secure NISSAN X-TRAIL 2003 Electronic Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2193 of 3066

EXHAUST SYSTEM

EX-3

C

D

E

F

G

H

I

J

K

L

MA

EX

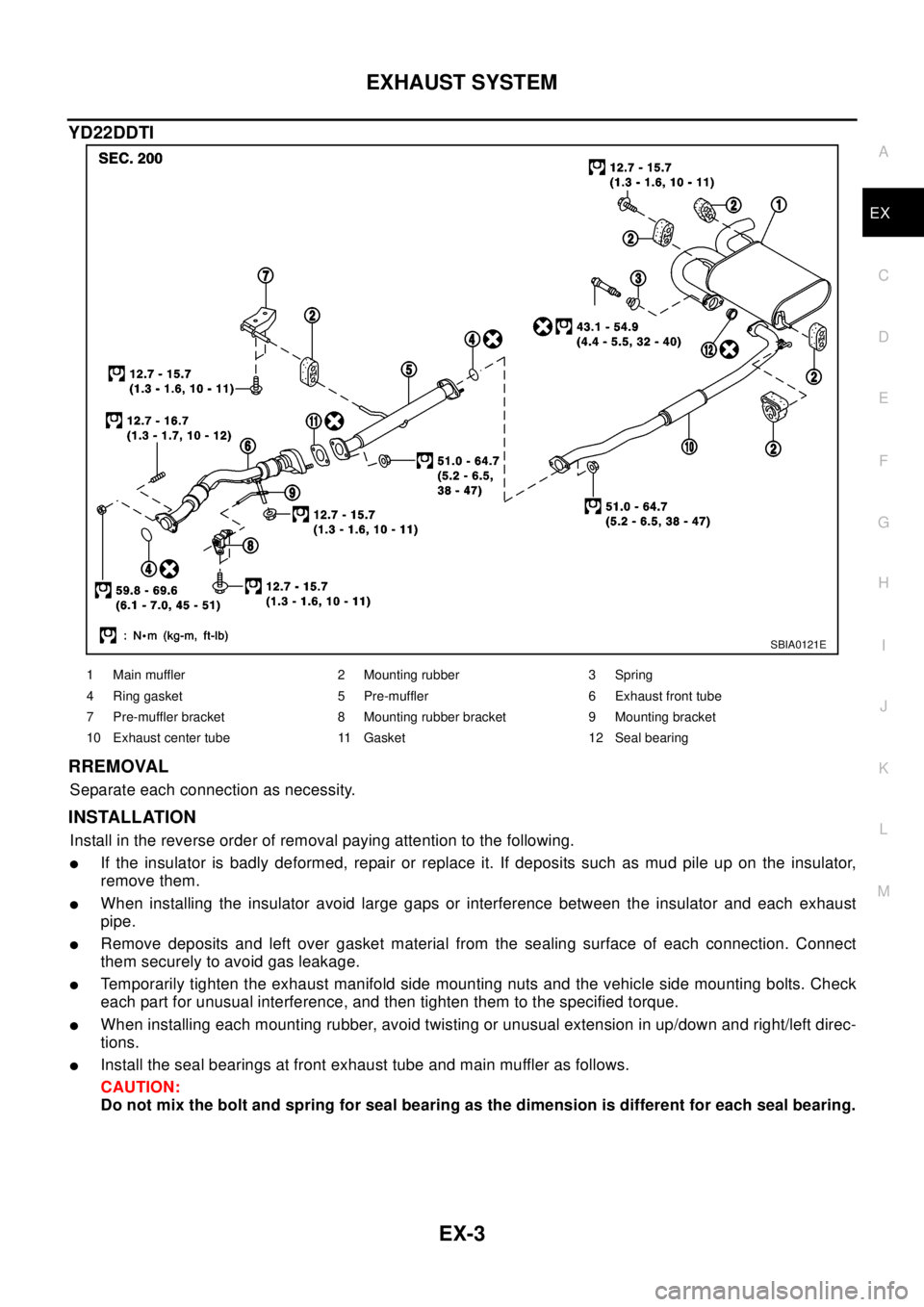

YD22DDTI

RREMOVAL

Separate each connection as necessity.

INSTALLATION

Install in the reverse order of removal paying attention to the following.

lIf the insulator is badly deformed, repair or replace it. If deposits such as mud pile up on the insulator,

remove them.

lWhen installing the insulator avoid large gaps or interference between the insulator and each exhaust

pipe.

lRemove deposits and left over gasket material from the sealing surface of each connection. Connect

them securely to avoid gas leakage.

lTemporarily tighten the exhaust manifold side mounting nuts and the vehicle side mounting bolts. Check

each part for unusual interference, and then tighten them to the specified torque.

lWhen installing each mounting rubber, avoid twisting or unusual extension in up/down and right/left direc-

tions.

lInstall the seal bearings at front exhaust tube and main muffler as follows.

CAUTION:

Do not mix the bolt and spring for seal bearing as the dimension is different for each seal bearing.

SBIA0121E

1 Main muffler 2 Mounting rubber 3 Spring

4 Ring gasket 5 Pre-muffler 6 Exhaust front tube

7 Pre-muffler bracket 8 Mounting rubber bracket 9 Mounting bracket

10 Exhaust center tube 11 Gasket 12 Seal bearing

Page 2208 of 3066

FAX-12

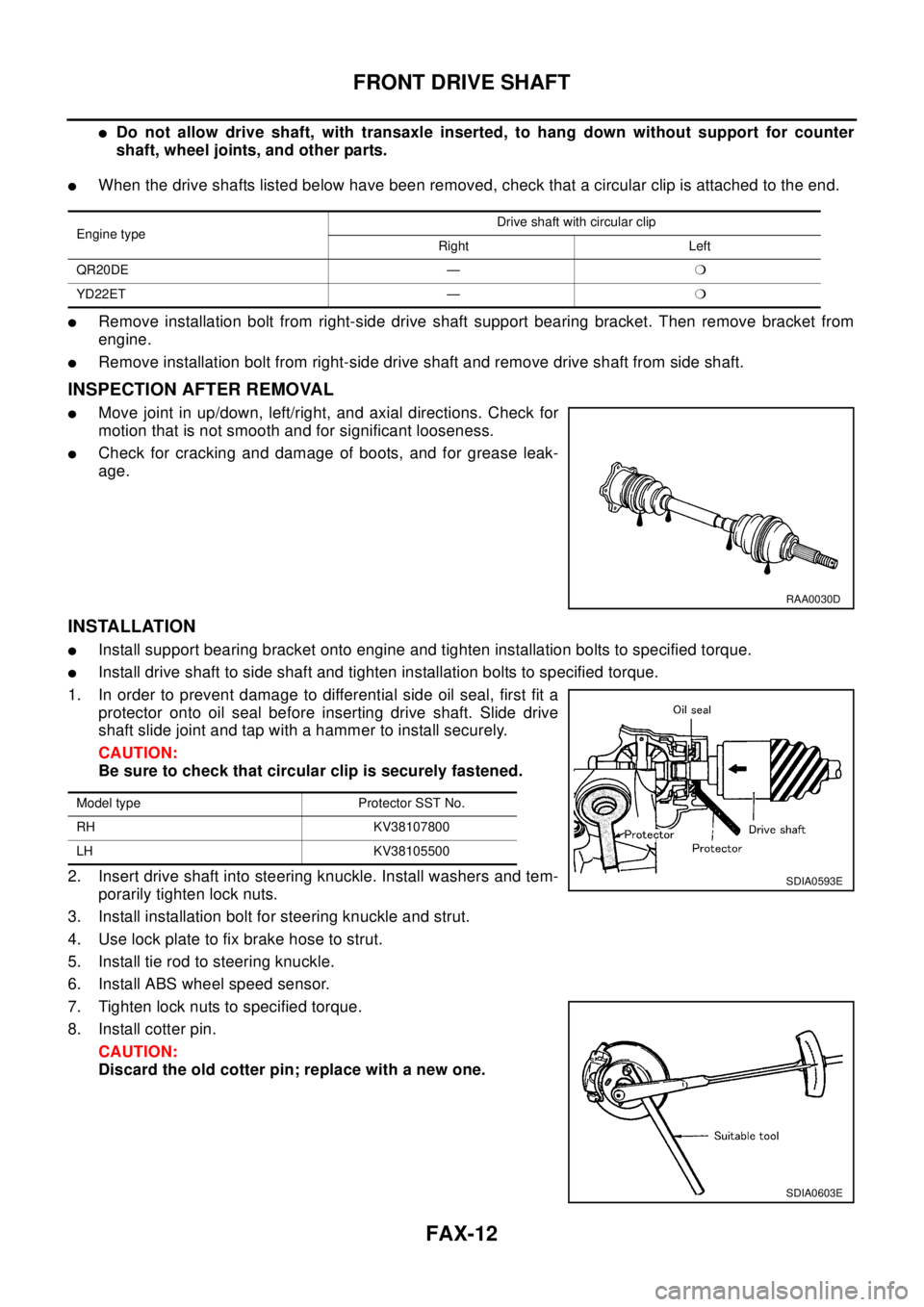

FRONT DRIVE SHAFT

lDo not allow drive shaft, with transaxle inserted, to hang down without support for counter

shaft, wheel joints, and other parts.

lWhen the drive shafts listed below have been removed, check that a circular clip is attached to the end.

lRemove installation bolt from right-side drive shaft support bearing bracket. Then remove bracket from

engine.

lRemove installation bolt from right-side drive shaft and remove drive shaft from side shaft.

INSPECTION AFTER REMOVAL

lMove joint in up/down, left/right, and axial directions. Check for

motion that is not smooth and for significant looseness.

lCheck for cracking and damage of boots, and for grease leak-

age.

INSTALLATION

lInstall support bearing bracket onto engine and tighten installation bolts to specified torque.

lInstall drive shaft to side shaft and tighten installation bolts to specified torque.

1. In order to prevent damage to differential side oil seal, first fit a

protector onto oil seal before inserting drive shaft. Slide drive

shaft slide joint and tap with a hammer to install securely.

CAUTION:

Be sure to check that circular clip is securely fastened.

2. Insert drive shaft into steering knuckle. Install washers and tem-

porarily tighten lock nuts.

3. Install installation bolt for steering knuckle and strut.

4. Use lock plate to fix brake hose to strut.

5. Install tie rod to steering knuckle.

6. Install ABS wheel speed sensor.

7. Tighten lock nuts to specified torque.

8. Install cotter pin.

CAUTION:

Discard the old cotter pin; replace with a new one.

Engine typeDrive shaft with circular clip

Right Left

QR20DE —m

YD22ET —m

RAA0030D

Model type Protector SST No.

RH KV38107800

LH KV38105500

SDIA0593E

SDIA0603E

Page 2211 of 3066

FRONT DRIVE SHAFT

FAX-15

C

E

F

G

H

I

J

K

L

MA

B

FA X

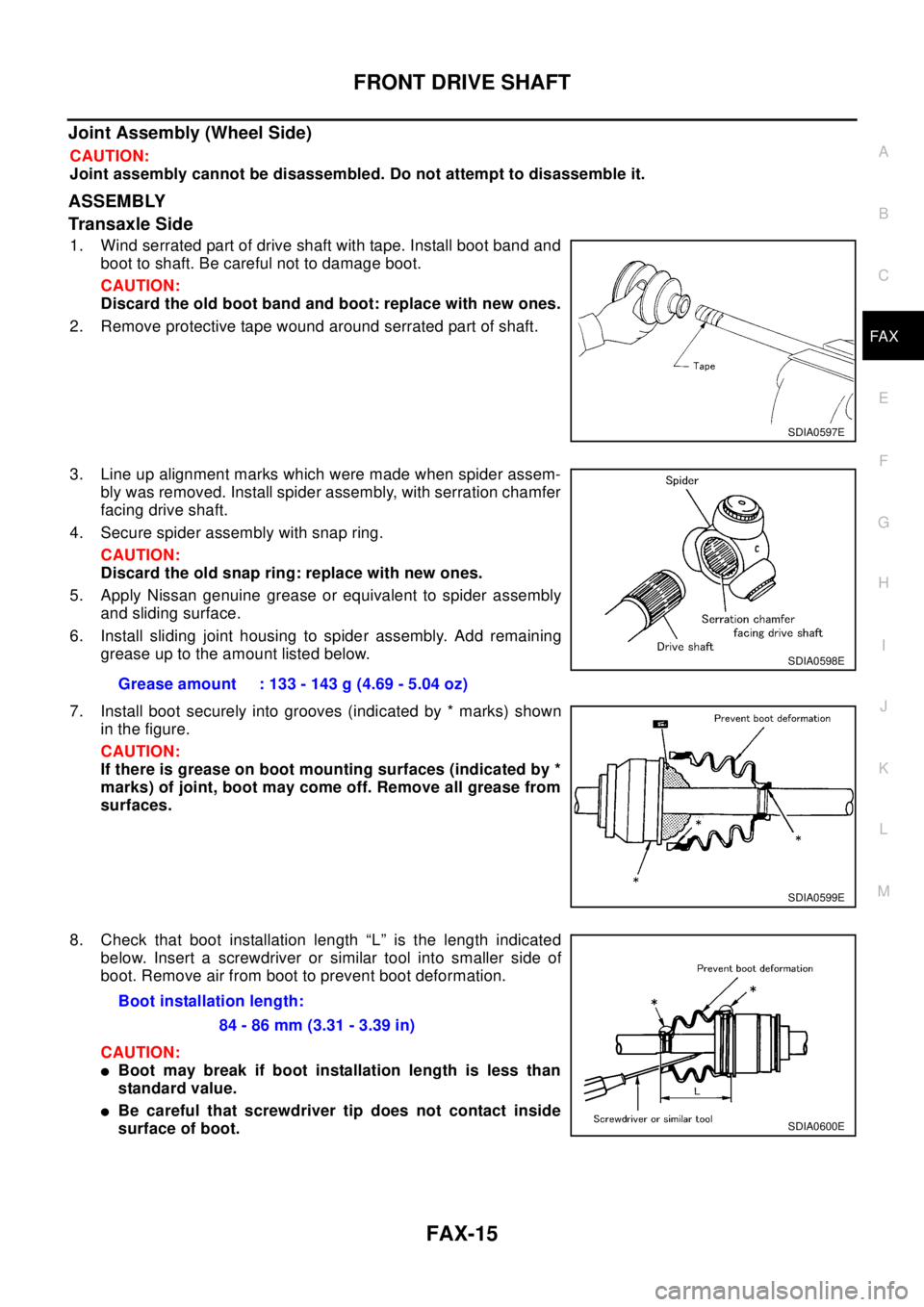

Joint Assembly (Wheel Side)

CAUTION:

Joint assembly cannot be disassembled. Do not attempt to disassemble it.

ASSEMBLY

Transaxle Side

1. Wind serrated part of drive shaft with tape. Install boot band and

boot to shaft. Be careful not to damage boot.

CAUTION:

Discard the old boot band and boot: replace with new ones.

2. Remove protective tape wound around serrated part of shaft.

3. Line up alignment marks which were made when spider assem-

bly was removed. Install spider assembly, with serration chamfer

facing drive shaft.

4. Secure spider assembly with snap ring.

CAUTION:

Discard the old snap ring: replace with new ones.

5. Apply Nissan genuine grease or equivalent to spider assembly

and sliding surface.

6. Install sliding joint housing to spider assembly. Add remaining

grease up to the amount listed below.

7. Install boot securely into grooves (indicated by * marks) shown

in the figure.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of joint, boot may come off. Remove all grease from

surfaces.

8. Check that boot installation length “L” is the length indicated

below. Insert a screwdriver or similar tool into smaller side of

boot. Remove air from boot to prevent boot deformation.

CAUTION:

lBoot may break if boot installation length is less than

standard value.

lBe careful that screwdriver tip does not contact inside

surface of boot.

SDIA0597E

Grease amount : 133 - 143 g (4.69 - 5.04 oz)

SDIA0598E

SDIA0599E

Boot installation length:

84 - 86 mm (3.31 - 3.39 in)

SDIA0600E

Page 2212 of 3066

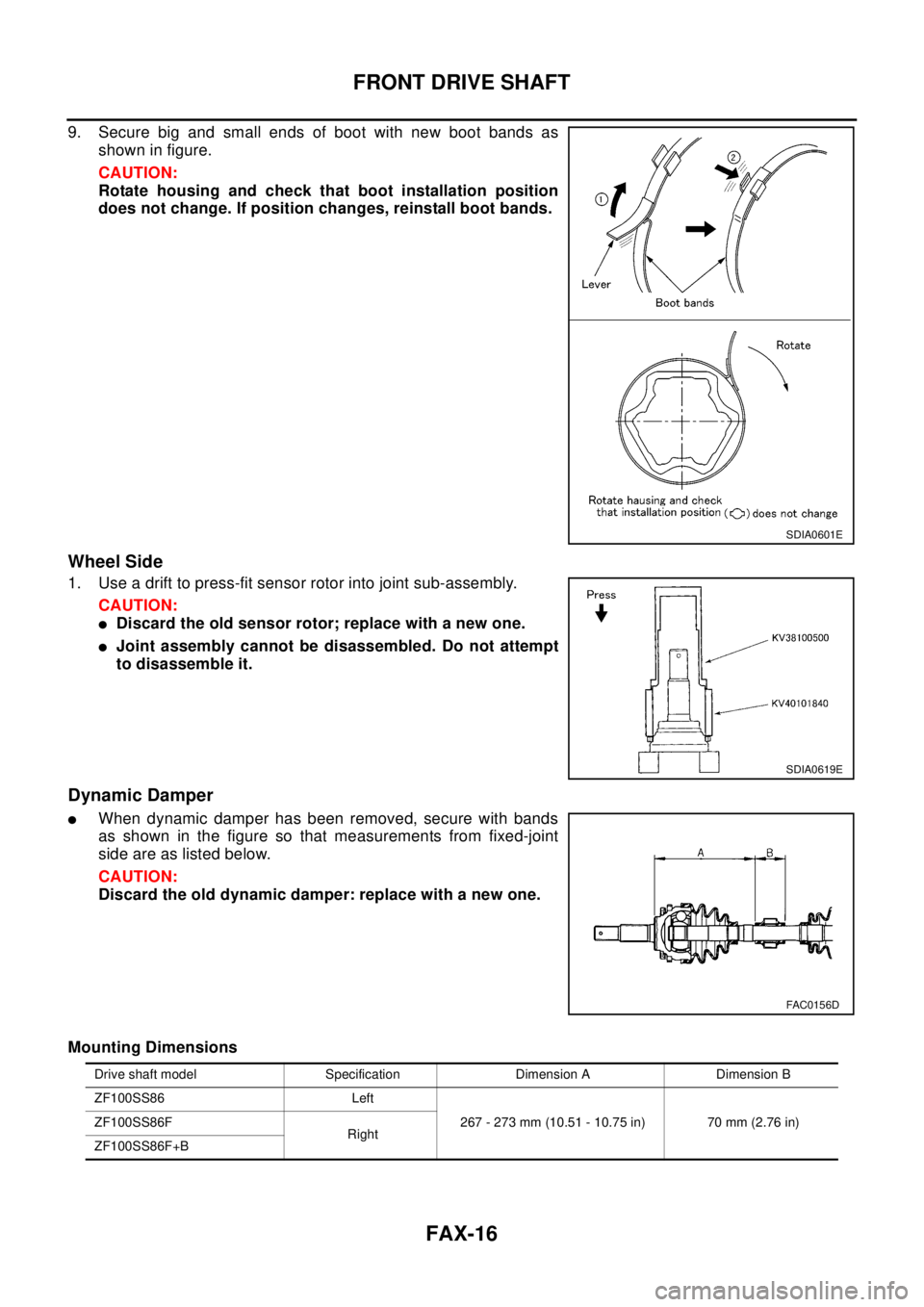

FAX-16

FRONT DRIVE SHAFT

9. Secure big and small ends of boot with new boot bands as

shown in figure.

CAUTION:

Rotate housing and check that boot installation position

does not change. If position changes, reinstall boot bands.

Wheel Side

1. Use a drift to press-fit sensor rotor into joint sub-assembly.

CAUTION:

lDiscard the old sensor rotor; replace with a new one.

lJoint assembly cannot be disassembled. Do not attempt

to disassemble it.

Dynamic Damper

lWhen dynamic damper has been removed, secure with bands

as shown in the figure so that measurements from fixed-joint

side are as listed below.

CAUTION:

Discard the old dynamic damper: replace with a new one.

Mounting Dimensions

SDIA0601E

SDIA0619E

FAC0156D

Drive shaft model Specification Dimension A Dimension B

ZF100SS86 Left

267 - 273 mm (10.51 - 10.75 in) 70 mm (2.76 in) ZF100SS86F

Right

ZF100SS86F+B

Page 2218 of 3066

![NISSAN X-TRAIL 2003 Electronic Manual PDF FUEL SYSTEM

FL-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

FL

FUEL SYSTEMPFP:17503

Checking Fuel LinesEBS00BKP

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose conne NISSAN X-TRAIL 2003 Electronic Manual PDF FUEL SYSTEM

FL-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

FL

FUEL SYSTEMPFP:17503

Checking Fuel LinesEBS00BKP

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose conne](/img/5/57402/w960_57402-2217.png)

FUEL SYSTEM

FL-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

FL

FUEL SYSTEMPFP:17503

Checking Fuel LinesEBS00BKP

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration.

If necessary, repair or replace faulty parts.

General PrecautionsEBS00BKQ

WA RN ING:

when replacing fuel line parts, be sure to observe the following.

lPut a “ CAUTION: FLAMABLE” sign in workshop.

lBe sure to work in a well-ventilated area and furnish workshop with a CO2fire extinguisher.

lDo not smoke while servicing fuel system, keep open flames and spark away from work area.

CAUTION:

lBefore removing fuel line parts, carry out the following procedures.

–a) Put drained fuel in an explosion-proof container and put the lid on securely, keep the container

in safe area.

–b) Release fuel pressure from fuel line, Refer toEC-34, "Fuel Pressure Check",EC-399, "Fuel

Pressure Check".

–c) Disconnect battery ground cable.

lAlways replace O-ring and clamps with new ones.

lDo not tighten hose clamps excessively to avoid damaging hoses.

lDo not kink or twist tubes when they are being installed.

lAfter installing tubes, run engine and check for fuel leaks at connections.

SMA803A

Page 2221 of 3066

![NISSAN X-TRAIL 2003 Electronic Manual PDF FL-6

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

7. Using a lock ring wrench, remove the lock ring.

8. Remove main fuel level sensor unit, fuel filter and fuel pump

assembly, a NISSAN X-TRAIL 2003 Electronic Manual PDF FL-6

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

7. Using a lock ring wrench, remove the lock ring.

8. Remove main fuel level sensor unit, fuel filter and fuel pump

assembly, a](/img/5/57402/w960_57402-2220.png)

FL-6

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

7. Using a lock ring wrench, remove the lock ring.

8. Remove main fuel level sensor unit, fuel filter and fuel pump

assembly, and sub fuel level sensor unit.

CAUTION:

lDo not bend the float arm during removal.

lAvoid impacts such as falling when handling compo-

nents.

lRemoval of main fuel level sensor unit, fuel filter, fuel pump

assembly.

lRaise the sender unit, and remove the jet pump to remove the

sender unit.

lLeave the jet pump on the fuel tank with the fuel hose.

lIf necessary, remove the chamber from the bottom of the fuel tank.

lRemove the chamber by sliding toward the rear of the vehicle.

Removal of sub fuel level sensor unit.

lRaise and release the sub fuel level sensor unit to remove.

lIf necessary, remove the jet pump inlet from the bottom of the fuel tank.

To remove it, pinch the tabs (2 places).

INSPECTION AFTER REMOVAL

Make sure the fuel pump strainer is free from foreign materials, If any are found, remove them.

INSTALLATION

Install in the reverse order of removal paying attention to the follow-

ing.

lWhen installing the chamber and jet pump, insert them fully until

a click sound of full stopper engagement is heard (Ditto for jet

pump inlet).

lConnect the quick connector as follows.

1. Check the connection for damage and foreign materials.

2. Align the connector with the tube, then insert the connector straight into the tube until a click is heard.

3. After connecting, make sure that the connection is secure by following the steps below.

lVisually confirm that the two retainer tabs are connected to the connector.

lPull the tube and the connector to make sure they are securely connected.

PBIC0240E

KBIA0281E

KBIA0302E

Page 2223 of 3066

![NISSAN X-TRAIL 2003 Electronic Manual PDF FL-8

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

2. Disconnect fuel pump harness connector.

3. Separate the fuel filter and fuel level sensor unit.

a. Fit a used O-ring into sp NISSAN X-TRAIL 2003 Electronic Manual PDF FL-8

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

2. Disconnect fuel pump harness connector.

3. Separate the fuel filter and fuel level sensor unit.

a. Fit a used O-ring into sp](/img/5/57402/w960_57402-2222.png)

FL-8

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

2. Disconnect fuel pump harness connector.

3. Separate the fuel filter and fuel level sensor unit.

a. Fit a used O-ring into space between fuel level sensor unit and

fuel filter. Undo catches and separate fuel level sensor unit and

fuel filter.

lFor reference when reassembling, put a mating mark on outer

edges of fuel level sensor unit and fuel filter with some means

which cannot be erased by fuel.

b. Insert blade end screwdriver to the gap between the fuel filter

and fuel level sensor unit to separate them.

CAUTION:

Put cloth or similar one on the edge of screwdriver not to

damage the inserted portion.

4. Remove pressure regulator from fuel filter.

a. Open and remove the clip.

b. Pull the pressure regulator straight out during removal.

CAUTION:

lAvoid impacts such as falling during removal.

lDo not disassemble or adjust.

ASSEMBLY

Install in the reverse order of removal paying attention to the following.

lInstall the fuel filter and fuel pump with the tabs aligned, Make sure a click sound of secure engagement

is heard.

lSecurely connect the harness connector of the fuel pump.

lInstall the pressure regulator O-ring as follows.

CAUTION:

lWhen replacing, always use a new O-ring.

lHandle it with bare hands. (Do not use gloves.)

lVisually check the O-ring, mounting parts and mating parts for foreign materials and flaws.

lBefore installing, apply new engine oil.

lTo avid damage, do not apply an excessive force (pulling or starching).

lInstall the pressure regulator as follows.

1. Insert the clip to the groove of the regulator.

2. With the clip installed, insert the regulator straight by matching

the fuel filter protrusion and the clip notch.

3. Make sure that the fuel filter protrusion and clip notch are

securely engaged.

PBIC0243E

PBIC0244E

PBIC0245E

Page 2225 of 3066

![NISSAN X-TRAIL 2003 Electronic Manual PDF FL-10

[QR20DE]

FUEL TANK

8. Remove propeller shaft. Refer toPR-3, "Removal and Installation".

9. Using a transmission jack, support the bottom of the rear final

drive.

10. Remove the mounting nuts on NISSAN X-TRAIL 2003 Electronic Manual PDF FL-10

[QR20DE]

FUEL TANK

8. Remove propeller shaft. Refer toPR-3, "Removal and Installation".

9. Using a transmission jack, support the bottom of the rear final

drive.

10. Remove the mounting nuts on](/img/5/57402/w960_57402-2224.png)

FL-10

[QR20DE]

FUEL TANK

8. Remove propeller shaft. Refer toPR-3, "Removal and Installation".

9. Using a transmission jack, support the bottom of the rear final

drive.

10. Remove the mounting nuts on the rear suspension member, and

lower the transmission jack carefully until just before the rear

suspension member is removed from the stud bolts on the vehi-

cle.

11. Disconnect fuel filler hose, EVAP hose and vent hose at fuel

tank side.

12. For disconnection procedure of the quick connector on the

evaporator hose, Refer toFL-4, "

FUEL LEVEL SENSOR UNIT,

FUEL FILTER AND FUEL PUMP ASSEMBLY".

13. Remove fuel tank protector.

14. Remove fuel tank band mounting bolts while supporting fuel

tank.

15. Remove fuel tank.

INSTALLATION

Install in the reverse order of removal paying attention to the following.

lSurely clamp fuel hoses and insert hose to the length below.

lBe sure hose clamp is not placed on swelled area of fuel tube.

lTighten fuel hose clamp so that the distance between its lugs becomes to the following.

lPush the mounting band pin to the vehicle side securely.

lBefore fixing the fuel tank, temporarily install the filler tube.

CAUTION:

Use genuine fuel filler tube mounting bolts or equivalent. Make sure to tighten them to the speci-

fied torque.

lTo connect the quick connector, refer toFL-4, "FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL

PUMP ASSEMBLY".

KBIA0285E

KBIA0286E

KBIA0290E

Fuel filler hose : 35mm (1.38 in)

The other hoses : 25mm (0.98 in)

Fuel tank side : 5 - 9 mm (0.20 - 0.35 in)

Fuel filler tube side : 7 - 11 mm (0.28 - 0.43 in)

Page 2229 of 3066

![NISSAN X-TRAIL 2003 Electronic Manual PDF FL-14

[YD22DDTi]

FUEL SYSTEM

FUEL SYSTEM

PFP:17503

Checking Fuel LinesEBS00BKH

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or det NISSAN X-TRAIL 2003 Electronic Manual PDF FL-14

[YD22DDTi]

FUEL SYSTEM

FUEL SYSTEM

PFP:17503

Checking Fuel LinesEBS00BKH

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or det](/img/5/57402/w960_57402-2228.png)

FL-14

[YD22DDTi]

FUEL SYSTEM

FUEL SYSTEM

PFP:17503

Checking Fuel LinesEBS00BKH

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration.

If necessary, repair or replace faulty parts.

General PrecautionsEBS00BKI

WAR NIN G:

When replacing fuel line parts, be sure to observe the following.

lPut a “CAUTION: FLAMMABLE” sign in workshop.

lBe sure to work in a well-ventilated area and furnish workshop with a CO2fire extinguisher.

lDo not smoke while servicing fuel system. Keep open flames and spark away from work area.

CAUTION:

lBefore removing fuel line parts, carry out the following procedures:

–a) Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container

in safe area.

–b) Disconnect battery ground cable.

lAlways replace O-ring and clamps with new ones.

lDo not kink or twist tubes when they are being installed.

lDo not tighten hose clamps excessively to avoid damaging hoses.

lAfter installing tubes, run engine and check for fuel leaks at connections.

SMA803A

Page 2234 of 3066

![NISSAN X-TRAIL 2003 Electronic Manual PDF FUEL LEVEL SENSOR UNIT

FL-19

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

FL

lTo keep clean the connecting portion and to avoid damage

and foreign materials, cover them completely with plastic

bags or something NISSAN X-TRAIL 2003 Electronic Manual PDF FUEL LEVEL SENSOR UNIT

FL-19

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

FL

lTo keep clean the connecting portion and to avoid damage

and foreign materials, cover them completely with plastic

bags or something](/img/5/57402/w960_57402-2233.png)

FUEL LEVEL SENSOR UNIT

FL-19

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

FL

lTo keep clean the connecting portion and to avoid damage

and foreign materials, cover them completely with plastic

bags or something similar.

8. Using a lock ring wrench, remove the lock ring.

9. Remove main fuel level sensor unit and sub fuel level sensor

unit.

CAUTION:

lDo not bend the float arm during removal.

lAvoid impacts such as falling when handling components.

Removal of main fuel level sensor unit:

lRaise the fuel level sensor unit, and remove the jet pump.

lLeave the jet pump on the fuel tank with the fuel hose.

lIf necessary, remove the chamber from the bottom of the fuel

tank.

lRemove the chamber by sliding toward the rear of the vehicle.

Removal of sub fuel level sensor unit:

lRaise and release the sub fuel level sensor unit to remove.

lIf necessary, remove the jet pump inlet from the bottom of the fuel tank.

To remove it, pinch the tabs (2 places).

INSPECTION AFTER REMOVAL

Make sure the fuel pump strainer is free from foreign materials, If any are found, remove them.

INSTALLATION

Install in the reverse order of removal paying attention to the follow-

ing.

lWhen installing the chamber and jet pump, insert them fully until

a click sound of full stopper engagement is heard (for jet pump

inlet).

lConnect the quick connector as follows.

1. Check the connection for damage and foreign materials.

2. Align the connector with the tube, then insert the connector

straight into the tube until a click is heard.

3. After connecting, make sure that the connection is secure by fol-

lowing the steps below.

PBIC0163E

PBIC0240E

SBIA0142E

SBIA0143E