wiper fluid NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2364 of 3066

IDX-7

A

C

D

E

F

G

H

I

J

K

L B

IDX

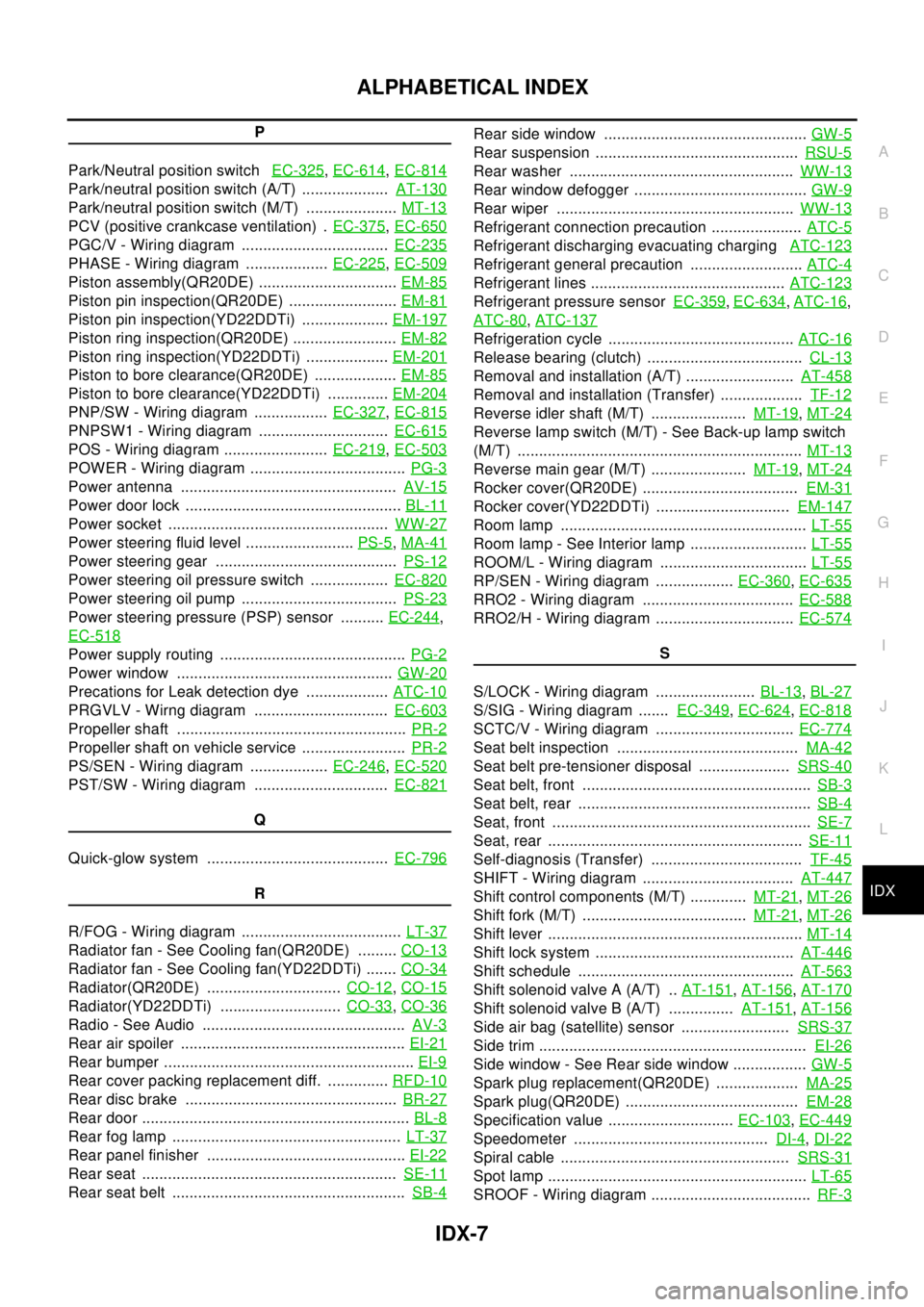

ALPHABETICAL INDEX

P

Park/Neutral position switchEC-325

,EC-614,EC-814

Park/neutral position switch (A/T) ....................AT-130

Park/neutral position switch (M/T) .....................MT-13

PCV (positive crankcase ventilation) .EC-375,EC-650

PGC/V - Wiring diagram ..................................EC-235

PHASE - Wiring diagram ...................EC-225,EC-509

Piston assembly(QR20DE) ................................EM-85

Piston pin inspection(QR20DE) .........................EM-81

Piston pin inspection(YD22DDTi) ....................EM-197

Piston ring inspection(QR20DE) ........................EM-82

Piston ring inspection(YD22DDTi) ...................EM-201

Piston to bore clearance(QR20DE) ...................EM-85

Piston to bore clearance(YD22DDTi) ..............EM-204

PNP/SW - Wiring diagram .................EC-327,EC-815

PNPSW1 - Wiring diagram ..............................EC-615

POS - Wiring diagram ........................EC-219,EC-503

POWER - Wiring diagram ....................................PG-3

Power antenna ..................................................AV-15

Power door lock ..................................................BL-11

Power socket ...................................................WW-27

Power steering fluid level .........................PS-5,MA-41

Power steering gear ..........................................PS-12

Power steering oil pressure switch ..................EC-820

Power steering oil pump ....................................PS-23

Power steering pressure (PSP) sensor ..........EC-244,

EC-518

Power supply routing ...........................................PG-2

Power window ..................................................GW-20

Precations for Leak detection dye ...................ATC-10

PRGVLV - Wirng diagram ...............................EC-603

Propeller shaft .....................................................PR-2

Propeller shaft on vehicle service ........................PR-2

PS/SEN - Wiring diagram ..................EC-246,EC-520

PST/SW - Wiring diagram ...............................EC-821

Q

Quick-glow system ..........................................EC-796

R

R/FOG - Wiring diagram .....................................LT-37

Radiator fan - See Cooling fan(QR20DE) .........CO-13

Radiator fan - See Cooling fan(YD22DDTi) .......CO-34

Radiator(QR20DE) ...............................CO-12,CO-15

Radiator(YD22DDTi) ............................CO-33,CO-36

Radio - See Audio ...............................................AV-3

Rear air spoiler ....................................................EI-21

Rear bumper ..........................................................EI-9

Rear cover packing replacement diff. ..............RFD-10

Rear disc brake .................................................BR-27

Rear door ..............................................................BL-8

Rear fog lamp .....................................................LT-37

Rear panel finisher ..............................................EI-22

Rear seat ...........................................................SE-11

Rear seat belt ......................................................SB-4

Rear side window ...............................................GW-5

Rear suspension ...............................................RSU-5

Rear washer ....................................................WW-13

Rear window defogger ........................................GW-9

Rear wiper .......................................................WW-13

Refrigerant connection precaution .....................ATC-5

Refrigerant discharging evacuating chargingATC-123

Refrigerant general precaution ..........................ATC-4

Refrigerant lines .............................................ATC-123

Refrigerant pressure sensorEC-359,EC-634,ATC-16,

ATC-80

,ATC-137

Refrigeration cycle ...........................................ATC-16

Release bearing (clutch) ....................................CL-13

Removal and installation (A/T) .........................AT-458

Removal and installation (Transfer) ...................TF-12

Reverse idler shaft (M/T) ......................MT-19,MT-24

Reverselampswitch(M/T)-SeeBack-uplampswitch

(M/T) ..................................................................MT-13

Reverse main gear (M/T) ......................MT-19,MT-24

Rocker cover(QR20DE) ....................................EM-31

Rocker cover(YD22DDTi) ...............................EM-147

Room lamp .........................................................LT-55

Room lamp - See Interior lamp ...........................LT-55

ROOM/L - Wiring diagram ..................................LT-55

RP/SEN - Wiring diagram ..................EC-360,EC-635

RRO2 - Wiring diagram ...................................EC-588

RRO2/H - Wiring diagram ................................EC-574

S

S/LOCK - Wiring diagram .......................BL-13

,BL-27

S/SIG - Wiring diagram .......EC-349,EC-624,EC-818

SCTC/V - Wiring diagram ................................EC-774

Seat belt inspection ..........................................MA-42

Seat belt pre-tensioner disposal .....................SRS-40

Seat belt, front .....................................................SB-3

Seat belt, rear ......................................................SB-4

Seat, front ............................................................SE-7

Seat, rear ...........................................................SE-11

Self-diagnosis (Transfer) ...................................TF-45

SHIFT - Wiring diagram ...................................AT-447

Shift control components (M/T) .............MT-21,MT-26

Shift fork (M/T) ......................................MT-21,MT-26

Shift lever ...........................................................MT-14

Shift lock system ..............................................AT-446

Shift schedule ..................................................AT-563

Shift solenoid valve A (A/T) ..AT-151,AT-156,AT-170

Shift solenoid valve B (A/T) ...............AT-151,AT-156

Side air bag (satellite) sensor .........................SRS-37

Side trim ..............................................................EI-26

Side window - See Rear side window .................GW-5

Spark plug replacement(QR20DE) ...................MA-25

Spark plug(QR20DE) ........................................EM-28

Specification value .............................EC-103,EC-449

Speedometer .............................................DI-4,DI-22

Spiral cable .....................................................SRS-31

Spot lamp ............................................................LT-65

SROOF - Wiring diagram .....................................RF-3

Page 2496 of 3066

MA-4

DESCRIPTION

DESCRIPTION

PFP:00000

Pre-delivery Inspection ItemsELS000AK

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Page 2498 of 3066

MA-6

GENERAL MAINTENANCE

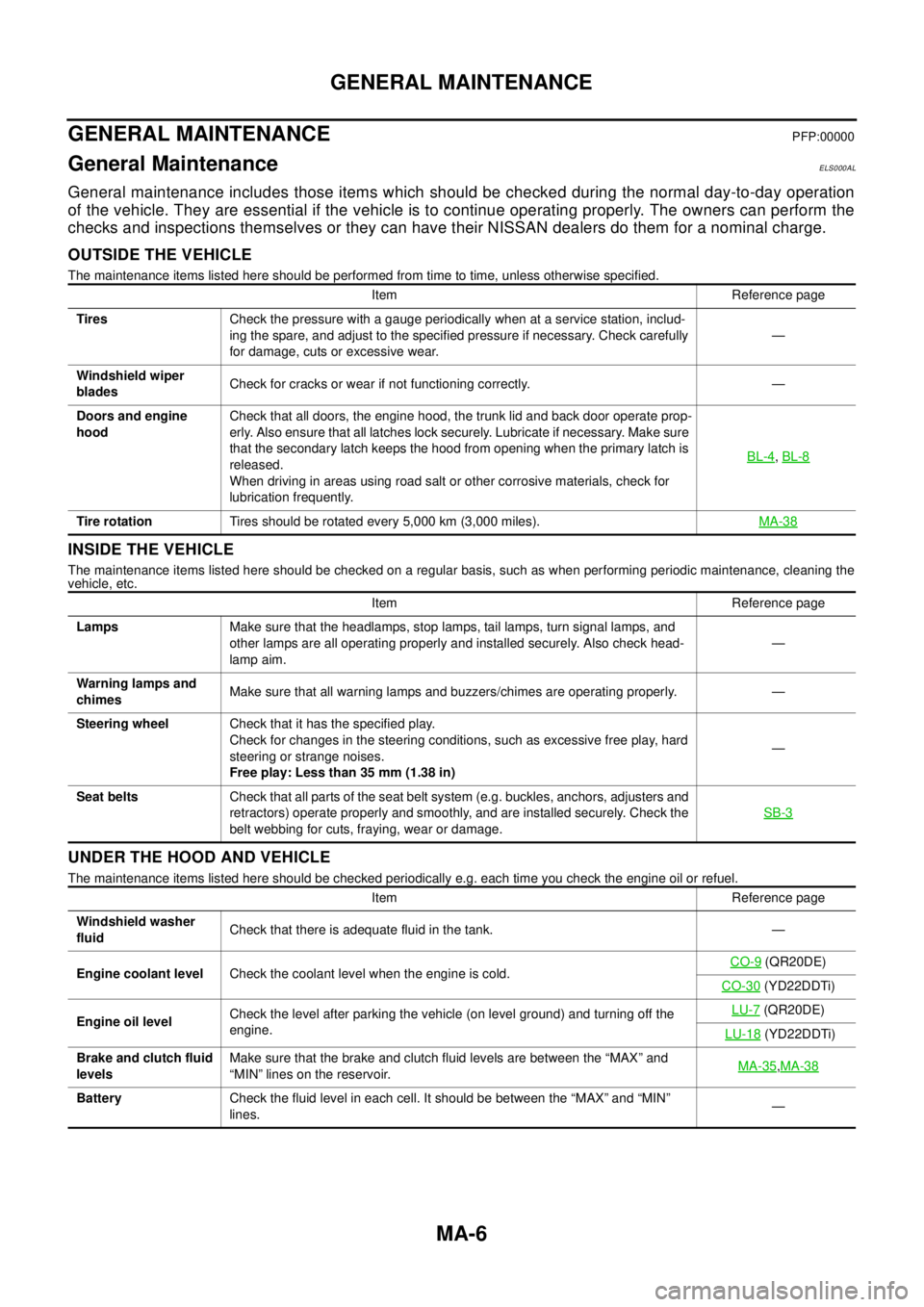

GENERAL MAINTENANCE

PFP:00000

General MaintenanceELS000AL

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station, includ-

ing the spare, and adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate prop-

erly. Also ensure that all latches lock securely. Lubricate if necessary. Make sure

that the secondary latch keeps the hood from opening when the primary latch is

released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.BL-4

,BL-8

Tire rotationTires should be rotated every 5,000 km (3,000 miles).MA-38

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head-

lamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating properly. —

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.SB-3

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold.CO-9

(QR20DE)

CO-30

(YD22DDTi)

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off the

engine.LU-7

(QR20DE)

LU-18

(YD22DDTi)

Brake and clutch fluid

levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.MA-35

,MA-38

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—

Page 3045 of 3066

FRONT WIPER AND WASHER SYSTEM

WW-7

C

D

E

F

G

H

I

J

L

MA

B

WW

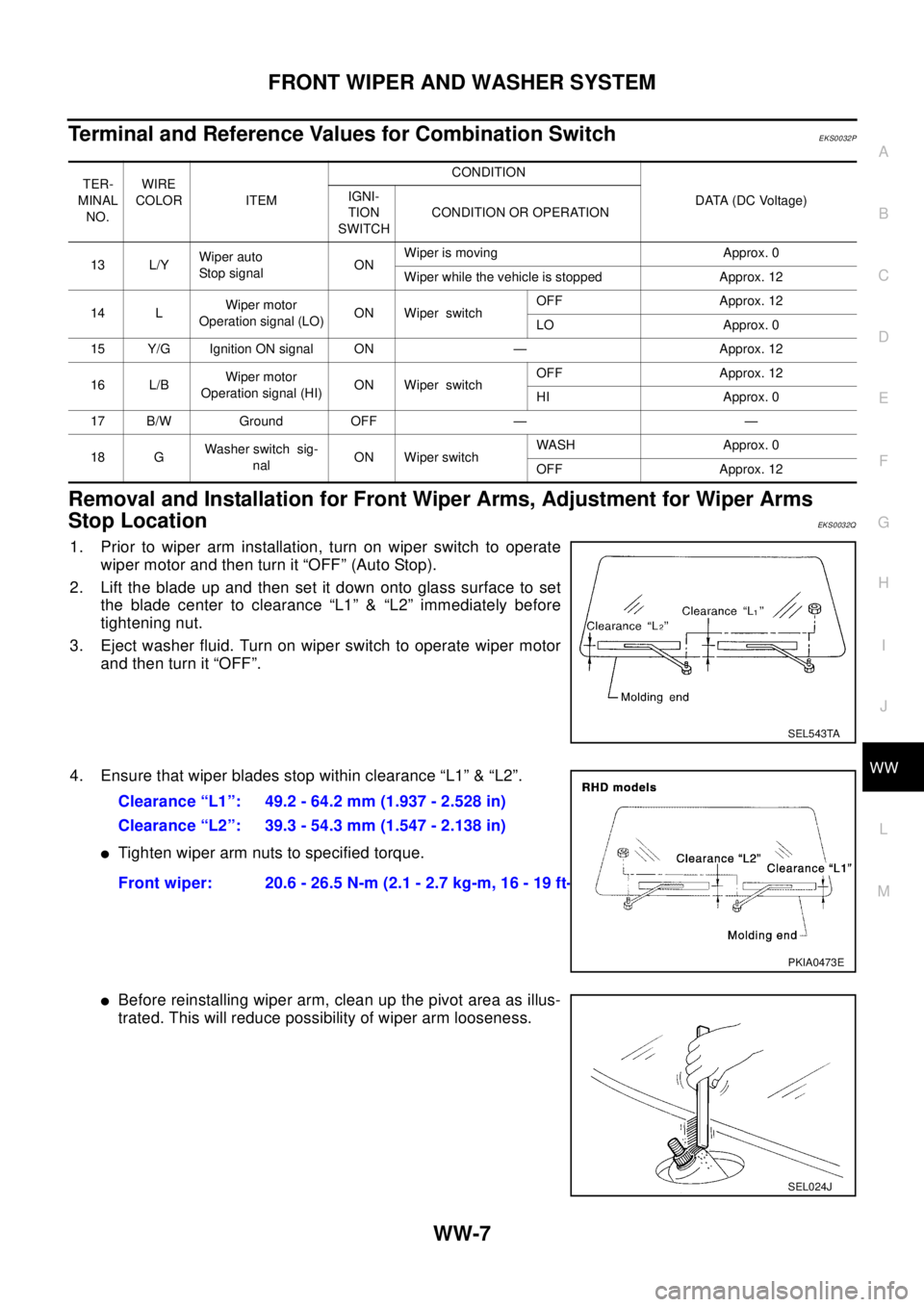

Terminal and Reference Values for Combination SwitchEKS0032P

Removal and Installation for Front Wiper Arms, Adjustment for Wiper Arms

Stop Location

EKS0032Q

1. Prior to wiper arm installation, turn on wiper switch to operate

wiper motor and then turn it “OFF” (Auto Stop).

2. Lift the blade up and then set it down onto glass surface to set

the blade center to clearance “L1” & “L2” immediately before

tightening nut.

3. Eject washer fluid. Turn on wiper switch to operate wiper motor

and then turn it “OFF”.

4. Ensure that wiper blades stop within clearance “L1” & “L2”.

lTighten wiper arm nuts to specified torque.

lBefore reinstalling wiper arm, clean up the pivot area as illus-

trated. This will reduce possibility of wiper arm looseness.

TER-

MINAL

NO.WIRE

COLOR ITEMCONDITION

DATA (DC Voltage) IGNI-

TION

SWITCHCONDITION OR OPERATION

13 L/YWiper auto

Stop signalONWiper is moving Approx. 0

Wiper while the vehicle is stopped Approx. 12

14 LWiper motor

Operation signal (LO)ON Wiper switchOFF Approx. 12

LO Approx. 0

15 Y/G Ignition ON signal ON — Approx. 12

16 L/BWiper motor

Operation signal (HI)ON Wiper switchOFF Approx. 12

HI Approx. 0

17 B/W Ground OFF — —

18 GWasher switch sig-

nalON Wiper switchWASH Approx. 0

OFF Approx. 12

SEL543TA

Clearance “L1”: 49.2 - 64.2 mm (1.937 - 2.528 in)

Clearance “L2”: 39.3 - 54.3 mm (1.547 - 2.138 in)

Front wiper: 20.6 - 26.5 N-m (2.1 - 2.7 kg-m, 16 - 19 ft-lb)

PKIA0473E

SEL024J

Page 3053 of 3066

REAR WIPER AND WASHER SYSTEM

WW-15

C

D

E

F

G

H

I

J

L

MA

B

WW

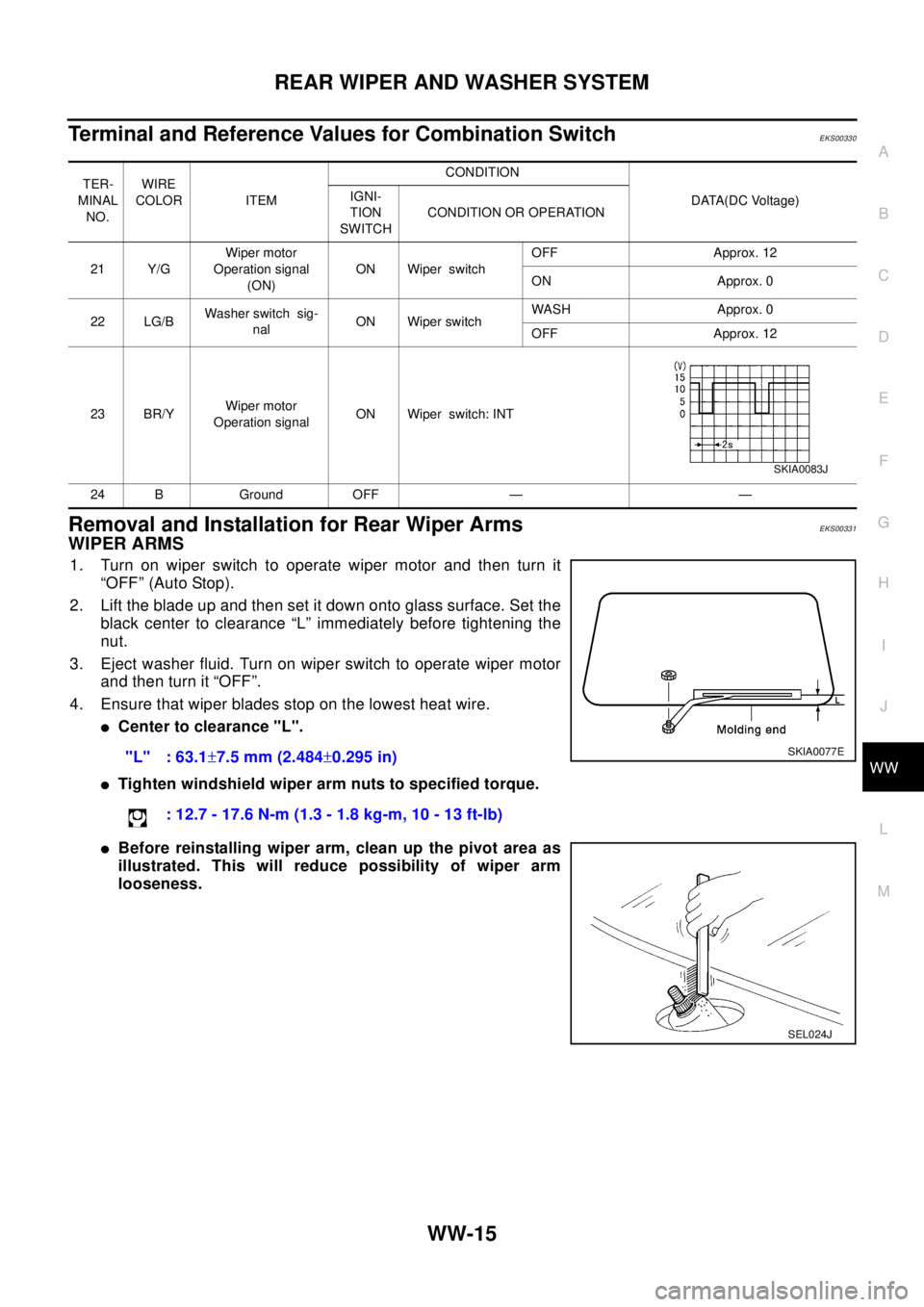

Terminal and Reference Values for Combination SwitchEKS00330

Removal and Installation for Rear Wiper ArmsEKS00331

WIPER ARMS

1. Turn on wiper switch to operate wiper motor and then turn it

“OFF” (Auto Stop).

2. Lift the blade up and then set it down onto glass surface. Set the

black center to clearance “L” immediately before tightening the

nut.

3. Eject washer fluid. Turn on wiper switch to operate wiper motor

and then turn it “OFF”.

4. Ensure that wiper blades stop on the lowest heat wire.

lCenter to clearance "L".

lTighten windshield wiper arm nuts to specified torque.

lBefore reinstalling wiper arm, clean up the pivot area as

illustrated. This will reduce possibility of wiper arm

looseness.

TER-

MINAL

NO.WIRE

COLOR ITEMCONDITION

DATA(DC Voltage) IGNI-

TION

SWITCHCONDITION OR OPERATION

21 Y/GWiper motor

Operation signal

(ON)ON Wiper switchOFF Approx. 12

ON Approx. 0

22 LG/BWasher switch sig-

nalON Wiper switchWASH Approx. 0

OFF Approx. 12

23 BR/YWiper motor

Operation signalON Wiper switch: INT

24 B Ground OFF — —

SKIA0083J

"L" : 63.1±7.5 mm (2.484±0.295 in)

: 12.7 - 17.6 N-m (1.3 - 1.8 kg-m, 10 - 13 ft-lb)SKIA0077E

SEL024J