NISSAN X-TRAIL 2003 Service Repair Manual

X-TRAIL 2003

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57404/w960_57404-0.png

NISSAN X-TRAIL 2003 Service Repair Manual

Trending: brakes, towing, tow bar, maintenance, horn, low beam, center console

Page 3261 of 4179

POWER WINDOW SYSTEM

GW-75

C

D

E

F

G

H

J

K

L

MA

B

GW

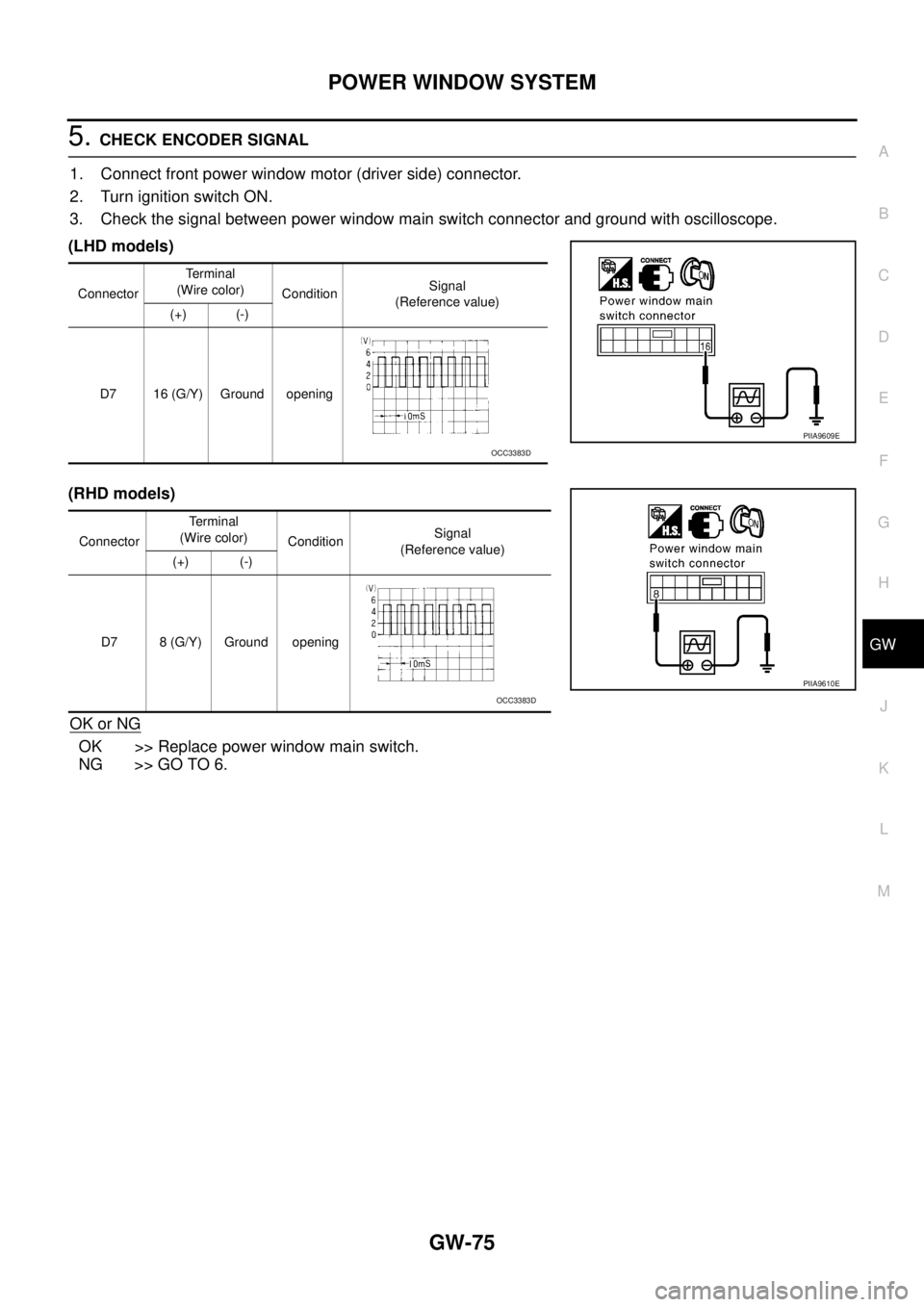

5. CHECK ENCODER SIGNAL

1. Connect front power window motor (driver side) connector.

2. Turn ignition switch ON.

3. Check the signal between power window main switch connector and ground with oscilloscope.

(LHD models)

(RHD models)

OK or NG

OK >> Replace power window main switch.

NG >> GO TO 6.

Connector Terminal

(Wire color)

ConditionSignal

(Reference value)

(+) (-)

D7 16 (G/Y) Ground opening

Connector Terminal

(Wire color)

ConditionSignal

(Reference value)

(+) (-)

D7 8 (G/Y) Ground opening

PIIA9609E

OCC3383D

PIIA9610E

OCC3383D

Page 3262 of 4179

GW-76

POWER WINDOW SYSTEM

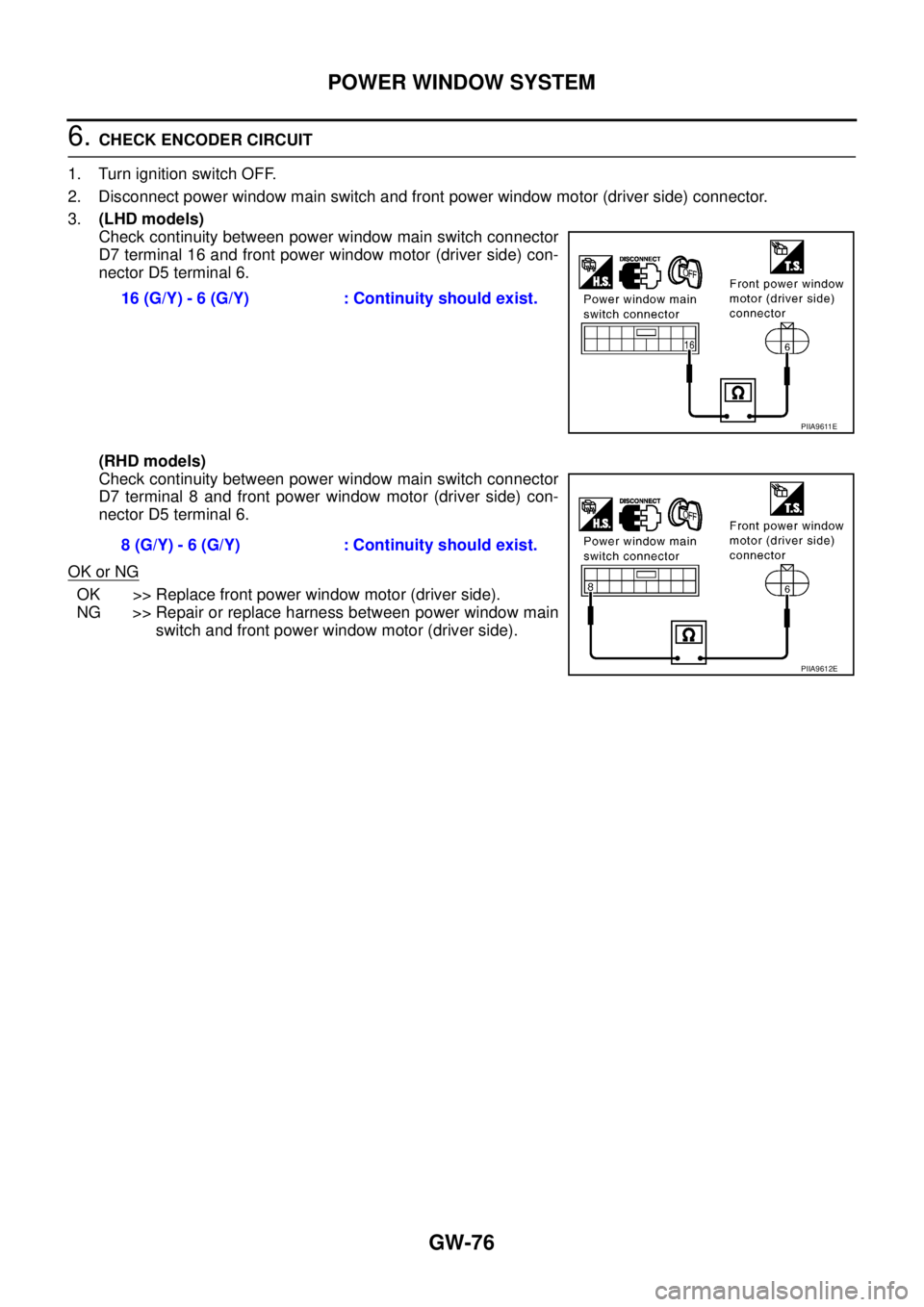

6. CHECK ENCODER CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect power window main switch and front power window motor (driver side) connector.

3.(LHD models)

Check continuity between power window main switch connector

D7 terminal 16 and front power window motor (driver side) con-

nector D5 terminal 6.

(RHD models)

Check continuity between power window main switch connector

D7 terminal 8 and front power window motor (driver side) con-

nector D5 terminal 6.

OK or NG

OK >> Replace front power window motor (driver side).

NG >> Repair or replace harness between power window main

switch and front power window motor (driver side). 16 (G/Y) - 6 (G/Y) : Continuity should exist.

PIIA9611E

8 (G/Y) - 6 (G/Y) : Continuity should exist.

PIIA9612E

Page 3263 of 4179

POWER WINDOW SYSTEM

GW-77

C

D

E

F

G

H

J

K

L

MA

B

GW

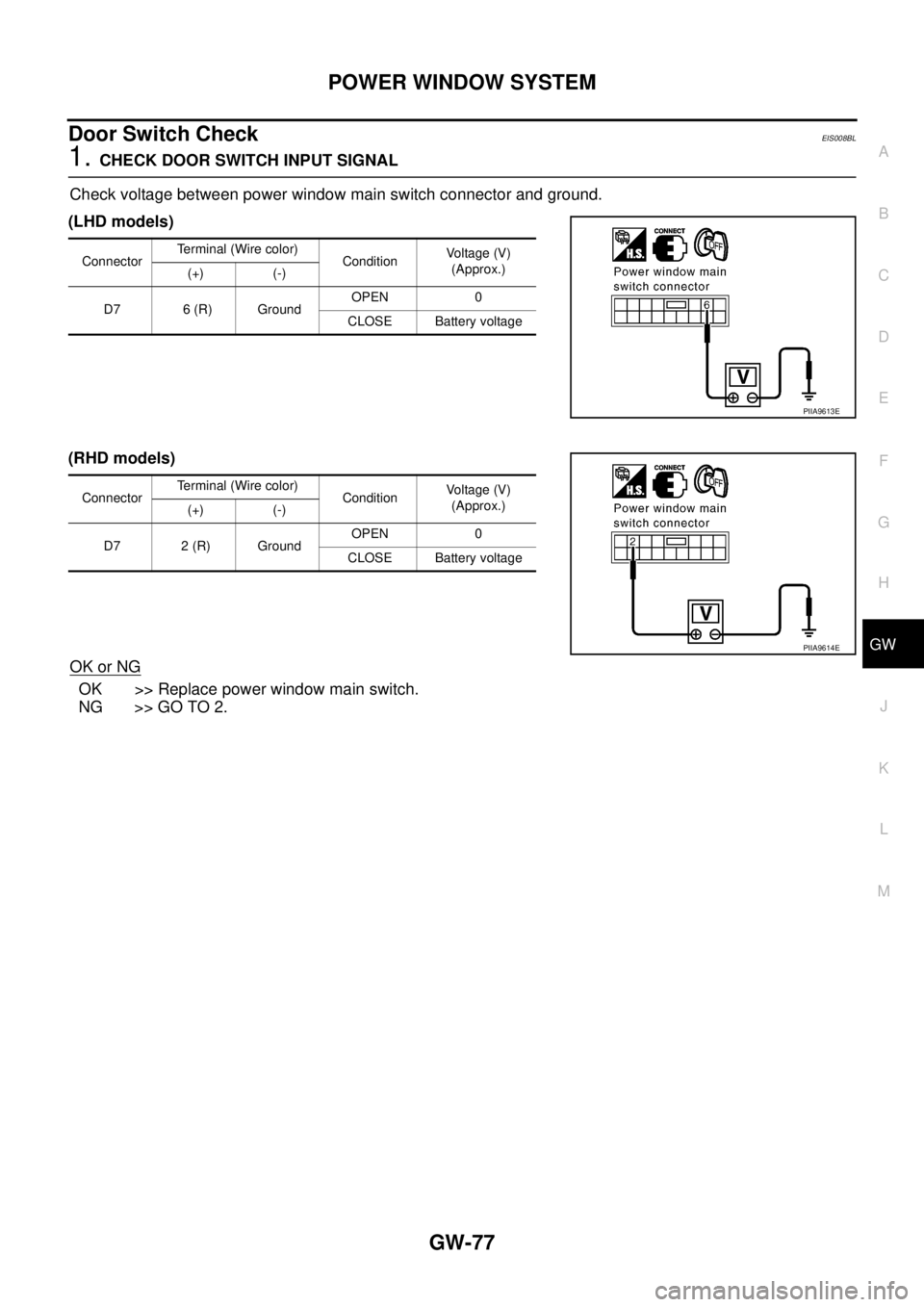

Door Switch CheckEIS008BL

1. CHECK DOOR SWITCH INPUT SIGNAL

Check voltage between power window main switch connector and ground.

(LHD models)

(RHD models)

OK or NG

OK >> Replace power window main switch.

NG >> GO TO 2.

Connector Terminal (Wire color)

ConditionVoltage (V)

(Approx.)

(+) (-)

D7 6 (R) GroundOPEN 0

CLOSE Battery voltage

PIIA9613E

Connector Terminal (Wire color)

ConditionVoltage (V)

(Approx.)

(+) (-)

D7 2 (R) GroundOPEN 0

CLOSE Battery voltage

PIIA9614E

Page 3264 of 4179

GW-78

POWER WINDOW SYSTEM

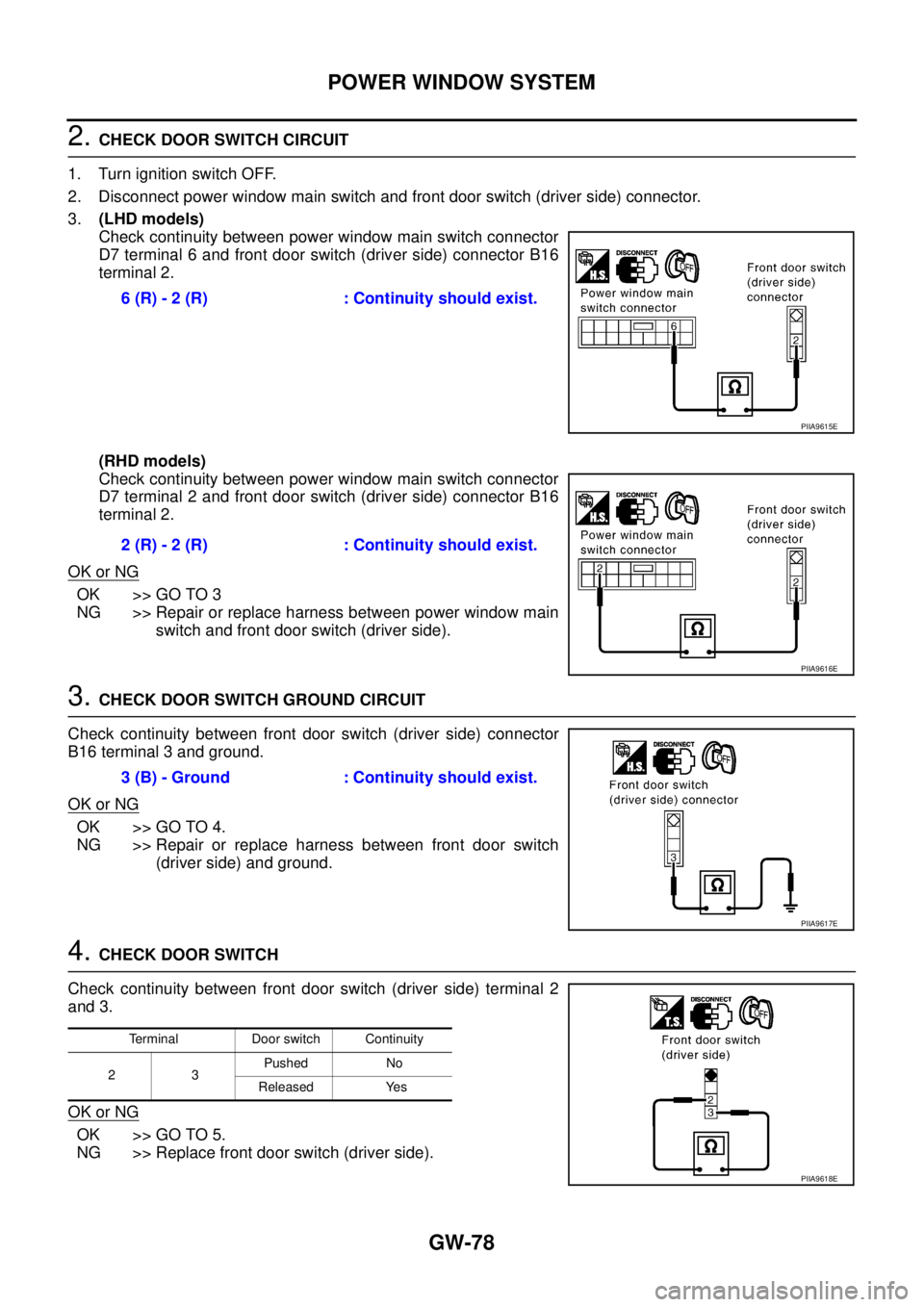

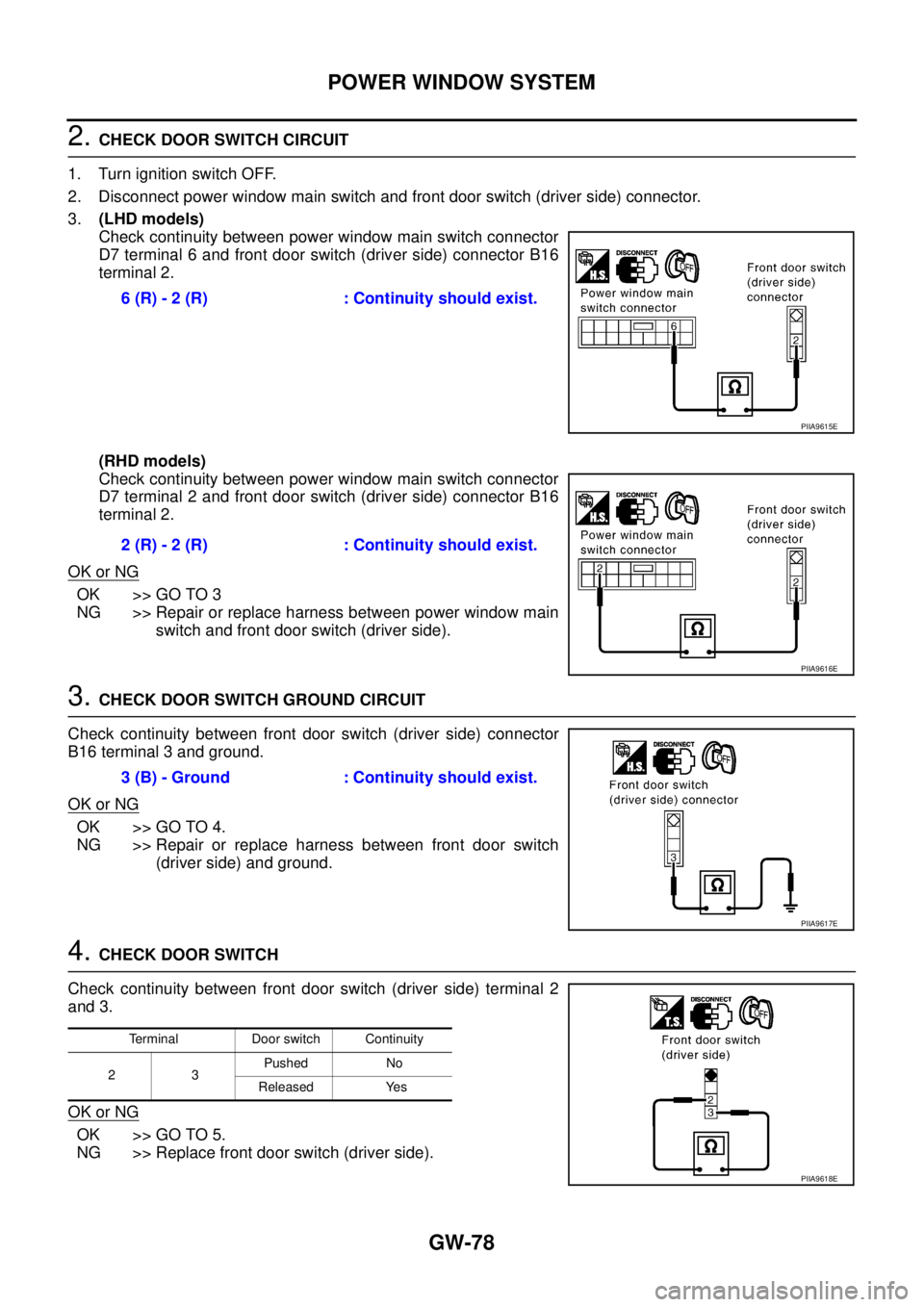

2. CHECK DOOR SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect power window main switch and front door switch (driver side) connector.

3.(LHD models)

Check continuity between power window main switch connector

D7 terminal 6 and front door switch (driver side) connector B16

terminal 2.

(RHD models)

Check continuity between power window main switch connector

D7 terminal 2 and front door switch (driver side) connector B16

terminal 2.

OK or NG

OK >> GO TO 3

NG >> Repair or replace harness between power window main

switch and front door switch (driver side).

3. CHECK DOOR SWITCH GROUND CIRCUIT

Check continuity between front door switch (driver side) connector

B16 terminal 3 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness between front door switch

(driver side) and ground.

4. CHECK DOOR SWITCH

Check continuity between front door switch (driver side) terminal 2

and 3.

OK or NG

OK >> GO TO 5.

NG >> Replace front door switch (driver side).6 (R) - 2 (R) : Continuity should exist.

PIIA9615E

2 (R) - 2 (R) : Continuity should exist.

PIIA9616E

3 (B) - Ground : Continuity should exist.

PIIA9617E

Terminal Door switch Continuity

23Pushed No

Released Yes

PIIA9618E

Page 3265 of 4179

POWER WINDOW SYSTEM

GW-79

C

D

E

F

G

H

J

K

L

MA

B

GW

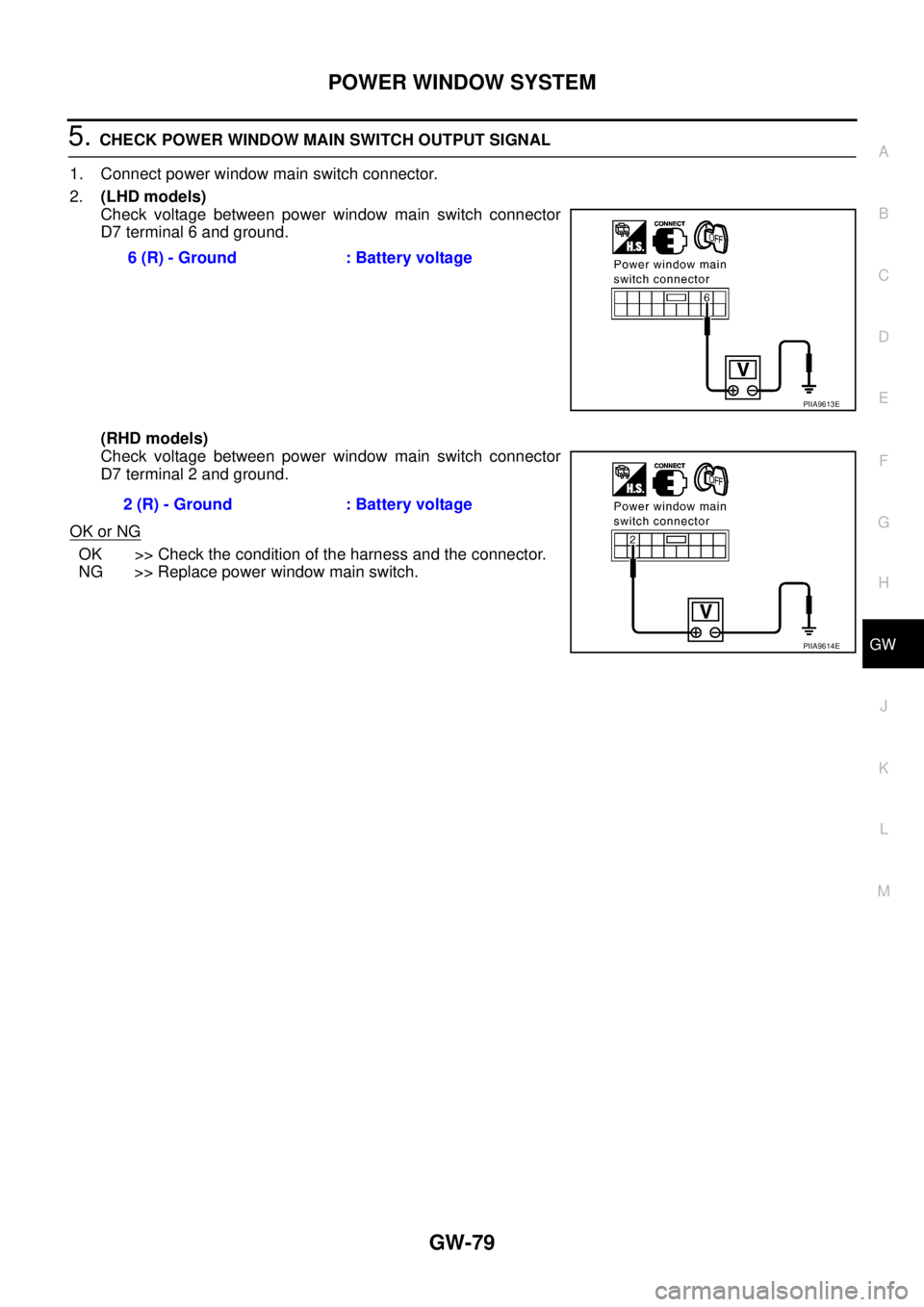

5. CHECK POWER WINDOW MAIN SWITCH OUTPUT SIGNAL

1. Connect power window main switch connector.

2.(LHD models)

Check voltage between power window main switch connector

D7 terminal 6 and ground.

(RHD models)

Check voltage between power window main switch connector

D7 terminal 2 and ground.

OK or NG

OK >> Check the condition of the harness and the connector.

NG >> Replace power window main switch. 6 (R) - Ground : Battery voltage

PIIA9613E

2 (R) - Ground : Battery voltage

PIIA9614E

Page 3266 of 4179

GW-80

FRONT DOOR GLASS AND REGULATOR

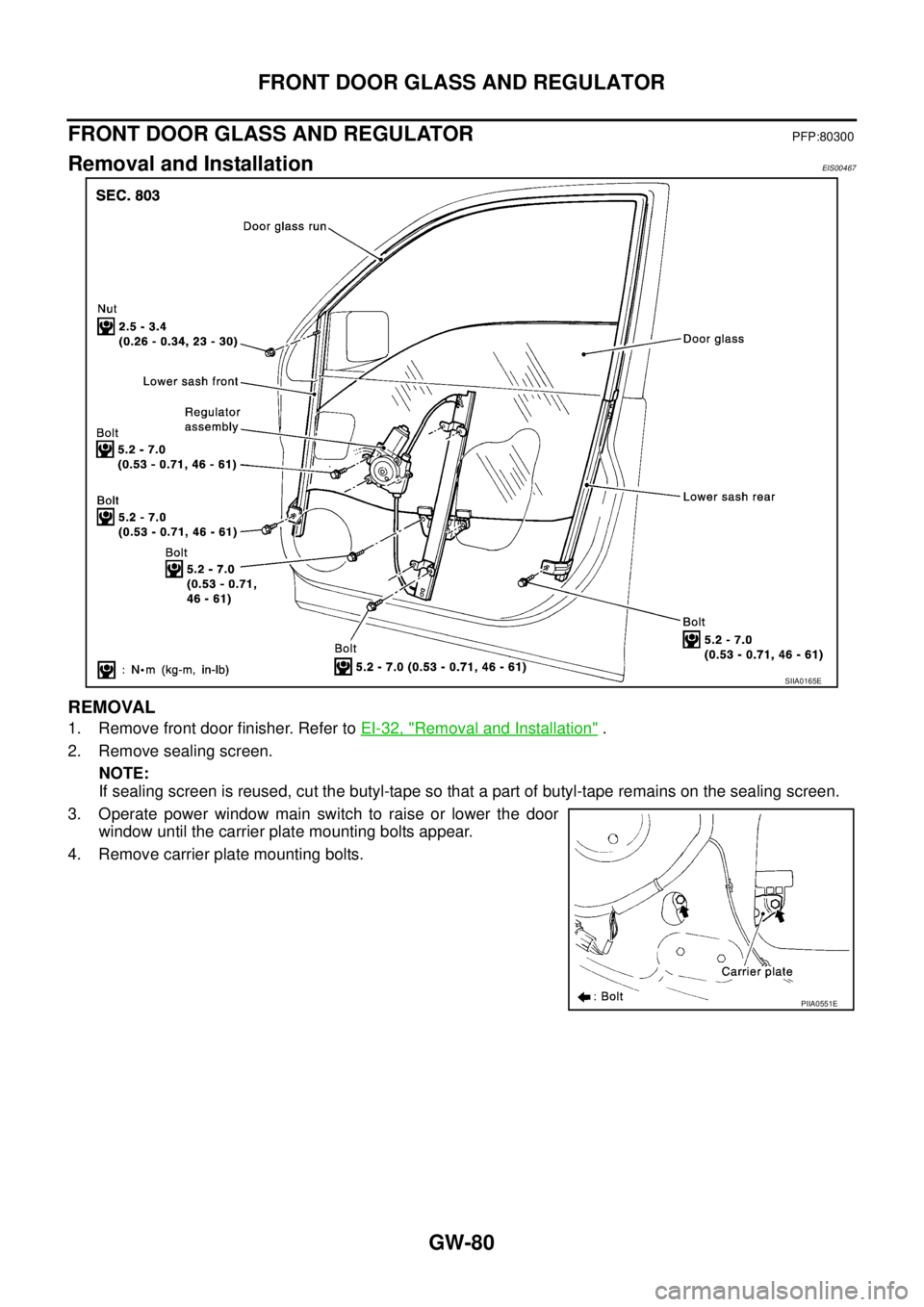

FRONT DOOR GLASS AND REGULATORPFP:80300

Removal and InstallationEIS00467

REMOVAL

1. Remove front door finisher. Refer to EI-32, "Removal and Installation" .

2. Remove sealing screen.

NOTE:

If sealing screen is reused, cut the butyl-tape so that a part of butyl-tape remains on the sealing screen.

3. Operate power window main switch to raise or lower the door

window until the carrier plate mounting bolts appear.

4. Remove carrier plate mounting bolts.

SIIA0165E

PIIA0551E

Page 3267 of 4179

FRONT DOOR GLASS AND REGULATOR

GW-81

C

D

E

F

G

H

J

K

L

MA

B

GW

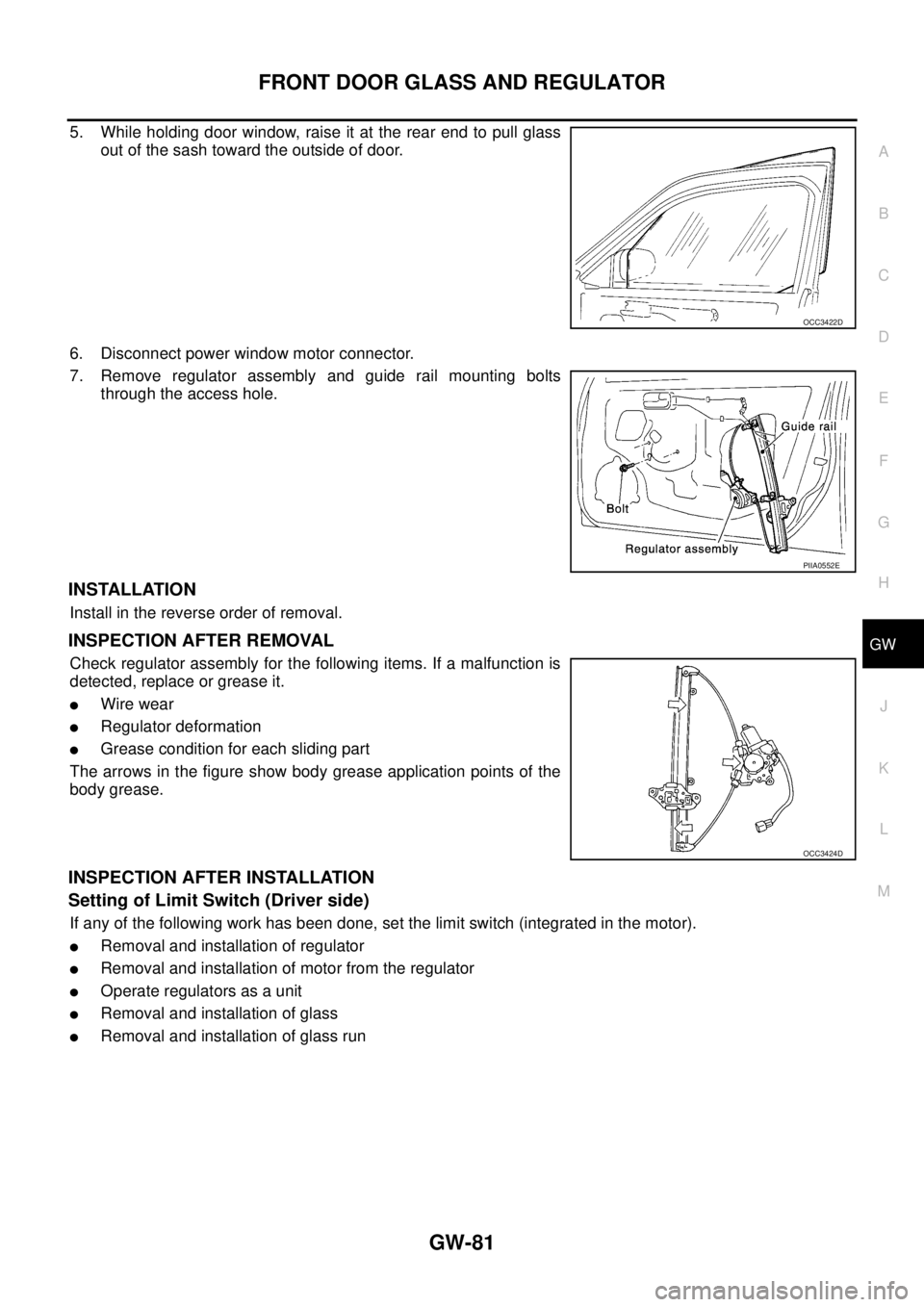

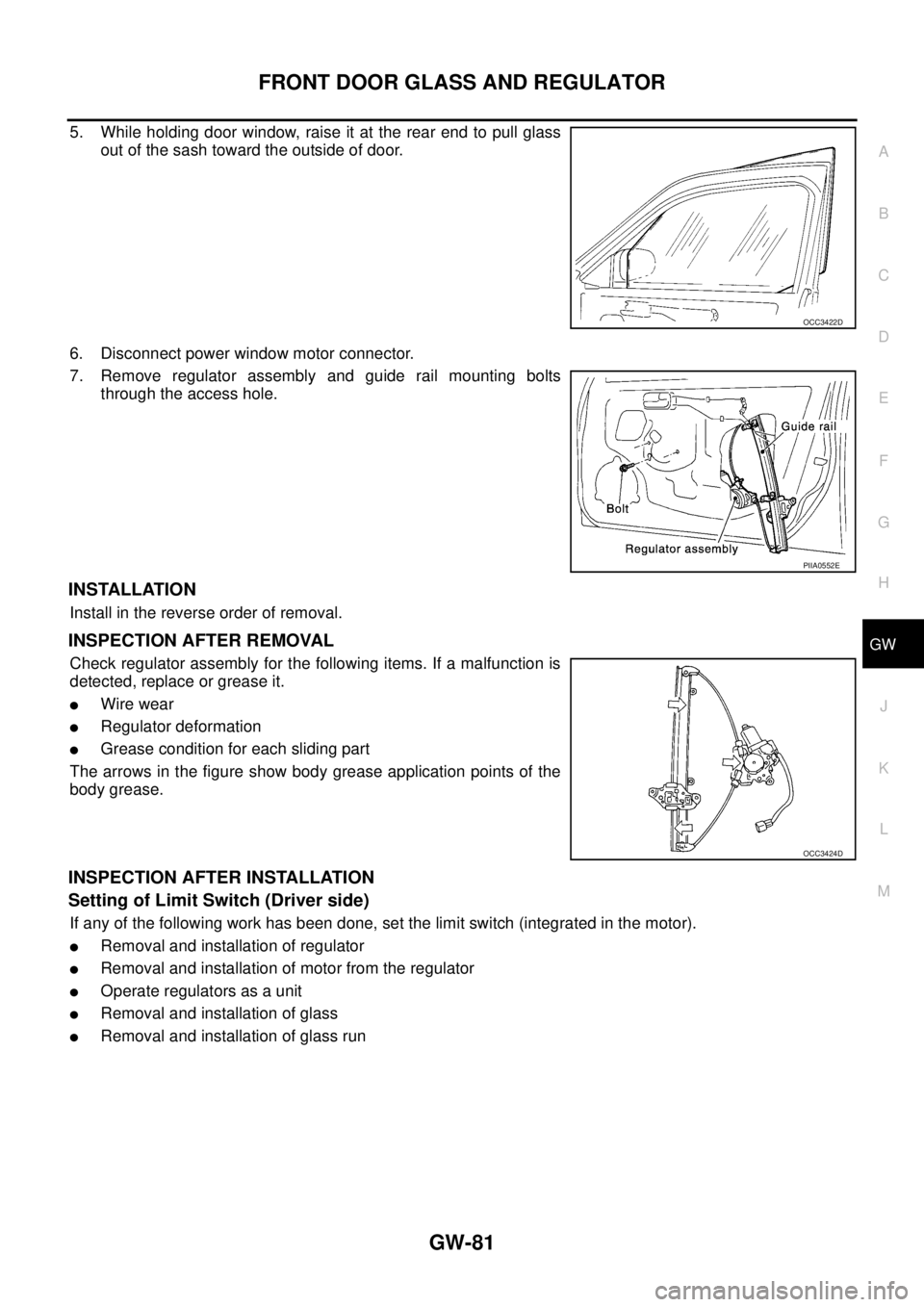

5. While holding door window, raise it at the rear end to pull glass

out of the sash toward the outside of door.

6. Disconnect power window motor connector.

7. Remove regulator assembly and guide rail mounting bolts

through the access hole.

INSTALLATION

Install in the reverse order of removal.

INSPECTION AFTER REMOVAL

Check regulator assembly for the following items. If a malfunction is

detected, replace or grease it.

�Wire wear

�Regulator deformation

�Grease condition for each sliding part

The arrows in the figure show body grease application points of the

body grease.

INSPECTION AFTER INSTALLATION

Setting of Limit Switch (Driver side)

If any of the following work has been done, set the limit switch (integrated in the motor).

�Removal and installation of regulator

�Removal and installation of motor from the regulator

�Operate regulators as a unit

�Removal and installation of glass

�Removal and installation of glass run

OCC3422D

PIIA0552E

OCC3424D

Page 3268 of 4179

GW-82

FRONT DOOR GLASS AND REGULATOR

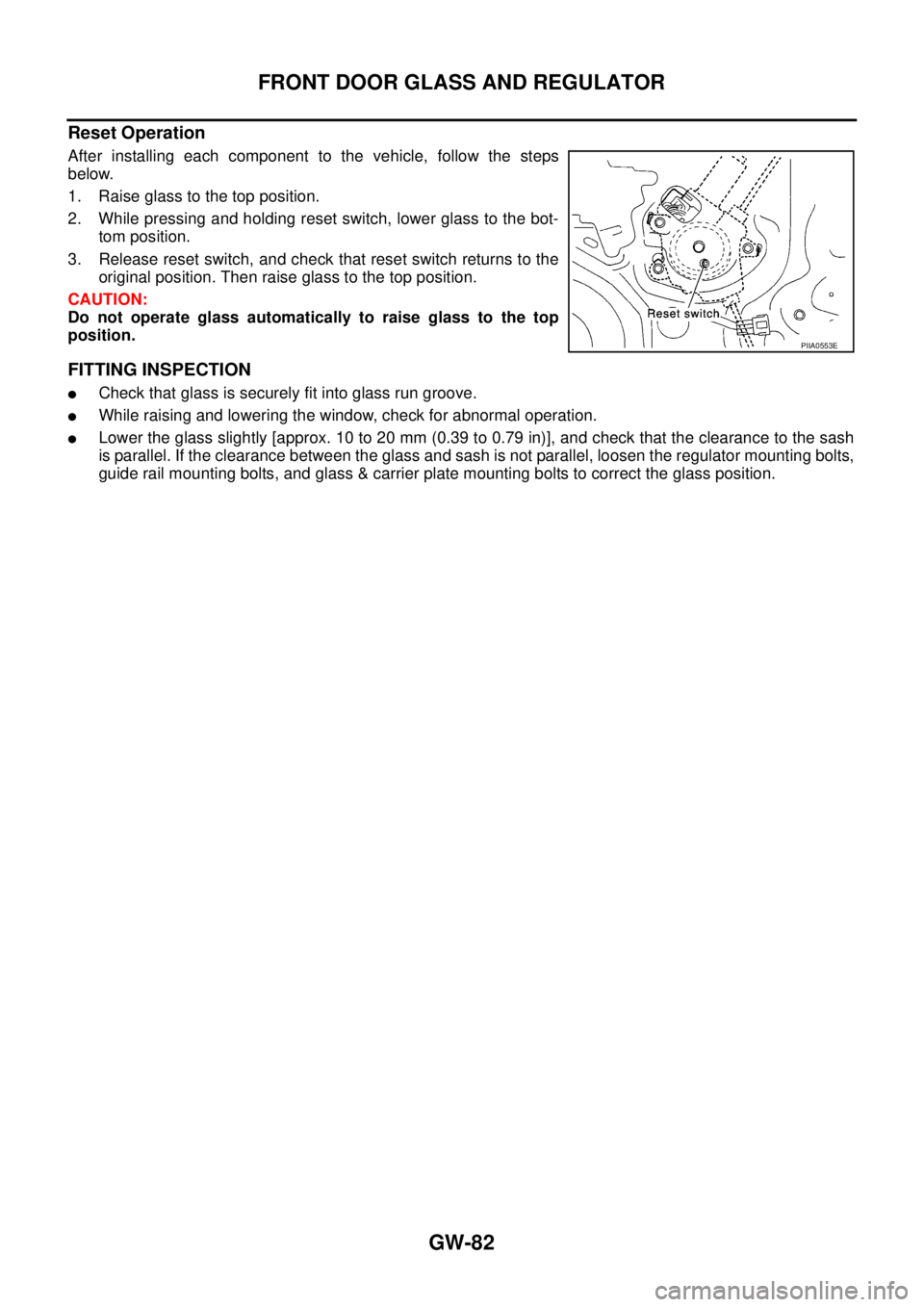

Reset Operation

After installing each component to the vehicle, follow the steps

below.

1. Raise glass to the top position.

2. While pressing and holding reset switch, lower glass to the bot-

tom position.

3. Release reset switch, and check that reset switch returns to the

original position. Then raise glass to the top position.

CAUTION:

Do not operate glass automatically to raise glass to the top

position.

FITTING INSPECTION

�Check that glass is securely fit into glass run groove.

�While raising and lowering the window, check for abnormal operation.

�Lower the glass slightly [approx. 10 to 20 mm (0.39 to 0.79 in)], and check that the clearance to the sash

is parallel. If the clearance between the glass and sash is not parallel, loosen the regulator mounting bolts,

guide rail mounting bolts, and glass & carrier plate mounting bolts to correct the glass position.

PIIA0553E

Page 3269 of 4179

REAR DOOR GLASS AND REGULATOR

GW-83

C

D

E

F

G

H

J

K

L

MA

B

GW

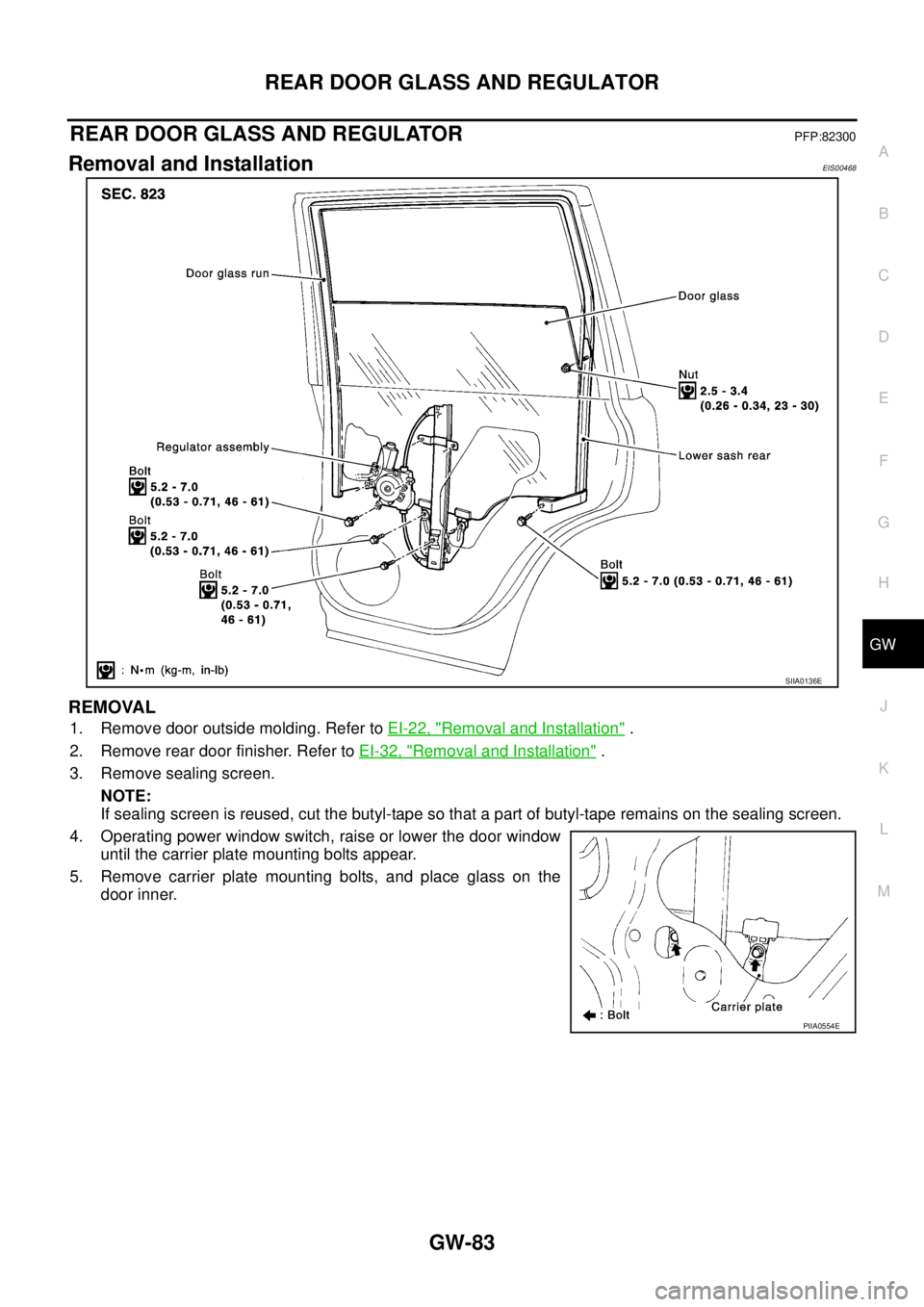

REAR DOOR GLASS AND REGULATORPFP:82300

Removal and InstallationEIS00468

REMOVAL

1. Remove door outside molding. Refer to EI-22, "Removal and Installation" .

2. Remove rear door finisher. Refer to EI-32, "

Removal and Installation" .

3. Remove sealing screen.

NOTE:

If sealing screen is reused, cut the butyl-tape so that a part of butyl-tape remains on the sealing screen.

4. Operating power window switch, raise or lower the door window

until the carrier plate mounting bolts appear.

5. Remove carrier plate mounting bolts, and place glass on the

door inner.

SIIA0136E

PIIA0554E

Page 3270 of 4179

GW-84

REAR DOOR GLASS AND REGULATOR

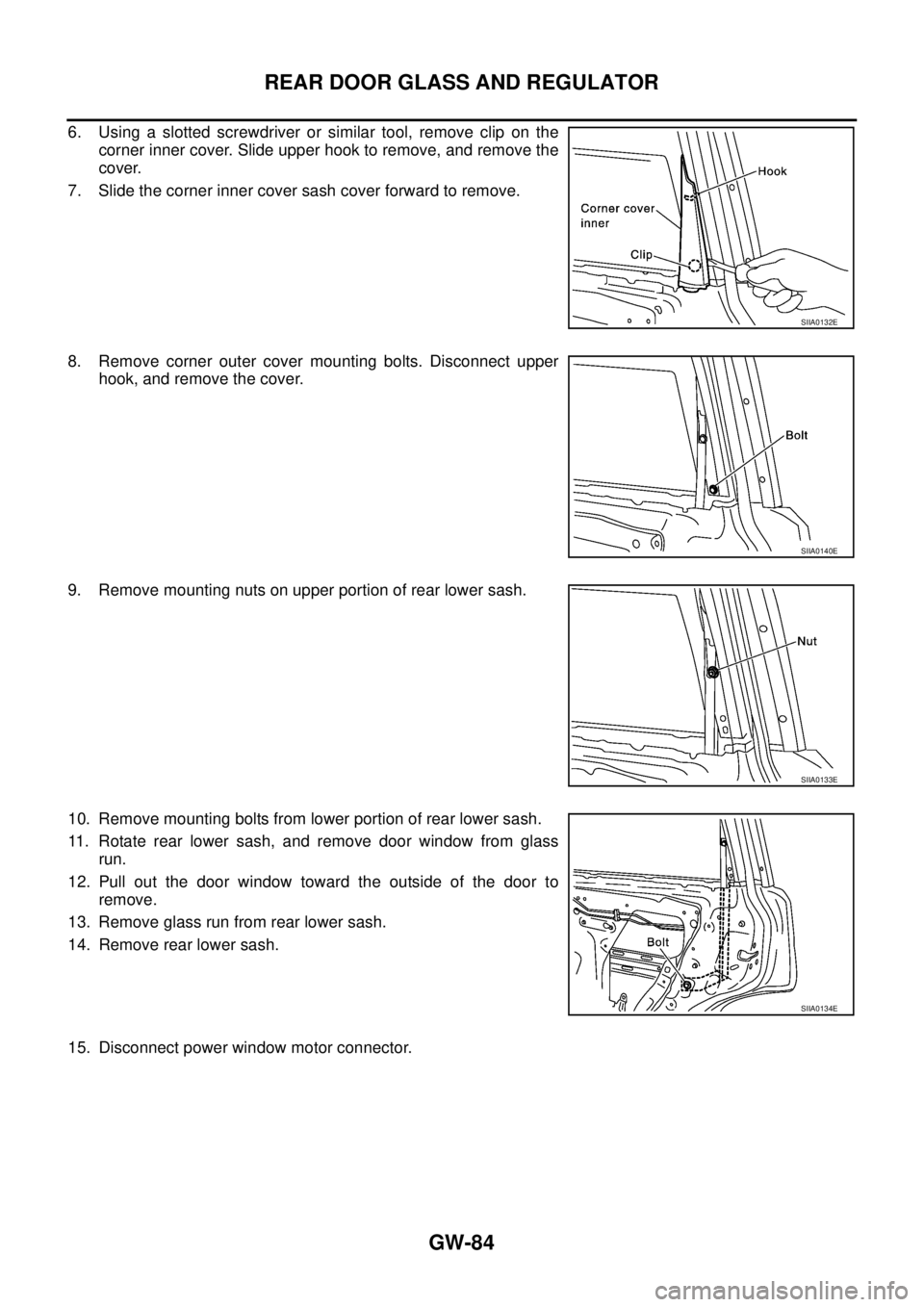

6. Using a slotted screwdriver or similar tool, remove clip on the

corner inner cover. Slide upper hook to remove, and remove the

cover.

7. Slide the corner inner cover sash cover forward to remove.

8. Remove corner outer cover mounting bolts. Disconnect upper

hook, and remove the cover.

9. Remove mounting nuts on upper portion of rear lower sash.

10. Remove mounting bolts from lower portion of rear lower sash.

11. Rotate rear lower sash, and remove door window from glass

run.

12. Pull out the door window toward the outside of the door to

remove.

13. Remove glass run from rear lower sash.

14. Remove rear lower sash.

15. Disconnect power window motor connector.

SIIA0132E

SIIA0140E

SIIA0133E

SIIA0134E

Trending: hood release, jack points, warning light, front axle, brake sensor, center console, fuel fill door release