tow OLDSMOBILE SILHOUETTE 2003 Workshop Manual

[x] Cancel search | Manufacturer: OLDSMOBILE, Model Year: 2003, Model line: SILHOUETTE, Model: OLDSMOBILE SILHOUETTE 2003Pages: 466, PDF Size: 21.55 MB

Page 321 of 466

Engine Oil

LOW

ENG OIL

LEVEL

United States

Canada

If the low engine oil level message appears on the

instrument cluster, it means you need to check your

engine oil level right away. For more information,

see

Low Engine Oil Level Message on page 3-55.

You should check your engine oil level regularly; this is

an added reminder.

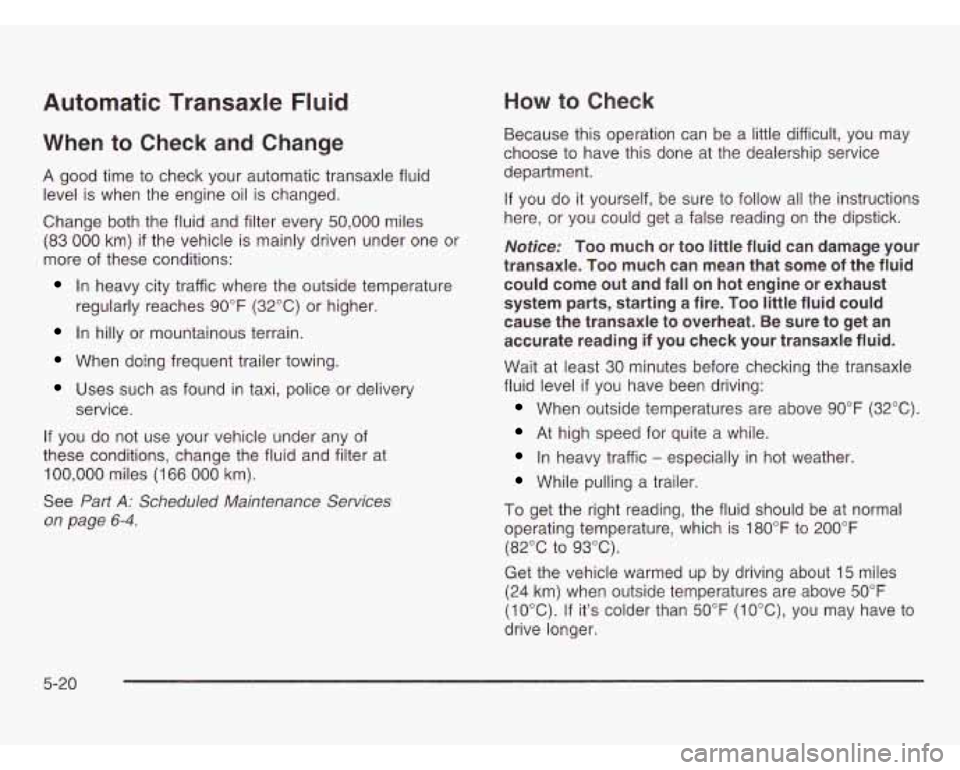

Checking Engine Oil

It’s a good idea to check your engine oil every time you

get fuel. In order to get an accurate reading, the oil

must be warm and the vehicle must be on level ground.

The engine oil dipstick is

located at the front of the

engine compartment,

near the center. The

dipstick handle has a

bright, yellow loop design

for easy identification. See

Engine Compartment

Overview on page

5- 12

for more information on location.

Turn

off the engine and give the oil several minutes to

drain back into the oil pan. If you don’t, the oil

dipstick might not

show the actual level.

Pull out the dipstick and clean it with a paper towel or

cloth, then push

it back in all the way. Remove it again,

keeping the tip down, and check the level.

5-1 4

Page 327 of 466

Automatic Transaxle Fluid

When to Check and Change

A good time to check your automatic transaxle fluid

level is when the engine oil is changed.

Change both the fluid and filter every

50,000 miles

(83

000 km) if the vehicle is mainly driven under one or

more of these conditions:

In heavy city traffic where the outside temperature

regularly reaches 90°F (32°C) or higher.

In hilly or mountainous terrain.

When doing frequent trailer towing.

Uses such as found in taxi, police or delivery

service.

If you do not use your vehicle under any of

these conditions, change the fluid and filter at

100,000 miles (1 66 000 km).

See

Part A: Scheduled Maintenance Services

on page

6-4.

How to Check

Because this operation can be a little difficult, you may

choose to have this done at the dealership service

department.

If you do it yourself, be sure to follow all the instructions

here, or you could get a false reading on the dipstick.

Notice: Too much or too little fluid can damage your

transaxle.

Too much can mean that some of the fluid

could come out and fall

on hot engine or exhaust

system parts, starting a fire.

Too little fluid could

cause the transaxle to overheat. Be sure to get an

accurate reading if you check your transaxle fluid.

Wait at least

30 minutes before checking the transaxle

fluid level

if you have been driving:

When outside temperatures are above 90°F (32°C).

At high speed for quite a while.

In heavy traffic - especially in hot weather.

While pulling a trailer.

To get the right reading, the fluid should be at normal

operating temperature, which

is 180°F to 200°F

(82°C to 93°C).

Get the vehicle warmed up by driving about

15 miles

(24 km) when outside temperatures are above 50°F

(1 0°C). If it's colder than 50°F (1 OOC), you may have to

drive longer.

5-20

Page 328 of 466

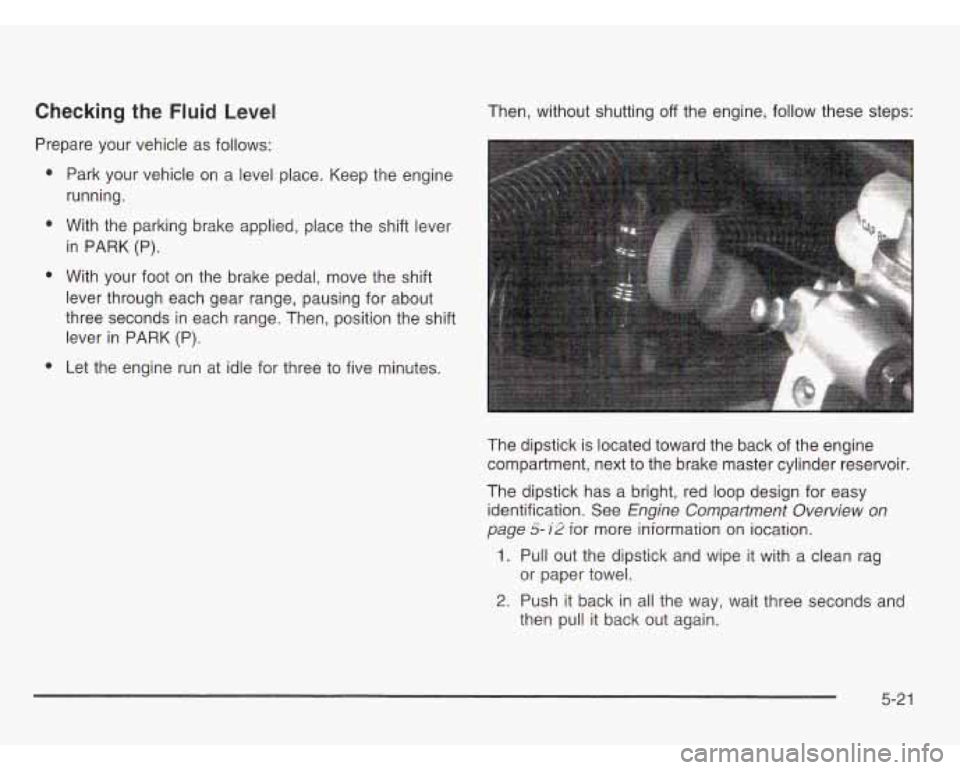

Checking the Fluid Level

Prepare your vehicle as follows:

e

e

e

Park your vehicle on a level place. Keep the engine

running.

With the parking brake applied, place the shift lever

in PARK (P).

With your foot on the brake pedal, move the shift

lever through each gear range, pausing for about

three seconds in each range. Then, position the shift

lever in PARK (P).

Let the engine run at idle for three to five minutes. rhen,

without shutting

off the engine, follow these steps:

The dipstick is located toward the back of the engine

compartment, next to the brake master cylinder reservoir

The dipstick has a bright, red loop design for easy

identification. See

Engine Compartment Overview on

page

5- 12 ior more information on iocation.

1. Pull out the dipstick and wipe it with a clean rag

2. Push it back in all the way, wait three seconds and

or

paper towel.

then pull

it back out again.

5-2 1

Page 333 of 466

Radiator Pressure Cap

Notice: Your radiator cap is a pressure-type cap

and must be tightly installed to prevent coolant

loss

and possible engine damage from overheating.

Be sure the arrows on the cap line

up with the

overflow tube on the radiator filler neck.

The radiator pressure cap is located at the front of the

engine compartment on the passenger’s side of the

vehicle. See

Engine Compartment Overview on

page 5-72 for more information on location.

Engine Overheating

You will find an engine coolant temperature gage on

your vehicle’s instrument panel cluster. See

Engine

Coolant Temperature Gage

on page 3-47. You also

have an engine coolant temperature warning message

on your instrument panel. See

Engine Coolant

Temperature Warning Message

on page 3-53.

Overheated Engine Protection

Operating Mode

This emergency operating mode allows your vehicle to

be driven to a safe place in an emergency situation.

If an overheated engine condition exists, an overheat

protection mode which alternates firing groups of

cylinders helps prevent engine damage.

In this mode,

you will notice a significant

loss in power and engine

performance. The temperature gage will indicate

an overheat condition exists. Driving extended miles

(km) and/or towing a trailer in the overheat protection

mode should be avoided.

Notice: After driving in the overheated engine

protection operating mode, to avoid engine damage,

allow the engine to cool before attempting any repair. The engine oil will be severely degraded.

Repair the cause

of coolant loss, change the oil

and reset the

oil life system. See “Engine Oil” in

the Index.

5-26

Page 335 of 466

If No Steam Is Coming From

Your Engine

If you get an engine overheat warning but see or

hear no steam, the problem may not be too serious.

Sometimes the engine can get a little

too hot when you:

Climb a long hill on a hot day.

Stop after high-speed driving.

Idle for long periods in traffic.

Tow a trailer.

If you get the overheat warning with no sign of steam,

try this for a minute or

so:

1. If your air conditioner is on, turn it off.

2. Turn on your heater to full hot at the highest fan

speed and open the window as necessary.

3. If you’re in a traffic jam, shift to NEUTRAL (N);

otherwise, shift to the highest gear while

driving

- AUTOMATIC OVERDRIVE (D) or

THIRD

(3).

If you no longer have the overheat warning, you can

drive. Just to be safe, drive slower for about

10 minutes.

If the warning doesn’t come back on, you can drive

normally.

If the warning continues, pull over, stop, and park your

vehicle right away.

If there’s still no sign of steam, idle the engine for

three minutes while you’re parked. If you still have the

warning,

turn off the engine and get everyone out of

the vehicle until it cools down. Also, see “Overheated

Engine Protection Operating Mode” listed previously in

this section.

You may decide not to

lift the hood but to get service

help right away.

5-28

Page 366 of 466

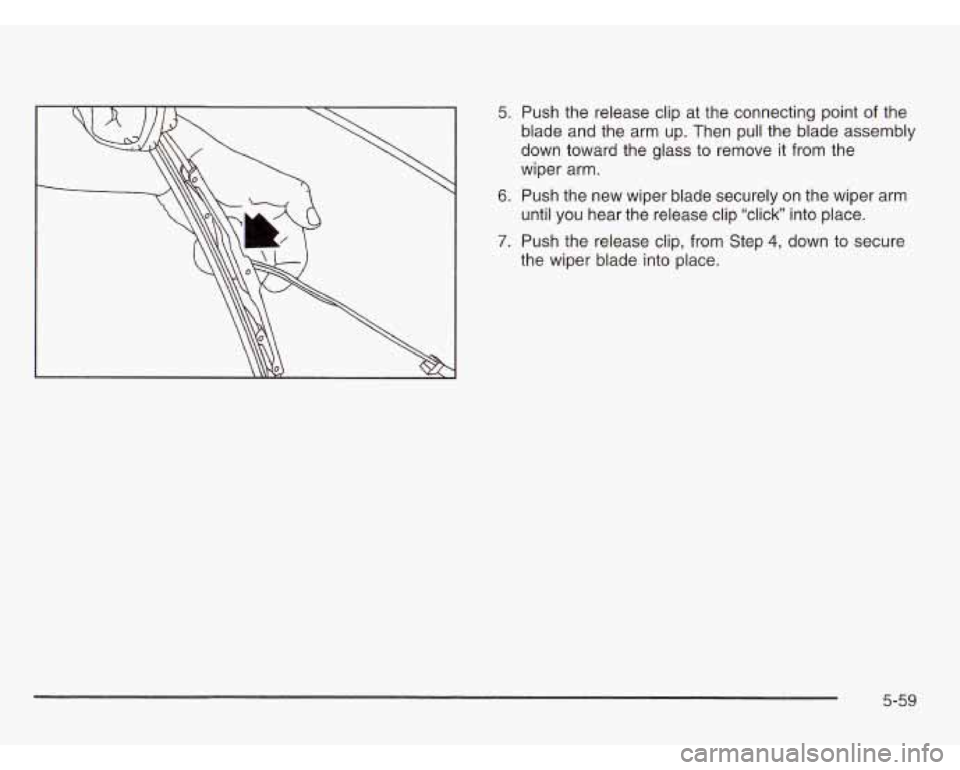

5. Push the release clip at the connecting point of the

blade and the arm up. Then pull the blade assembly

down toward the glass to remove it from the

wiper arm.

6. Push the new wiper blade securely on the wiper arm

until you hear the release clip “click” into place.

7. Push the release clip, from Step 4, down to secure

the wiper blade into place.

5-59

Page 370 of 466

After the tires have been rotated, adjust the front and rear

inflation pressures as shown on the Certification/Tire

label. Make certain that all wheel nuts are properly

tightened. See “Wheel Nut Torque” under

Capacities and

Specifications on page 5-

103.

-3ust or dirt on a wheel, or on the parts to

which

it is fastened, can make wheel nuts

become loose after a time. The wheel could

come

off and cause an accident. When you

change a wheel, remove any rust or

dirt from

places where the wheel attaches to the vehicle.

In an emergency, you can use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if you need to, to

get all the rust or dirt

off. See “Changing a Flat

Tire”

in the Index.

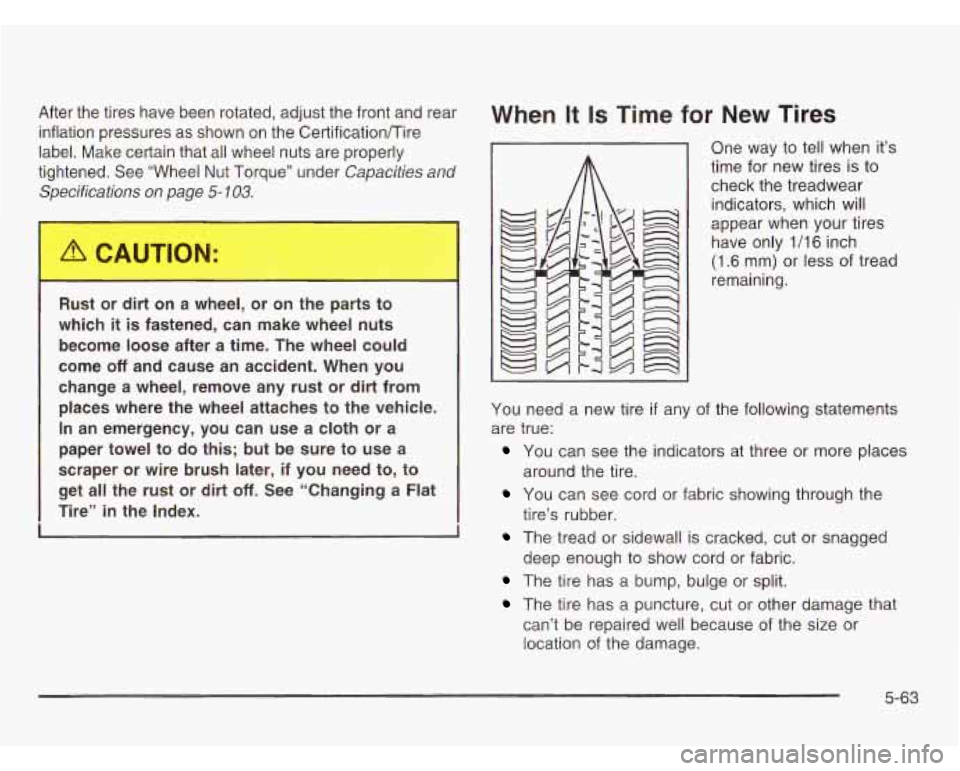

When It Is Time for New Tires

One way to tell when it’s

time for new tires is to

check the treadwear

indicators, which will

appear when your tires

have only

1/16 inch

(1.6 mm) or less of tread

remaining.

You need a new tire

if any of the following statements

are true:

You can see the indicators at three or more places

You can see cord or fabric showing through the

The tread or sidewall is cracked, cut or snagged

The tire has a bump, bulge or split.

The tire has a puncture, cut or other damage that

around the tire.

tire’s rubber. deep enough to show cord or fabric.

__ can’t be repaired well because of the size or

location

of the damage.

5-63

Page 376 of 466

Your air inflator will automatically shut off after about

10 minutes. The light in the switch will blink. After about

one minute you can use the system again. Press the

inflator switch and the indicator light will come on.

Notice: Don’t run your air inflator for longer than

30 minutes at one time. If you do, you may damage

the system.

After running the air inflator for

30 minutes, wait at least

10 minutes before restarting the air inflator.

To turn off the inflator, do the following:

1. Press the switch and detach the hose, first from the

2. Put the protective cap back on.

3. Place the inflator kit tools in the pouch, and store in

inflated

object, then from the outlet.

the glove box.

To put the cover back on, line up the tabs at the back

of the cover and put it in place. Push down the tab

to secure the cover.

If a Tire Goes Flat

It’s unusual for a tire to “blow out” while you’re driving,

especially

if you maintain your tires properly. If air

goes out of a tire, it’s much more likely to leak out

slowly. But if you should ever have a “blowout”, here are

a few tips about what to expect and what to do:

If a front tire fails, the flat tire will create a drag that

pulls the vehicle toward that side. Take your foot

off the

accelerator pedal and grip the steering wheel firmly.

Steer to maintain lane position, and then gently brake

to a stop well out of the traffic lane.

A rear blowout, particularly on a curve, acts much like

a skid and may require the same correction you’d use

in a skid. In any rear blowout, remove your foot from

the accelerator pedal. Get the vehicle under control by

steering the way you want the vehicle to go. It may

be very bumpy and noisy, but you can still steer.

Gently brake to a stop

- well off the road if possible.

If a tire goes flat, the next part shows how to use

your jacking equipment to change a flat tire safely.

5-69

Page 380 of 466

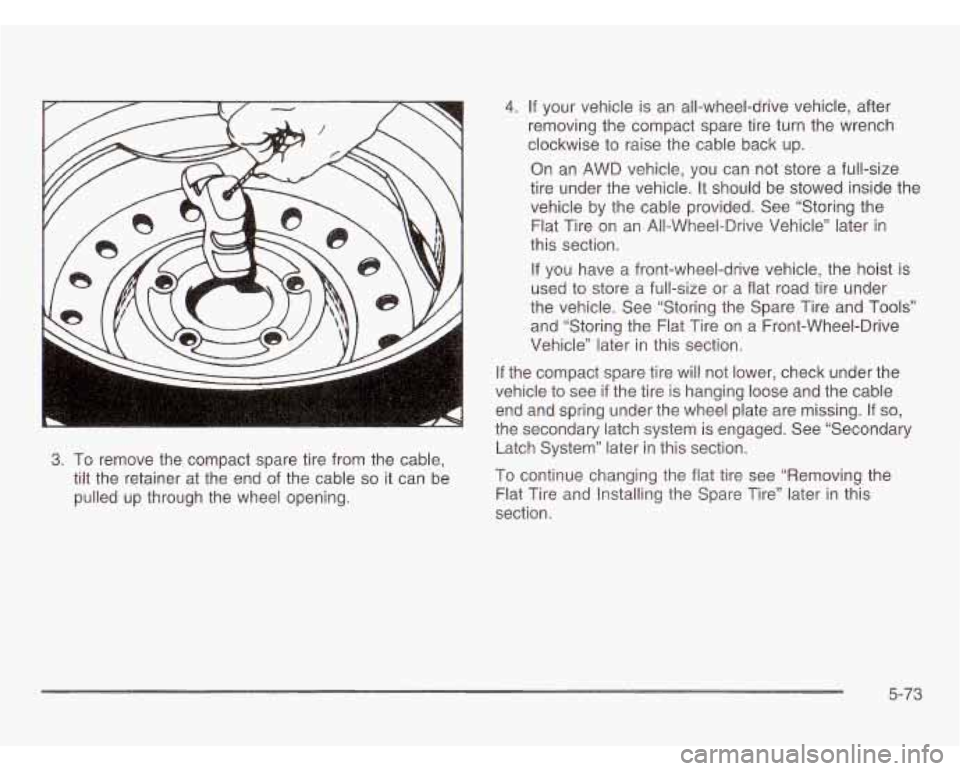

3. To remove the compact spare tire from the cable,

tilt the retainer at the end

of the cable so it can be

pulled up through the wheel opening.

-. If your vehicle is an all-wheel-drive vehicle, after

removing the compact spare tire turn the wrench

clockwise to raise the cable back up.

On an AWD vehicle, you can not store

a full-size

tire under the vehicle. It should be stowed inside the

vehicle by the cable provided. See “Storing the

Flat Tire on an All-Wheel-Drive Vehicle” later

in

this section.

If you have a front-wheel-drive vehicle, the hoist is

used to store a full-size or a flat road tire under

the vehicle. See “Storing the Spare Tire and

Tools”

and “Storing the Flat Tire on a Front-Wheel-Drive

Vehicle” later

in this section.

If the compact spare tire will not lower, check under the

vehicle to see

if the tire is hanging loose and the cable

end and spring under the wheel plate are missing. If

so,

the secondary latch system is engaged. See “Secondary

Latch System” later

in this section.

To continue changing the flat tire see “Removing the

Flat Tire and Installing the Spare Tire” later in this

section.

5-73

Page 381 of 466

Secondary Latch System

Your vehicle may have an underbody mounted tire hoist

assembly equipped with a secondary latch system.

It‘s designed to stop a tire from suddenly falling off your

vehicle

if the cable holding the spare tire is damaged.

For the secondary latch to work, the tire must be stowed

with the valve stem pointing down.

Front-wheel-drive vehicles use the underbody tire hoist

assembly to store either the compact spare or a flat

road tire. See “Storing a Flat or Spare Tire and

Tools”

in the Index for instructions on storing the spare or

flat tire correctly.

If your vehicle is equipped with all-wheel-drive, the

underbody tire hoist assembly stores only the compact

spare tire. See “Storing the Spare Tire and Tools”

later in this section for instructions. To store a flat

full-size tire correctly, see “Storing the Flat Tire

on

an All-Wheel-Drive Vehicle” later in this section. Before beginning this procedure read all the

instructions. Failure to read and follow the

instructions could damage the hoist assembly

and you and others could get hurt. Read and

follow the instructions listed below.

To release the spare tire from the secondary latch,

do the

f .. )wing:

Someone standing too close during the procedure could be injured by the jack.

If the

spare tire does not slide

off the jack completely,

make sure no one is behind you or on either

side of you as you pull the jack out from

the spare.

5-74