torque NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 3 of 3066

ACC-1

ACCELERATOR CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

ACC

ACCELERATOR CONTROL SYSTEM

ACCELERATOR CONTROL SYSTEM ...................... 2

Removal and Installation .......................................... 2

QR20DE ................................................................ 2

YD22DDTI ............................................................. 2

REMOVAL ............................................................. 2

INSTALLATION ..................................................... 3

INSPECTION AFTER INSTALLATION ................. 3SERVICE DATA AND SPECIFICATIONS (SDS) ........ 4

Tightening Torque ..................................................... 4

Page 6 of 3066

ACC-4

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Tightening TorqueEBS003CI

Unit: N·m (Kg-m, in-lb)

Accelerator pedal assembly 4.3 - 5.9 (0.44 - 0.60, 39 - 52)

Accelerator pedal assembly (work unit) (YD22DDTi) 4.3 - 5.9 (0.44 - 0.60, 39 - 52)

Accelerator pedal bracket (YD22DDTi) 4.3 - 5.9 (0.44 - 0.60, 39 - 52)

Page 8 of 3066

AT-2

DTC P0732 A/T 2ND GEAR FUNCTION ................158

Description ............................................................158

Wiring Diagram — AT — 2ND ..............................161

Diagnostic Procedure ...........................................162

Component Inspection ..........................................163

DTC P0733 A/T 3RD GEAR FUNCTION ................165

Description ............................................................165

Wiring Diagram — AT — 3RD ..............................168

Diagnostic Procedure ...........................................169

Component Inspection ..........................................170

DTC P0734 A/T 4TH GEAR FUNCTION ................172

Description ............................................................172

Wiring Diagram — AT — 4TH ...............................175

Diagnostic Procedure ...........................................176

Component Inspection ..........................................179

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE .................................................181

Description ............................................................181

Wiring Diagram — AT — TCV ..............................183

Diagnostic Procedure ...........................................184

Component Inspection ..........................................185

DTC P0745 LINE PRESSURE SOLENOID VALVE. 186

Description ............................................................186

Wiring Diagram — AT — LPSV ............................188

Diagnostic Procedure ...........................................189

Component Inspection ..........................................191

DTC P0750 SHIFT SOLENOID VALVE A ...............193

Description ............................................................193

Wiring Diagram — AT — SSV/A ...........................195

Diagnostic Procedure ...........................................196

Component Inspection ..........................................197

DTC P0755 SHIFT SOLENOID VALVE B ...............198

Description ............................................................198

Wiring Diagram — AT — SSV/B ...........................200

Diagnostic Procedure ...........................................201

Component Inspection ..........................................202

DTC P1705 ACCELERATOR PEDAL POSITION

(APP) SENSOR .......................................................203

Description ............................................................203

Wiring Diagram — AT — TPS ..............................205

Diagnostic Procedure ...........................................206

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE .....................................................................208

Description ............................................................208

Wiring Diagram — AT — OVRCSV ......................210

Diagnostic Procedure ...........................................211

Component Inspection ..........................................212

DTC U1000 CAN COMMUNICATION LINE ............213

Description ............................................................213

On Board Diagnosis Logic ....................................213

..............................................................................213

Wiring Diagram — AT ...........................................214

Diagnostic Procedure ...........................................215

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE). 216

Description ............................................................216

Wiring Diagram — AT — BA/FTS .........................218Diagnostic Procedure ............................................ 219

Component Inspection .......................................... 221

DTC VEHICLE SPEED SENSOR MTR ................... 222

Description ............................................................ 222

Wiring Diagram — AT — VSSMTR ....................... 224

Diagnostic Procedure ............................................ 225

DTC CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ...................................................................... 226

Description ............................................................ 226

Diagnostic Procedure ............................................ 227

DTC CONTROL UNIT(EEPROM) ........................... 228

Description ............................................................ 228

Diagnostic Procedure ............................................ 229

TROUBLE DIAGNOSES FOR SYMPTOMS ........... 230

.............................................................................. 230

1. O/D OFF Indicator Lamp Does Not Come On .. 232

2. Engine Cannot Be Started In “P” and “N” Position. 233

3. In “P” Position, Vehicle Moves Forward Or Back-

ward When Pushed ............................................... 234

4. In “N” Position, Vehicle Moves .......................... 234

5. Large Shock. “N”®“R” Position ...................... 236

6. Vehicle Does Not Creep Backward In “R” Position. 237

7. Vehicle Does Not Creep Forward In “D”, “2” Or

“1” Position ............................................................ 240

8. Vehicle Cannot Be Started From D

1................. 242

9. A/T Does Not Shift: D

1®D2Or Does Not Kick-

down: D

4®D2..................................................... 244

10. A/T Does Not Shift: D

2®D3.......................... 246

11.A/TDoesNotShift:D

3®D4........................... 249

12. A/T Does Not Perform Lock-up ....................... 252

13. A/T Does Not Hold Lock-up Condition ............ 253

14. Lock-up Is Not Released ................................. 254

15. Engine Speed Does Not Return To Idle (Light

Braking D

4®D3) ................................................. 255

16. Vehicle Does Not Start From D

1..................... 257

17. A/T Does Not Shift: D

4®D3, When Overdrive

Control Switch “ON”®“OFF” ............................... 258

18. A/T Does Not Shift: D

3®22, When Selector

Lever “D”®“2” Position ....................................... 258

19. A/T Does Not Shift: 2

2®11, When Selector

Lever “2”®“1” Position ........................................ 259

20. Vehicle Does Not Decelerate By Engine Brake. 259

21. TCM Self-diagnosis Does Not Activate (PNP &

Overdrive Control Switches, and Throttle Position

Sensor Circuit Checks) ......................................... 260

EXC.F/EURO-OBD

ON BOARD DIAGNOSTIC SYSTEM DESCRIP-

TION ........................................................................ 267

CONSULT-II .......................................................... 267

Diagnostic Procedure Without CONSULT-II ......... 273

TROUBLE DIAGNOSIS — INTRODUCTION ......... 279

Introduction ........................................................... 279

Work Flow ............................................................. 284

TROUBLE DIAGNOSIS — BASIC INSPECTION ... 286

A/T Fluid Check .................................................... 286

Stall Test ................................................................ 287

Page 9 of 3066

AT-3

D

E

F

G

H

I

J

K

L

MA

B

AT Line Pressure Test ............................................... 290

Road Test ............................................................. 291

TROUBLE DIAGNOSIS — GENERAL DESCRIP-

TION ........................................................................ 308

Symptom Chart .................................................... 308

TCM Terminals and Reference Value ................... 347

CAN COMMUNICATION ........................................ 351

System Description .............................................. 351

TROUBLE DIAGNOSES FOR SYMPTOMS .......... 352

............................................................................. 352

1. O/D OFF Indicator Lamp Does Not Come On . 354

2. Engine Cannot Be Started In “P” and “N” Position. 355

3. In “P” Position, Vehicle Moves Forward Or Back-

ward When Pushed .............................................. 356

4. In “N” Position, Vehicle Moves ......................... 356

5. Large Shock. “N”®“R” Position ...................... 358

6. Vehicle Does Not Creep Backward In “R” Position. 359

7. Vehicle Does Not Creep Forward In “D”, “2” Or

“1” Position ........................................................... 362

8. Vehicle Cannot Be Started From D

1................. 364

9. A/T Does Not Shift: D

1®D2Or Does Not Kick-

down: D

4®D2..................................................... 366

10. A/T Does Not Shift: D

2®D3......................... 368

11.A/TDoesNotShift:D

3®D4.......................... 371

12. A/T Does Not Perform Lock-up ...................... 374

13. A/T Does Not Hold Lock-up Condition ........... 375

14. Lock-up Is Not Released ................................ 376

15. Engine Speed Does Not Return To Idle (Light

Braking D

4®D3) ................................................ 377

16. Vehicle Does Not Start From D

1..................... 379

17. A/T Does Not Shift: D

4®D3, When Overdrive

Control Switch “ON”®“OFF” .............................. 380

18. A/T Does Not Shift: D

3®22, When Selector

Lever “D”®“2” Position ...................................... 380

19. A/T Does Not Shift: 2

2®11, When Selector

Lever “2”®“1” Position ....................................... 381

20. Vehicle Does Not Decelerate By Engine Brake. 381

21. TCM Self-diagnosis Does Not Activate (PNP &

Overdrive Control Switches, and Throttle Position

Sensor Circuit Checks) ........................................ 382

ALL

MAIN POWER SUPPLY AND GROUND CIRCUIT. 389

Wiring Diagram — AT — MAIN ............................ 389

Diagnostic Procedure ........................................... 390

VEHICLE SPEED SENSOR·A/T (REVOLUTION

SENSOR) ................................................................ 392

Description ........................................................... 392

Wiring Diagram — AT — VSSA/T ........................ 394

Diagnostic Procedure ........................................... 395

DTC VEHICLE SPEED SENSOR MTR .................. 397

Description ........................................................... 397

Wiring Diagram — AT — VSSMTR ...................... 399

Diagnostic Procedure ........................................... 400

ACCELE RATOR PEDAL POSITION (APP) SEN-

SOR ........................................................................ 401

Description ........................................................... 401Wiring Diagram — AT — TPS ..............................403

Diagnostic Procedure ...........................................404

SHIFT SOLENOID VALVE A ..................................406

Description ............................................................406

Wiring Diagram — AT — SSV/A ...........................408

Diagnostic Procedure ...........................................409

Component Inspection ..........................................410

SHIFT SOLENOID VALVE B ..................................411

Description ............................................................411

Wiring Diagram — AT — SSV/B ...........................413

Diagnostic Procedure ...........................................414

Component Inspection ..........................................415

OVERRUN CLUTCH SOLENOID VALVE ...............416

Description ............................................................416

Wiring Diagram — AT — OVRCSV ......................418

Diagnostic Procedure ...........................................419

Component Inspection ..........................................420

TORQUE CONVERTER CLUTCH SOLENOID

VALVE .....................................................................421

Description ............................................................421

Wiring Diagram — AT — TCV ..............................423

Diagnostic Procedure ...........................................424

Component Inspection ..........................................425

BATT/FLUID TEMP SEN (A/T FLUID TEMP SEN-

SOR CIRCUIT AND TCM POWER SOURCE) .......426

Description ............................................................426

Wiring Diagram — AT — BA/FTS .........................428

Diagnostic Procedure ...........................................429

Component Inspection ..........................................431

ENGINE SPEED SIGNAL .......................................432

Description ............................................................432

Wiring Diagram — AT — ENGSS .........................433

Diagnostic Procedure ...........................................434

LINE PRESSURE SOLENOID VALVE ...................436

Description ............................................................436

Wiring Diagram — AT — LPSV ............................438

Diagnostic Procedure ...........................................439

Component Inspection ..........................................441

CAN CAMMUNICATION LINE ................................443

Description ............................................................443

On Board Diagnosis Logic ....................................443

Self-Diagnosis Code Confirmation Procedure ......443

Wiring Diagram — AT — CAN ..............................444

Diagnostic Procedure ...........................................445

A/T SHIFT LOCK SYSTEM ....................................446

Description ............................................................446

Shift Lock System Electrical Parts Location .........446

Wiring Diagram — SHIFT — ................................447

Diagnostic Procedure ...........................................448

KEY INTERLOCK CABLE ......................................452

Components .........................................................452

Removal ...............................................................452

Installation ............................................................453

ON-VEHICLE SERVICE ..........................................454

Control Valve Assembly and Accumulators ..........454

Control Cable Adjustment .....................................456

Park/Neutral Position (PNP) Switch Adjustment ..456

Page 13 of 3066

PRECAUTIONS

AT-7

D

E

F

G

H

I

J

K

L

MA

B

AT

lAfter performing each TROUBLE DIAGNOSIS, perform

“DTC (Diagnostic Trouble Code) CONFIRMATION PROCE-

DURE”.

The DTC should not be displayed in the “DTC CONFIRMA-

TION PROCEDURE” if the repair is completed.

lBefore proceeding with disassembly, thoroughly clean the out-

side of the transaxle. It is important to prevent the internal parts

from becoming contaminated by dirt or other foreign matter.

lDisassembly should be done in a clean work area.

lUse lint-free cloth or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the operation

of the transaxle.

lPlace disassembled parts in order for easier and proper assembly.

lAll parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

lGaskets, seals and O-rings should be replaced any time the transaxle is disassembled.

lIt is very important to perform functional tests whenever they are indicated.

lThe valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent

springs and small parts from becoming scattered or lost.

lProperly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

lBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, or hold bearings and washers in place during assembly. Do not use grease.

lExtreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

lAfter overhaul, refill the transaxle with new ATF.

lWhen the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque

converter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer

to “Changing A/T Fluid”,AT-13, "

A/T FLUID".

Service Notice or PrecautionsECS004Q3

FAI L-S AFE

The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of “1”, “2” or “D”. The cus-

tomer may complain of sluggish or poor acceleration.

When the ignition key is turned “ON” following Fail-Safe operation, O/D OFF indicator lamp blinks for about 8

seconds. Refer to SELF-DIAGNOSTIC PROCEDURE(WITHOUT CONSULT-II)",AT- 2 7 3 , "

Diagnostic Proce-

dure Without CONSULT-II"(EXCEPT FOR EURO-OBD) or "TCM Self-diagnostic Procedure(NO TOOLS)",

AT- 5 1 , "

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)"(EURO-OBD).

The blinking of the O/D OFF indicator lamp for about 8 seconds will appear only once and be cleared. The

customer may resume normal driving conditions.

Always follow the “WORK FLOW”, refer toAT-284, "

Work Flow"(EXCEPT FOR Euro-OBD) orAT-61, "Work

Flow"(Euro-OBD).

The SELF-DIAGNOSIS results will be as follows:

lThe first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

lDuring the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

TORQUE CONVERTER SERVICE

The torque converter should be replaced under any of the following conditions:

lExternal leaks in the hub weld area.

lConverter hub is scored or damaged.

lConverter pilot is broken, damaged or fits poorly into crankshaft.

lSteel particles are found after flushing the cooler and cooler lines.

lPump is damaged or steel particles are found in the converter.

SAT652J

Page 14 of 3066

AT-8

PRECAUTIONS

lVehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

lConverter is contaminated with engine coolant containing antifreeze.

lInternal failure of stator roller clutch.

lHeavy clutch debris due to overheating (blue converter).

lSteel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

The torque converter should not be replaced if:

lThe fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

lThe threads in one or more of the converter bolt holes are damaged.

lTransaxle failure did not display evidence of damaged or worn internal parts, steel particles or clutch plate

lining material in unit and inside the fluid filter.

lVehicle has been exposed to high mileage (only). The exception may be where the torque converter

clutch dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic,

such as taxi, delivery or police use.

EURO-OBD SELF-DIAGNOSIS — EURO-OBD —

lA/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the O/D OFF indicator lamp or the malfunction indicator lamp (MIL). Refer to the

table onAT-42, "

SELF-DIAGNOSTIC RESULT TEST MODE"for the indicator used to display each self-

diagnostic result.

lThe self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM mem-

ories.

Always perform the procedure “HOW TO ERASE DTC” onAT-39, "

HOW TO ERASE DTC"to com-

plete the repair and avoid unnecessary blinking of the MIL.

lThe following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when

the O/D OFF indicator lamp does not indicate any malfunctions.

–PNP switch

–A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of EURO-OBD, refer toAT - 3 7 , "

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION".

lCertain systems and components, especially those related to EURO-OBD, may use a new style

slide-locking type harness connector.

For description and how to disconnect, refer toPG-70, "

HARNESS CONNECTOR".

Wiring Diagrams and Trouble DiagnosisECS004Q4

When you read wiring diagrams, refer to the following:

lGI-14, "How to Read Wiring Diagrams".

lPG-2, "POWER SUPPLY ROUTING".

When you perform trouble diagnosis, refer to the following:

lGI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES".

l"", “HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT”

Page 19 of 3066

A/T FLUID

AT-13

D

E

F

G

H

I

J

K

L

MA

B

AT

A/T FLUIDPFP:KLE40

Checking A/T FluidECS004Q7

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50°C (86 to 122°F) using “COLD” range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of either

range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on dipstick.

6. Check fluid condition.

lIf fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

lIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer toCO-12,

"RADIATOR",CO-15, "RADIATOR (ALUMINUM TYPE)",,.

Changing A/T FluidECS004Q8

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to “Checking A/T Fluid”. If fluid is still dirty, repeat steps 2 through 5.

SMA827CA

SMA853B

Fluid grade:

Genuine Nissan ATF or equivalent. Refer toMA-

17, "RECOMMENDED FLUIDS AND LUBRI-

CANTS".

Fluid capacity (With torque converter):

Approx. 8.0 (7.01 lmp qt)

Drain plug:

:29-39N·m(3.0-4.0kg-m,22-29ft-lb)

SMA027D

Page 23 of 3066

OVERALL SYSTEM

AT-17

D

E

F

G

H

I

J

K

L

MA

B

AT

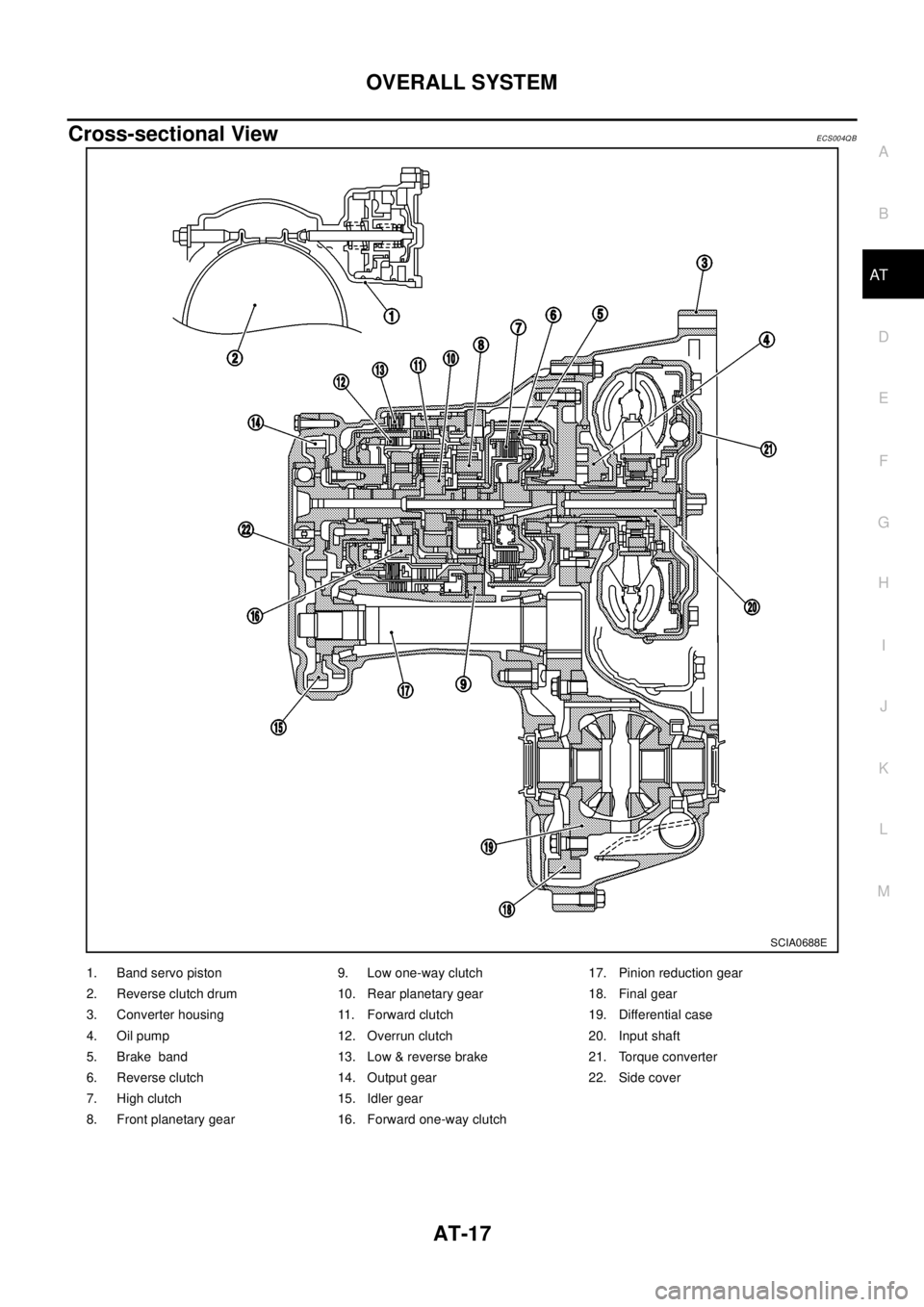

Cross-sectional ViewECS004QB

SCIA0688E

1. Band servo piston 9. Low one-way clutch 17. Pinion reduction gear

2. Reverse clutch drum 10. Rear planetary gear 18. Final gear

3. Converter housing 11. Forward clutch 19. Differential case

4. Oil pump 12. Overrun clutch 20. Input shaft

5. Brake band 13. Low & reverse brake 21. Torque converter

6. Reverse clutch 14. Output gear 22. Side cover

7. High clutch 15. Idler gear

8. Front planetary gear 16. Forward one-way clutch

Page 25 of 3066

OVERALL SYSTEM

AT-19

D

E

F

G

H

I

J

K

L

MA

B

AT

Shift MechanismECS004QD

CONSTRUCTION

FUNCTION OF CLUTCH AND BRAKE

CLUTCH AND BAND CHART

1. Torque converter 2. Oil pump 3. Input shaft

4. Brake band 5. Reverse clutch 6. High clutch

7. Front sun gear 8. Front pinion gear 9. Front internal gear

10. Front planetary carrier 11. Rear sun gear 12. Rear pinion gear

13. Rear internal gear 14. Rear planetary carrier 15. Forward clutch

16. Forward one-way clutch 17. Overrun clutch 18. Low one-way clutch

19. Low & reverse brake 20. Parking pawl 21. Parking gear

22. Output shaft 23. Idle gear 24. Output gear

SAT998I

Clutch and brake components Abbr. Function

5Reverse clutch R/C To transmit input power to front sun gear7.

6High clutch H/C To transmit input power to front planetary carrier10.

15Forward clutch F/C To connect front planetary carrier10with forward one-way clutch16.

17Overrun clutch O/C To connect front planetary carrier10with rear internal gear13.

4Brake band B/B To lock front sun gear7.

16Forward one-way clutch F/O.C When forward clutch15is engaged, to stop rear internal gear13from rotating in

opposite direction against engine revolution.

18Low one-way clutch L/O.C To stop front planetary carrier10from rotating in opposite direction against

engine revolution.

19Low & reverse brake L & R/B To lock front planetary carrier10.

Shift positionRever

se

clutch

5High

clutch

6For-

ward

clutch

15Over-

run

clutch

17Band servo

Forward

one-way

clutch

16Low

one-

way

clutch

18Low &

revers

e

brake

19Lock-

upRemarks

2nd

apply3rd

releas

e4th

apply

PPA R K

POSITION

RREVERSE

POSITION

Page 33 of 3066

OVERALL SYSTEM

AT-27

D

E

F

G

H

I

J

K

L

MA

B

AT

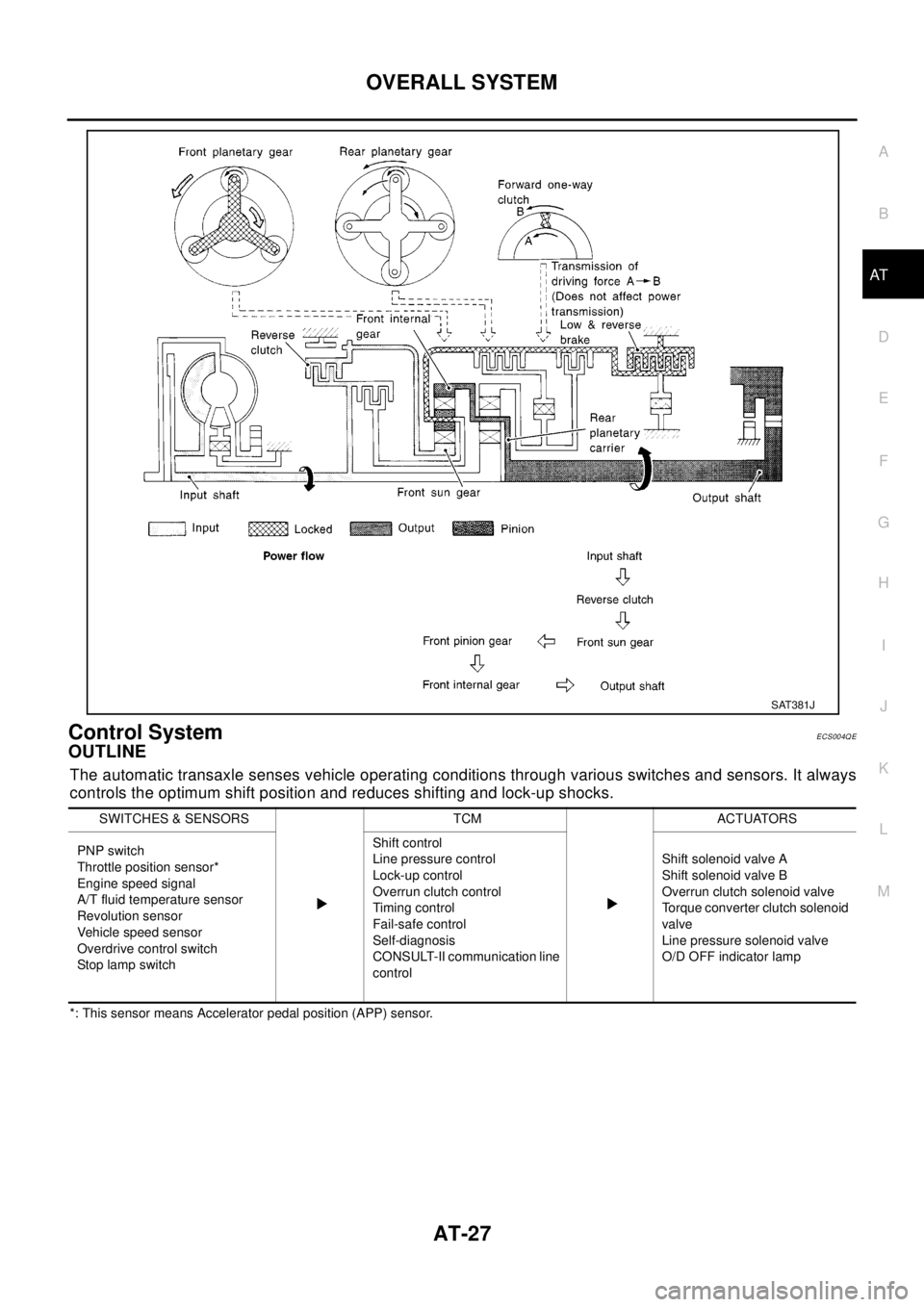

Control SystemECS004QE

OUTLINE

The automatic transaxle senses vehicle operating conditions through various switches and sensors. It always

controls the optimum shift position and reduces shifting and lock-up shocks.

*: This sensor means Accelerator pedal position (APP) sensor.

SAT381J

SWITCHES & SENSORS TCM ACTUATORS

PNP switch

Throttle position sensor*

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed sensor

Overdrive control switch

Stop la mp s witchShift control

Line pressure control

Lock-up control

Overrunclutchcontrol

Timing control

Fail-safe control

Self-diagnosis

CONSULT-II communication line

controlShift solenoid valve A

Shift solenoid valve B

Overrun clutch solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

O/D OFF indicator lamp