secure NISSAN X-TRAIL 2003 Electronic Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2235 of 3066

![NISSAN X-TRAIL 2003 Electronic Manual PDF FL-20

[YD22DDTi]

FUEL LEVEL SENSOR UNIT

lVisually confirm that the two retainer tabs are connected to the connector.

lPull the tube and the connector to make sure they are securely connected.

lInstall NISSAN X-TRAIL 2003 Electronic Manual PDF FL-20

[YD22DDTi]

FUEL LEVEL SENSOR UNIT

lVisually confirm that the two retainer tabs are connected to the connector.

lPull the tube and the connector to make sure they are securely connected.

lInstall](/img/5/57402/w960_57402-2234.png)

FL-20

[YD22DDTi]

FUEL LEVEL SENSOR UNIT

lVisually confirm that the two retainer tabs are connected to the connector.

lPull the tube and the connector to make sure they are securely connected.

lInstall fuel level sensor unit with mating mark (triangular protrusion) facing between two carved lines on

fuel tank. (Figure shows left side of fuel tank.)

NOTE:

On right side of fuel tank, there are three carved lines on fuel tank. Set mating mark between two outer

carved lines.

lInstall the inspection hole cover with the front mark (arrow) fac-

ing front of the vehicle (Both for RH and LH).

INSPECTION AFTER INSTALLATION

lStart the engine and rev it up, and make sure there is no fuel leakage at connections.

SBIA0144E

Page 2237 of 3066

![NISSAN X-TRAIL 2003 Electronic Manual PDF FL-22

[YD22DDTi]

FUEL TANK

10. Using a transmission jack, support the bottom of the rear final

drive.

11. Remove the mounting nuts on the rear suspension member, and

lower the transmission jack carefu NISSAN X-TRAIL 2003 Electronic Manual PDF FL-22

[YD22DDTi]

FUEL TANK

10. Using a transmission jack, support the bottom of the rear final

drive.

11. Remove the mounting nuts on the rear suspension member, and

lower the transmission jack carefu](/img/5/57402/w960_57402-2236.png)

FL-22

[YD22DDTi]

FUEL TANK

10. Using a transmission jack, support the bottom of the rear final

drive.

11. Remove the mounting nuts on the rear suspension member, and

lower the transmission jack carefully until just before the rear

suspension member is removed from the stud bolts on the vehi-

cle.

12. Disconnect fuel filler hose, EVAP hose and vent hose at fuel

tank side.

For disconnection procedure of the quick connector. Refer to

FL-17, "

FUEL LEVEL SENSOR UNIT".

13. Remove fuel tank protector.

14. Remove fuel tank band mounting bolts while supporting fuel

tank.

15. Remove fuel tank.

INSTALLATION

lInstall in the reverse order of removal paying attention to the following.

lSurely clamp fuel hoses and insert hose to the length below.

lBe sure hose clamp is not positioned on swelled area of fuel tube.

lTighten fuel hose clamp so that the distance between its lugs becomes to the following.

lPush the mounting band pin to the vehicle side securely.

lBefore fixing the fuel tank, temporarily install the fuel filler tube.

CAUTION:

Use genuine fuel filler tube mounting bolts or equivalent. Make sure to tighten them to the speci-

fied torque.

lTo connect the quick connector. Refer toFL-17, "FUEL LEVEL SENSOR UNIT".

Inspection After InstallationEBS00BL4

Run engine and check for fuel leaks at connections.

KBIA0285E

KBIA0286E

KBIA0290E

Fuel filler hose : 35 mm (1.38 in)

The other hose : 25 mm (0.98 in)

Fuel tank side : 5 - 9 mm (0.20 - 0.35 in)

Fuel filler tube side : 7 - 11 mm (0.28 - 0.43 in)

Page 2248 of 3066

COIL SPRING AND SHOCK ABSORBER

FSU-9

C

D

F

G

H

I

J

K

L

MA

B

FSU

Insulator and Rubber Parts Inspection

Check strut mount insulator for cracks and rubber parts for wear. Replace them if necessary.

Coil Spring Inspection

Check for cracks, wear, and damage, and replace if necessary.

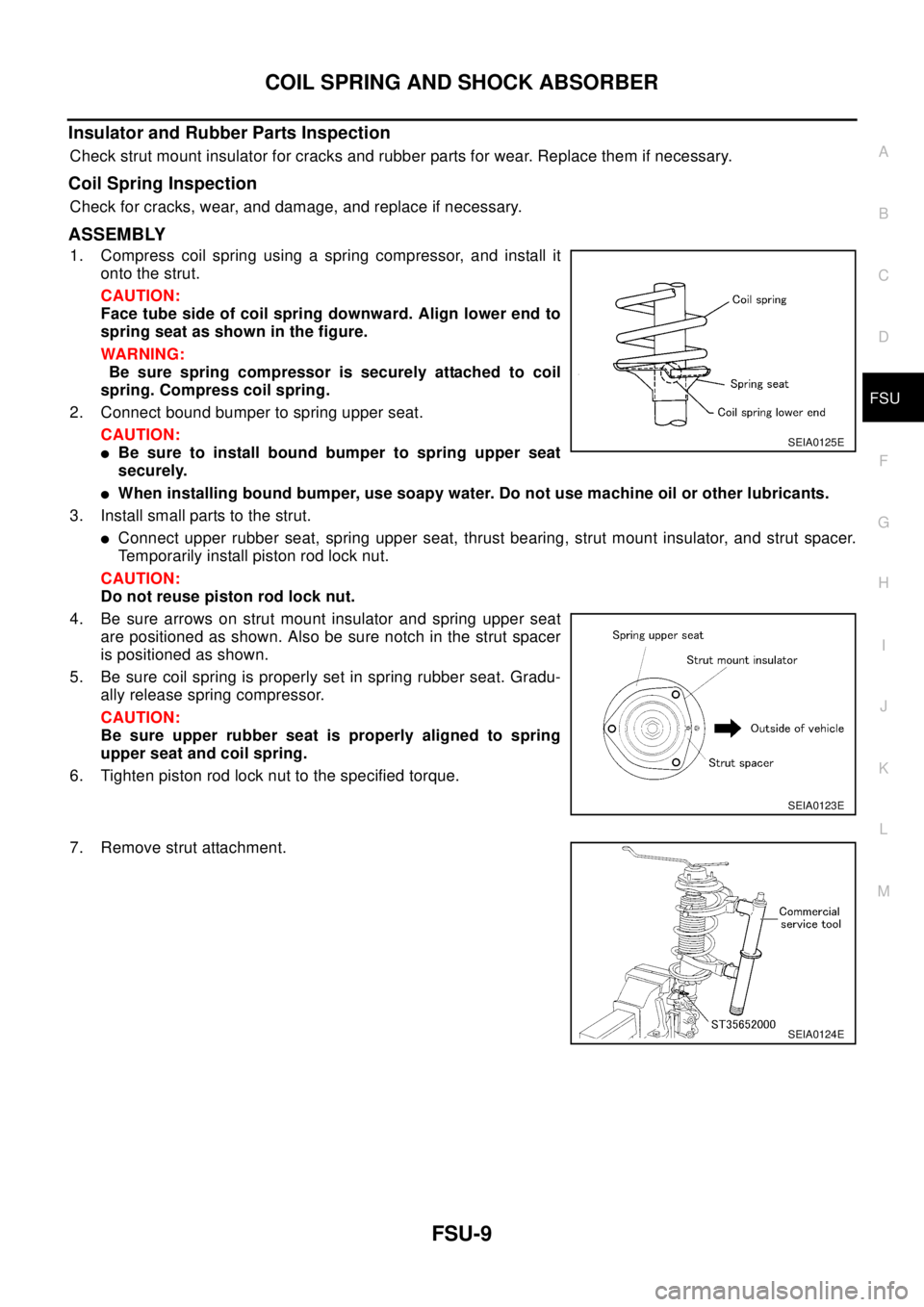

ASSEMBLY

1. Compress coil spring using a spring compressor, and install it

onto the strut.

CAUTION:

Face tube side of coil spring downward. Align lower end to

spring seat as shown in the figure.

WAR NIN G:

Be sure spring compressor is securely attached to coil

spring. Compress coil spring.

2. Connect bound bumper to spring upper seat.

CAUTION:

lBe sure to install bound bumper to spring upper seat

securely.

lWhen installing bound bumper, use soapy water. Do not use machine oil or other lubricants.

3. Install small parts to the strut.

lConnect upper rubber seat, spring upper seat, thrust bearing, strut mount insulator, and strut spacer.

Temporarily install piston rod lock nut.

CAUTION:

Do not reuse piston rod lock nut.

4. Be sure arrows on strut mount insulator and spring upper seat

are positioned as shown. Also be sure notch in the strut spacer

is positioned as shown.

5. Be sure coil spring is properly set in spring rubber seat. Gradu-

ally release spring compressor.

CAUTION:

Be sure upper rubber seat is properly aligned to spring

upper seat and coil spring.

6. Tighten piston rod lock nut to the specified torque.

7. Remove strut attachment.

SEIA0125E

SEIA0123E

SEIA0124E

Page 2259 of 3066

GI-6

PRECAUTIONS

Precautions for Multiport Fuel Injection System or Engine Control System

EAS000FT

lBefore connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

lBefore disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

lBe careful not to jar components such as ECM and mass air

flow sensor.

Precautions for Turbocharger (If Equipped)EAS000FU

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean sup-

ply of oil flowing through the turbocharger and to follow all required

maintenance instructions and operating procedures.

lAlways use the recommended oil. Follow the instructions for

proper time to change the oil and proper oil level.

lAvoid accelerating engine to a high rpm immediately after start-

ing.

lIf engine had been operating at high rpm for an extended period

of time, let it idle for a few minutes prior to shutting if off.

Precautions for HosesEAS000FV

HOSE REMOVAL AND INSTALLATION

lTo prevent damage to rubber hose, do not pry off rubber hose

with tapered tool or screwdriver.

lTo reinstall the rubber hose securely, make sure that hose inser-

tion length and orientation is correct. (If tube is equipped with

hose stopper, insert rubber hose into tube until it butts up

against hose stopper.)

SGI787

SGI292

SMA019D

SMA020D

Page 2282 of 3066

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-29

lWith SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

lWith SW1 closed, relay and solenoid disconnected and the DMM leads across both fuse terminals, check

for voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

lWith SW1 closed, relay contacts jumped with fused jumper wire check for voltage.

voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

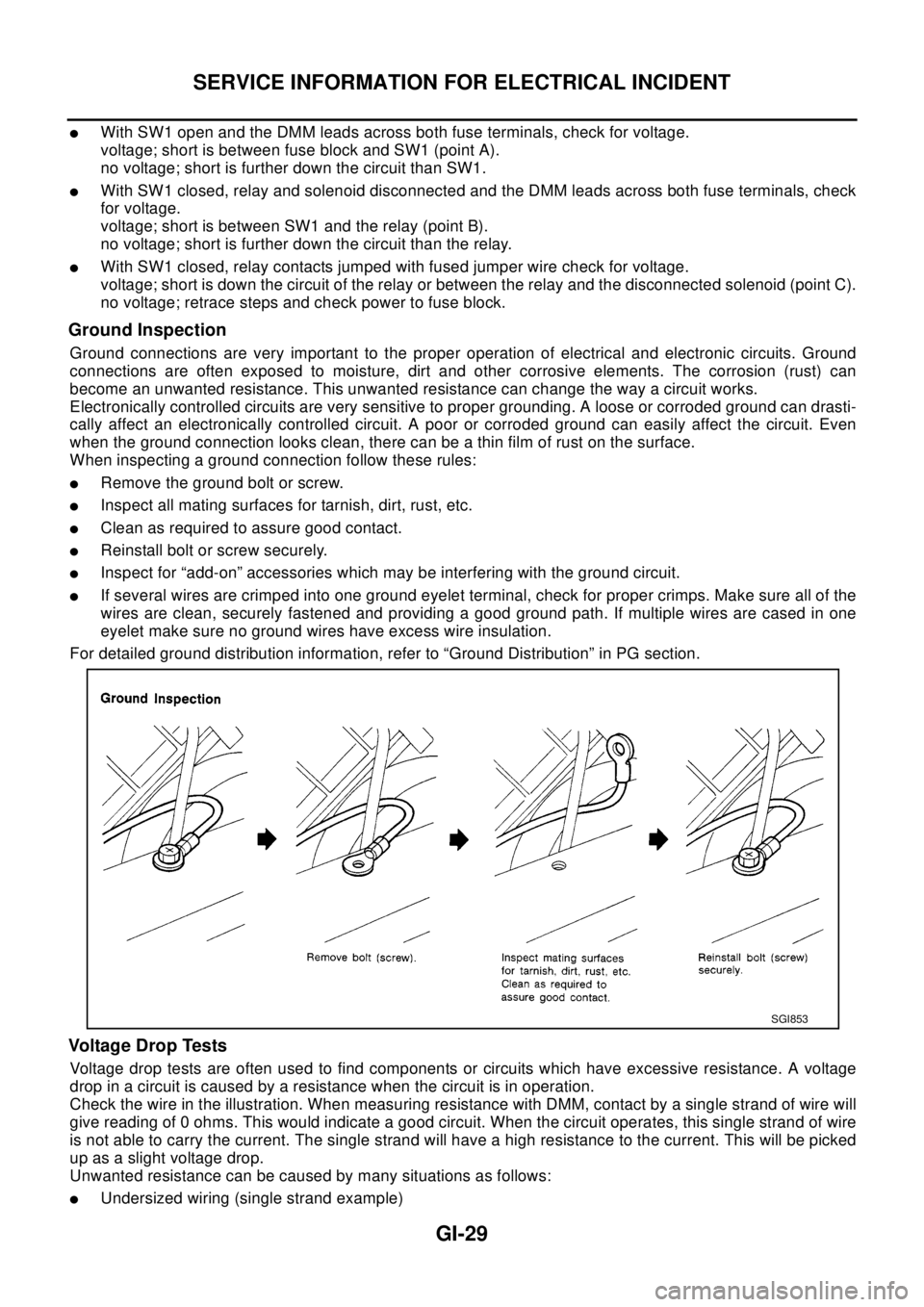

Ground Inspection

Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper grounding. A loose or corroded ground can drasti-

cally affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit. Even

when the ground connection looks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

lRemovethegroundboltorscrew.

lInspect all mating surfaces for tarnish, dirt, rust, etc.

lClean as required to assure good contact.

lReinstall bolt or screw securely.

lInspect for “add-on” accessories which may be interfering with the ground circuit.

lIf several wires are crimped into one ground eyelet terminal, check for proper crimps. Make sure all of the

wires are clean, securely fastened and providing a good ground path. If multiple wires are cased in one

eyelet make sure no ground wires have excess wire insulation.

For detailed ground distribution information, refer to “Ground Distribution” in PG section.

Voltage Drop Tests

Voltage drop tests are often used to find components or circuits which have excessive resistance. A voltage

drop in a circuit is caused by a resistance when the circuit is in operation.

Check the wire in the illustration. When measuring resistance with DMM, contact by a single strand of wire will

give reading of 0 ohms. This would indicate a good circuit. When the circuit operates, this single strand of wire

is not able to carry the current. The single strand will have a high resistance to the current. This will be picked

up as a slight voltage drop.

Unwanted resistance can be caused by many situations as follows:

lUndersized wiring (single strand example)

SGI853

Page 2306 of 3066

WINDSHIELD GLASS AND MOLDING

GW-3

C

D

E

F

G

H

J

K

L

MA

B

GW

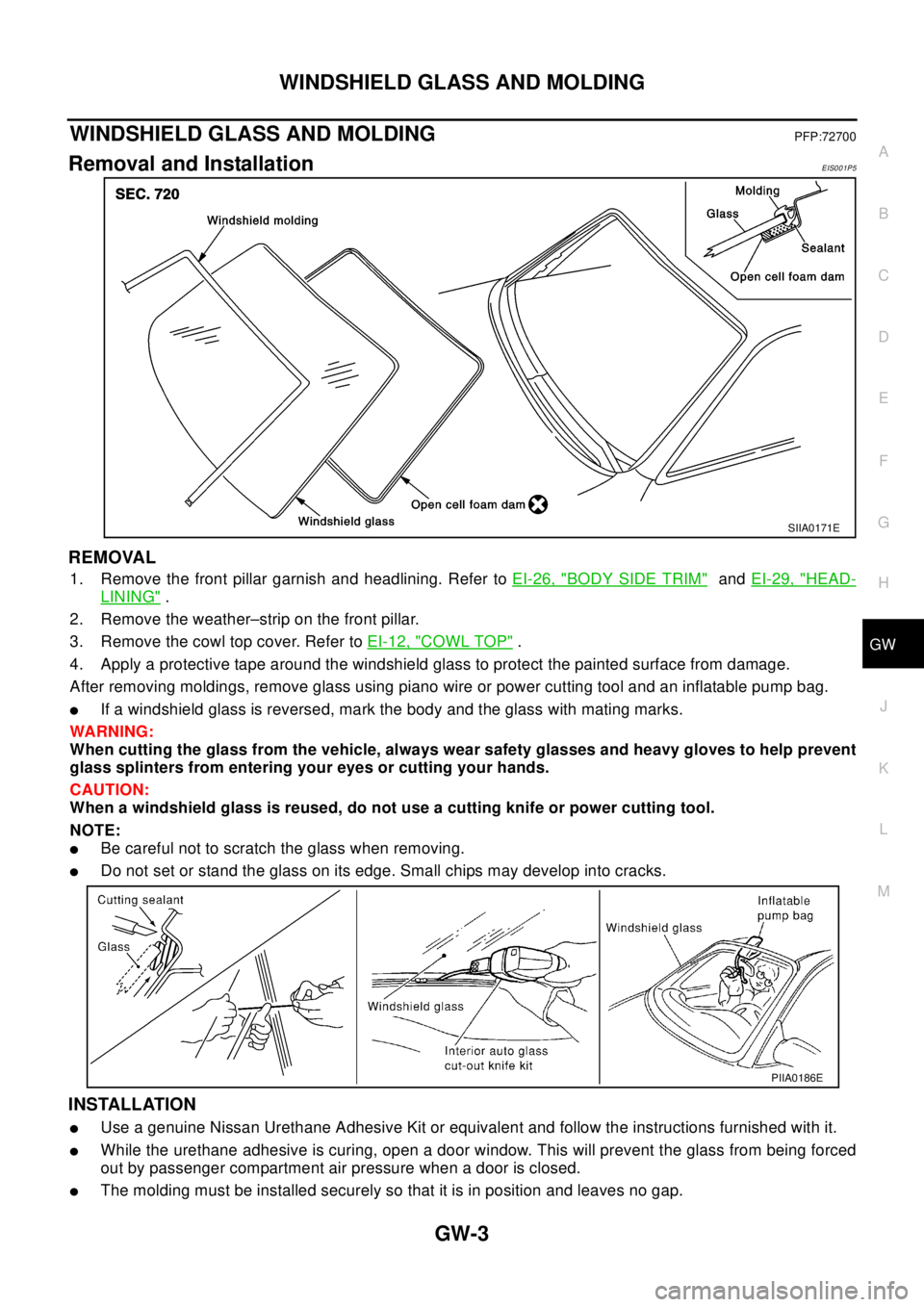

WINDSHIELD GLASS AND MOLDINGPFP:72700

Removal and InstallationEIS001P5

REMOVAL

1. Remove the front pillar garnish and headlining. Refer toEI-26, "BODY SIDE TRIM"andEI-29, "HEAD-

LINING".

2. Remove the weather–strip on the front pillar.

3. Remove the cowl top cover. Refer toEI-12, "

COWL TOP".

4. Apply a protective tape around the windshield glass to protect the painted surface from damage.

After removing moldings, remove glass using piano wire or power cutting tool and an inflatable pump bag.

lIf a windshield glass is reversed, mark the body and the glass with mating marks.

WA RN ING:

When cutting the glass from the vehicle, always wear safety glasses and heavy gloves to help prevent

glass splinters from entering your eyes or cutting your hands.

CAUTION:

When a windshield glass is reused, do not use a cutting knife or power cutting tool.

NOTE:

lBe careful not to scratch the glass when removing.

lDo not set or stand the glass on its edge. Small chips may develop into cracks.

INSTALLATION

lUse a genuine Nissan Urethane Adhesive Kit or equivalent and follow the instructions furnished with it.

lWhile the urethane adhesive is curing, open a door window. This will prevent the glass from being forced

out by passenger compartment air pressure when a door is closed.

lThe molding must be installed securely so that it is in position and leaves no gap.

SIIA0171E

PIIA0186E

Page 2345 of 3066

GW-42

FRONT DOOR GLASS AND REGULATOR

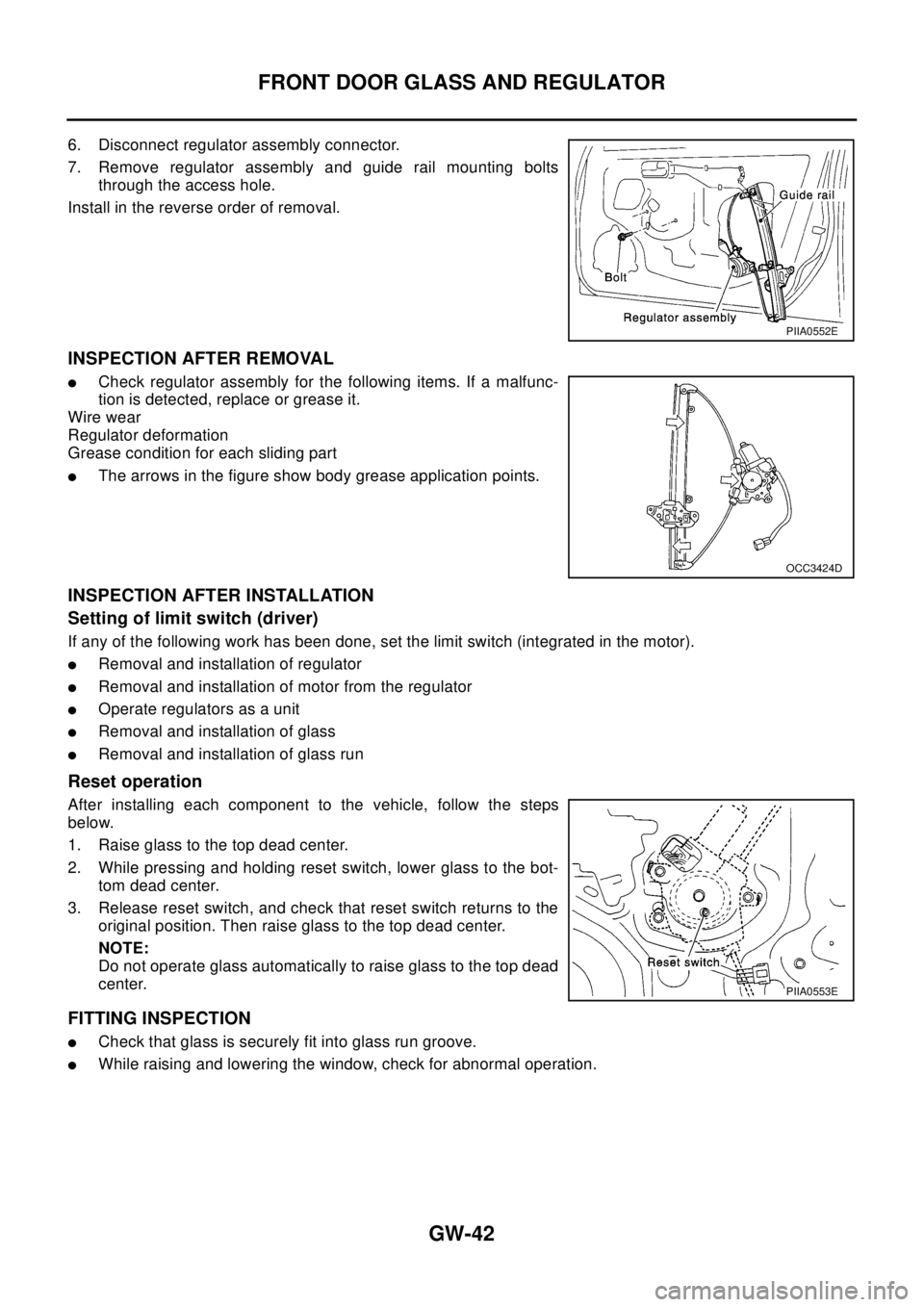

6. Disconnect regulator assembly connector.

7. Remove regulator assembly and guide rail mounting bolts

through the access hole.

Install in the reverse order of removal.

INSPECTION AFTER REMOVAL

lCheck regulator assembly for the following items. If a malfunc-

tion is detected, replace or grease it.

Wire wear

Regulator deformation

Grease condition for each sliding part

lThe arrows in the figure show body grease application points.

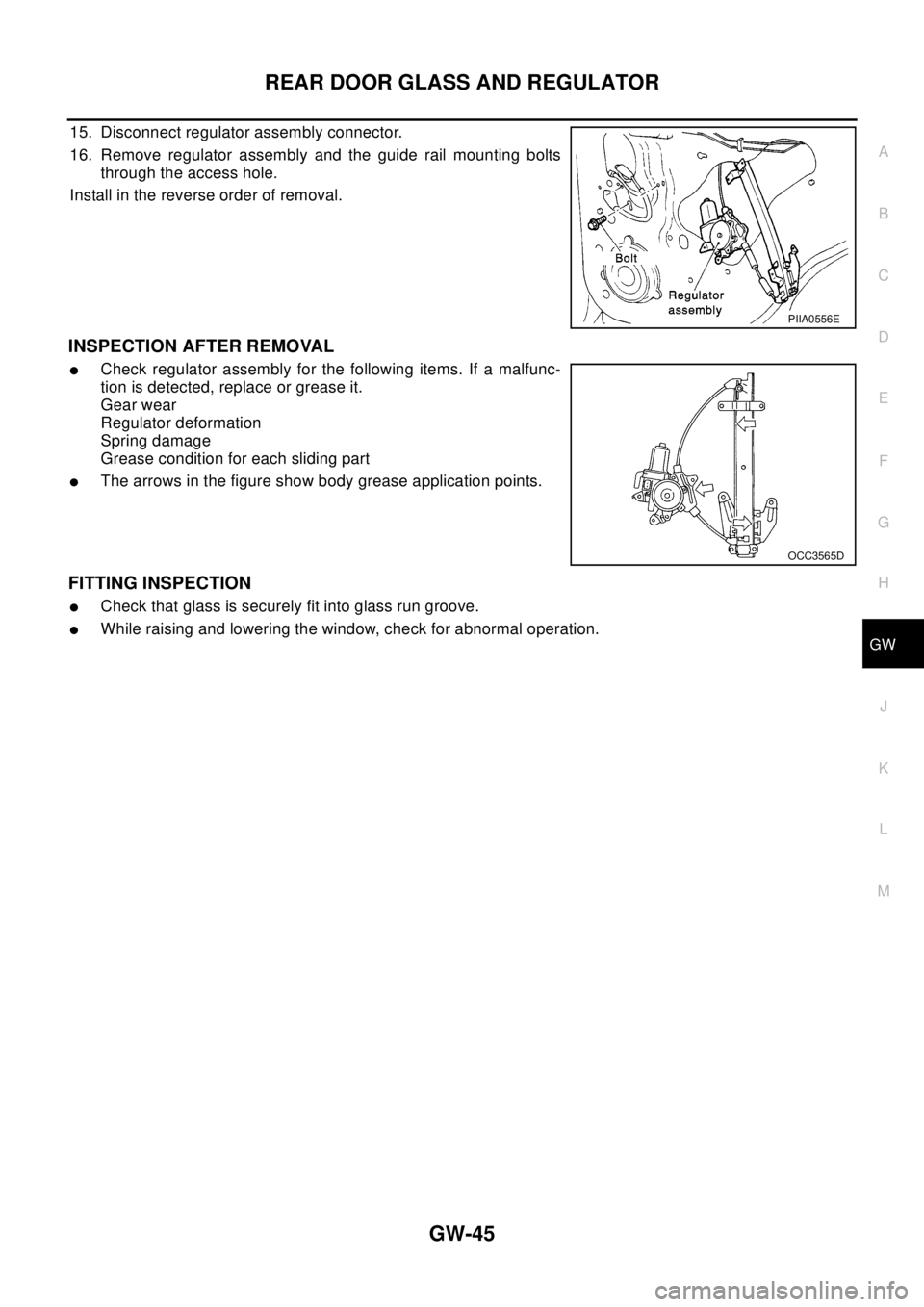

INSPECTION AFTER INSTALLATION

Setting of limit switch (driver)

If any of the following work has been done, set the limit switch (integrated in the motor).

lRemoval and installation of regulator

lRemoval and installation of motor from the regulator

lOperate regulators as a unit

lRemoval and installation of glass

lRemoval and installation of glass run

Reset operation

After installing each component to the vehicle, follow the steps

below.

1. Raise glass to the top dead center.

2. While pressing and holding reset switch, lower glass to the bot-

tom dead center.

3. Release reset switch, and check that reset switch returns to the

original position. Then raise glass to the top dead center.

NOTE:

Do not operate glass automatically to raise glass to the top dead

center.

FITTING INSPECTION

lCheck that glass is securely fit into glass run groove.

lWhile raising and lowering the window, check for abnormal operation.

PIIA0552E

OCC3424D

PIIA0553E

Page 2348 of 3066

REAR DOOR GLASS AND REGULATOR

GW-45

C

D

E

F

G

H

J

K

L

MA

B

GW

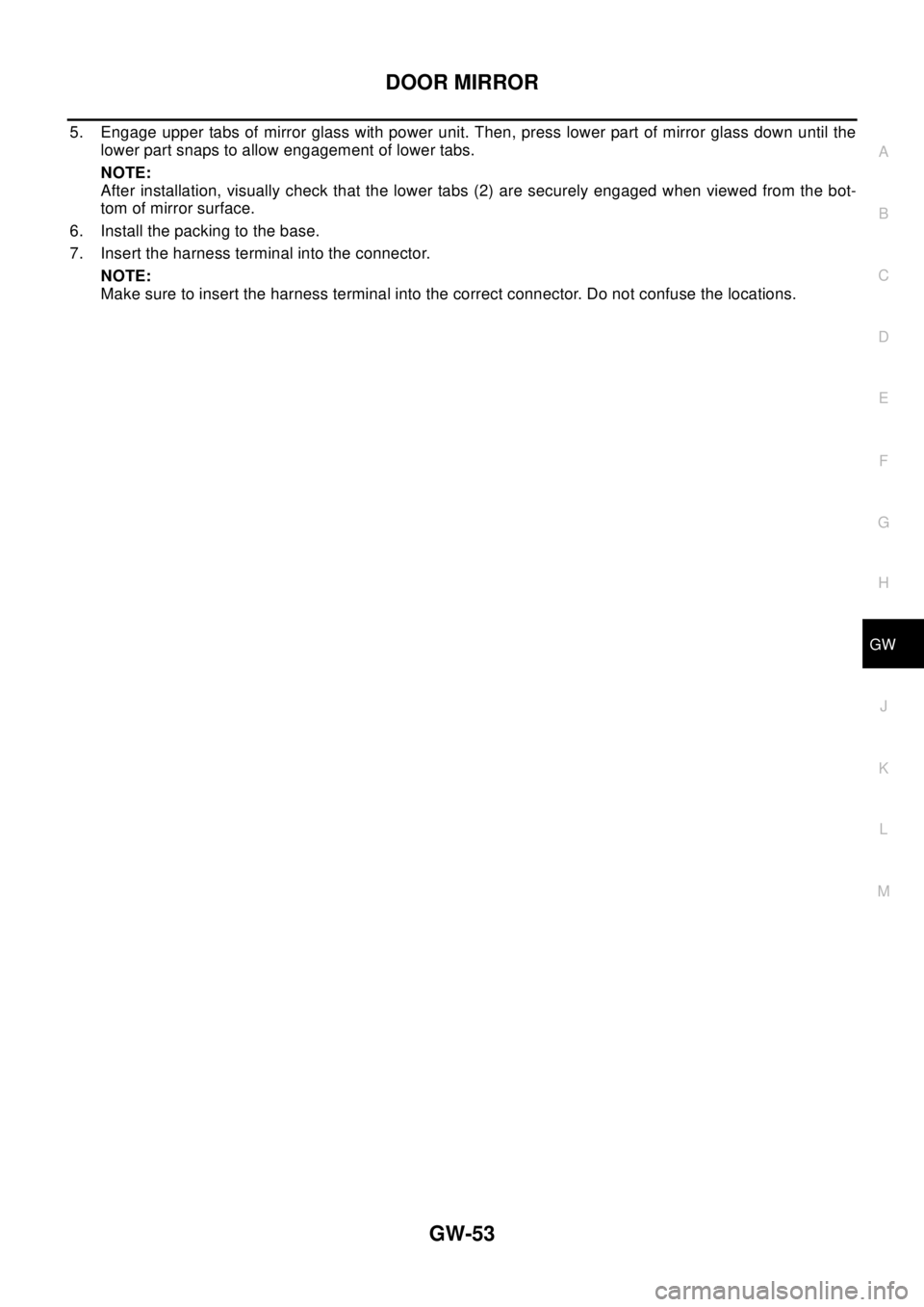

15. Disconnect regulator assembly connector.

16. Remove regulator assembly and the guide rail mounting bolts

through the access hole.

Install in the reverse order of removal.

INSPECTION AFTER REMOVAL

lCheck regulator assembly for the following items. If a malfunc-

tion is detected, replace or grease it.

Gear wear

Regulator deformation

Spring damage

Grease condition for each sliding part

lThe arrows in the figure show body grease application points.

FITTING INSPECTION

lCheck that glass is securely fit into glass run groove.

lWhile raising and lowering the window, check for abnormal operation.

PIIA0556E

OCC3565D

Page 2356 of 3066

DOOR MIRROR

GW-53

C

D

E

F

G

H

J

K

L

MA

B

GW

5. Engage upper tabs of mirror glass with power unit. Then, press lower part of mirror glass down until the

lower part snaps to allow engagement of lower tabs.

NOTE:

After installation, visually check that the lower tabs (2) are securely engaged when viewed from the bot-

tom of mirror surface.

6. Install the packing to the base.

7. Insert the harness terminal into the connector.

NOTE:

Make sure to insert the harness terminal into the correct connector. Do not confuse the locations.

Page 2498 of 3066

MA-6

GENERAL MAINTENANCE

GENERAL MAINTENANCE

PFP:00000

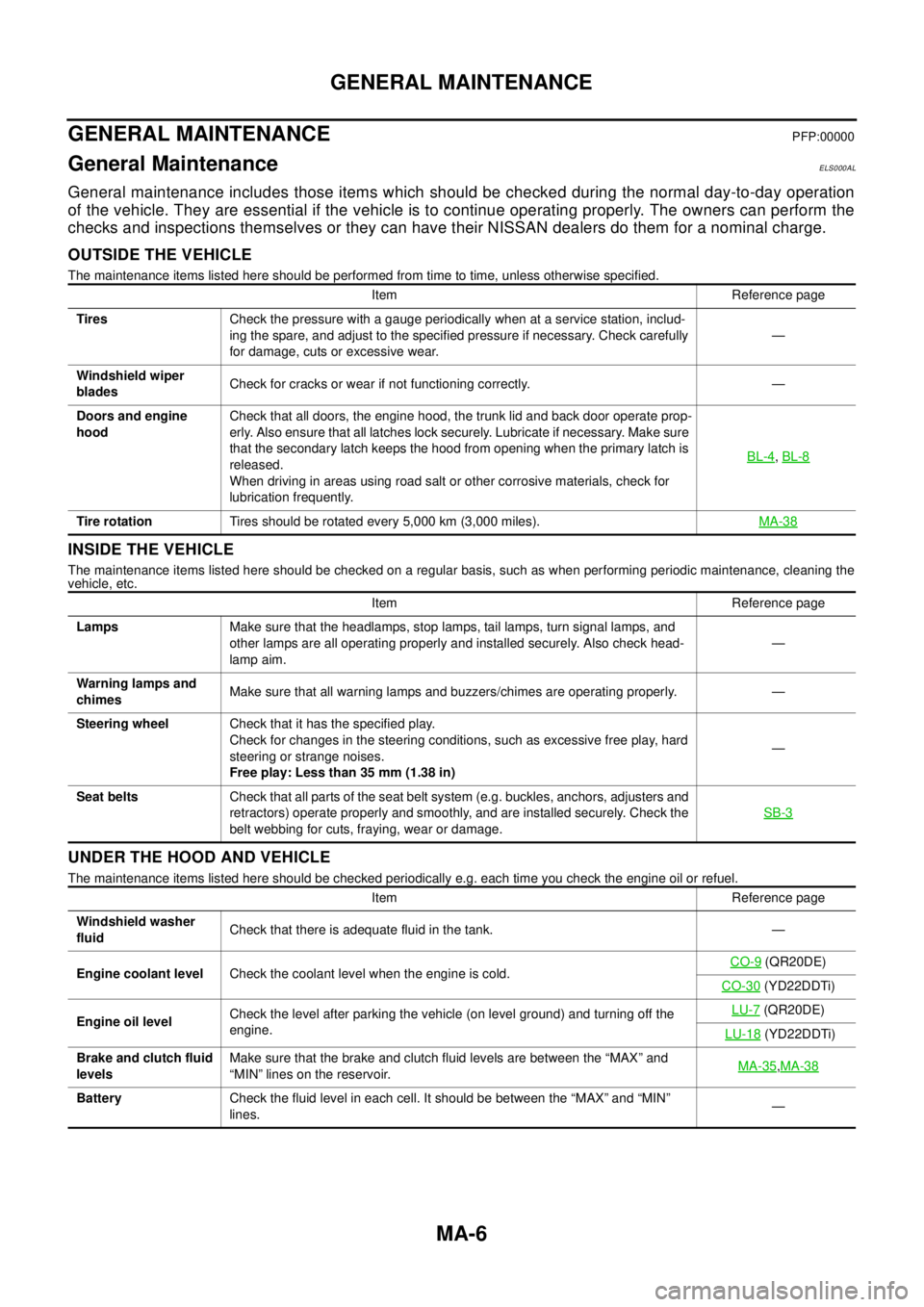

General MaintenanceELS000AL

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station, includ-

ing the spare, and adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate prop-

erly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch keeps the hood from opening when the primary latch is

released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.BL-4

,BL-8

Tire rotationTires should be rotated every 5,000 km (3,000 miles).MA-38

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head-

lamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating properly. —

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.SB-3

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold.CO-9

(QR20DE)

CO-30

(YD22DDTi)

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off the

engine.LU-7

(QR20DE)

LU-18

(YD22DDTi)

Brake and clutch fluid

levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.MA-35

,MA-38

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—