secure NISSAN X-TRAIL 2003 Electronic Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2570 of 3066

MT-34

TRANSAXLE ASSEMBLY

a. Install selected mainshaft rear bearing adjusting shim into transaxle case.

lFor selection of adjusting shims, refer toMT-46, "MAINSHAFT END PLAY".

b. Temporarily install snap ring of mainshaft rear bearing into transaxle case.

CAUTION:

Do not reuse the snap ring.

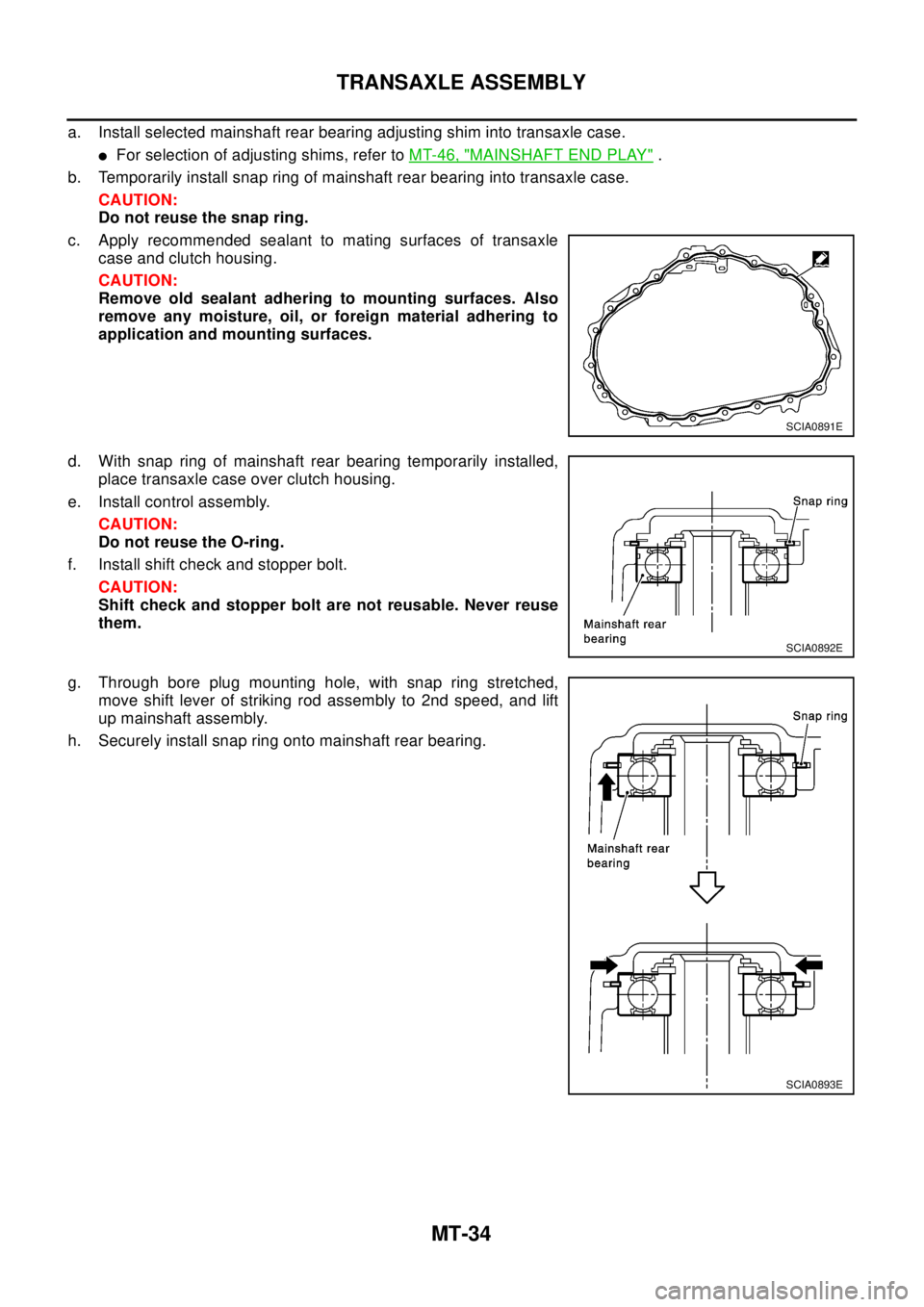

c. Apply recommended sealant to mating surfaces of transaxle

case and clutch housing.

CAUTION:

Remove old sealant adhering to mounting surfaces. Also

remove any moisture, oil, or foreign material adhering to

application and mounting surfaces.

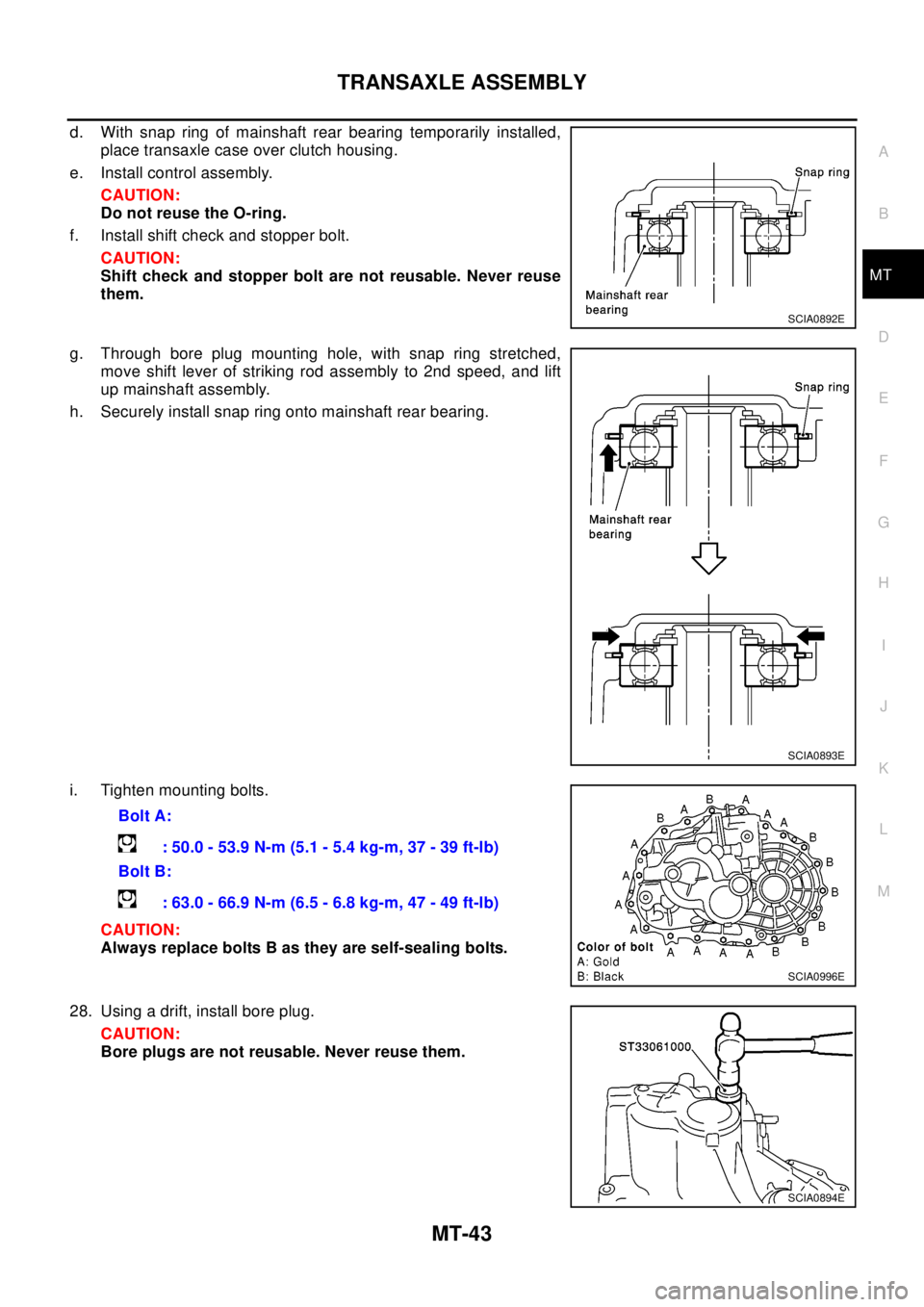

d. With snap ring of mainshaft rear bearing temporarily installed,

place transaxle case over clutch housing.

e. Install control assembly.

CAUTION:

Do not reuse the O-ring.

f. Install shift check and stopper bolt.

CAUTION:

Shift check and stopper bolt are not reusable. Never reuse

them.

g. Through bore plug mounting hole, with snap ring stretched,

move shift lever of striking rod assembly to 2nd speed, and lift

up mainshaft assembly.

h. Securely install snap ring onto mainshaft rear bearing.

SCIA0891E

SCIA0892E

SCIA0893E

Page 2579 of 3066

TRANSAXLE ASSEMBLY

MT-43

D

E

F

G

H

I

J

K

L

MA

B

MT

d. With snap ring of mainshaft rear bearing temporarily installed,

place transaxle case over clutch housing.

e. Install control assembly.

CAUTION:

Do not reuse the O-ring.

f. Install shift check and stopper bolt.

CAUTION:

Shift check and stopper bolt are not reusable. Never reuse

them.

g. Through bore plug mounting hole, with snap ring stretched,

move shift lever of striking rod assembly to 2nd speed, and lift

up mainshaft assembly.

h. Securely install snap ring onto mainshaft rear bearing.

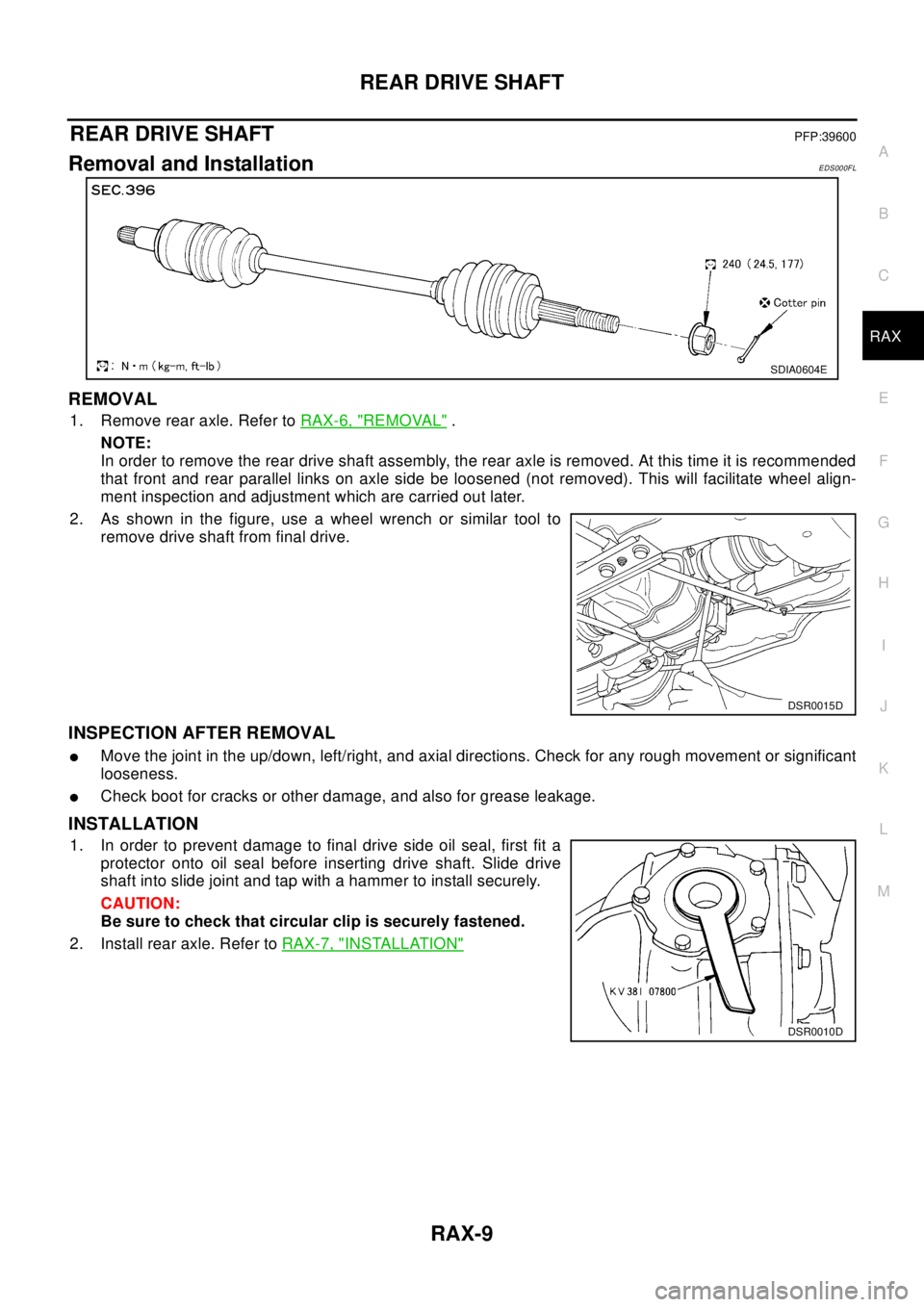

i. Tighten mounting bolts.

CAUTION:

Always replace bolts B as they are self-sealing bolts.

28. Using a drift, install bore plug.

CAUTION:

Bore plugs are not reusable. Never reuse them.

SCIA0892E

SCIA0893E

Bolt A:

: 50.0 - 53.9 N-m (5.1 - 5.4 kg-m, 37 - 39 ft-lb)

Bolt B:

: 63.0 - 66.9 N-m (6.5 - 6.8 kg-m, 47 - 49 ft-lb)

SCIA0996E

SCIA0894E

Page 2805 of 3066

REAR DRIVE SHAFT

RAX-9

C

E

F

G

H

I

J

K

L

MA

B

RAX

REAR DRIVE SHAFTPFP:39600

Removal and InstallationEDS000FL

REMOVAL

1. Remove rear axle. Refer toRAX-6, "REMOVAL".

NOTE:

In order to remove the rear drive shaft assembly, the rear axle is removed. At this time it is recommended

that front and rear parallel links on axle side be loosened (not removed). This will facilitate wheel align-

ment inspection and adjustment which are carried out later.

2. As shown in the figure, use a wheel wrench or similar tool to

remove drive shaft from final drive.

INSPECTION AFTER REMOVAL

lMove the joint in the up/down, left/right, and axial directions. Check for any rough movement or significant

looseness.

lCheck boot for cracks or other damage, and also for grease leakage.

INSTALLATION

1. In order to prevent damage to final drive side oil seal, first fit a

protector onto oil seal before inserting drive shaft. Slide drive

shaft into slide joint and tap with a hammer to install securely.

CAUTION:

Be sure to check that circular clip is securely fastened.

2. Install rear axle. Refer toRAX-7, "

INSTALLATION"

SDIA0604E

DSR0015D

DSR0010D

Page 2808 of 3066

RAX-12

REAR DRIVE SHAFT

Steel Ball

lCheck that there is no damage or unusual wear.

Inner Case

lCheck that there is no damage or other irregular conditions of ball rolling surface.

lCheck that there is no damage to serrated part.

ASSEMBLY

Final Drive Side

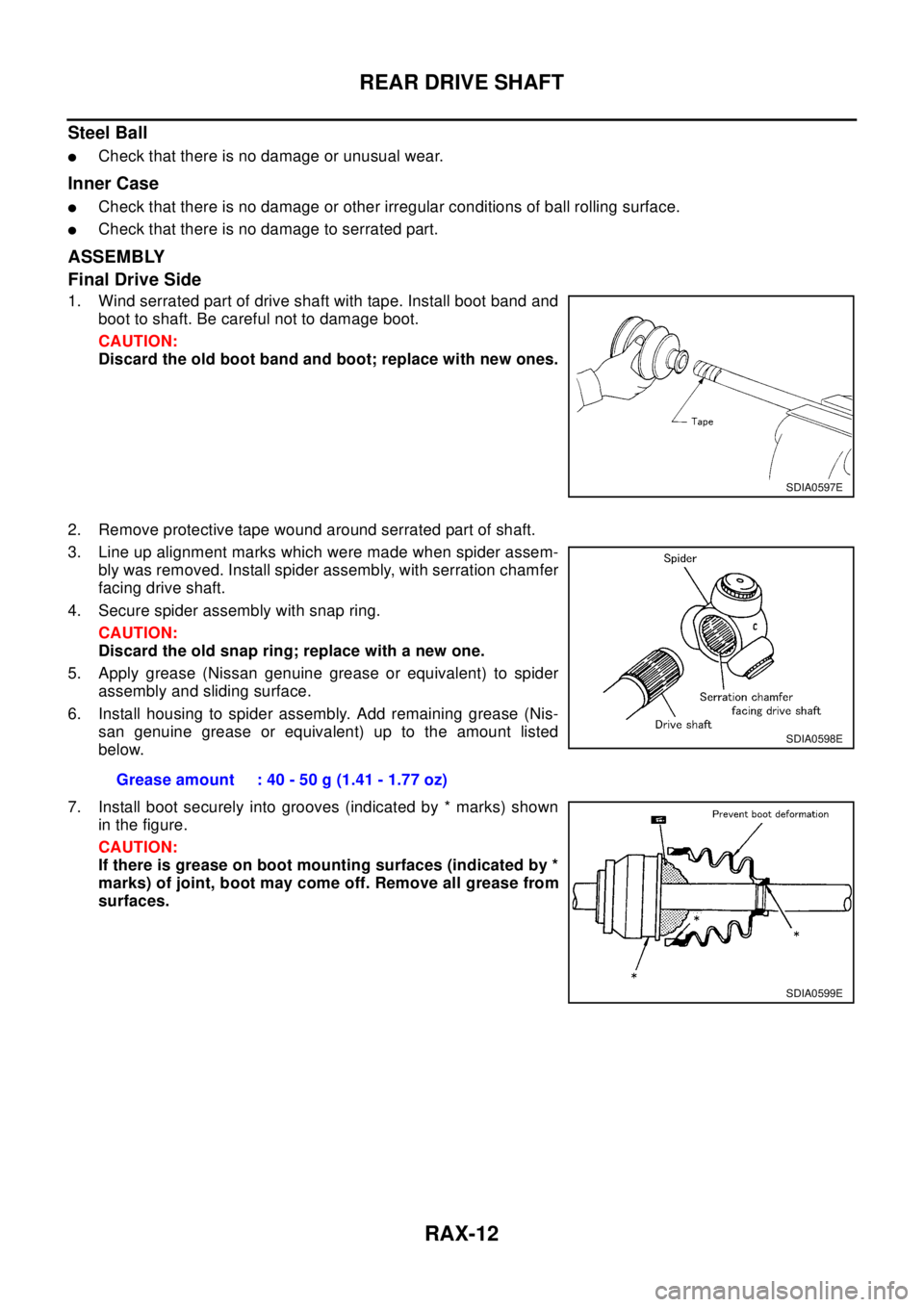

1. Wind serrated part of drive shaft with tape. Install boot band and

boot to shaft. Be careful not to damage boot.

CAUTION:

Discard the old boot band and boot; replace with new ones.

2. Remove protective tape wound around serrated part of shaft.

3. Line up alignment marks which were made when spider assem-

bly was removed. Install spider assembly, with serration chamfer

facing drive shaft.

4. Secure spider assembly with snap ring.

CAUTION:

Discard the old snap ring; replace with a new one.

5. Apply grease (Nissan genuine grease or equivalent) to spider

assembly and sliding surface.

6. Install housing to spider assembly. Add remaining grease (Nis-

san genuine grease or equivalent) up to the amount listed

below.

7. Install boot securely into grooves (indicated by * marks) shown

in the figure.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of joint, boot may come off. Remove all grease from

surfaces.

SDIA0597E

Grease amount : 40 - 50 g (1.41 - 1.77 oz)

SDIA0598E

SDIA0599E

Page 2809 of 3066

REAR DRIVE SHAFT

RAX-13

C

E

F

G

H

I

J

K

L

MA

B

RAX

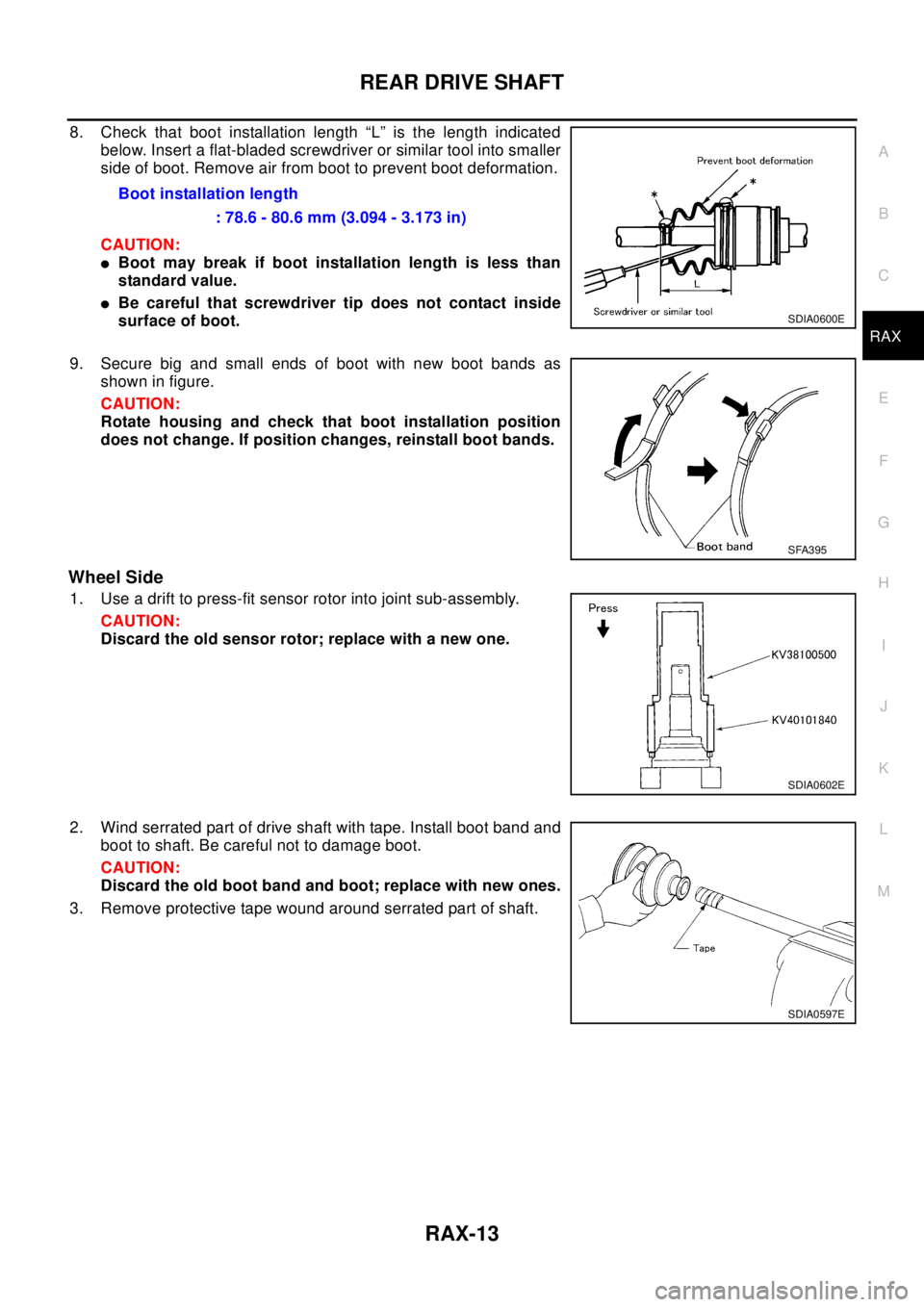

8. Check that boot installation length “L” is the length indicated

below. Insert a flat-bladed screwdriver or similar tool into smaller

side of boot. Remove air from boot to prevent boot deformation.

CAUTION:

lBoot may break if boot installation length is less than

standard value.

lBe careful that screwdriver tip does not contact inside

surface of boot.

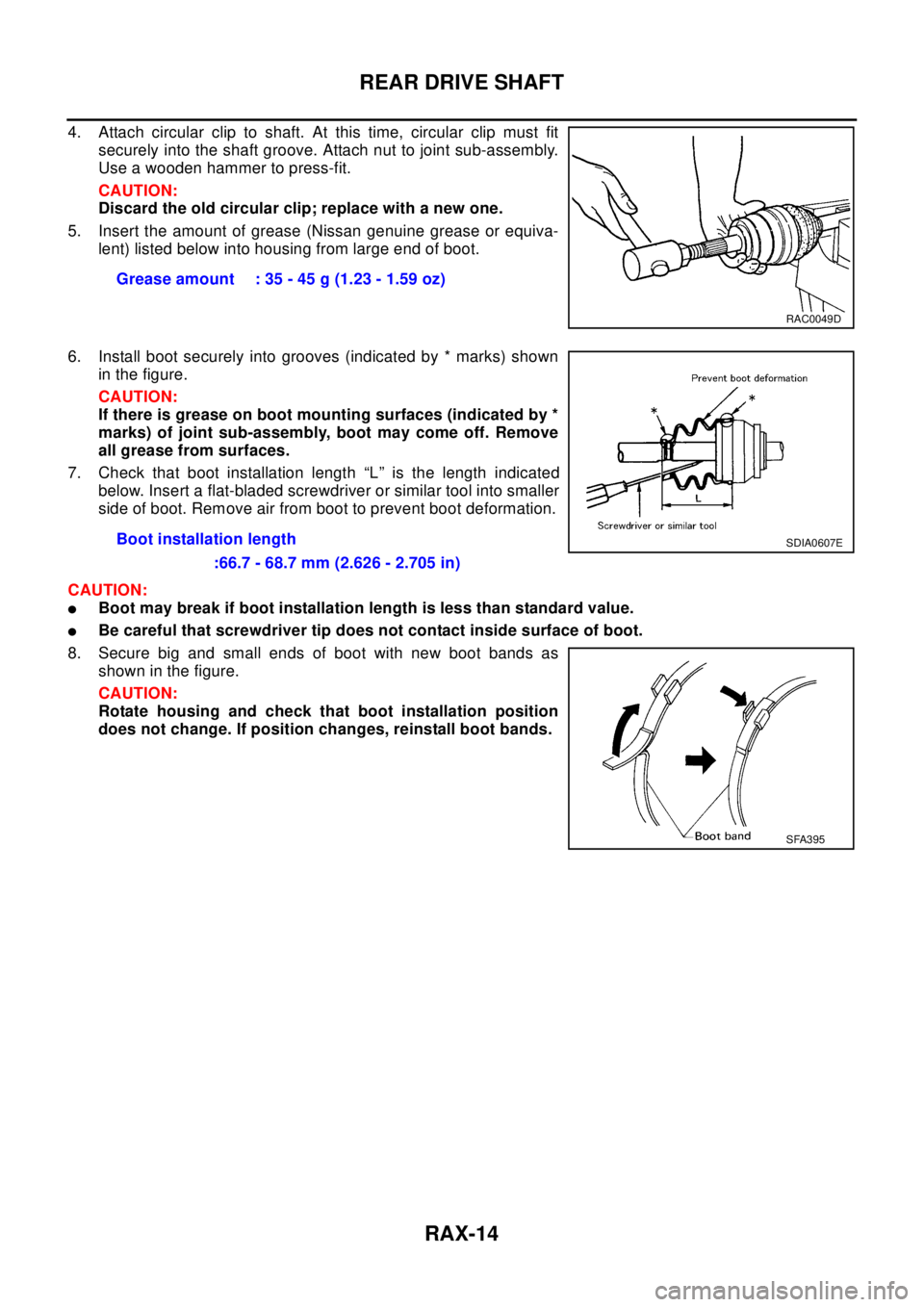

9. Secure big and small ends of boot with new boot bands as

shown in figure.

CAUTION:

Rotate housing and check that boot installation position

does not change. If position changes, reinstall boot bands.

Wheel Side

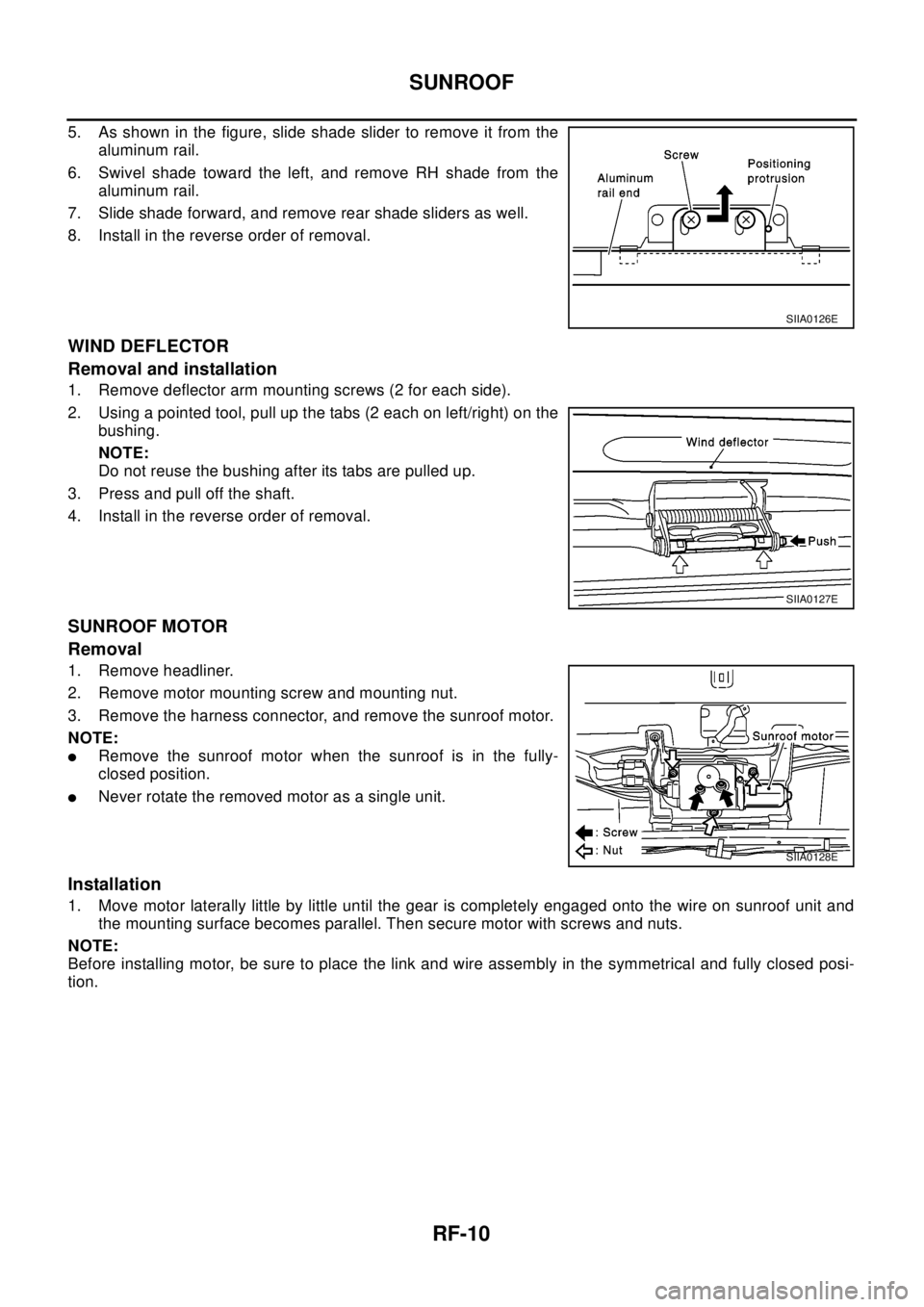

1. Use a drift to press-fit sensor rotor into joint sub-assembly.

CAUTION:

Discard the old sensor rotor; replace with a new one.

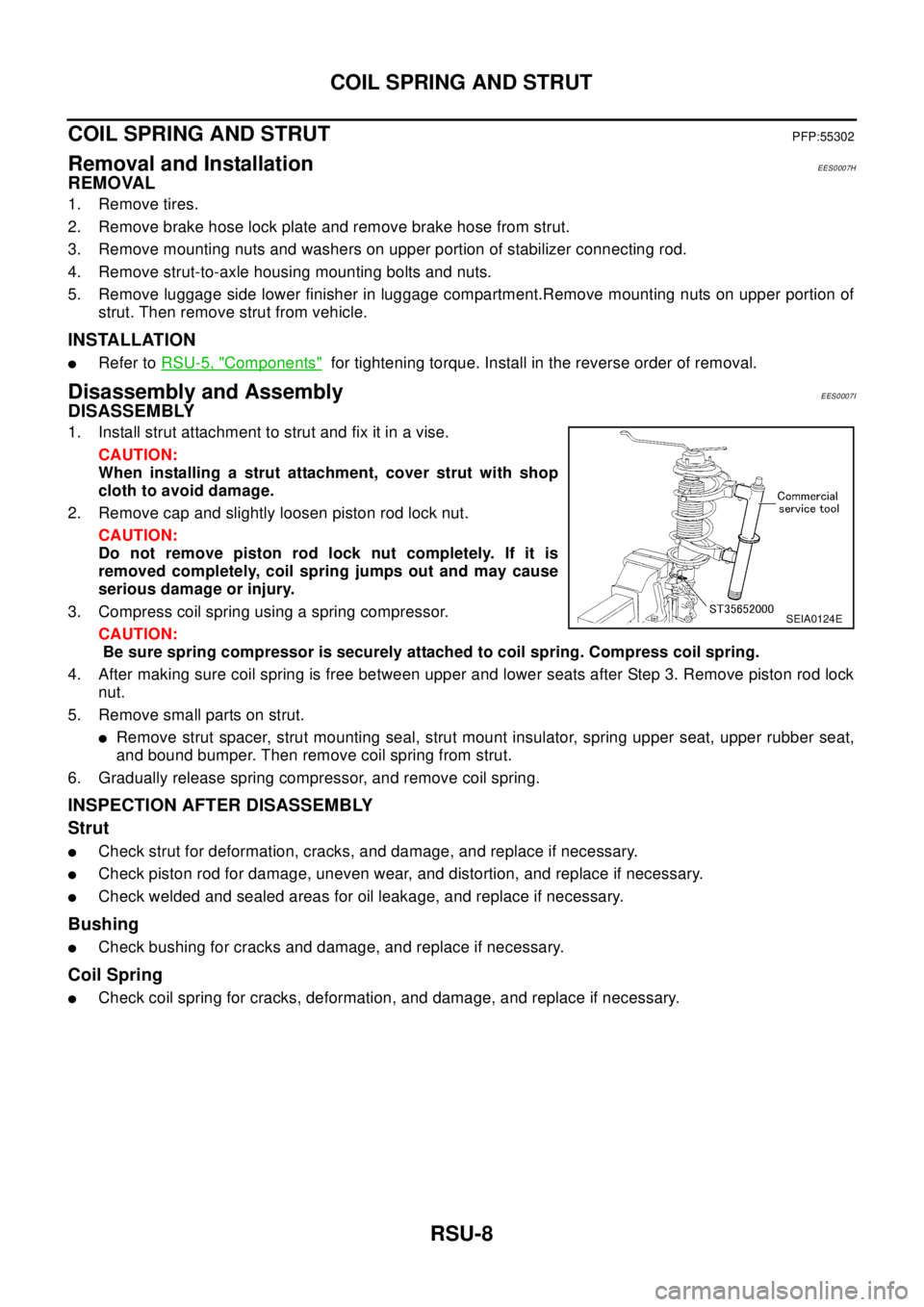

2. Wind serrated part of drive shaft with tape. Install boot band and

boot to shaft. Be careful not to damage boot.

CAUTION:

Discard the old boot band and boot; replace with new ones.

3. Remove protective tape wound around serrated part of shaft.Boot installation length

: 78.6 - 80.6 mm (3.094 - 3.173 in)

SDIA0600E

SFA395

SDIA0602E

SDIA0597E

Page 2810 of 3066

RAX-14

REAR DRIVE SHAFT

4. Attach circular clip to shaft. At this time, circular clip must fit

securely into the shaft groove. Attach nut to joint sub-assembly.

Use a wooden hammer to press-fit.

CAUTION:

Discard the old circular clip; replace with a new one.

5. Insert the amount of grease (Nissan genuine grease or equiva-

lent) listed below into housing from large end of boot.

6. Install boot securely into grooves (indicated by * marks) shown

in the figure.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of joint sub-assembly, boot may come off. Remove

all grease from surfaces.

7. Check that boot installation length “L” is the length indicated

below. Insert a flat-bladed screwdriver or similar tool into smaller

side of boot. Remove air from boot to prevent boot deformation.

CAUTION:

lBoot may break if boot installation length is less than standard value.

lBe careful that screwdriver tip does not contact inside surface of boot.

8. Secure big and small ends of boot with new boot bands as

shown in the figure.

CAUTION:

Rotate housing and check that boot installation position

does not change. If position changes, reinstall boot bands.Grease amount : 35 - 45 g (1.23 - 1.59 oz)

RAC0049D

Boot installation length

:66.7 - 68.7 mm (2.626 - 2.705 in)SDIA0607E

SFA395

Page 2822 of 3066

RF-10

SUNROOF

5. As shown in the figure, slide shade slider to remove it from the

aluminum rail.

6. Swivel shade toward the left, and remove RH shade from the

aluminum rail.

7. Slide shade forward, and remove rear shade sliders as well.

8. Install in the reverse order of removal.

WIND DEFLECTOR

Removal and installation

1. Remove deflector arm mounting screws (2 for each side).

2. Using a pointed tool, pull up the tabs (2 each on left/right) on the

bushing.

NOTE:

Do not reuse the bushing after its tabs are pulled up.

3. Press and pull off the shaft.

4. Install in the reverse order of removal.

SUNROOF MOTOR

Removal

1. Remove headliner.

2. Remove motor mounting screw and mounting nut.

3. Remove the harness connector, and remove the sunroof motor.

NOTE:

lRemove the sunroof motor when the sunroof is in the fully-

closed position.

lNever rotate the removed motor as a single unit.

Installation

1. Move motor laterally little by little until the gear is completely engaged onto the wire on sunroof unit and

the mounting surface becomes parallel. Then secure motor with screws and nuts.

NOTE:

Before installing motor, be sure to place the link and wire assembly in the symmetrical and fully closed posi-

tion.

SIIA0126E

SIIA0127E

SIIA0128E

Page 2860 of 3066

RSU-8

COIL SPRING AND STRUT

COIL SPRING AND STRUT

PFP:55302

Removal and InstallationEES0007H

REMOVAL

1. Remove tires.

2. Remove brake hose lock plate and remove brake hose from strut.

3. Remove mounting nuts and washers on upper portion of stabilizer connecting rod.

4. Remove strut-to-axle housing mounting bolts and nuts.

5. Remove luggage side lower finisher in luggage compartment.Remove mounting nuts on upper portion of

strut. Then remove strut from vehicle.

INSTALLATION

lRefer toRSU-5, "Components"for tightening torque. Install in the reverse order of removal.

Disassembly and AssemblyEES0007I

DISASSEMBLY

1. Install strut attachment to strut and fix it in a vise.

CAUTION:

When installing a strut attachment, cover strut with shop

cloth to avoid damage.

2. Remove cap and slightly loosen piston rod lock nut.

CAUTION:

Do not remove piston rod lock nut completely. If it is

removed completely, coil spring jumps out and may cause

serious damage or injury.

3. Compress coil spring using a spring compressor.

CAUTION:

Be sure spring compressor is securely attached to coil spring. Compress coil spring.

4. After making sure coil spring is free between upper and lower seats after Step 3. Remove piston rod lock

nut.

5. Remove small parts on strut.

lRemove strut spacer, strut mounting seal, strut mount insulator, spring upper seat, upper rubber seat,

and bound bumper. Then remove coil spring from strut.

6. Gradually release spring compressor, and remove coil spring.

INSPECTION AFTER DISASSEMBLY

Strut

lCheck strut for deformation, cracks, and damage, and replace if necessary.

lCheck piston rod for damage, uneven wear, and distortion, and replace if necessary.

lCheck welded and sealed areas for oil leakage, and replace if necessary.

Bushing

lCheck bushing for cracks and damage, and replace if necessary.

Coil Spring

lCheck coil spring for cracks, deformation, and damage, and replace if necessary.

SEIA0124E

Page 2861 of 3066

COIL SPRING AND STRUT

RSU-9

C

D

F

G

H

I

J

K

L

MA

B

RSU

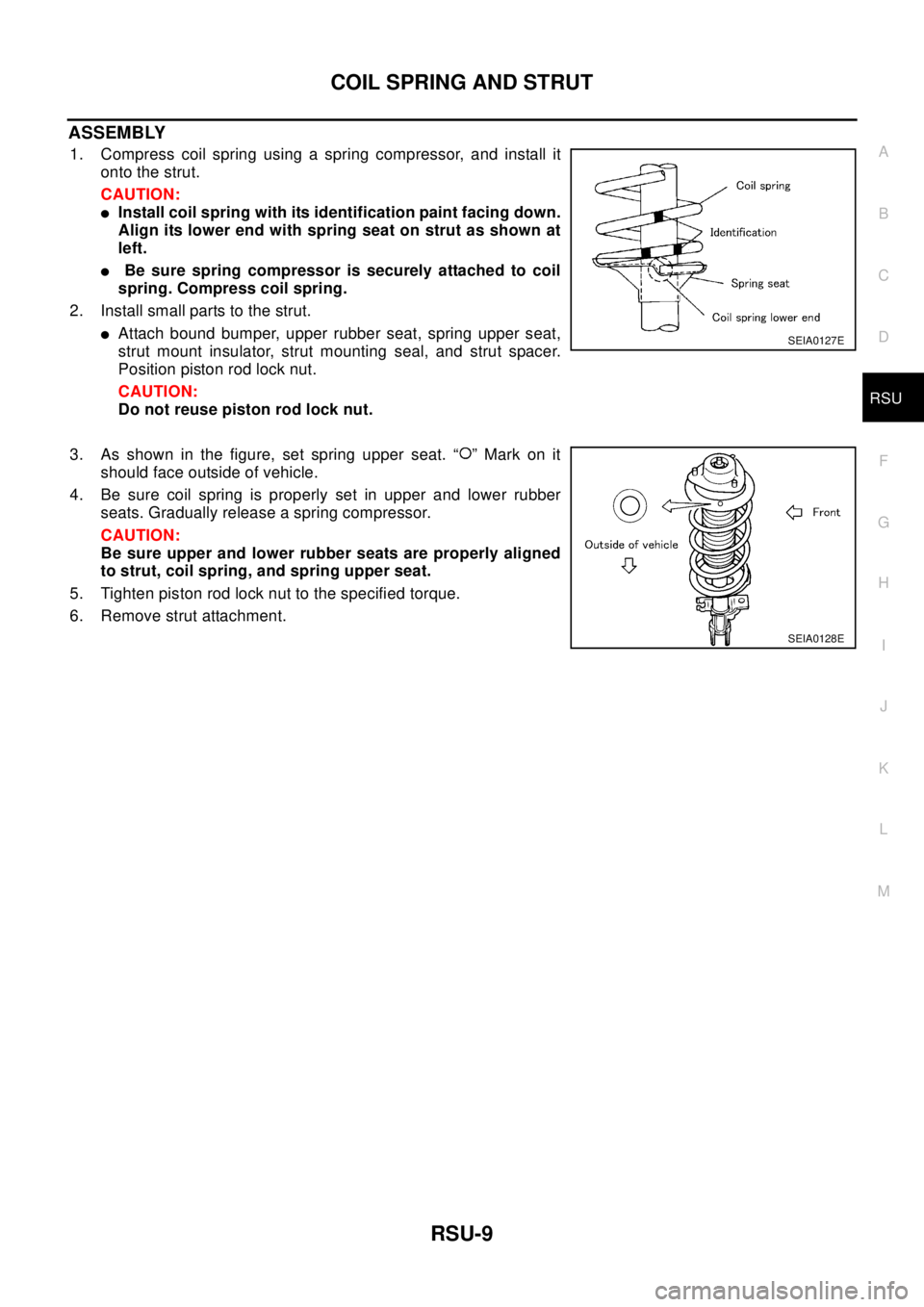

ASSEMBLY

1. Compress coil spring using a spring compressor, and install it

onto the strut.

CAUTION:

lInstall coil spring with its identification paint facing down.

Align its lower end with spring seat on strut as shown at

left.

lBe sure spring compressor is securely attached to coil

spring. Compress coil spring.

2. Install small parts to the strut.

lAttach bound bumper, upper rubber seat, spring upper seat,

strut mount insulator, strut mounting seal, and strut spacer.

Position piston rod lock nut.

CAUTION:

Do not reuse piston rod lock nut.

3. As shown in the figure, set spring upper seat. “ ” Mark on it

should face outside of vehicle.

4. Be sure coil spring is properly set in upper and lower rubber

seats. Gradually release a spring compressor.

CAUTION:

Be sure upper and lower rubber seats are properly aligned

to strut, coil spring, and spring upper seat.

5. Tighten piston rod lock nut to the specified torque.

6. Remove strut attachment.SEIA0127E

SEIA0128E

Page 2902 of 3066

SC-30

STARTING SYSTEM

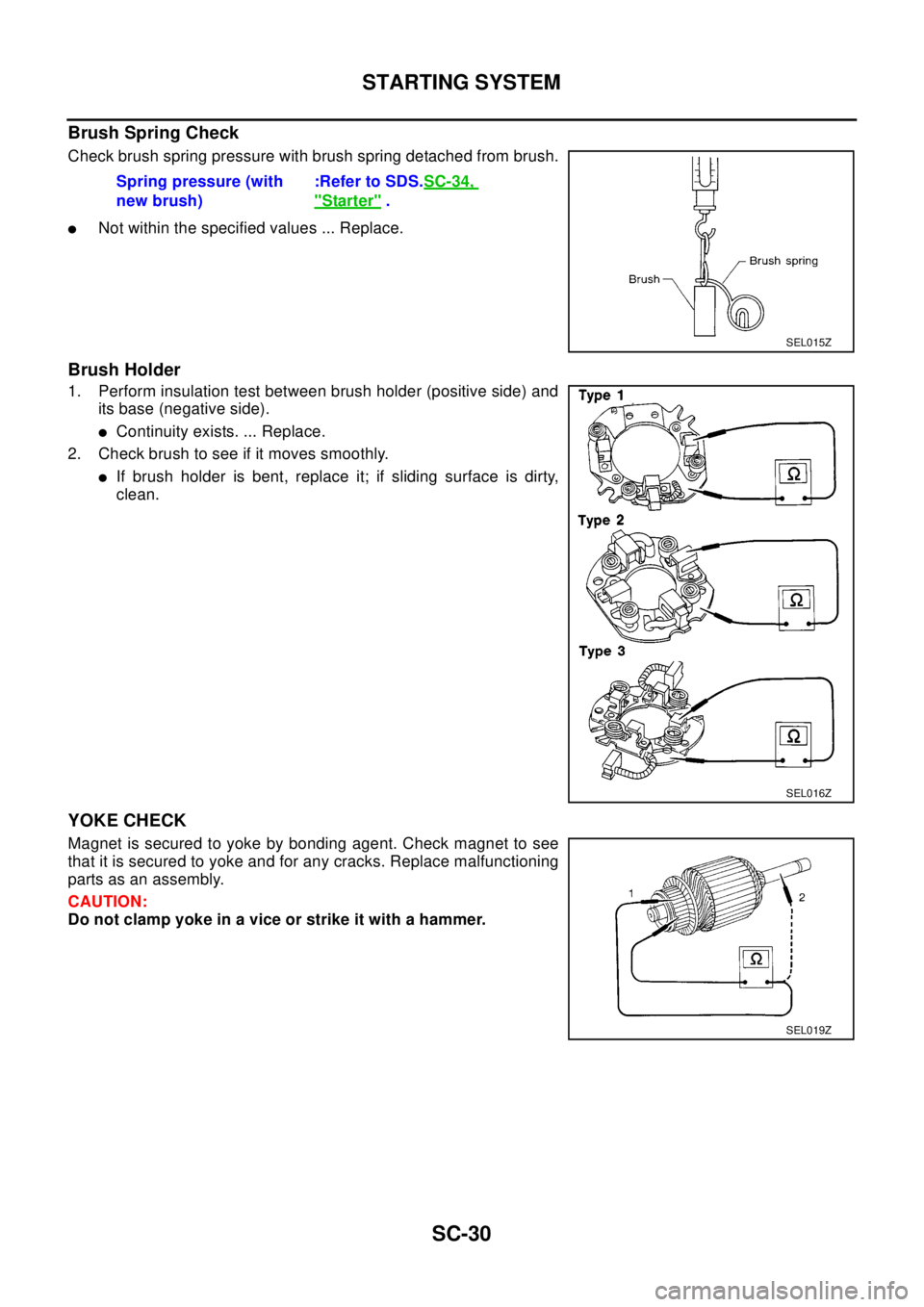

Brush Spring Check

Check brush spring pressure with brush spring detached from brush.

lNot within the specified values ... Replace.

Brush Holder

1. Perform insulation test between brush holder (positive side) and

its base (negative side).

lContinuity exists. ... Replace.

2. Check brush to see if it moves smoothly.

lIf brush holder is bent, replace it; if sliding surface is dirty,

clean.

YOKE CHECK

Magnet is secured to yoke by bonding agent. Check magnet to see

that it is secured to yoke and for any cracks. Replace malfunctioning

parts as an assembly.

CAUTION:

Do not clamp yoke in a vice or strike it with a hammer.Spring pressure (with

new brush):Refer to SDS.SC-34,

"Starter".

SEL015Z

SEL016Z

SEL019Z