service OLDSMOBILE SILHOUETTE 2003 Workshop Manual

[x] Cancel search | Manufacturer: OLDSMOBILE, Model Year: 2003, Model line: SILHOUETTE, Model: OLDSMOBILE SILHOUETTE 2003Pages: 466, PDF Size: 21.55 MB

Page 355 of 466

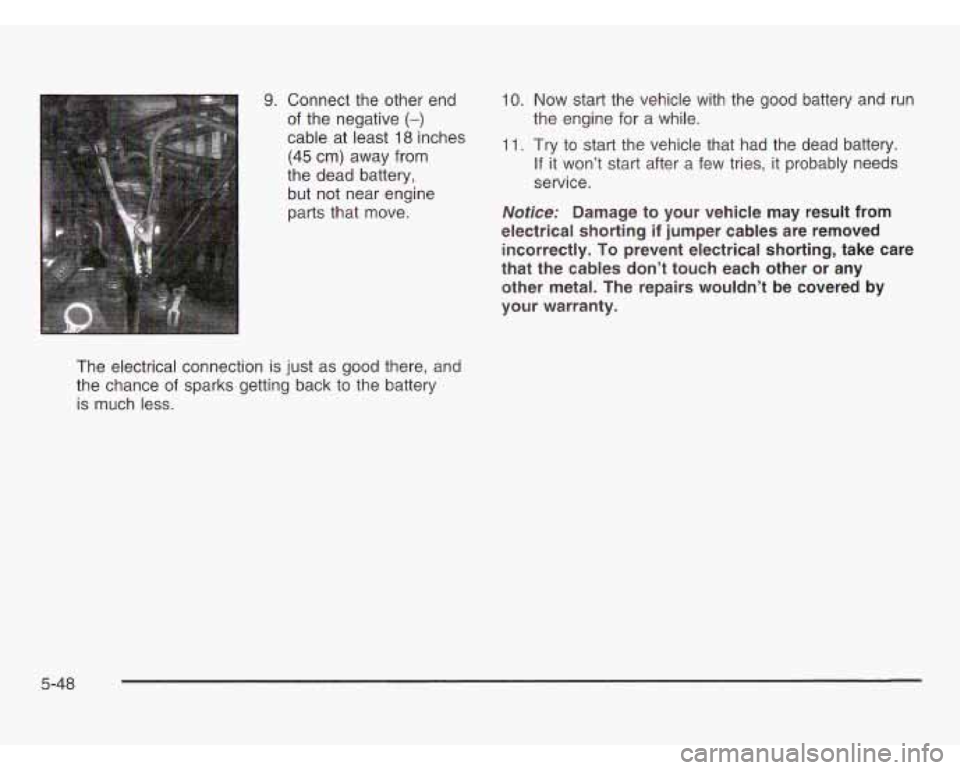

9. Connect the other end

of the negative

(-)

cable at least 18 inches

(45 cm) away from

the dead battery, but not near engine

parts that move.

The electrical connection is just as good there, and

the chance

of sparks getting back to the battery

is much less.

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle that had the dead battery.

If it won’t start after a few tries, it probably needs

service.

Notice: Damage to your vehicle may result from

electrical shorting

if jumper cables are removed

incorrectly.

To prevent electrical shorting, take care

that the cables don’t touch each other or any

other metal. The repairs wouldn’t be covered by

your warranty.

5-48

Page 358 of 466

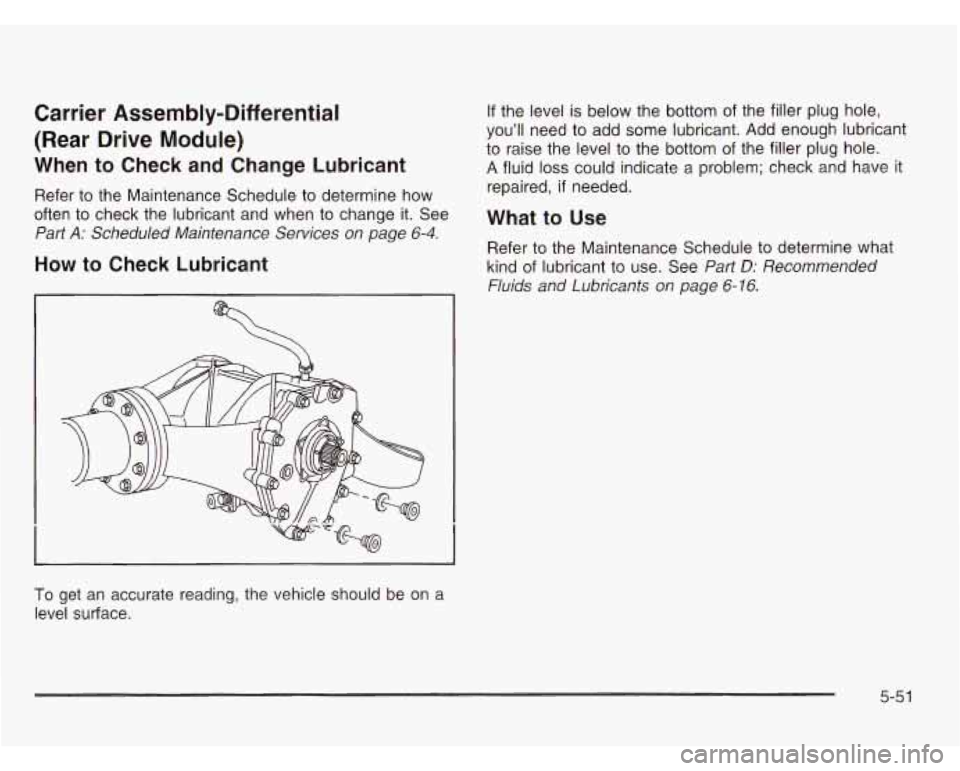

Carrier Assembly-Differential

(Rear Drive Module)

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant and when to change it. See

Part A: Scheduled Maintenance Services on page 6-4.

How to Check Lubricant

If the level is below the bottom of the filler plug hole,

you’ll need to add some lubricant. Add enough lubricant

to raise the level

to the bottom of the filler plug hole.

A fluid loss could indicate a problem; check and have it

repaired,

if needed.

What to Use

Refer to the Maintenance Schedule to determine what

kind

of lubricant to use. See Part D: Recommended

Fluids and Lubricants on page

6-16.

To get an accurate reading, the vehicle should be on a

level surface.

5-51

Page 367 of 466

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer.

If you ever have questions

about your tire warranty and where to obtain service,

see your Oldsmobile Warranty booklet for details.

Poorly maintained and improperly used tires

are dangerous.

Overloading your tires can cause

overheating as a result of too much

friction. You could have an air-out and a

serious accident. See “Loading Your

Vehicle” in the Index.

CAUTION: (Continued]

0 Underinflated tires pose the same danger

as overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be checked

when your tires are cold.

Overinflated tires are more likely to be

cut, punctured or broken by a sudden impact

- such as when you hit a pothole.

Keep tires at the recommended pressure.

Worn, old tires can cause accidents.

If your tread is badly worn, or if your

tires have been damaged, replace them.

5-60

Page 369 of 466

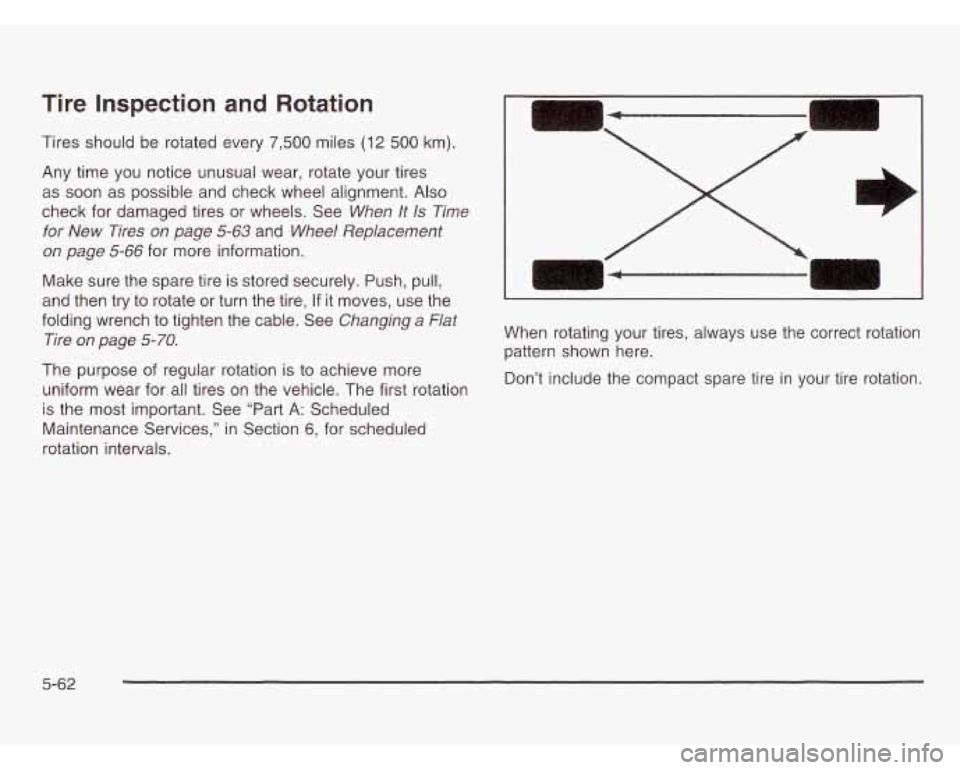

Tire Inspection and Rotation

Tires should be rotated every 7,500 miles (12 500 km).

Any time you notice unusual wear, rotate your tires

as soon as possible and check wheel alignment. Also

check for damaged tires or wheels. See

When It Is Time

for New Tires on page

5-63 and Wheel Replacement

on page

5-66 for more information.

Make sure the spare tire is stored securely. Push, pull,

and then try to rotate or turn the tire,

If it moves, use the

folding wrench to tighten the cable. See

Changing a Flat

Tire on page

5-70.

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The first rotation

is the most important. See “Part A: Scheduled

Maintenance Services,” in Section

6, for scheduled

rotation intervals.

I,‘

/I

When rotating your tires, always use the correct rotation

pattern shown here.

Don’t include the compact spare tire in your tire rotation.

5-62

Page 371 of 466

Buying New Tires

To find out what kind and size of tires you need, look at

the Certificationflire label.

The tires installed on your vehicle when it was new had a

Tire Petformance Criteria Specification (TPC Spec)

number on each tire’s sidewall. When you get new tires,

get ones with that same TPC Spec number. That way

your vehicle will continue to have tires that are designed

to give proper endurance, handling, speed rating,

traction, ride and other things during normal service on

your vehicle. If your tires have an all-season tread design,

the TPC number will be followed by an

“MS” (for mud

and snow).

If you ever replace your tires with those not having a

TPC Spec number, make sure they are the same

size, load range, speed rating and construction type

(bias, bias-belted or radial) as your original tires. Mixing tires coul-.

Lause you to lose control

while driving. If you mix tires of different sizes

or types (radial and bias-belted tires), the

vehicle may not handle properly, and you

could have a crash. Using tires

of different

sizes may also cause damage to your vehicle.

Be sure to use the same size and type tires on

all wheels. It’s

all right to drive with your

compact spare temporarily,

it was developed

for use on your vehicle. See “Compact Spare

Tire”

in the index.

If you use bias-ply

1 1s on your vehicle, the

wheel rim flanges could develop cracks after

many miles

of driving. A tire and/or wheel

could fail suddenly, causing

a crash. Use only

radial-ply tires with the wheels on your vehicle.

5-64

Page 372 of 466

Uniform Tire Quality Grading

Quality grades can be found where applicable on the

tire sidewall between tread shoulder and maximum

section width. For example:

Treadwear 200 Traction AA Temperature A

The following information relates to the system

developed by the United States National Highway

Traffic Safety Administration, which grades tires by

treadwear, traction and temperature performance.

(This applies only to vehicles sold in the United States.)

The grades are molded on the sidewalls of most

passenger car tires. The Uniform Tire Quality Grading

system does not apply to deep tread, winter-type

snow tires, space-saver or temporary use spare tires,

tires with nominal rim diameters of 10 to

12 inches

(25 to 30 cm), or to some limited-production tires.

While the tires available on General Motors passenger

cars and light trucks may vary with respect to these

grades, they must also conform to federal safety

Performance Criteria (TPC) standards.

-.-A -A-l:*:---l fi,,,,,I ill^+-”, T:”- It=~Ullt=lllelltb allu ~UUI~IUIIQI UCIICI~~ lvlulula I IIG

Treadwear

The treadwear grade is a comparative rating based on

the wear rate of the tire when tested under controlled

conditions on a specified government test course.

For example, a tire graded 150 would wear one and

a half (1

5) times as well on the government course as

a tire graded 100. The relative performance of tires

depends upon the actual conditions of their use,

however, and may depart significantly from the norm

due to variations in driving habits, service practices and differences in road characteristics and climate.

Traction - AA, A, 9, C

The traction grades, from highest to lowest, are AA, A,

B, and C. Those grades represent the tire’s ability

to stop on wet pavement as measured under controlled

conditions on specified government test surfaces of

asphalt and concrete. A tire marked C may have poor

traction performance. Warning: The traction grade

assigned to this tire is based on straight-ahead braking

traction tests, and does not include acceleration,

wrrlerir~ly, ilydlupih1Gl^ly, wr pea“ tIdwuI I cII la1 c~wz;I 1aL1t-a. ._ - - 1. A..- -A: - .- -L. -+--:-+:--

5-65

Page 375 of 466

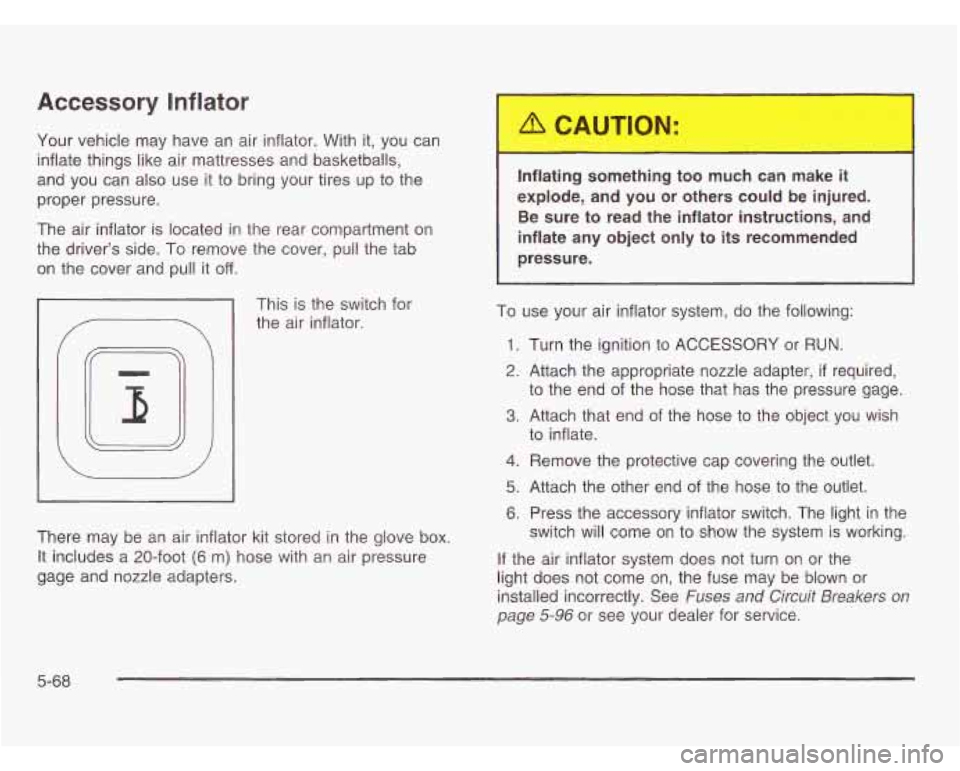

Accessory Inflator

Your vehicle may have an air inflator. With it, you can

inflate things like air mattresses and basketballs,

and you can also use it to bring your tires up to the

proper pressure.

The air inflator is located in the rear compartment on

the driver’s side. To remove the cover, pull the tab

on the cover and pull it

off.

This is the switch for

the air inflator.

There may be an air inflator kit stored in the glove box.

It includes a 20-foot

(6 m) hose with an air pressure

gage and nozzle adapters.

....___ ting something too much can make it

explode, and you or others could be injured.

Be sure to read the inflator instructions, and

inflate any object only

to its recommended

pressure.

To use your air inflator system, do the following:

1. Turn the ignition to ACCESSORY or RUN.

2. Attach the appropriate nozzle adapter, if required,

to the end

of the hose that has the pressure gage.

3. Attach that end of the hose to the object you wish

to inflate.

4. Remove the protective cap covering the outlet.

5. Attach the other end of the hose to the outlet.

6. Press the accessory inflator switch. The light in the

switch will come on to show the system is working.

If the air inflator system does not turn on or the

light does not come on, the fuse may be blown or

installed incorrectly. See

Fuses and Circuit Breakers on

page 5-96 or see your dealer for service.

5-68

Page 399 of 466

Aluminum Wheels

Keep your wheels clean using a soft clean cloth

with mild soap and water. Rinse with clean water.

After rinsing thoroughly, dry with a soft clean towel.

A wax may then be applied.

The surface of these wheels is similar to the painted

surface of your vehicle. Don’t use strong soaps,

chemicals, abrasive polishes, abrasive cleaners,

cleaners with acid, or abrasive cleaning brushes on

them because you could damage the surface.

Do not

use chrome polish on aluminum wheels.

Don’t take your vehicle through an automatic car wash

that has silicone carbide tire cleaning brushes. These

brushes can also damage the surface of these wheels

Tires

To clean your tires, use a stiff brush with tire cleaner.

Notice: When applying a tire dressing, always take

care to wipe

off any overspray or splash from all

painted surfaces on the body or wheels of the

vehicle. Petroleum-based products may damage the

paint finish and tires.

Sheet Metal Damage

If your vehicle is damaged and requires sheet metal

repair or replacement, make sure the body repair shop

applies anti-corrosion material to parts repaired or

replaced to restore corrosion protection.

Original manufacturer replacement parts will provide the

corrosion protection while maintaining the warranty.

Finish Damage

Any stone chips, fractures or deep scratches in the

finish should be repaired right away. Bare metal

will corrode quickly and may develop into major repair

expense.

Minor chips and scratches can be repaired with touch-up

materials avaliable from your dealer or other service

outlets. Larger areas

of finish damage can be corrected

in your dealer’s body and paint shop.

5-92

Page 402 of 466

Vehicle Identification

Vehicle Identification Number (VIN)

This is the legal identifier for your vehicle. It appears

on a plate in the front corner of the instrument panel,

on the driver’s side. You can see it if you

look through

the windshield from outside your vehicle. The VIN

also appears on the Vehicle Certification and Service

Parts labels and the certificates of title and registration.

Engine Identification

Th- O+h -hnr--+nr :- ..-..r \Ilk1 :r. +Lr. -mm:-n r.nA- I I IG OLI I b~ IUI abttl 11 I YUUI v IIY IJ LI IC GI IYII IG ~WUG.

This code will help you identify your engine,

specifications and replacement parts.

Service Parts Identification Label

You’ll find this label on the inside of the glove box door.

It’s very helpful

if you ever need to order parts.

On this label is:

0 your VIN,

the model designation,

0 paint information and

0 a list of all production options and special

equipment.

Be sure that this label is not removed from the vehicle.

5-95

Page 414 of 466

Section 6 Maintenance Schedule

Maintenance Schedule ...................................... 6.2

Introduction

................................................... 6.2

Your Vehicle and the Environment

.................... 6-2

Maintenance Requirements

.............................. 6.2

How This Section is Organized

......................... 6.3

Part

A: Scheduled Maintenance Services ........... 6.4

Scheduled Maintenance

................................... 6-5

Part

B: Owner Checks and Services ................ 6-10

At Each Fuel Fill .......................................... 6-10

At Least Once a Month ................................. 6-10

At Least Twice a Year ................................... 6-10

At Least Once a Year ................................... 6-11

Using Your Maintenance

Schedule

.................... 6.4

Part C: Periodic Maintenance Inspections

......... 6-14 Steering.

Suspension and Front Drive Axle

Boot and Seal Inspection

............................ 6.14

Exhaust System Inspection

............................ 6.14

Fuel System Inspection

.................................. 6.14

Engine Cooling System Inspection

................... 6.14

Throttle System Inspection

............................. 6.15

Transfer Case (Power Transfer Unit) and

Carrier Assembly-Differential

(Rear Drive Module) All-Wheel Drive

Inspection

................................................ 6.15

Brake System Inspection

................................ 6.15

Part D: Recommended Fluids and

Lubricants

................................................ 6.16

Part

E: Maintenance Record ........................... 6.18

6-

1