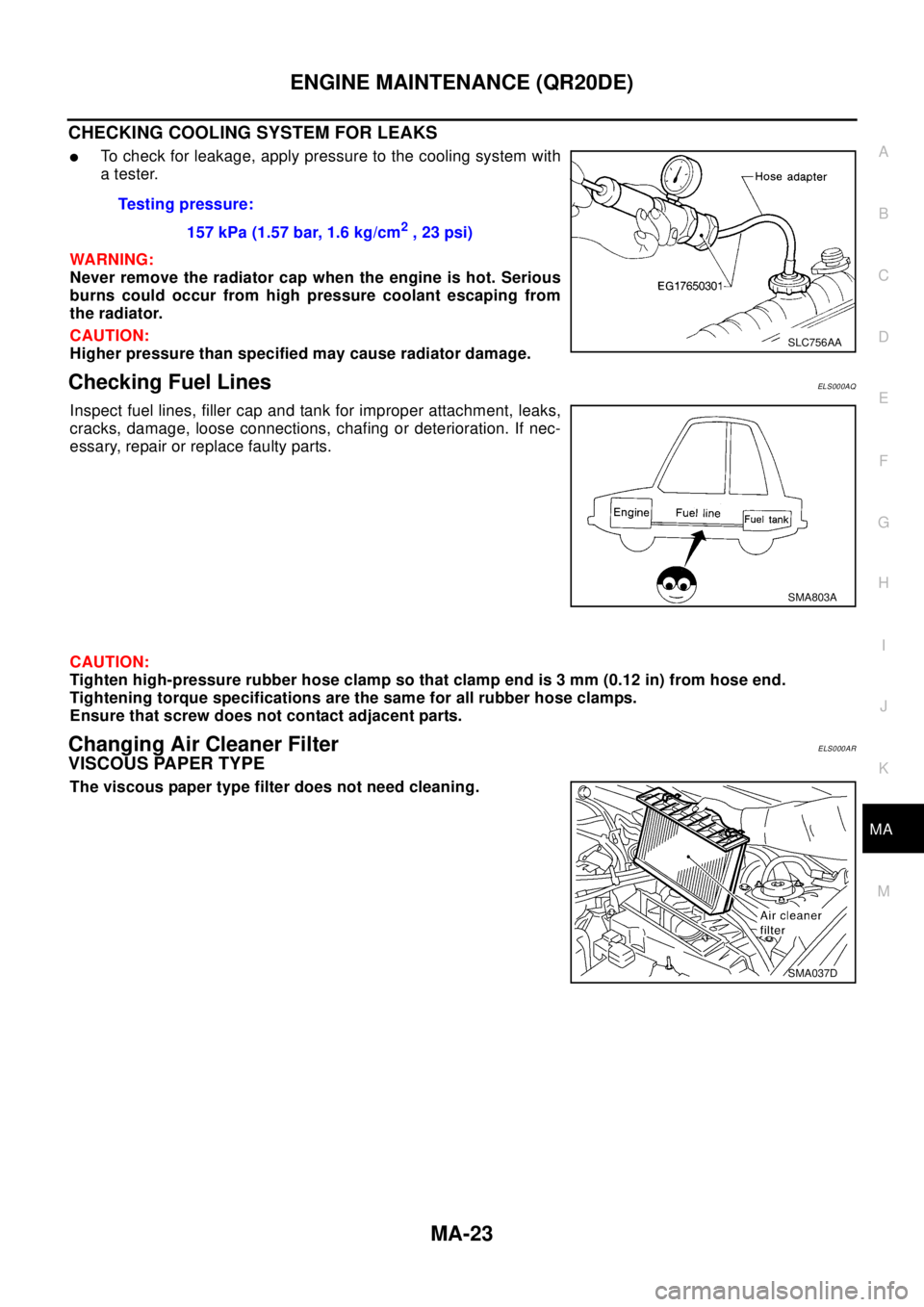

CHECKING COOLING SYSTEM FOR LEAKS

lTo check for leakage, apply pressure to the cooling system with

atester.

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Checking Fuel LinesELS000AQ

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration. If nec-

essary, repair or replace faulty parts.

CAUTION:

Tighten high-pressure rubber hose clamp so that clamp end is 3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber hose clamps.

Ensure that screw does not contact adjacent parts.

Changing Air Cleaner FilterELS000AR

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning.Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2,23psi)

SLC756AA

SMA803A

SMA037D

Page 2516 of 3066

MA-24

ENGINE MAINTENANCE (QR20DE)

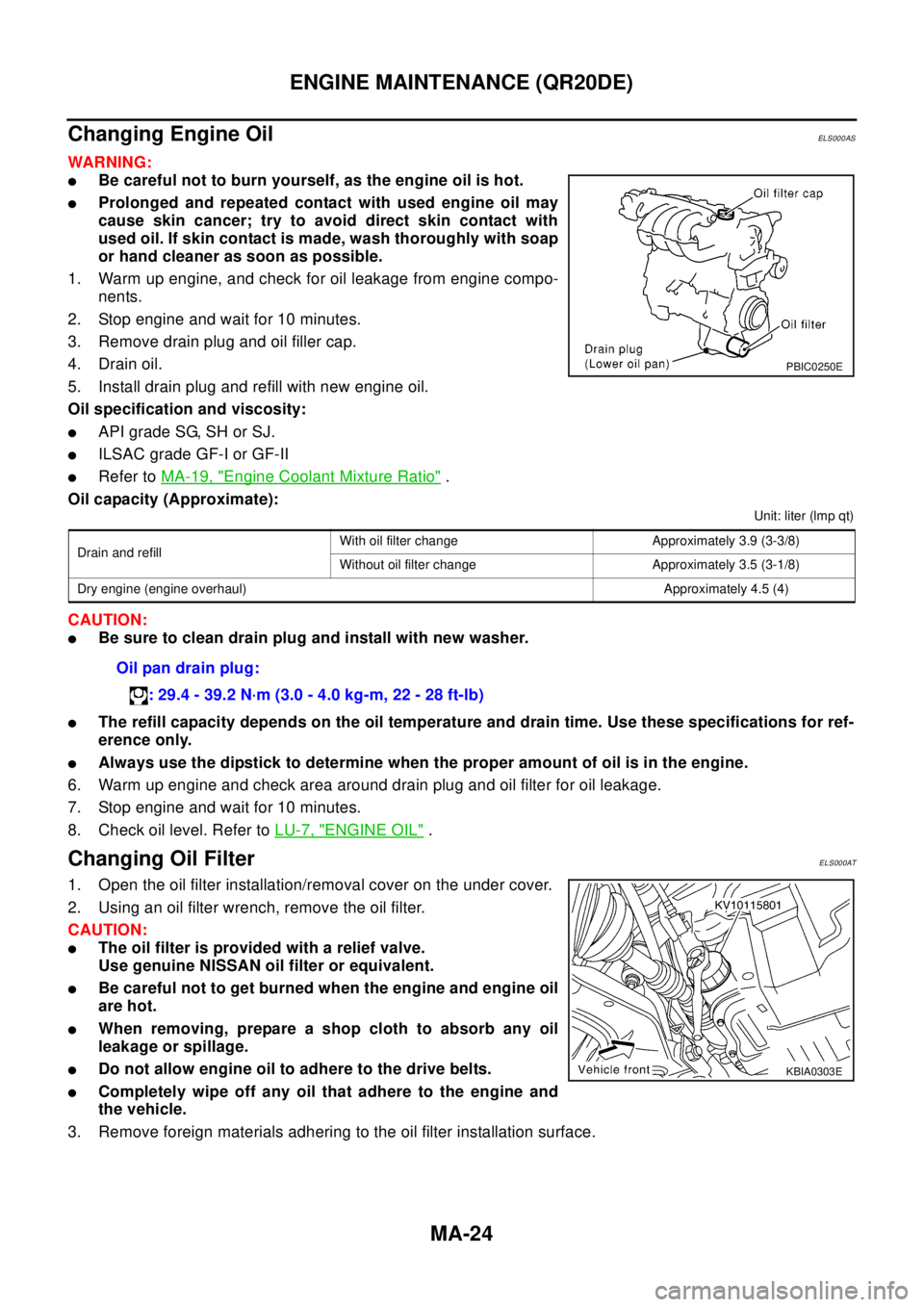

Changing Engine Oil

ELS000AS

WAR NIN G:

lBe careful not to burn yourself, as the engine oil is hot.

lProlonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with soap

or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine compo-

nents.

2. Stop engine and wait for 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil.

5. Install drain plug and refill with new engine oil.

Oil specification and viscosity:

lAPI grade SG, SH or SJ.

lILSAC grade GF-I or GF-II

lRefer toMA-19, "Engine Coolant Mixture Ratio".

Oil capacity (Approximate):

Unit: liter (lmp qt)

CAUTION:

lBe sure to clean drain plug and install with new washer.

lThe refill capacity depends on the oil temperature and drain time. Use these specifications for ref-

erence only.

lAlways use the dipstick to determine when the proper amount of oil is in the engine.

6. Warm up engine and check area around drain plug and oil filter for oil leakage.

7. Stop engine and wait for 10 minutes.

8. Check oil level. Refer toLU-7, "

ENGINE OIL".

Changing Oil FilterELS000AT

1. Open the oil filter installation/removal cover on the under cover.

2. Using an oil filter wrench, remove the oil filter.

CAUTION:

lThe oil filter is provided with a relief valve.

Use genuine NISSAN oil filter or equivalent.

lBe careful not to get burned when the engine and engine oil

are hot.

lWhen removing, prepare a shop cloth to absorb any oil

leakage or spillage.

lDo not allow engine oil to adhere to the drive belts.

lCompletely wipe off any oil that adhere to the engine and

the vehicle.

3. Remove foreign materials adhering to the oil filter installation surface.

PBIC0250E

Drain and refillWith oil filter change Approximately 3.9 (3-3/8)

Without oil filter change Approximately 3.5 (3-1/8)

Dry engine (engine overhaul) Approximately 4.5 (4)

Oil pan drain plug:

: 29.4 - 39.2 N·m (3.0 - 4.0 kg-m, 22 - 28 ft-lb)

KBIA0303E

Page 2517 of 3066

ENGINE MAINTENANCE (QR20DE)

MA-25

C

D

E

F

G

H

I

J

K

MA

B

MA

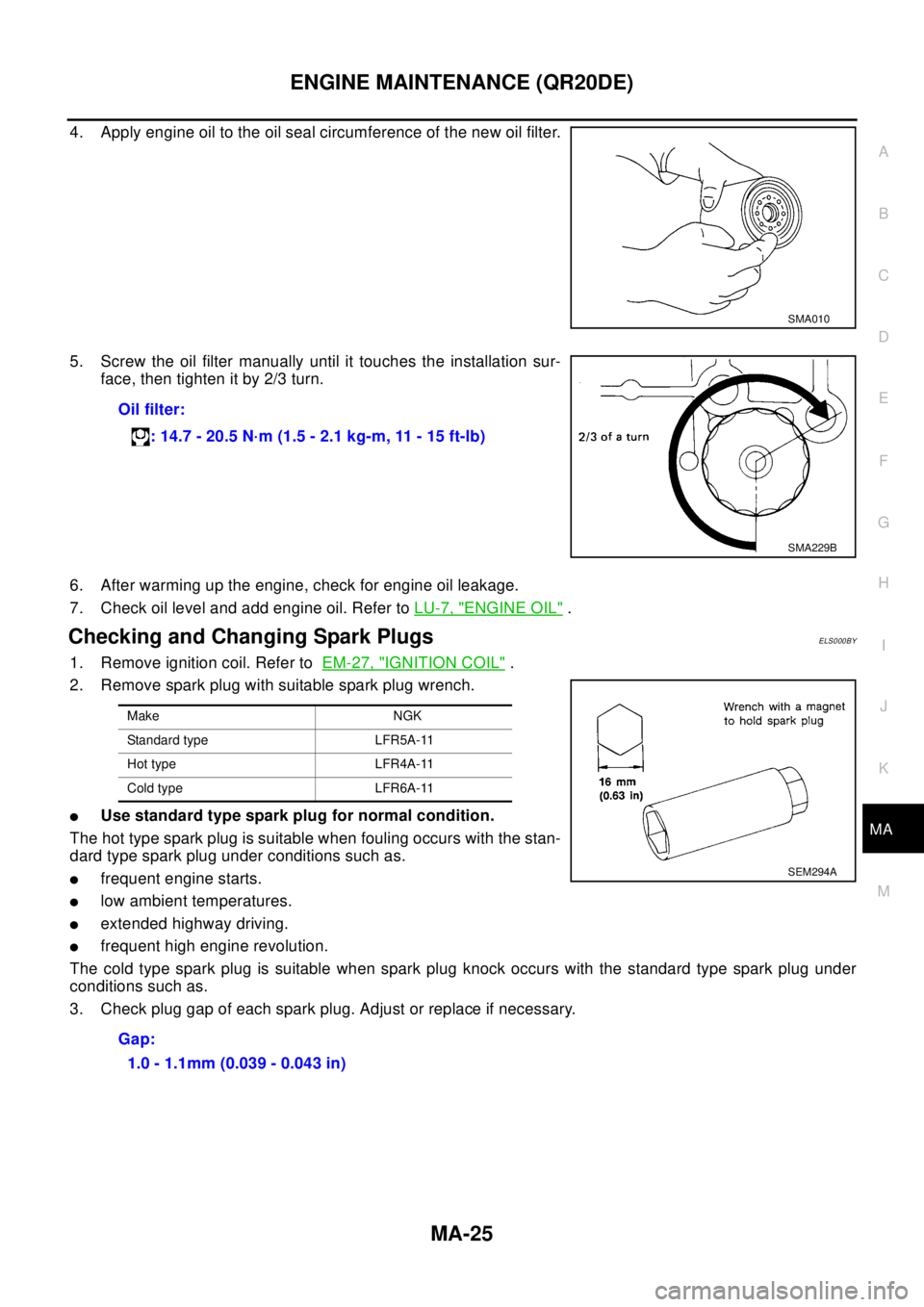

4. Apply engine oil to the oil seal circumference of the new oil filter.

5. Screw the oil filter manually until it touches the installation sur-

face, then tighten it by 2/3 turn.

6. After warming up the engine, check for engine oil leakage.

7. Check oil level and add engine oil. Refer toLU-7, "

ENGINE OIL".

Checking and Changing Spark PlugsELS000BY

1. Remove ignition coil. Refer toEM-27, "IGNITION COIL".

2. Remove spark plug with suitable spark plug wrench.

lUse standard type spark plug for normal condition.

The hot type spark plug is suitable when fouling occurs with the stan-

dard type spark plug under conditions such as.

lfrequent engine starts.

llow ambient temperatures.

lextended highway driving.

lfrequent high engine revolution.

The cold type spark plug is suitable when spark plug knock occurs with the standard type spark plug under

conditions such as.

3. Check plug gap of each spark plug. Adjust or replace if necessary.

SMA010

Oil filter:

: 14.7 - 20.5 N·m (1.5 - 2.1 kg-m, 11 - 15 ft-lb)

SMA229B

Make NGK

Standard type LFR5A-11

Hot type LFR4A-11

Cold type LFR6A-11

Gap:

1.0 - 1.1mm (0.039 - 0.043 in)

SEM294A

Page 2522 of 3066

MA-30

ENGINE MAINTENANCE (YD22DDTI)

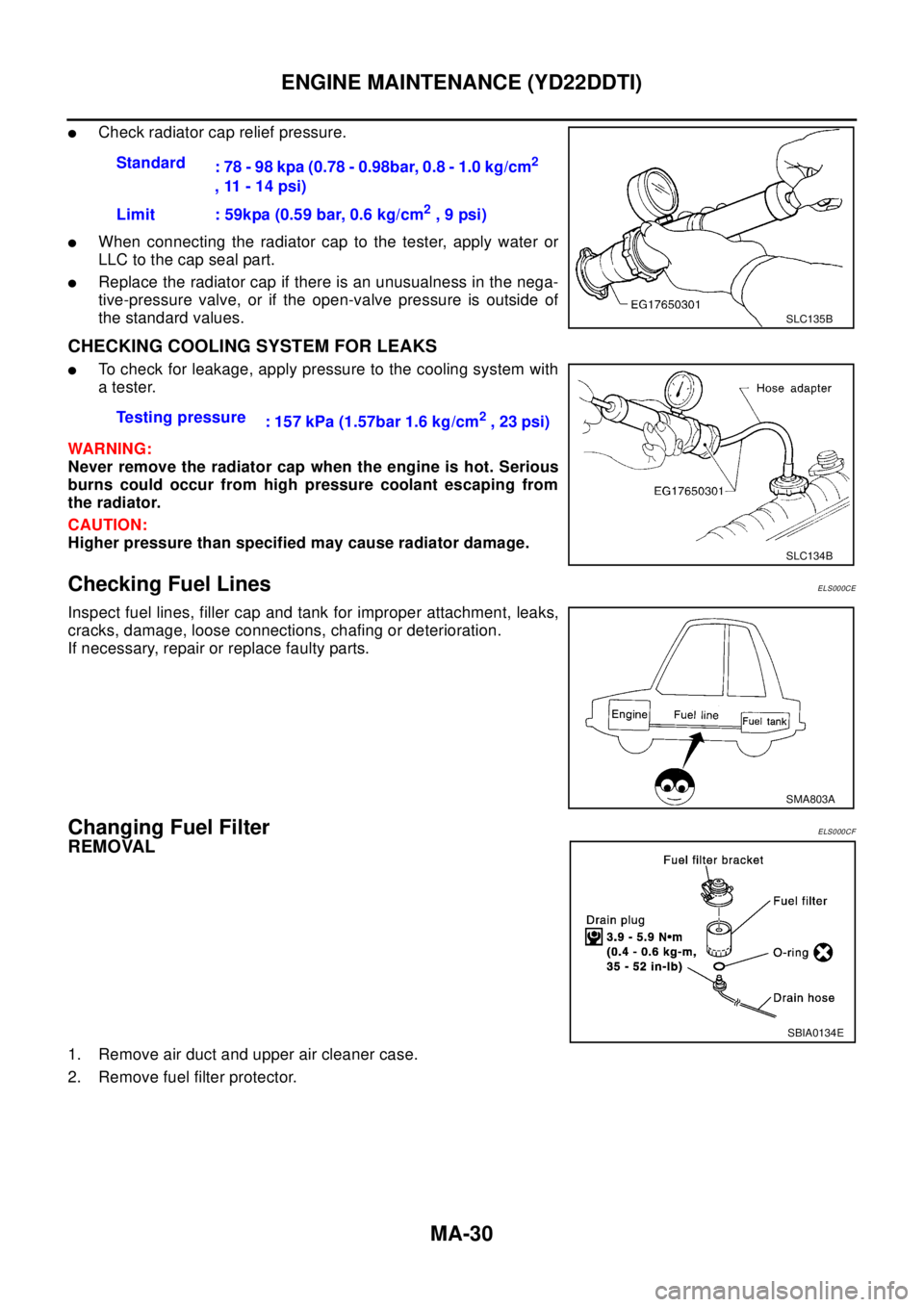

lCheck radiator cap relief pressure.

lWhen connecting the radiator cap to the tester, apply water or

LLC to the cap seal part.

lReplace the radiator cap if there is an unusualness in the nega-

tive-pressure valve, or if the open-valve pressure is outside of

the standard values.

CHECKING COOLING SYSTEM FOR LEAKS

lTo check for leakage, apply pressure to the cooling system with

atester.

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Checking Fuel LinesELS000CE

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration.

If necessary, repair or replace faulty parts.

Changing Fuel FilterELS000CF

REMOVAL

1. Remove air duct and upper air cleaner case.

2. Remove fuel filter protector.Standard

: 78 - 98 kpa (0.78 - 0.98bar, 0.8 - 1.0 kg/cm

2

,11-14psi)

Limit : 59kpa (0.59 bar, 0.6 kg/cm

2,9psi)

SLC135B

Testing pressure

: 157 kPa (1.57bar 1.6 kg/cm2,23psi)

SLC134B

SMA803A

SBIA0134E

Page 2523 of 3066

ENGINE MAINTENANCE (YD22DDTI)

MA-31

C

D

E

F

G

H

I

J

K

MA

B

MA

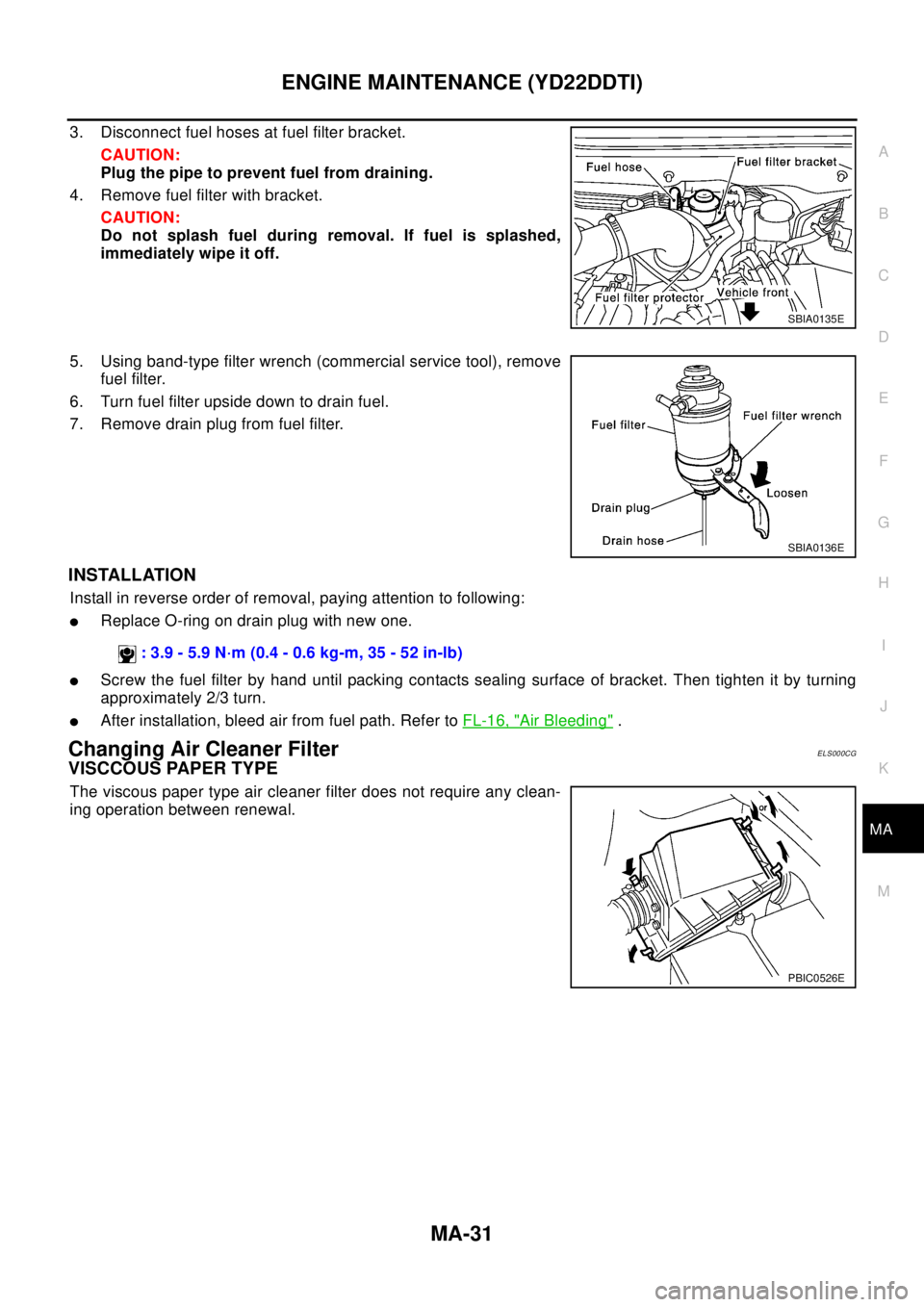

3. Disconnect fuel hoses at fuel filter bracket.

CAUTION:

Plug the pipe to prevent fuel from draining.

4. Remove fuel filter with bracket.

CAUTION:

Do not splash fuel during removal. If fuel is splashed,

immediately wipe it off.

5. Using band-type filter wrench (commercial service tool), remove

fuel filter.

6. Turn fuel filter upside down to drain fuel.

7. Remove drain plug from fuel filter.

INSTALLATION

Install in reverse order of removal, paying attention to following:

lReplace O-ring on drain plug with new one.

lScrew the fuel filter by hand until packing contacts sealing surface of bracket. Then tighten it by turning

approximately 2/3 turn.

lAfter installation, bleed air from fuel path. Refer toFL-16, "Air Bleeding".

Changing Air Cleaner FilterELS000CG

VISCCOUS PAPER TYPE

The viscous paper type air cleaner filter does not require any clean-

ing operation between renewal.

SBIA0135E

SBIA0136E

: 3.9 - 5.9 N·m (0.4 - 0.6 kg-m, 35 - 52 in-lb)

PBIC0526E

Page 2524 of 3066

MA-32

ENGINE MAINTENANCE (YD22DDTI)

Changing Engine Oil

ELS000CH

WAR NIN G:

lBe careful not to burn yourself, as the engine oil is hot.

lProlonged and repeated contact with used engine oil may

cause skin cancer: try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with soap

or hand cleaner as soon as possible.

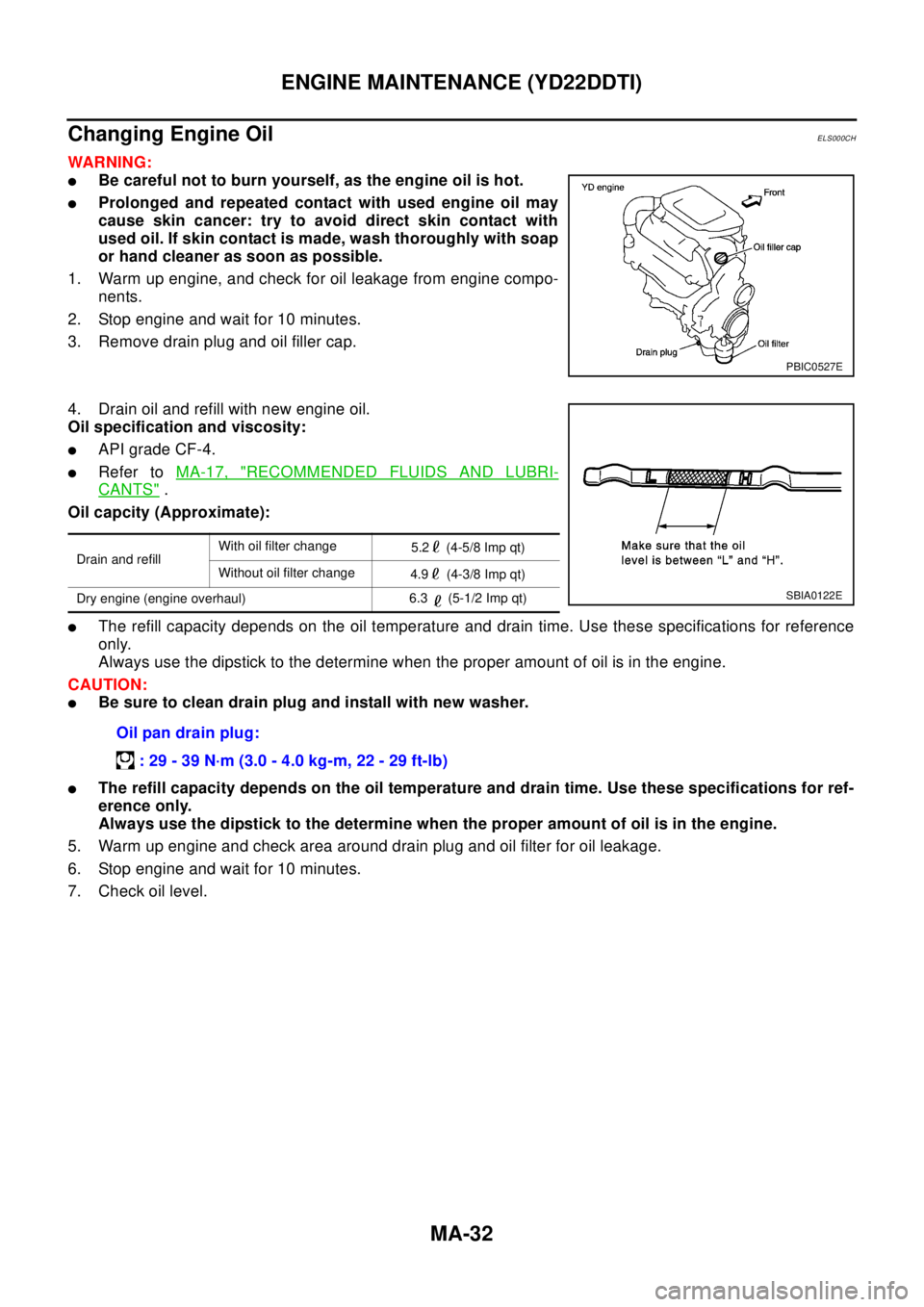

1. Warm up engine, and check for oil leakage from engine compo-

nents.

2. Stop engine and wait for 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil specification and viscosity:

lAPI grade CF-4.

lRefer toMA-17, "RECOMMENDED FLUIDS AND LUBRI-

CANTS".

Oil capcity (Approximate):

lThe refill capacity depends on the oil temperature and drain time. Use these specifications for reference

only.

Always use the dipstick to the determine when the proper amount of oil is in the engine.

CAUTION:

lBe sure to clean drain plug and install with new washer.

lThe refill capacity depends on the oil temperature and drain time. Use these specifications for ref-

erence only.

Always use the dipstick to the determine when the proper amount of oil is in the engine.

5. Warm up engine and check area around drain plug and oil filter for oil leakage.

6. Stop engine and wait for 10 minutes.

7. Check oil level.

PBIC0527E

Drain and refillWith oil filter change

5.2 (4-5/8 Imp qt)

Without oil filter change

4.9 (4-3/8 Imp qt)

Dry engine (engine overhaul)6.3 (5-1/2 Imp qt)

Oil pan drain plug:

:29-39N·m(3.0-4.0kg-m,22-29ft-lb)

SBIA0122E

Page 2525 of 3066

ENGINE MAINTENANCE (YD22DDTI)

MA-33

C

D

E

F

G

H

I

J

K

MA

B

MA

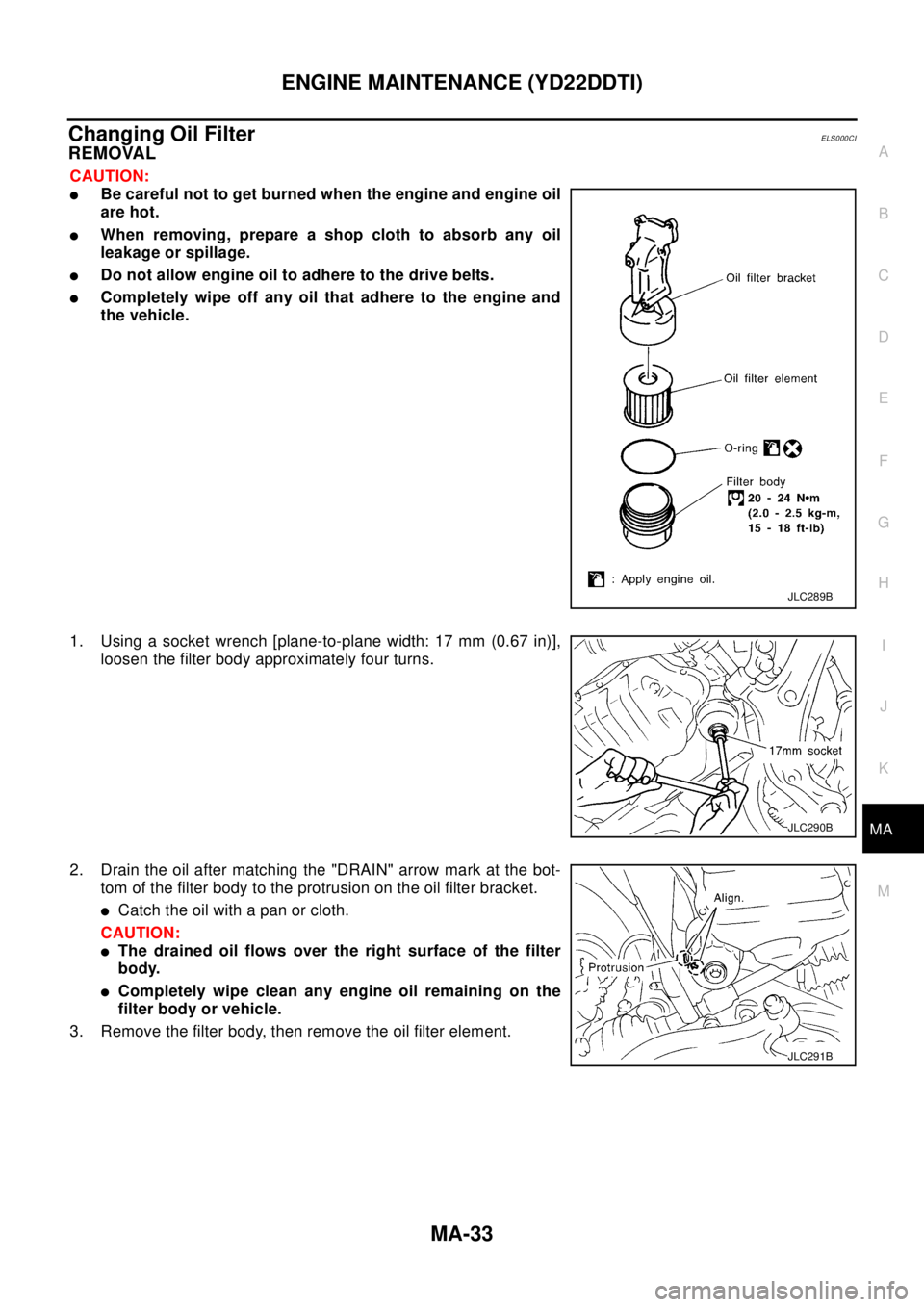

Changing Oil FilterELS000CI

REMOVAL

CAUTION:

lBe careful not to get burned when the engine and engine oil

are hot.

lWhen removing, prepare a shop cloth to absorb any oil

leakage or spillage.

lDo not allow engine oil to adhere to the drive belts.

lCompletely wipe off any oil that adhere to the engine and

the vehicle.

1. Using a socket wrench [plane-to-plane width: 17 mm (0.67 in)],

loosen the filter body approximately four turns.

2. Drain the oil after matching the "DRAIN" arrow mark at the bot-

tom of the filter body to the protrusion on the oil filter bracket.

lCatch the oil with a pan or cloth.

CAUTION:

lThe drained oil flows over the right surface of the filter

body.

lCompletely wipe clean any engine oil remaining on the

filter body or vehicle.

3. Remove the filter body, then remove the oil filter element.

JLC289B

JLC290B

JLC291B