NISSAN X-TRAIL 2003 Service Repair Manual

X-TRAIL 2003

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57404/w960_57404-0.png

NISSAN X-TRAIL 2003 Service Repair Manual

Trending: battery replacement, change wheel, cruise control, open hood, horn, Atf, spark plugs

Page 3541 of 4179

REFRIGERANT LINES

ATC-145

C

D

E

F

G

H

I

K

L

MA

B

AT C

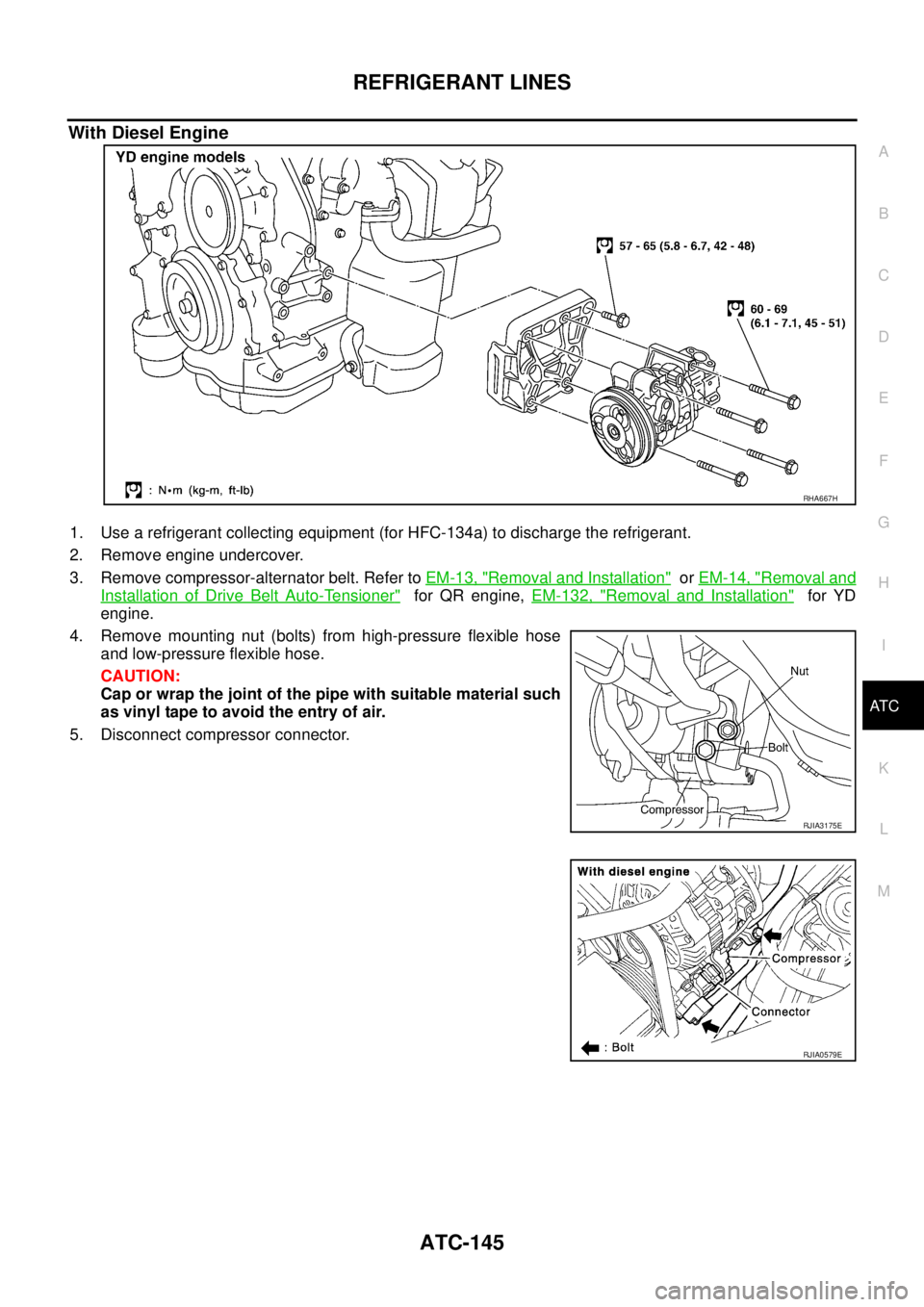

With Diesel Engine

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2. Remove engine undercover.

3. Remove compressor-alternator belt. Refer to EM-13, "

Removal and Installation" or EM-14, "Removal and

Installation of Drive Belt Auto-Tensioner" for QR engine, EM-132, "Removal and Installation" for YD

engine.

4. Remove mounting nut (bolts) from high-pressure flexible hose

and low-pressure flexible hose.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

5. Disconnect compressor connector.

RHA667H

RJIA3175E

RJIA0579E

Page 3542 of 4179

ATC-146

REFRIGERANT LINES

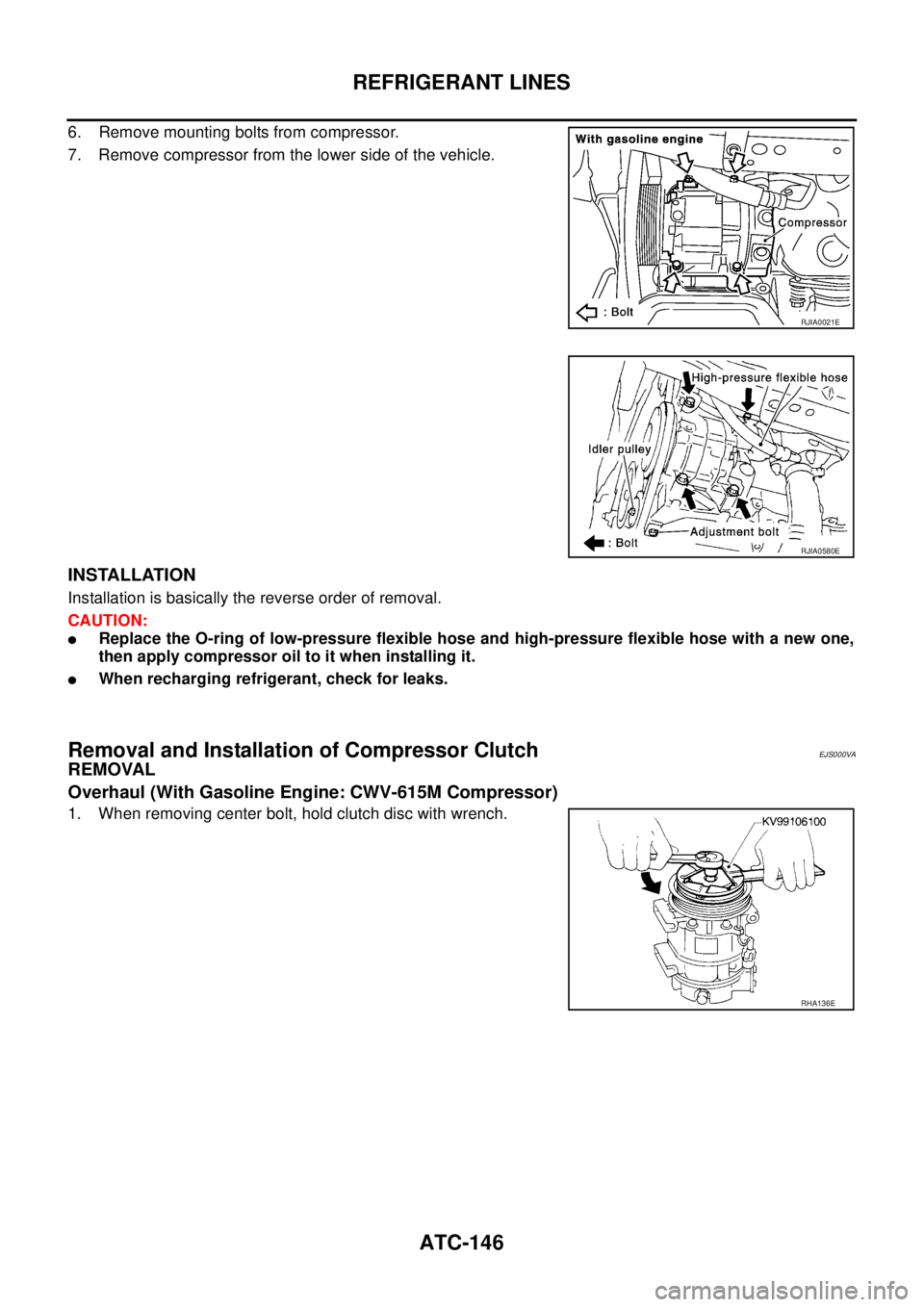

6. Remove mounting bolts from compressor.

7. Remove compressor from the lower side of the vehicle.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

�Replace the O-ring of low-pressure flexible hose and high-pressure flexible hose with a new one,

then apply compressor oil to it when installing it.

�When recharging refrigerant, check for leaks.

Removal and Installation of Compressor ClutchEJS000VA

REMOVAL

Overhaul (With Gasoline Engine: CWV-615M Compressor)

1. When removing center bolt, hold clutch disc with wrench.

RJIA0021E

RJIA0580E

RHA136E

Page 3543 of 4179

REFRIGERANT LINES

ATC-147

C

D

E

F

G

H

I

K

L

MA

B

AT C

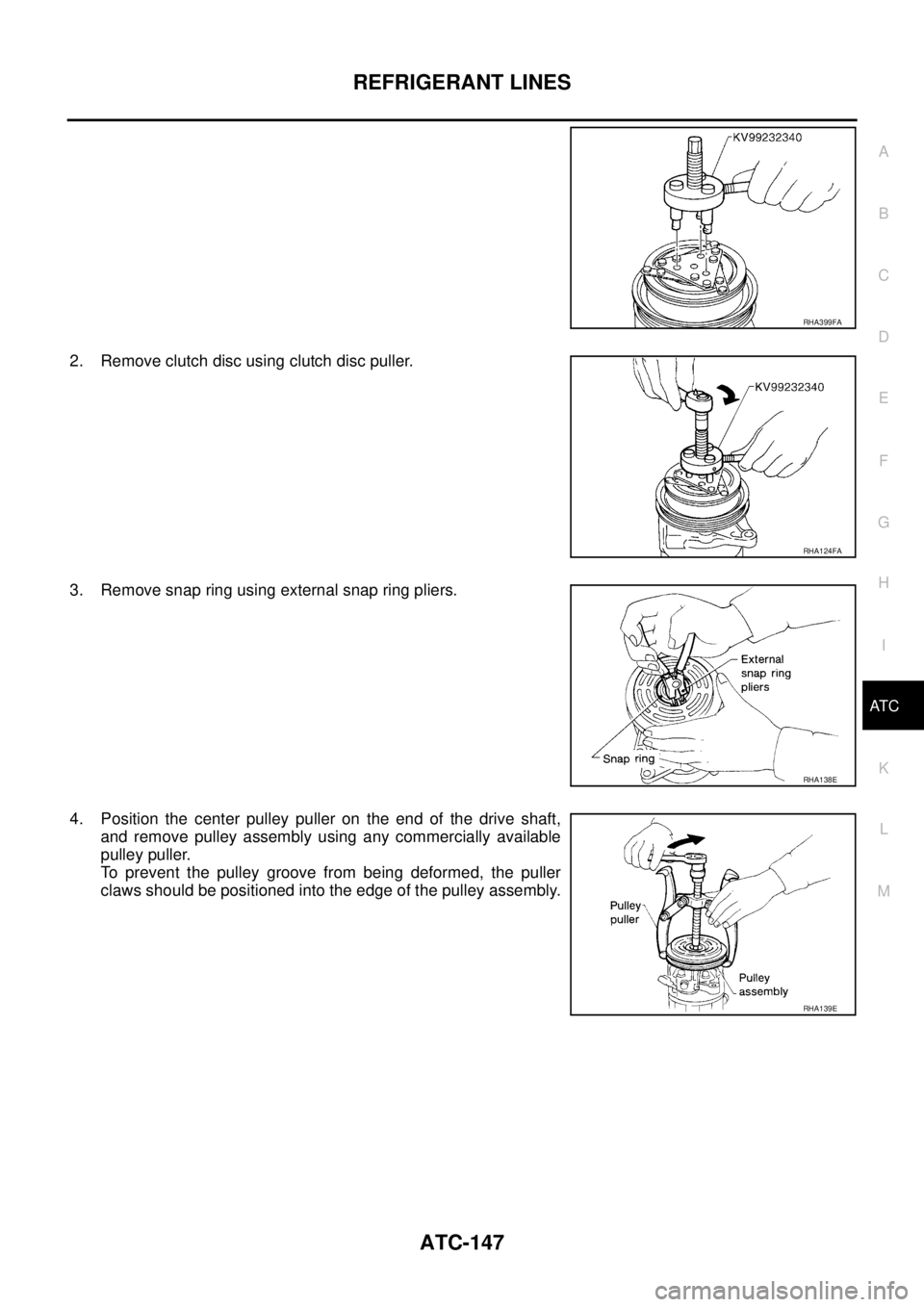

2. Remove clutch disc using clutch disc puller.

3. Remove snap ring using external snap ring pliers.

4. Position the center pulley puller on the end of the drive shaft,

and remove pulley assembly using any commercially available

pulley puller.

To prevent the pulley groove from being deformed, the puller

claws should be positioned into the edge of the pulley assembly.

RHA399FA

RHA124FA

RHA138E

RHA139E

Page 3544 of 4179

ATC-148

REFRIGERANT LINES

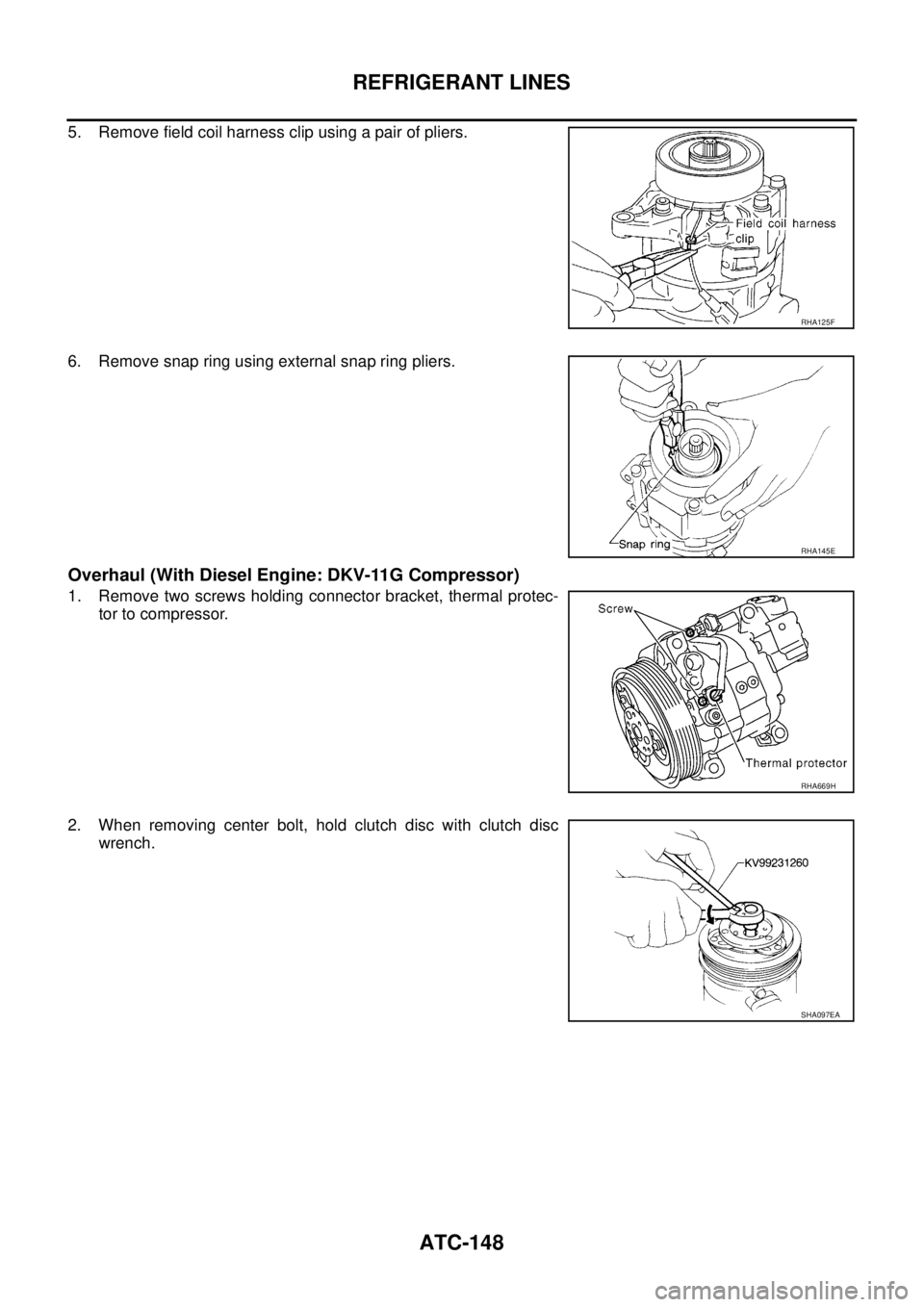

5. Remove field coil harness clip using a pair of pliers.

6. Remove snap ring using external snap ring pliers.

Overhaul (With Diesel Engine: DKV-11G Compressor)

1. Remove two screws holding connector bracket, thermal protec-

tor to compressor.

2. When removing center bolt, hold clutch disc with clutch disc

wrench.

RHA125F

RHA145E

RHA669H

SHA097EA

Page 3545 of 4179

REFRIGERANT LINES

ATC-149

C

D

E

F

G

H

I

K

L

MA

B

AT C

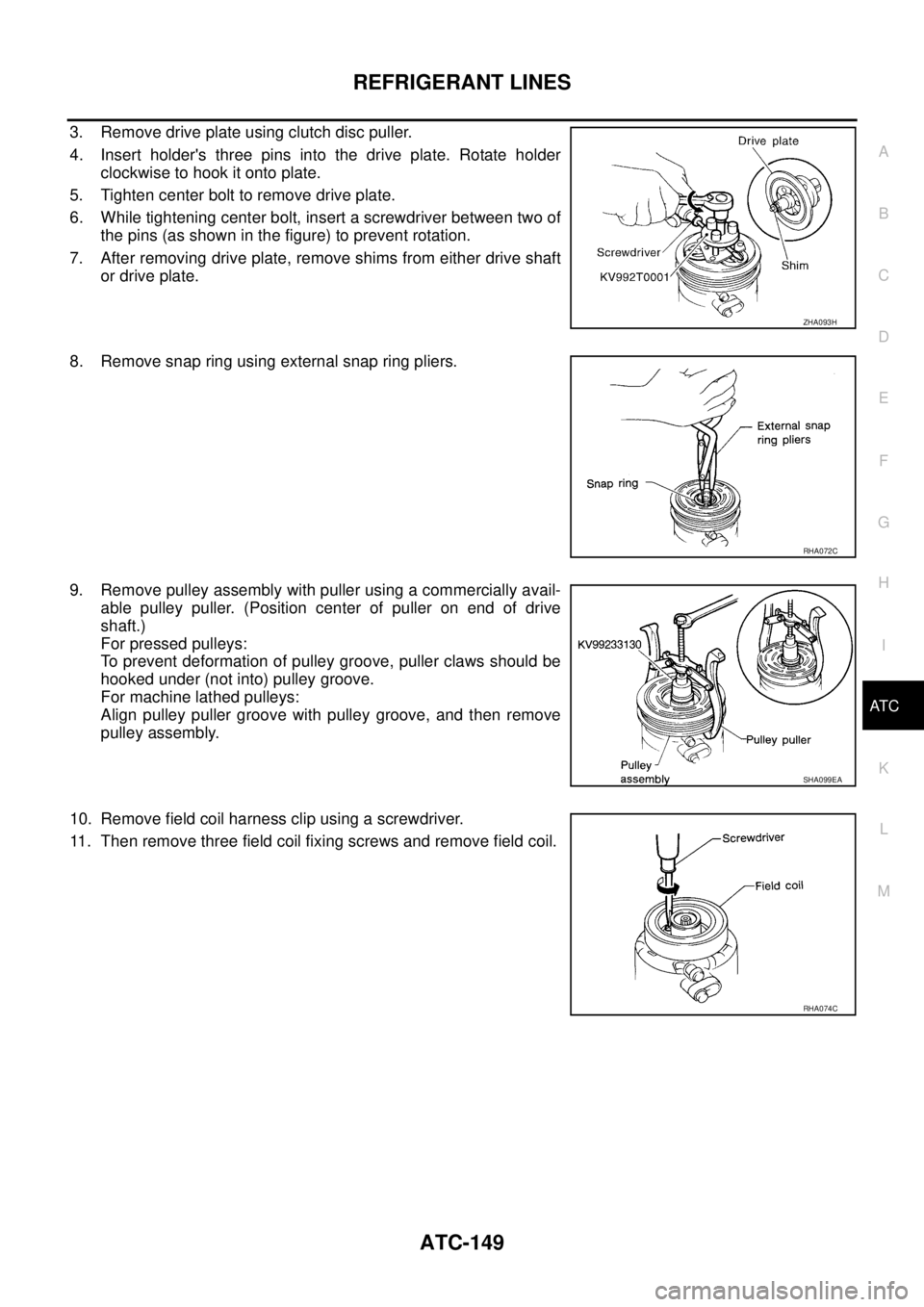

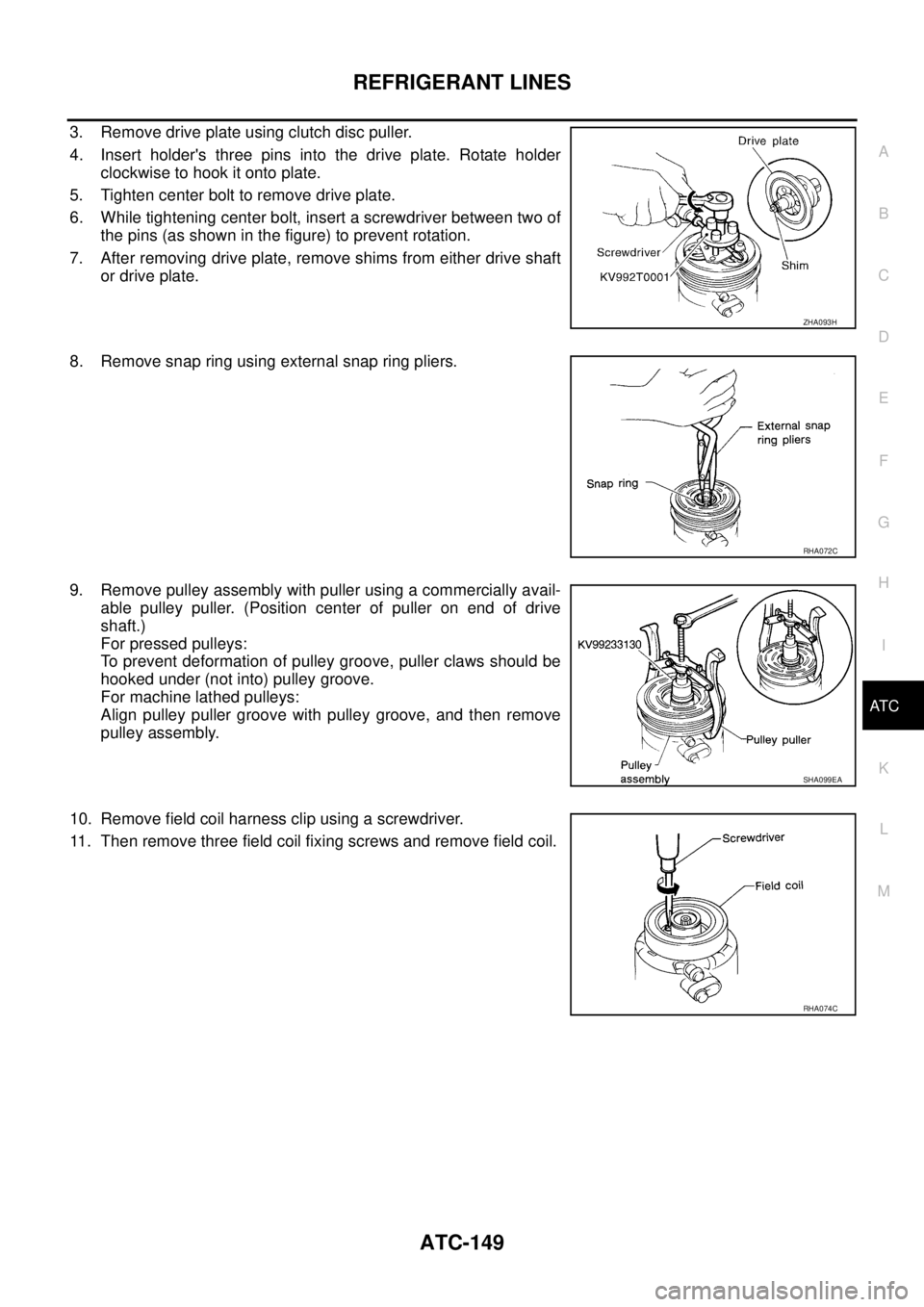

3. Remove drive plate using clutch disc puller.

4. Insert holder's three pins into the drive plate. Rotate holder

clockwise to hook it onto plate.

5. Tighten center bolt to remove drive plate.

6. While tightening center bolt, insert a screwdriver between two of

the pins (as shown in the figure) to prevent rotation.

7. After removing drive plate, remove shims from either drive shaft

or drive plate.

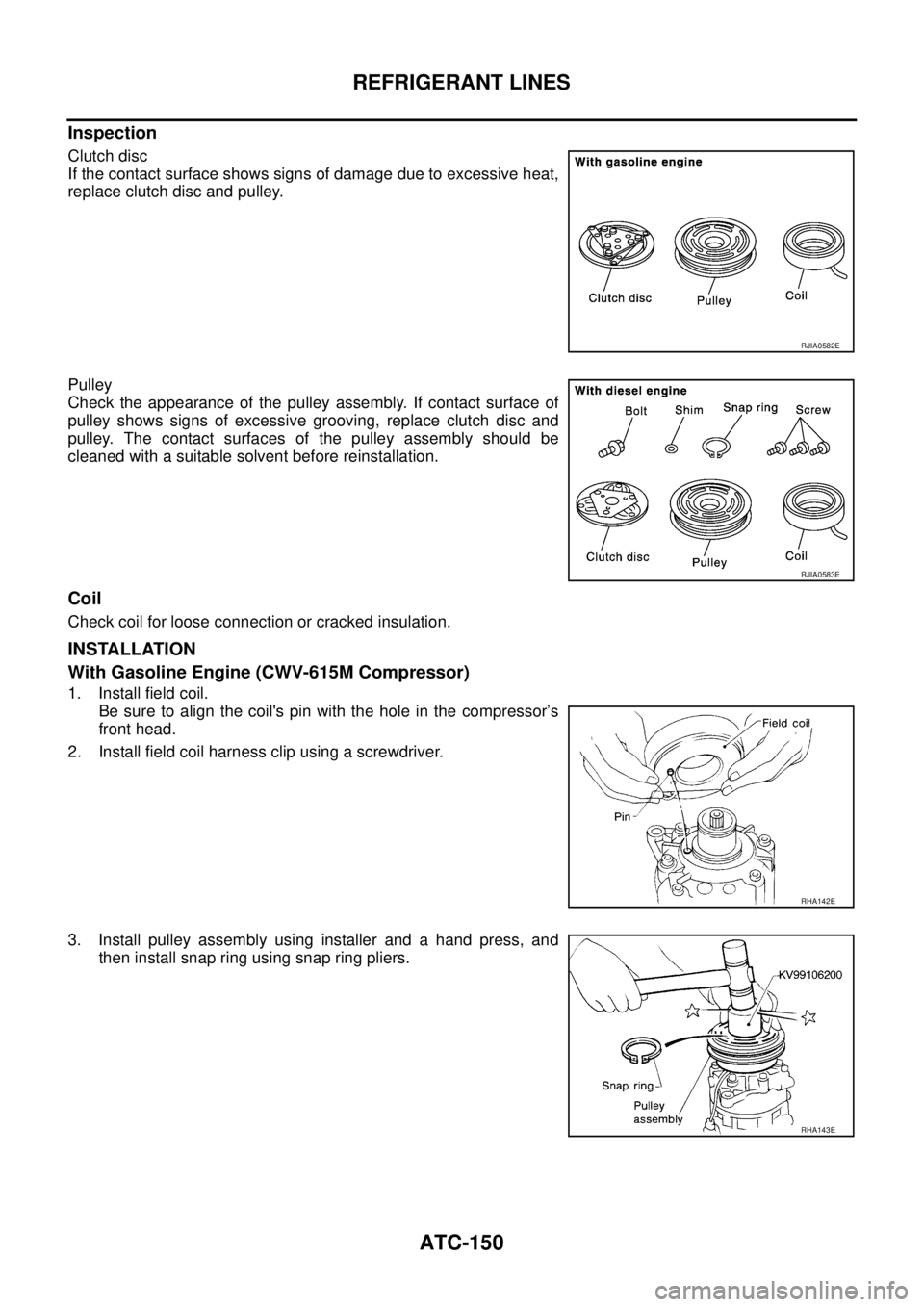

8. Remove snap ring using external snap ring pliers.

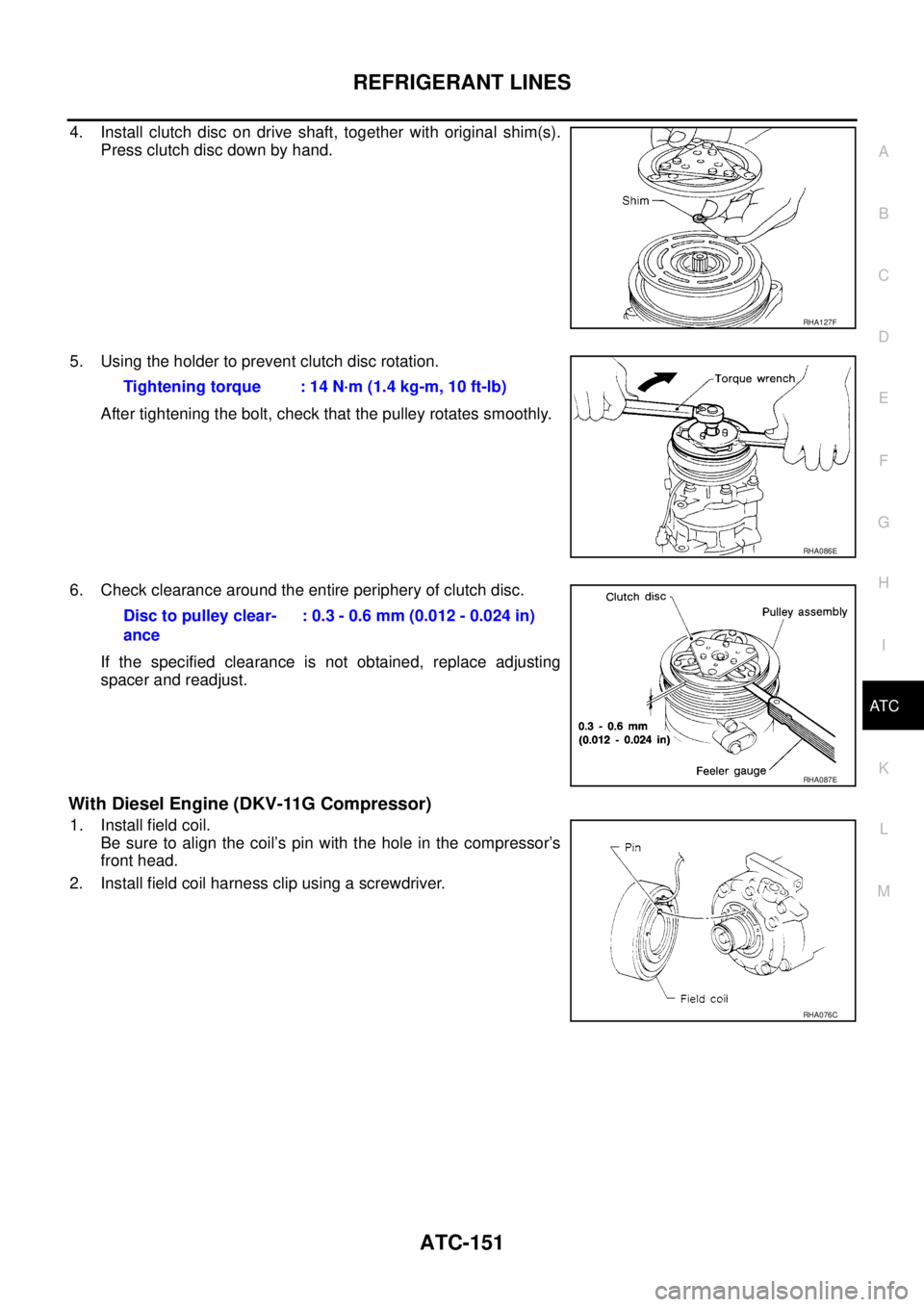

9. Remove pulley assembly with puller using a commercially avail-

able pulley puller. (Position center of puller on end of drive

shaft.)

For pressed pulleys:

To prevent deformation of pulley groove, puller claws should be

hooked under (not into) pulley groove.

For machine lathed pulleys:

Align pulley puller groove with pulley groove, and then remove

pulley assembly.

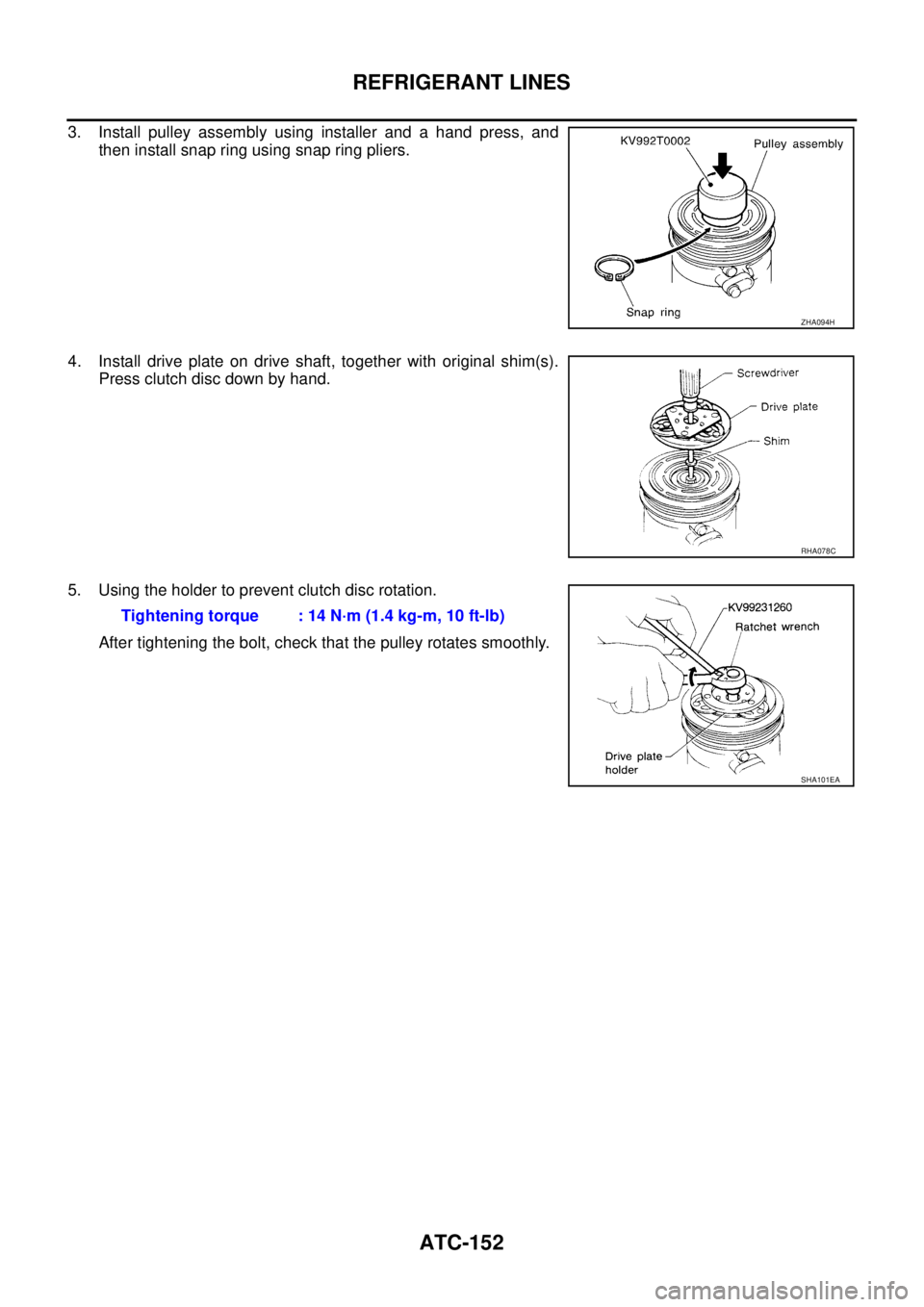

10. Remove field coil harness clip using a screwdriver.

11. Then remove three field coil fixing screws and remove field coil.

ZHA093H

RHA072C

SHA099EA

RHA074C

Page 3546 of 4179

ATC-150

REFRIGERANT LINES

Inspection

Clutch disc

If the contact surface shows signs of damage due to excessive heat,

replace clutch disc and pulley.

Pulley

Check the appearance of the pulley assembly. If contact surface of

pulley shows signs of excessive grooving, replace clutch disc and

pulley. The contact surfaces of the pulley assembly should be

cleaned with a suitable solvent before reinstallation.

Coil

Check coil for loose connection or cracked insulation.

INSTALLATION

With Gasoline Engine (CWV-615M Compressor)

1. Install field coil.

Be sure to align the coil's pin with the hole in the compressor’s

front head.

2. Install field coil harness clip using a screwdriver.

3. Install pulley assembly using installer and a hand press, and

then install snap ring using snap ring pliers.

RJIA0582E

RJIA0583E

RHA142E

RHA143E

Page 3547 of 4179

REFRIGERANT LINES

ATC-151

C

D

E

F

G

H

I

K

L

MA

B

AT C

4. Install clutch disc on drive shaft, together with original shim(s).

Press clutch disc down by hand.

5. Using the holder to prevent clutch disc rotation.

After tightening the bolt, check that the pulley rotates smoothly.

6. Check clearance around the entire periphery of clutch disc.

If the specified clearance is not obtained, replace adjusting

spacer and readjust.

With Diesel Engine (DKV-11G Compressor)

1. Install field coil.

Be sure to align the coil’s pin with the hole in the compressor’s

front head.

2. Install field coil harness clip using a screwdriver.

RHA127F

Tightening torque : 14 N·m (1.4 kg-m, 10 ft-lb)

RHA086E

Disc to pulley clear-

ance: 0.3 - 0.6 mm (0.012 - 0.024 in)

RHA087E

RHA076C

Page 3548 of 4179

ATC-152

REFRIGERANT LINES

3. Install pulley assembly using installer and a hand press, and

then install snap ring using snap ring pliers.

4. Install drive plate on drive shaft, together with original shim(s).

Press clutch disc down by hand.

5. Using the holder to prevent clutch disc rotation.

After tightening the bolt, check that the pulley rotates smoothly.

ZHA094H

RHA078C

Tightening torque : 14 N·m (1.4 kg-m, 10 ft-lb)

SHA101EA

Page 3549 of 4179

REFRIGERANT LINES

ATC-153

C

D

E

F

G

H

I

K

L

MA

B

AT C

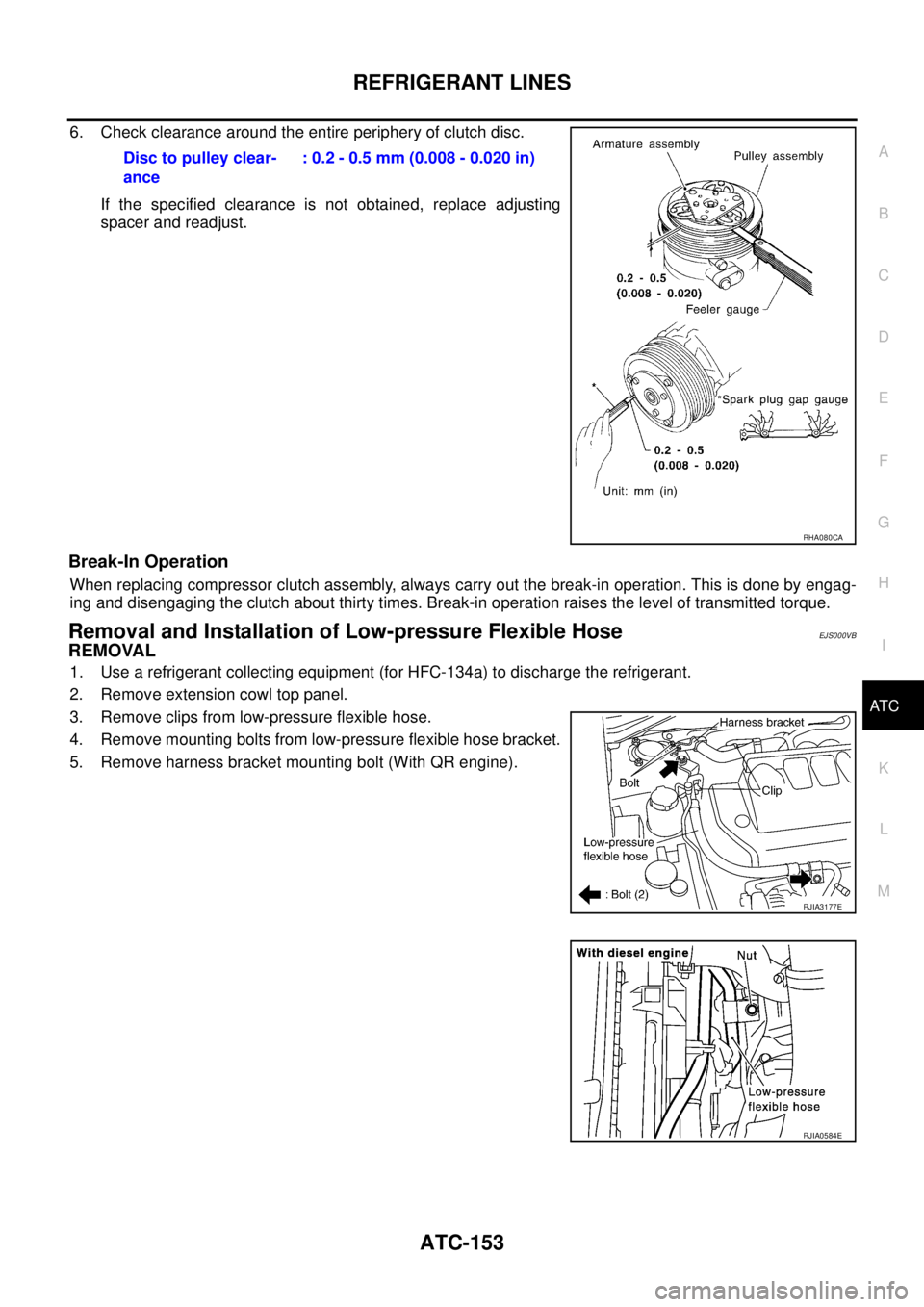

6. Check clearance around the entire periphery of clutch disc.

If the specified clearance is not obtained, replace adjusting

spacer and readjust.

Break-In Operation

When replacing compressor clutch assembly, always carry out the break-in operation. This is done by engag-

ing and disengaging the clutch about thirty times. Break-in operation raises the level of transmitted torque.

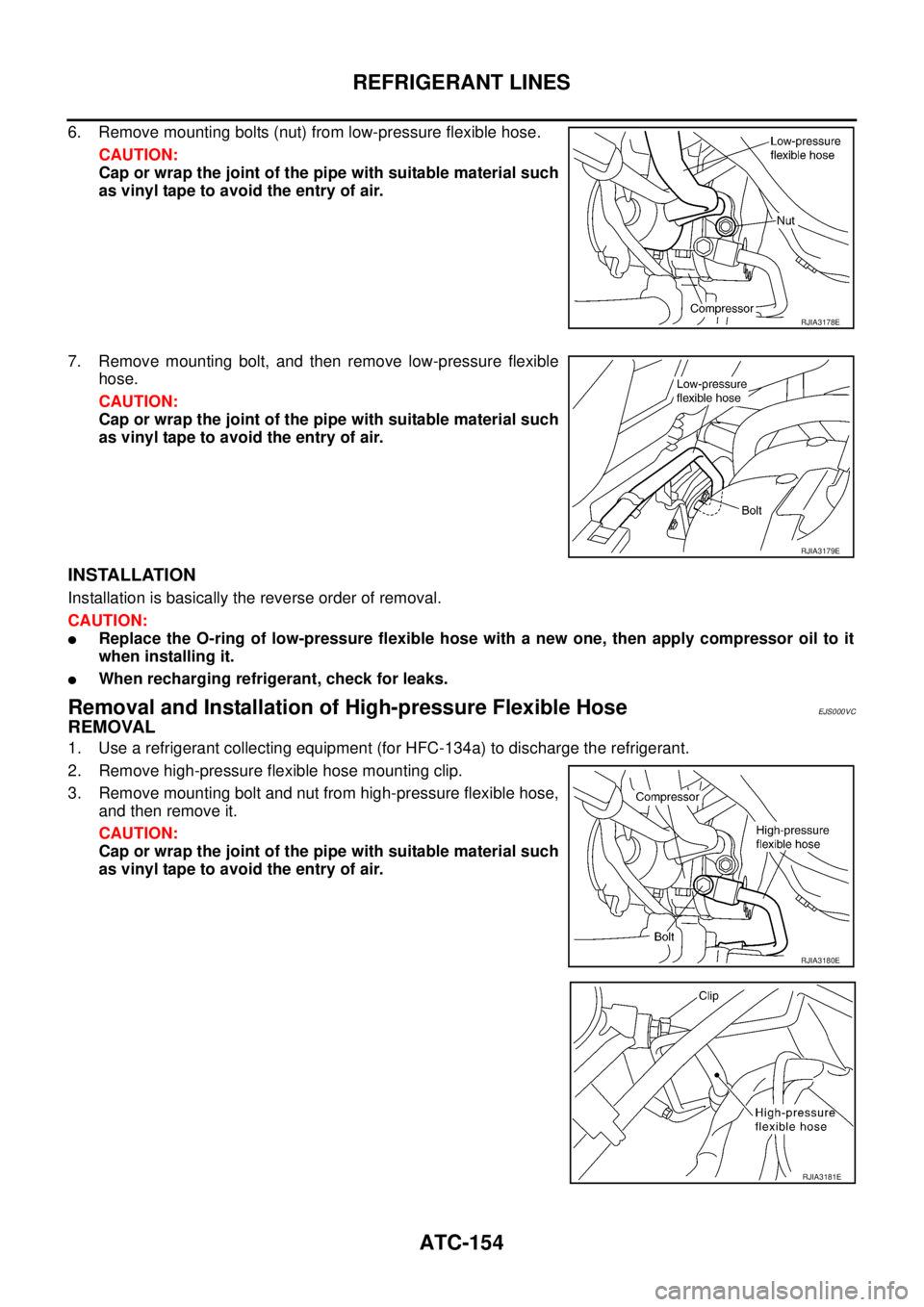

Removal and Installation of Low-pressure Flexible HoseEJS000VB

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2. Remove extension cowl top panel.

3. Remove clips from low-pressure flexible hose.

4. Remove mounting bolts from low-pressure flexible hose bracket.

5. Remove harness bracket mounting bolt (With QR engine).Disc to pulley clear-

ance: 0.2 - 0.5 mm (0.008 - 0.020 in)

RHA080CA

RJIA3177E

RJIA0584E

Page 3550 of 4179

ATC-154

REFRIGERANT LINES

6. Remove mounting bolts (nut) from low-pressure flexible hose.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

7. Remove mounting bolt, and then remove low-pressure flexible

hose.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

�Replace the O-ring of low-pressure flexible hose with a new one, then apply compressor oil to it

when installing it.

�When recharging refrigerant, check for leaks.

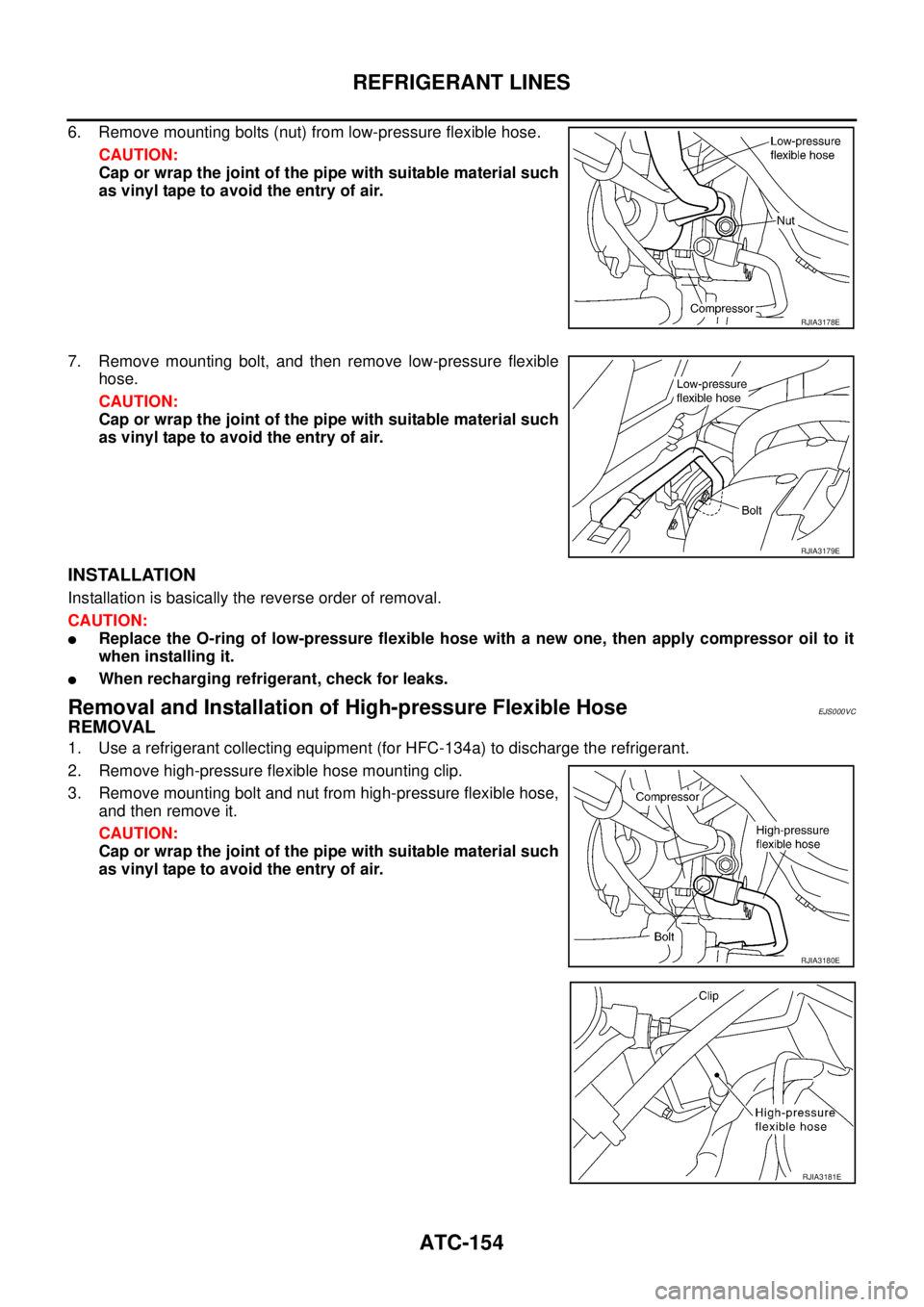

Removal and Installation of High-pressure Flexible HoseEJS000VC

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2. Remove high-pressure flexible hose mounting clip.

3. Remove mounting bolt and nut from high-pressure flexible hose,

and then remove it.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such

as vinyl tape to avoid the entry of air.

RJIA3178E

RJIA3179E

RJIA3180E

RJIA3181E

Trending: checking oil, auxiliary battery, fuse box, wheel torque, ignition, overheating, oil pressure