check engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 7 of 3066

AT-1

AUTOMATIC TRANSAXLE

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTION

A

B

AT

AUTOMATIC TRANSAXLE

PRECAUTIONS .......................................................... 5

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 5

Precautions for On Board Diagnostic (EURO-OBD)

System of A/T and Engine — Euro-OBD — ............. 5

Precautions For Trouble Diagnosis .......................... 5

Precautions For Harness Repair .............................. 5

Precautions .............................................................. 6

Service Notice or Precautions .................................. 7

Wiring Diagrams and Trouble Diagnosis .................. 8

PREPARATION ........................................................... 9

Special Service Tools ............................................... 9

Commercial Service Tools .......................................11

A/T FLUID ................................................................. 13

Checking A/T Fluid ................................................. 13

Changing A/T Fluid ................................................ 13

OVERALL SYSTEM ................................................. 14

A/T Electrical Parts Location .................................. 14

Circuit Diagram ...................................................... 16

Cross-sectional View .............................................. 17

Hydraulic Control Circuit ........................................ 18

Shift Mechanism ..................................................... 19

Control System ....................................................... 27

Control Mechanism ................................................ 29

Control Valve .......................................................... 33

EURO-OBD

TROUBLE DIAGNOSIS — INDEX ........................... 35

Alphabetical & P No. Index for DTC ....................... 35

ON BOARD DIAGNOSTIC SYSTEM DESCRIP-

TION .......................................................................... 37

Introduction ............................................................ 37

EURO-OBD Function for A/T System .................... 37

One or Two Trip Detection Logic of EURO-OBD ... 37

EURO-OBD Diagnostic Trouble Code (DTC) ......... 37

Malfunction Indicator lamp (MIL) ............................ 41

CONSULT-II ........................................................... 41

Diagnostic Procedure Without CONSULT-II ........... 50TROUBLE DIAGNOSIS — INTRODUCTION ........... 56

Introduction ............................................................. 56

Work Flow ............................................................... 61

TROUBLE DIAGNOSIS — BASIC INSPECTION .... 64

A/T Fluid Check ...................................................... 64

Stall Test ................................................................. 65

Line Pressure Test .................................................. 68

Road Test ............................................................... 69

TROUBLE DIAGNOSIS — GENERAL DESCRIP-

TION .......................................................................... 86

Symptom Chart ....................................................... 86

TCM Terminals and Reference Value ...................125

CAN COMMUNICATION .........................................129

System Description ...............................................129

DTC P0705 PARK/NEUTRAL POSITION (PNP)

SWITCH ..................................................................130

Description ............................................................130

Wiring Diagram — AT — PNP/SW .......................132

Diagnostic Procedure ...........................................133

Component Inspection ..........................................135

DTC P0710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT ..................................................................136

Description ............................................................136

Wiring Diagram — AT — FTS ..............................138

Diagnostic Procedure ...........................................139

Component Inspection ..........................................141

DTC P0720 VEHICLE SPEED SENSOR·A/T (REV-

OLUTION SENSOR) ...............................................142

Description ............................................................142

Wiring Diagram — AT — VSSA/T ........................144

Diagnostic Procedure ...........................................145

DTC P0725 ENGINESPEED SIGNAL ...................147

Description ............................................................147

Wiring Diagram — AT — ENGSS .........................148

Diagnostic Procedure ...........................................149

DTC P0731 A/T 1ST GEAR FUNCTION ................151

Description ............................................................151

Wiring Diagram — AT — 1ST ...............................154

Diagnostic Procedure ...........................................155

Component Inspection ..........................................156

Page 8 of 3066

AT-2

DTC P0732 A/T 2ND GEAR FUNCTION ................158

Description ............................................................158

Wiring Diagram — AT — 2ND ..............................161

Diagnostic Procedure ...........................................162

Component Inspection ..........................................163

DTC P0733 A/T 3RD GEAR FUNCTION ................165

Description ............................................................165

Wiring Diagram — AT — 3RD ..............................168

Diagnostic Procedure ...........................................169

Component Inspection ..........................................170

DTC P0734 A/T 4TH GEAR FUNCTION ................172

Description ............................................................172

Wiring Diagram — AT — 4TH ...............................175

Diagnostic Procedure ...........................................176

Component Inspection ..........................................179

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE .................................................181

Description ............................................................181

Wiring Diagram — AT — TCV ..............................183

Diagnostic Procedure ...........................................184

Component Inspection ..........................................185

DTC P0745 LINE PRESSURE SOLENOID VALVE. 186

Description ............................................................186

Wiring Diagram — AT — LPSV ............................188

Diagnostic Procedure ...........................................189

Component Inspection ..........................................191

DTC P0750 SHIFT SOLENOID VALVE A ...............193

Description ............................................................193

Wiring Diagram — AT — SSV/A ...........................195

Diagnostic Procedure ...........................................196

Component Inspection ..........................................197

DTC P0755 SHIFT SOLENOID VALVE B ...............198

Description ............................................................198

Wiring Diagram — AT — SSV/B ...........................200

Diagnostic Procedure ...........................................201

Component Inspection ..........................................202

DTC P1705 ACCELERATOR PEDAL POSITION

(APP) SENSOR .......................................................203

Description ............................................................203

Wiring Diagram — AT — TPS ..............................205

Diagnostic Procedure ...........................................206

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE .....................................................................208

Description ............................................................208

Wiring Diagram — AT — OVRCSV ......................210

Diagnostic Procedure ...........................................211

Component Inspection ..........................................212

DTC U1000 CAN COMMUNICATION LINE ............213

Description ............................................................213

On Board Diagnosis Logic ....................................213

..............................................................................213

Wiring Diagram — AT ...........................................214

Diagnostic Procedure ...........................................215

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE). 216

Description ............................................................216

Wiring Diagram — AT — BA/FTS .........................218Diagnostic Procedure ............................................ 219

Component Inspection .......................................... 221

DTC VEHICLE SPEED SENSOR MTR ................... 222

Description ............................................................ 222

Wiring Diagram — AT — VSSMTR ....................... 224

Diagnostic Procedure ............................................ 225

DTC CONTROL UNIT (RAM), CONTROL UNIT

(ROM) ...................................................................... 226

Description ............................................................ 226

Diagnostic Procedure ............................................ 227

DTC CONTROL UNIT(EEPROM) ........................... 228

Description ............................................................ 228

Diagnostic Procedure ............................................ 229

TROUBLE DIAGNOSES FOR SYMPTOMS ........... 230

.............................................................................. 230

1. O/D OFF Indicator Lamp Does Not Come On .. 232

2. Engine Cannot Be Started In “P” and “N” Position. 233

3. In “P” Position, Vehicle Moves Forward Or Back-

ward When Pushed ............................................... 234

4. In “N” Position, Vehicle Moves .......................... 234

5. Large Shock. “N”®“R” Position ...................... 236

6. Vehicle Does Not Creep Backward In “R” Position. 237

7. Vehicle Does Not Creep Forward In “D”, “2” Or

“1” Position ............................................................ 240

8. Vehicle Cannot Be Started From D

1................. 242

9. A/T Does Not Shift: D

1®D2Or Does Not Kick-

down: D

4®D2..................................................... 244

10. A/T Does Not Shift: D

2®D3.......................... 246

11.A/TDoesNotShift:D

3®D4........................... 249

12. A/T Does Not Perform Lock-up ....................... 252

13. A/T Does Not Hold Lock-up Condition ............ 253

14. Lock-up Is Not Released ................................. 254

15. Engine Speed Does Not Return To Idle (Light

Braking D

4®D3) ................................................. 255

16. Vehicle Does Not Start From D

1..................... 257

17. A/T Does Not Shift: D

4®D3, When Overdrive

Control Switch “ON”®“OFF” ............................... 258

18. A/T Does Not Shift: D

3®22, When Selector

Lever “D”®“2” Position ....................................... 258

19. A/T Does Not Shift: 2

2®11, When Selector

Lever “2”®“1” Position ........................................ 259

20. Vehicle Does Not Decelerate By Engine Brake. 259

21. TCM Self-diagnosis Does Not Activate (PNP &

Overdrive Control Switches, and Throttle Position

Sensor Circuit Checks) ......................................... 260

EXC.F/EURO-OBD

ON BOARD DIAGNOSTIC SYSTEM DESCRIP-

TION ........................................................................ 267

CONSULT-II .......................................................... 267

Diagnostic Procedure Without CONSULT-II ......... 273

TROUBLE DIAGNOSIS — INTRODUCTION ......... 279

Introduction ........................................................... 279

Work Flow ............................................................. 284

TROUBLE DIAGNOSIS — BASIC INSPECTION ... 286

A/T Fluid Check .................................................... 286

Stall Test ................................................................ 287

Page 9 of 3066

AT-3

D

E

F

G

H

I

J

K

L

MA

B

AT Line Pressure Test ............................................... 290

Road Test ............................................................. 291

TROUBLE DIAGNOSIS — GENERAL DESCRIP-

TION ........................................................................ 308

Symptom Chart .................................................... 308

TCM Terminals and Reference Value ................... 347

CAN COMMUNICATION ........................................ 351

System Description .............................................. 351

TROUBLE DIAGNOSES FOR SYMPTOMS .......... 352

............................................................................. 352

1. O/D OFF Indicator Lamp Does Not Come On . 354

2. Engine Cannot Be Started In “P” and “N” Position. 355

3. In “P” Position, Vehicle Moves Forward Or Back-

ward When Pushed .............................................. 356

4. In “N” Position, Vehicle Moves ......................... 356

5. Large Shock. “N”®“R” Position ...................... 358

6. Vehicle Does Not Creep Backward In “R” Position. 359

7. Vehicle Does Not Creep Forward In “D”, “2” Or

“1” Position ........................................................... 362

8. Vehicle Cannot Be Started From D

1................. 364

9. A/T Does Not Shift: D

1®D2Or Does Not Kick-

down: D

4®D2..................................................... 366

10. A/T Does Not Shift: D

2®D3......................... 368

11.A/TDoesNotShift:D

3®D4.......................... 371

12. A/T Does Not Perform Lock-up ...................... 374

13. A/T Does Not Hold Lock-up Condition ........... 375

14. Lock-up Is Not Released ................................ 376

15. Engine Speed Does Not Return To Idle (Light

Braking D

4®D3) ................................................ 377

16. Vehicle Does Not Start From D

1..................... 379

17. A/T Does Not Shift: D

4®D3, When Overdrive

Control Switch “ON”®“OFF” .............................. 380

18. A/T Does Not Shift: D

3®22, When Selector

Lever “D”®“2” Position ...................................... 380

19. A/T Does Not Shift: 2

2®11, When Selector

Lever “2”®“1” Position ....................................... 381

20. Vehicle Does Not Decelerate By Engine Brake. 381

21. TCM Self-diagnosis Does Not Activate (PNP &

Overdrive Control Switches, and Throttle Position

Sensor Circuit Checks) ........................................ 382

ALL

MAIN POWER SUPPLY AND GROUND CIRCUIT. 389

Wiring Diagram — AT — MAIN ............................ 389

Diagnostic Procedure ........................................... 390

VEHICLE SPEED SENSOR·A/T (REVOLUTION

SENSOR) ................................................................ 392

Description ........................................................... 392

Wiring Diagram — AT — VSSA/T ........................ 394

Diagnostic Procedure ........................................... 395

DTC VEHICLE SPEED SENSOR MTR .................. 397

Description ........................................................... 397

Wiring Diagram — AT — VSSMTR ...................... 399

Diagnostic Procedure ........................................... 400

ACCELE RATOR PEDAL POSITION (APP) SEN-

SOR ........................................................................ 401

Description ........................................................... 401Wiring Diagram — AT — TPS ..............................403

Diagnostic Procedure ...........................................404

SHIFT SOLENOID VALVE A ..................................406

Description ............................................................406

Wiring Diagram — AT — SSV/A ...........................408

Diagnostic Procedure ...........................................409

Component Inspection ..........................................410

SHIFT SOLENOID VALVE B ..................................411

Description ............................................................411

Wiring Diagram — AT — SSV/B ...........................413

Diagnostic Procedure ...........................................414

Component Inspection ..........................................415

OVERRUN CLUTCH SOLENOID VALVE ...............416

Description ............................................................416

Wiring Diagram — AT — OVRCSV ......................418

Diagnostic Procedure ...........................................419

Component Inspection ..........................................420

TORQUE CONVERTER CLUTCH SOLENOID

VALVE .....................................................................421

Description ............................................................421

Wiring Diagram — AT — TCV ..............................423

Diagnostic Procedure ...........................................424

Component Inspection ..........................................425

BATT/FLUID TEMP SEN (A/T FLUID TEMP SEN-

SOR CIRCUIT AND TCM POWER SOURCE) .......426

Description ............................................................426

Wiring Diagram — AT — BA/FTS .........................428

Diagnostic Procedure ...........................................429

Component Inspection ..........................................431

ENGINE SPEED SIGNAL .......................................432

Description ............................................................432

Wiring Diagram — AT — ENGSS .........................433

Diagnostic Procedure ...........................................434

LINE PRESSURE SOLENOID VALVE ...................436

Description ............................................................436

Wiring Diagram — AT — LPSV ............................438

Diagnostic Procedure ...........................................439

Component Inspection ..........................................441

CAN CAMMUNICATION LINE ................................443

Description ............................................................443

On Board Diagnosis Logic ....................................443

Self-Diagnosis Code Confirmation Procedure ......443

Wiring Diagram — AT — CAN ..............................444

Diagnostic Procedure ...........................................445

A/T SHIFT LOCK SYSTEM ....................................446

Description ............................................................446

Shift Lock System Electrical Parts Location .........446

Wiring Diagram — SHIFT — ................................447

Diagnostic Procedure ...........................................448

KEY INTERLOCK CABLE ......................................452

Components .........................................................452

Removal ...............................................................452

Installation ............................................................453

ON-VEHICLE SERVICE ..........................................454

Control Valve Assembly and Accumulators ..........454

Control Cable Adjustment .....................................456

Park/Neutral Position (PNP) Switch Adjustment ..456

Page 19 of 3066

A/T FLUID

AT-13

D

E

F

G

H

I

J

K

L

MA

B

AT

A/T FLUIDPFP:KLE40

Checking A/T FluidECS004Q7

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50°C (86 to 122°F) using “COLD” range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of either

range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on dipstick.

6. Check fluid condition.

lIf fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

lIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer toCO-12,

"RADIATOR",CO-15, "RADIATOR (ALUMINUM TYPE)",,.

Changing A/T FluidECS004Q8

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to “Checking A/T Fluid”. If fluid is still dirty, repeat steps 2 through 5.

SMA827CA

SMA853B

Fluid grade:

Genuine Nissan ATF or equivalent. Refer toMA-

17, "RECOMMENDED FLUIDS AND LUBRI-

CANTS".

Fluid capacity (With torque converter):

Approx. 8.0 (7.01 lmp qt)

Drain plug:

:29-39N·m(3.0-4.0kg-m,22-29ft-lb)

SMA027D

Page 40 of 3066

AT-34

OVERALL SYSTEM

Overrun clutch control valve Switches hydraulic circuits to prevent engagement of the overrun clutch simultaneously with appli-

cation of the brake band in D

4. (Interlocking occurs if the overrun clutch engages during D4.)

1st reducing valve Reduces low & reverse brake pressure to dampen engine-brake shock when down-shifting from

the “1” position 1

2to 11.

Overrun clutch reducing valve Reduces oil pressure directed to the overrun clutch and prevents engine-brake shock.

In “1” and “2” positions, line pressure acts on the overrun clutch reducing valve to increase the

pressure-regulating point, with resultant engine brake capability.

Torque converter relief valve Prevents an excessive rise in torque converter pressure.

Torque converter clutch control

valve, plug and sleeveActivates or inactivates the lock-up function.

Also provides smooth lock-up through transient application and release of the lock-up system.

1-2 accumulator valve and piston Dampens the shock encountered when 2nd gear band servo contracts, and provides smooth

shifting.

3-2 timing valve Switches oil pressure with 3-2 timing valve according to throttle opening.

Shuttle control valve Reduces shock when down-shifting from 3rd to 2nd and regulates overrun clutch.

Cooler check valve Regulates oil pressure which causes lock-up when driving at low speeds.Valve name Function

Page 41 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — INDEX

AT-35

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

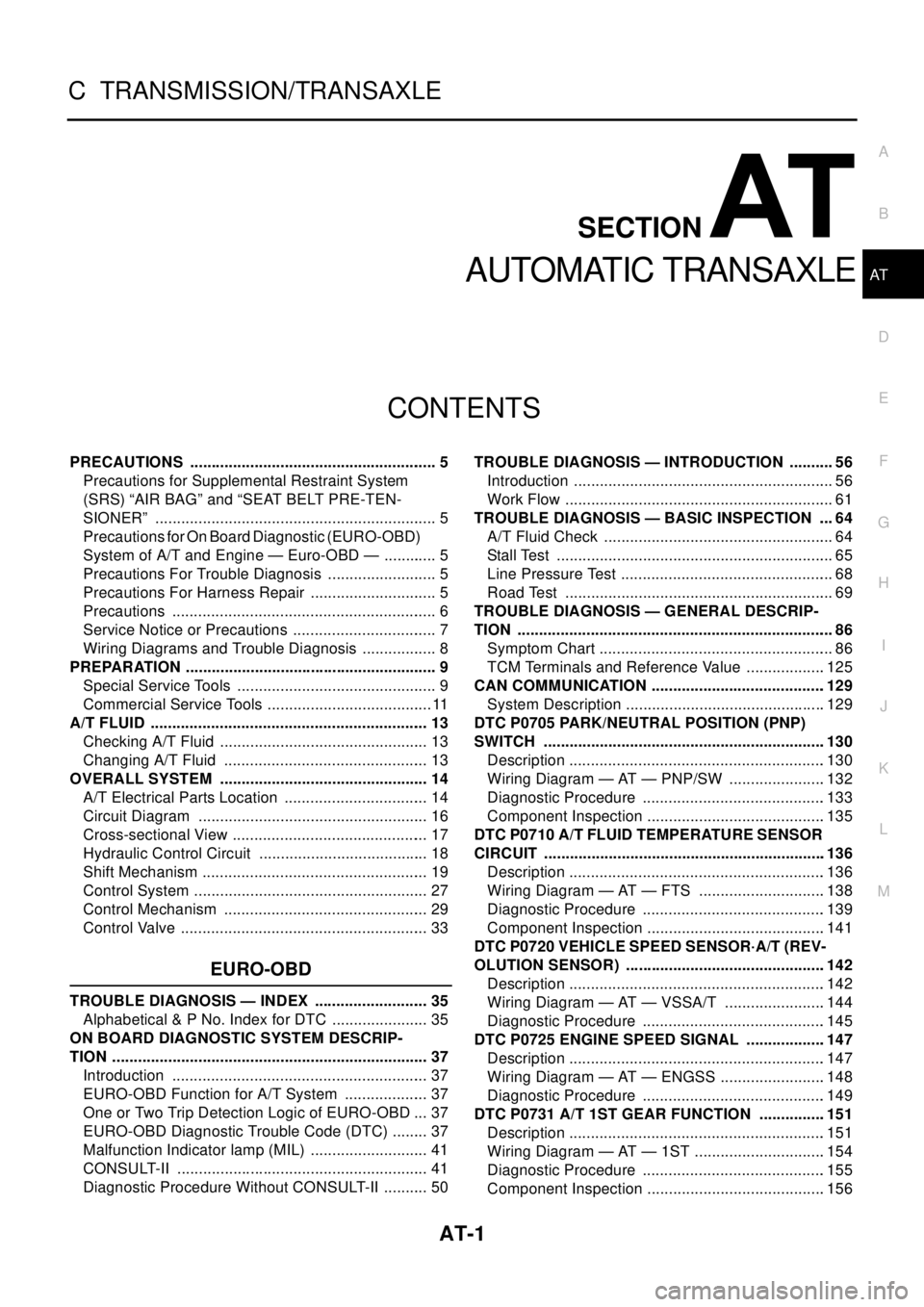

[EURO-OBD]TROUBLE DIAGNOSIS — INDEXPFP:00000

Alphabetical & P No. Index for DTCECS003VK

ALPHABETICAL INDEX FOR DTC

Check if the NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — INDEX

AT-35

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

[EURO-OBD]TROUBLE DIAGNOSIS — INDEXPFP:00000

Alphabetical & P No. Index for DTCECS003VK

ALPHABETICAL INDEX FOR DTC

Check if the](/img/5/57402/w960_57402-40.png)

TROUBLE DIAGNOSIS — INDEX

AT-35

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

[EURO-OBD]TROUBLE DIAGNOSIS — INDEXPFP:00000

Alphabetical & P No. Index for DTCECS003VK

ALPHABETICAL INDEX FOR DTC

Check if the vehicle is a model with Euro-OBD system or not by the “Type approval number” on the identifica-

tion plate. Refer toGI-45, "

IDENTIFICATION PLATE".

l*1: These numbers are prescribed by SAE J2012.

l*2: When the fail-safe operation occurs, the MIL illuminates.

l*3: The MIL illuminates when both the “Revolution sensor signal” and the “Vehicle speed sensor signal” meet the fail-safe condition at

thesametime.Type approval number Model

Available With Euro-OBD system

Not available (blank) Without Euro-OBD system

Items

(CONSULT-II screen terms)DTC

Reference page

CONSULT-II

GST*1

A/T 1ST GR FNCTN P0731AT- 1 5 1 , "

DTC P0731 A/T 1ST

GEAR FUNCTION"

A/T 2ND GR FNCTN P0732AT- 1 5 8 , "DTC P0732 A/T 2ND

GEAR FUNCTION"

A/T 3RD GR FNCTN P0733AT- 1 6 5 , "DTC P0733 A/T 3RD

GEAR FUNCTION"

A/T 4TH GR FNCTN P0734AT- 1 7 2 , "DTC P0734 A/T 4TH

GEAR FUNCTION"

ATF TEMP SEN/CIRC P0710AT- 1 3 6 , "

DTC P0710 A/T FLUID

TEMPERATURE SENSOR

CIRCUIT"

ENGINE SPEED SIG P0725AT- 1 4 7 , "DTC P0725 ENGINE

SPEED SIGNAL"

L/PRESS SOL/CIRC P0745AT-186, "

DTC P0745 LINE

PRESSURE SOLENOID

VA LV E"

O/R CLTCH SOL/CIRC P1760AT- 2 0 8 , "

DTC P1760 OVER-

RUN CLUTCH SOLENOID

VA LV E"

PNP SW/CIRC P0705AT-1 3 0 , "

DTC P0705 PARK/

NEUTRAL POSITION (PNP)

SWITCH"

SFT SOL A/CIRC*2 P0750AT- 1 9 3 , "DTC P0750 SHIFT

SOLENOID VALVE A"

SFT SOL B/CIRC*2 P0755AT- 1 9 8 , "DTC P0755 SHIFT

SOLENOID VALVE B"

TCC SOLENOID/CIRC P0740AT-181, "

DTC P0740 TORQUE

CONVERTER CLUTCH SOLE-

NOID VALVE"

TP SEN/CIRC A/T*2 P1705AT- 2 0 3 , "

DTC P1705 ACCEL-

ERATOR PEDAL POSITION

(APP) SENSOR"

VEH SPD SEN/CIR AT*3 P0720AT-142, "

DTC P0720 VEHICLE

SPEED SENSOR·A/T (REVO-

LUTION SENSOR)"

CAN COMM CIRCUIT U1000EC-114, "DTC U1000 CAN

COMMUNICATION LINE"

Page 42 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-36

[EURO-OBD]

TROUBLE DIAGNOSIS — INDEX

PNO.INDEXFORDTC

Check if the vehicle is a model with Euro-OBD system or not by the “Type approval number” on the identifica-

tion plate. Refer toGI-45, NISSAN X-TRAIL 2003 Electronic Repair Manual AT-36

[EURO-OBD]

TROUBLE DIAGNOSIS — INDEX

PNO.INDEXFORDTC

Check if the vehicle is a model with Euro-OBD system or not by the “Type approval number” on the identifica-

tion plate. Refer toGI-45,](/img/5/57402/w960_57402-41.png)

AT-36

[EURO-OBD]

TROUBLE DIAGNOSIS — INDEX

PNO.INDEXFORDTC

Check if the vehicle is a model with Euro-OBD system or not by the “Type approval number” on the identifica-

tion plate. Refer toGI-45, "

IDENTIFICATION PLATE".

l*1: These numbers are prescribed by SAE J2012.

l*2: When the fail-safe operation occurs, the MIL illuminates.

l*3: The MIL illuminates when both the “Revolution sensor signal” and the “Vehicle speed sensor signal” meet the fail-safe condition at

thesametime.Type approval number Model

Available With Euro-OBD system

Not available (blank) Without Euro-OBD system

DTC

Items

(CONSULT-II screen terms)Reference page

CONSULT-II

GST*1

P0705 PNP SW/CIRCAT- 1 3 0 , "

DTC P0705 PARK/

NEUTRAL POSITION (PNP)

SWITCH"

P0710 ATF TEMP SEN/CIRCAT-136, "

DTC P0710 A/T FLUID

TEMPERATURE SENSOR

CIRCUIT"

P0720 VEH SPD SEN/CIR AT*3AT- 1 4 2 , "

DTC P0720 VEHICLE

SPEED SENSOR·A/T (REVO-

LUTION SENSOR)"

P0725 ENGINE SPEED SIGAT- 1 4 7 , "DTC P0725 ENGINE

SPEED SIGNAL"

P0731 A/T 1ST GR FNCTNAT- 1 5 1 , "DTC P0731 A/T 1ST

GEAR FUNCTION"

P0732 A/T 2ND GR FNCTNAT- 1 5 8 , "DTC P0732 A/T 2ND

GEAR FUNCTION"

P0733 A/T 3RD GR FNCTNAT- 1 6 5 , "DTC P0733 A/T 3RD

GEAR FUNCTION"

P0734 A/T 4TH GR FNCTNAT- 1 7 2 , "DTC P0734 A/T 4TH

GEAR FUNCTION"

P0740 TCC SOLENOID/CIRCAT- 1 8 1 , "

DTC P0740 TORQUE

CONVERTER CLUTCH SOLE-

NOID VALVE"

P0745 L/PRESS SOL/CIRCAT-186, "

DTC P0745 LINE

PRESSURE SOLENOID

VA LV E"

P0750 SFT SOL A/CIRC*2AT-193, "DTC P0750 SHIFT

SOLENOID VALVE A"

P0755 SFT SOL B/CIRC*2AT-198, "DTC P0755 SHIFT

SOLENOID VALVE B"

P1705 TP SEN/CIRC A/T*2AT- 2 0 3 , "

DTC P1705 ACCEL-

ERATOR PEDAL POSITION

(APP) SENSOR"

P1760 O/R CLTCH SOL/CIRCAT-208, "

DTC P1760 OVER-

RUNCLUTCHSOLENOID

VA LV E"

U1000 CAN COMM CIRCUITEC-114, "DTC U1000 CAN

COMMUNICATION LINE"

Page 47 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-41

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Malfunction Indicator lamp (MIL)ECS004QL

1. The malfunction indicator lamp will light up when the ignition

switch is t NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-41

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Malfunction Indicator lamp (MIL)ECS004QL

1. The malfunction indicator lamp will light up when the ignition

switch is t](/img/5/57402/w960_57402-46.png)

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-41

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

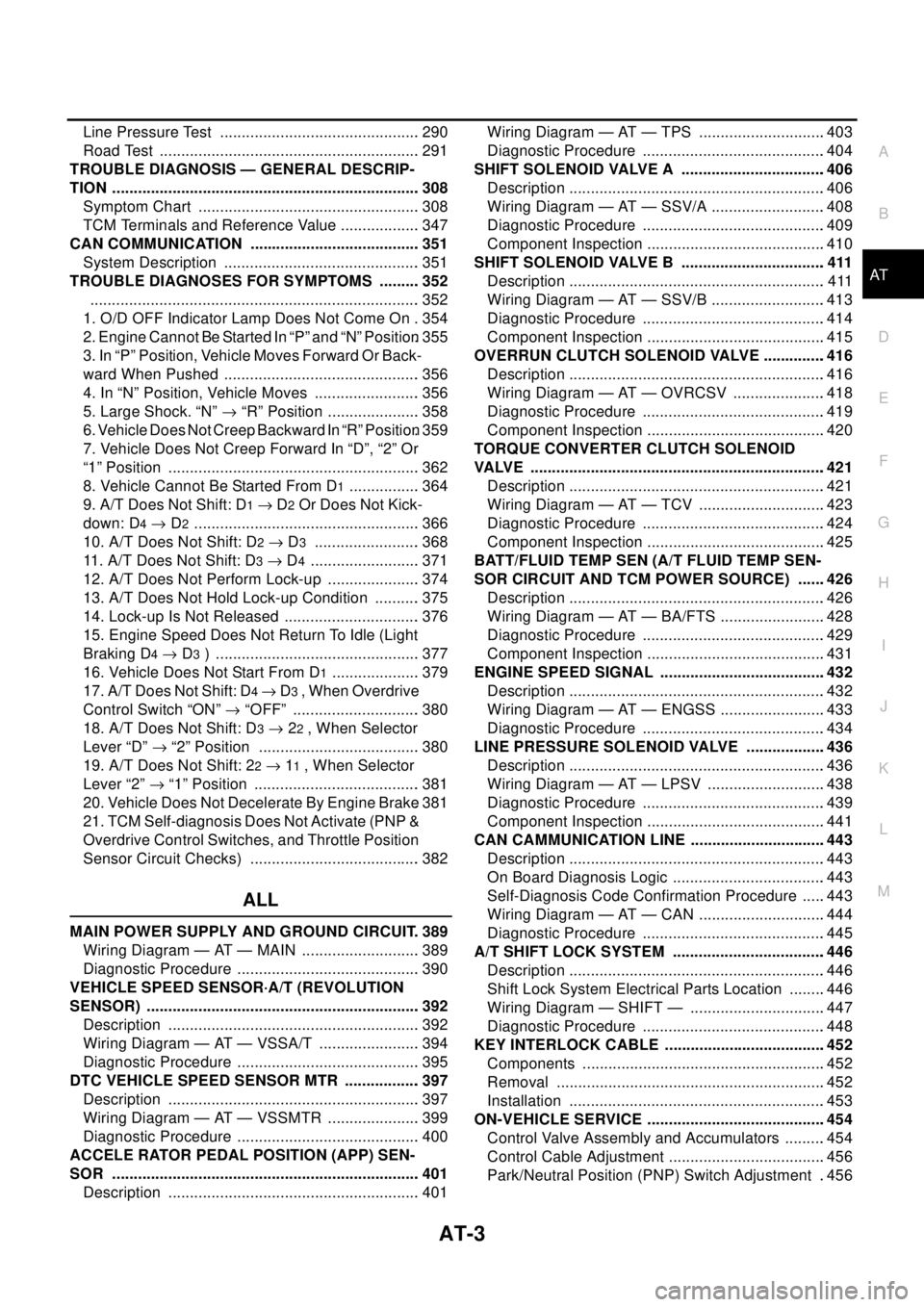

Malfunction Indicator lamp (MIL)ECS004QL

1. The malfunction indicator lamp will light up when the ignition

switch is turned ON without the engine running. This is for

checking the lamp.

lIf the malfunction indicator does not light up, refer to "",

“Warning Lamps”.

(Or see MIL & CONSULT-II in EC section. Refer toEC-48,

"Malfunction Indicator (MI)", “Description”, “Malfunction Indi-

cator lamp (MIL)” and "", “CONSULT-II”.)

2. When the engine is started, the malfunction indicator should go

off.

If the lamp remains on, the on board diagnostic system has

detected an emission-related (EURO-OBD) malfunction. For

detail, refer to "njec0029", “ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION”.

CONSULT-IIECS0 04 QM

After performing “SELF-DIAGNOSTIC PROCEDURE (WITH CONSULT-II)”AT- 4 1 , "SELF-DIAGNOSTIC

PROCEDURE (WITH CONSULT-II)", place check marks for results on the “DIAGNOSTIC WORKSHEET”,

AT- 5 7 , "

DIAGNOSTIC WORKSHEET". Reference pages are provided following the items.

NOTICE:

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each sole-

noid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

–Actual shift schedule has more or less tolerance or allowance,

–Shift schedule indicated in Service Manual refers to the point where shifts start, and

–Gear position displayed on CONSULT-II indicates the point where shifts are completed.

3. Shift solenoid valve “A” or “B” is displayed on CONSULT-II at the start of shifting. Gear position is dis-

played upon completion of shifting (which is computed by TCM).

4. Additional CONSULT-II information can be found in the Operation Manual supplied with the CONSULT-II

unit.

SELF-DIAGNOSTIC PROCEDURE (WITH CONSULT-II)

1. Turn on CONSULT-II and touch “ENGINE” for EURO-OBD

detected items or touch “A/T” for TCM self-diagnosis.

If A/T is not displayed, check TCM power supply and ground cir-

cuit. Refer toAT - 1 2 5 , "

TCM Terminals and Reference Value".If

result is NG, refer toPG-2, "

POWER SUPPLY ROUTING".

SAT652J

SAT014K

Page 57 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-51

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)

1.CHECK O/D OFF INDICATOR LAMP

1. Start engine and warm it up to normal opera NISSAN X-TRAIL 2003 Electronic Repair Manual ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-51

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)

1.CHECK O/D OFF INDICATOR LAMP

1. Start engine and warm it up to normal opera](/img/5/57402/w960_57402-56.png)

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

AT-51

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

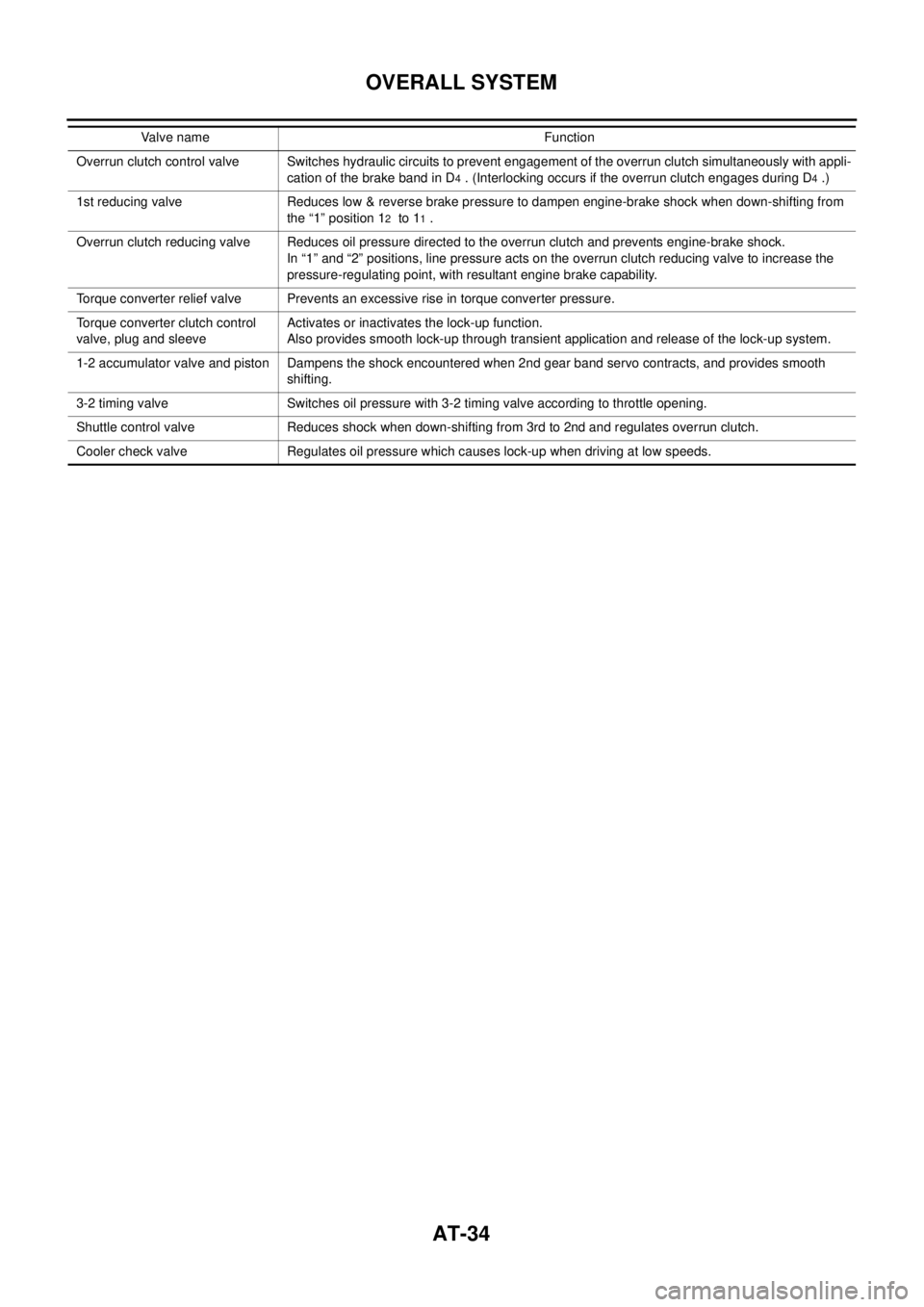

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)

1.CHECK O/D OFF INDICATOR LAMP

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch to “OFF” position.

Wait 5 seconds.

3. Turn ignition switch to “ACC” position.

4. Set overdrive control switch to “ON” position.

5. Move selector lever to “P” position.

6. Turn ignition switch to “ON” position. (Do not start engine.)

7. Does O/D OFF indicator lamp come on for about 2 seconds?

Ye s o r N o

Yes >>GOTO2

No >> Go toAT- 2 3 2 , "

1. O/D OFF Indicator Lamp Does Not Come On".

2.JUDGEMENT PROCEDURE STEP 1

1. Turn ignition switch to “OFF” position.

2. Turn ignition switch to “ACC” position.

3. Move selector lever to “D” position.

4. Set overdrive control switch to “OFF” position.

5. Turn ignition switch to “ON” position. (Do not start engine.)

–Wait more than 2 seconds after turning ignition switch “ON”.

>> GO TO 3

SAT774B

SCIA0693E

SAT653E

Page 62 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-56

[EURO-OBD]

TROUBLE DIAGNOSIS — INTRODUCTION

TROUBLE DIAGNOSIS — INTRODUCTION

PFP:00000

IntroductionECS0 04 QO

The TCM receives a signal from the vehicle speed sensor, throttle

position senso NISSAN X-TRAIL 2003 Electronic Repair Manual AT-56

[EURO-OBD]

TROUBLE DIAGNOSIS — INTRODUCTION

TROUBLE DIAGNOSIS — INTRODUCTION

PFP:00000

IntroductionECS0 04 QO

The TCM receives a signal from the vehicle speed sensor, throttle

position senso](/img/5/57402/w960_57402-61.png)

AT-56

[EURO-OBD]

TROUBLE DIAGNOSIS — INTRODUCTION

TROUBLE DIAGNOSIS — INTRODUCTION

PFP:00000

IntroductionECS0 04 QO

The TCM receives a signal from the vehicle speed sensor, throttle

position sensor or PNP switch and provides shift control or lock-up

control via A/T solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the EURO-OBD related parts

of the A/T system for malfunction-diagnostic purposes. The TCM is

capable of diagnosing malfunctioning parts while the ECM can store

malfunctions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. The A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

A visual check only, may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the “Work Flow”. Refer toAT- 6 1 , "

Work Flow".

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “Diagnostic Worksheet” like the exam-

ple (AT-57, "

DIAGNOSTIC WORKSHEET") should be used.

Start your diagnosis by looking for “conventional” problems first. This

will help troubleshoot driveability problems on an electronically con-

trolled engine vehicle.

Also check related Service bulletins for information.

SAT631IA

SAT632I

SEF234G