transmission OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2079 of 6000

6E–186

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Poor Fuel Economy Symptom

StepNo Ye s Va l u e ( s ) Action

111. Check the TCC operation. Refer to Transmission

Diagnosis

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 12

121. Check the exhaust system for possible restriction:

Inspect the exhaust system for damaged or

collapsed pipes.

Inspect the muffler for heat distress or possible

internal failure.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 13

13Check for proper calibration of the speedometer.

Does the speed indicated on the speedometer closely

match the vehicle speed displayed on the Tech 2?

—Go to Step 15Go to Step 14

14Diagnose and repair an inaccurate speedometer

condition as necessary. Refer to

Vehicle Speed

Sensor

in Electrical Diagnosis.

Was a problem found?

—Verify repair—

151. Check the air intake system and the crankcase for

air leaks. Refer to

Air Intake System and

Crankcase Ventilation System.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 16

161. Review all diagnostic procedures within this table.

2. When all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

Visual/physical inspection

Te c h 2 d a t a

Freeze Frame data/Failure Records buffer

All connections within a suspected circuit

and/or system.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 17

17Perform the procedure in Injector Test.

Was the fuel pressure normal?

—

Contact

Te c h n i c a l

Assistance

Verify repair

Page 2082 of 6000

6E–189 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Cuts Out, Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Steady pulsation or jerking that follows engine speed;

usually more pronounced as engine load increases.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Go to Step 7Go to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to Visual/

Physical

Check

41. Check the ECM grounds for clearness, tightness

and proper routing. Refer to the ECM wiring

diagrams in

Electrical Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 5

51. Check for incorrect idle speed. Ensure that the

following conditions are present:

The engine is fully warm.

The accessories are “off.”

2. Using a Tech 2, monitor the AP position.

Is the AP position within the specified values?

0%Go to Step 6Go to Step 7

61. Visually/physically inspect for the following

conditions:

Restricted air intake system. Check for a

possible collapsed air intake duct, restricted

air filter element, or foreign objects blocking

the air intake system.

Check the Throttle body.

Large vacuum leak. Check for a condition that

causes a large vacuum leak, such as an

incorrectly installed or faulty VSV or brake

booster hose disconnected .

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

7Using a Tech 2, monitor the AP angle with the engine

idling.

Is the AP angle at the specified value and steady?

0%Go to Step 8

Refer to DTC

P0123

for

further

diagnosis

81. Check the transmission range switch circuit. Use a

Tech 2 and be sure the Tech 2 indicates that the

vehicle is in drive with the gear selector in drive or

overdrive.

2. If a problem is found, diagnose and repair the

transmission range switch as necessary.

Was a problem found?

—Verify repairGo to Step 9

Page 2092 of 6000

6E–199 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

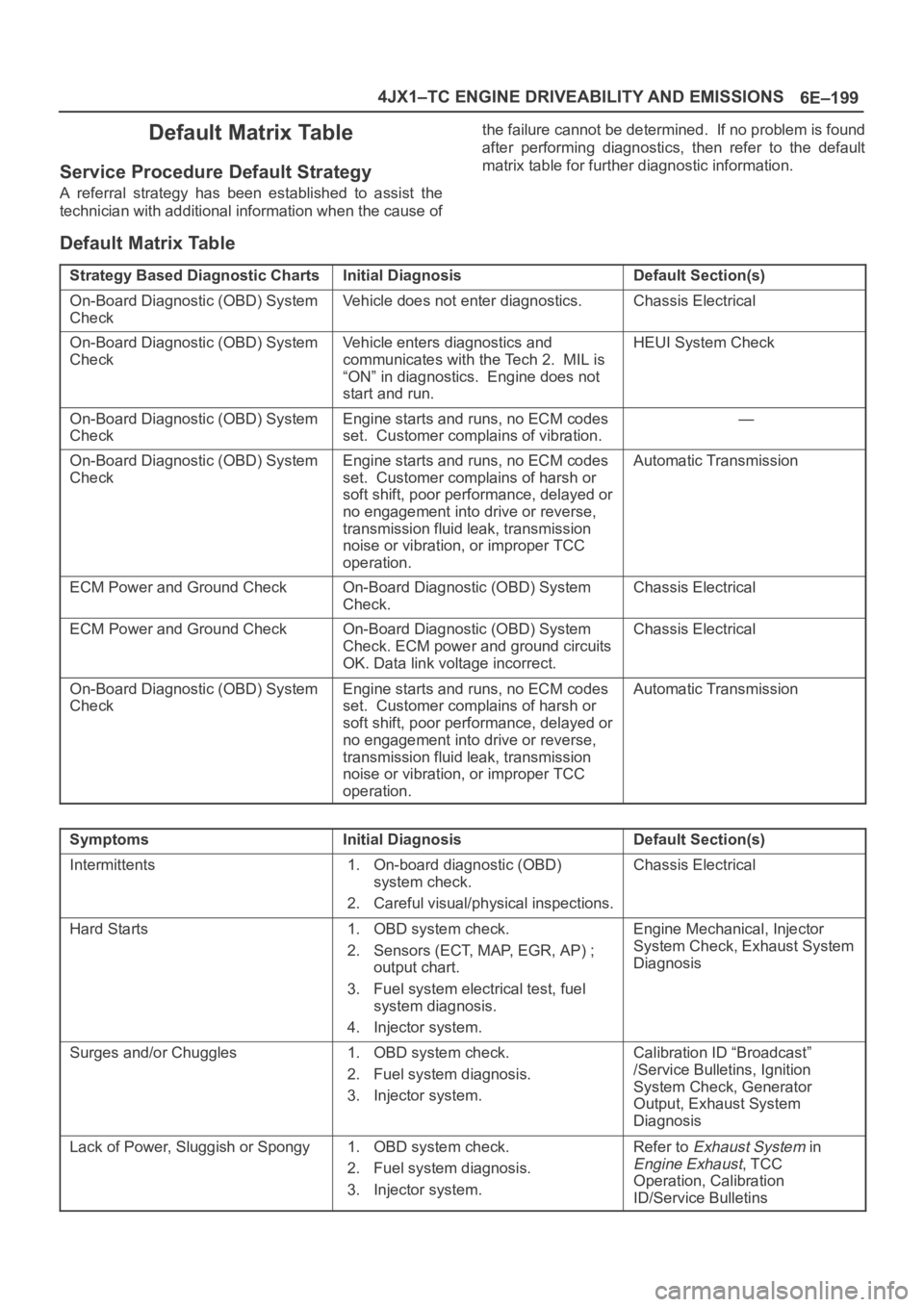

Default Matrix Table

Service Procedure Default Strategy

A referral strategy has been established to assist the

technician with additional information when the cause ofthe failure cannot be determined. If no problem is found

after performing diagnostics, then refer to the default

matrix table for further diagnostic information.

Default Matrix Table

Strategy Based Diagnostic ChartsInitial DiagnosisDefault Section(s)

On-Board Diagnostic (OBD) System

CheckVehicle does not enter diagnostics.Chassis Electrical

On-Board Diagnostic (OBD) System

CheckVehicle enters diagnostics and

communicates with the Tech 2. MIL is

“ON” in diagnostics. Engine does not

start and run.HEUI System Check

On-Board Diagnostic (OBD) System

CheckEngine starts and runs, no ECM codes

set. Customer complains of vibration.—

On-Board Diagnostic (OBD) System

CheckEngine starts and runs, no ECM codes

set. Customer complains of harsh or

soft shift, poor performance, delayed or

no engagement into drive or reverse,

transmission fluid leak, transmission

noise or vibration, or improper TCC

operation.Automatic Transmission

ECM Power and Ground CheckOn-Board Diagnostic (OBD) System

Check.Chassis Electrical

ECM Power and Ground CheckOn-Board Diagnostic (OBD) System

Check. ECM power and ground circuits

OK. Data link voltage incorrect.Chassis Electrical

On-Board Diagnostic (OBD) System

CheckEngine starts and runs, no ECM codes

set. Customer complains of harsh or

soft shift, poor performance, delayed or

no engagement into drive or reverse,

transmission fluid leak, transmission

noise or vibration, or improper TCC

operation.Automatic Transmission

SymptomsInitial DiagnosisDefault Section(s)

Intermittents1. On-board diagnostic (OBD)

system check.

2. Careful visual/physical inspections.Chassis Electrical

Hard Starts1. OBD system check.

2. Sensors (ECT, MAP, EGR, AP) ;

output chart.

3. Fuel system electrical test, fuel

system diagnosis.

4. Injector system.Engine Mechanical, Injector

System Check, Exhaust System

Diagnosis

Surges and/or Chuggles1. OBD system check.

2. Fuel system diagnosis.

3. Injector system.Calibration ID “Broadcast”

/Service Bulletins, Ignition

System Check, Generator

Output, Exhaust System

Diagnosis

Lack of Power, Sluggish or Spongy1. OBD system check.

2. Fuel system diagnosis.

3. Injector system.Refer to Exhaust System in

Engine Exhaust, TCC

Operation, Calibration

ID/Service Bulletins

Page 2120 of 6000

6E–227 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

QOS

Diagnostics

– Malfunction Indicator Lamp (Service Engine

Soon lamp)

– Data Link Connector (DLC)

– Data Output

ECM Service Precautions

The ECM is designed to withstand normal current draws

associated with vehicle operation. Avoid overloading any

circuit. When testing for opens and shorts, do not ground

or apply voltage to any of the ECM’s circuits unless

instructed to do so. These circuits should only be tested

using digital voltmeter. The ECM should remain

connected to the ECM or to a recommended breakout

box.

Intake Throttle Position (ITP) Sensor

ITP sensor is a potentiometer type and installed to the

intake throttle valve body. A voltage of 5V is applied

constantly from ECM to ITP sensor thereby to determine

by change in voltage the opening of the intake throttle

valve during warming up.

Transmission Range Switch

IMPORTANT:The vehicle should not be driven with the

transmission range switch disconnected; idle quality will

be affected.

The four inputs from the transmission range switch

indicate to the ECM which position is selected by the

transmission selector lever.

For more information on the transmission on the

transmission range switch, refer to

Automatic

Tr a n s m i s s i o n

.

Accelerator Position Sensor (AP)

AP sensor is a potentiometer type and installed to

accelerator pedal bracket. A voltage of 5V constantly

applied from ECM to the sensor thereby to determine the

accelerator pedaling angle by change in voltage. Further,

this sensor is provided with an accelerator switch, which

is set off only when the accelerator pedal is stepped on.

Aftermarket Electrical and Vacuum

Equipment

Aftermarket (add-on) electrical and vacuum equipment is

defined as any equipment which connects to the vehicle’s

electrical or vacuum systems that is installed on a vehicle

after it leaves the factory. No allowances have been

made in the vehicle design for this type of equipment.

NOTE: No add-on vacuum equipment should be added

to this vehicle.

NOTE: Add-on electrical equipment must only be

connected to the vehicle’s electrical system at the battery

(power and ground).

Add-on electrical equipment, even when installed to

these guidelines, may still cause the powertrain system to

malfunction. This may also include equipment not

connected to the vehicle electrical system such asportable telephones and radios. Therefore, the first step

in diagnosing any powertrain problem is to eliminate all

aftermarket electrical equipment from the vehicle. After

this is done, if the problem still exists, it may be diagnosed

in the normal manner.

Electrostatic Discharge Damage

Electronic components used in the ECM are often

designed to carry very low voltage. Electronic

components are susceptible to damage caused by

electrostatic discharge. Less than 100 volts of static

electricity can cause damage to some electronic

components. By comparison, it takes as much as 4000

volts for a person to feel even the zap of a static

discharge.

TS23793

There are several ways for a person to become statically

charged. The most common methods of charging are by

friction and induction.

An example of charging by friction is a person sliding

across a vehicle seat.

Charge by induction occurs when a person with well

insulated shoes stands near a highly charged object

and momentary touches ground. Charges of the

same polarity are drained off leaving the person

highly charged with the opposite polarity. Static

charges can cause damage, therefore it is important

to use care when handling and testing electronic

components.

NOTE: To prevent possible electrostatic discharge

damage, follow these guidelines:

Do not touch the ECM connector pins or soldered

components on the ECM circuit board.

Do not open the replacement part package until the

part is ready to be installed.

Before removing the part from the package, ground

the package to a known good ground on the vehicle.

If the part has been handled while sliding across the

seat, while sitting down from a standing position, or

while walking a distance, touch a known good ground

before installing the part.

Page 2155 of 6000

7A–1 AUTOMATIC TRANSMISSION (4L30–E)

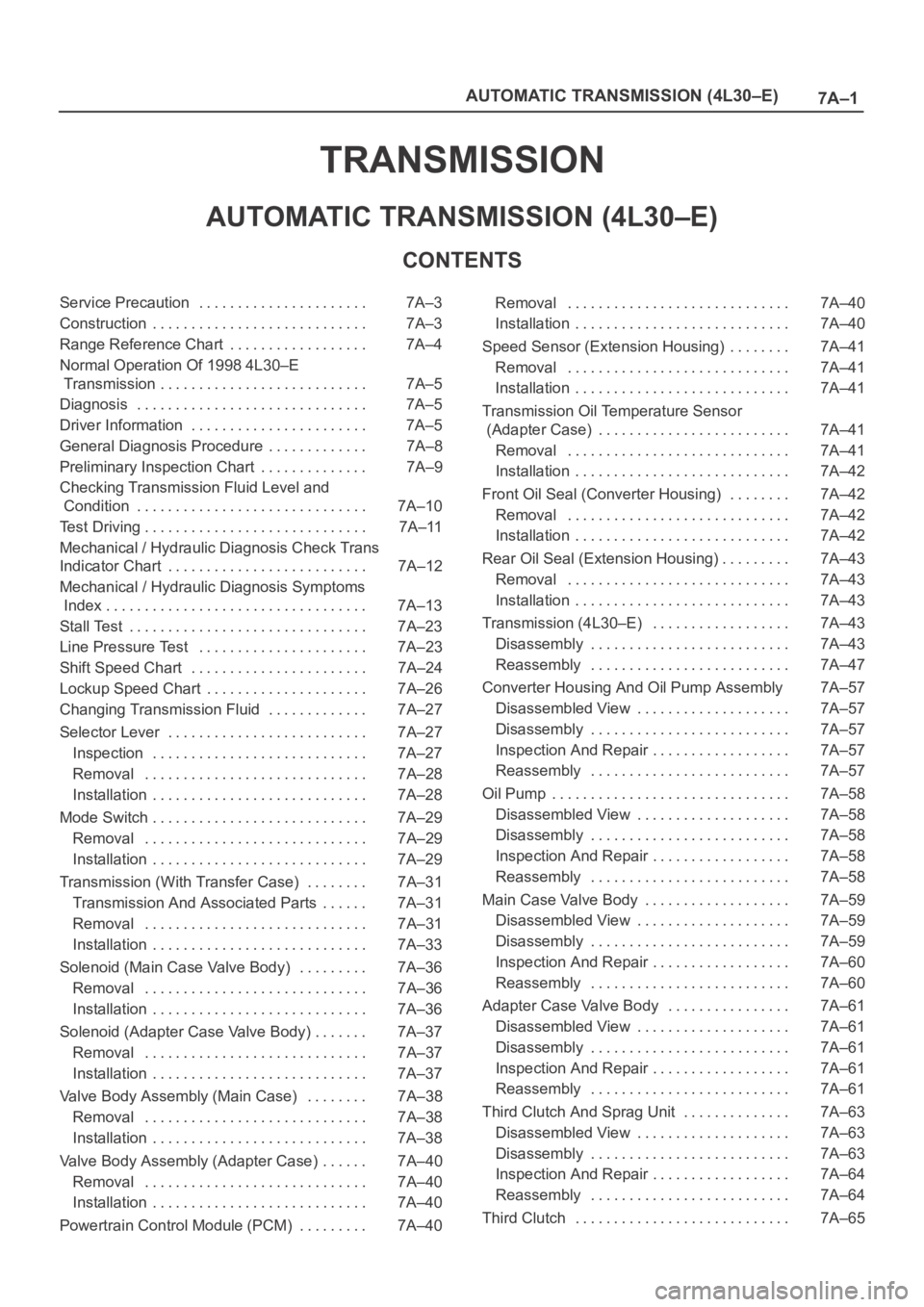

TRANSMISSION

AUTOMATIC TRANSMISSION (4L30–E)

CONTENTS

Service Precaution 7A–3. . . . . . . . . . . . . . . . . . . . . .

Construction 7A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Range Reference Chart 7A–4. . . . . . . . . . . . . . . . . .

Normal Operation Of 1998 4L30–E

Transmission 7A–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 7A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driver Information 7A–5. . . . . . . . . . . . . . . . . . . . . . .

General Diagnosis Procedure 7A–8. . . . . . . . . . . . .

Preliminary Inspection Chart 7A–9. . . . . . . . . . . . . .

Checking Transmission Fluid Level and

Condition 7A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Driving 7A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical / Hydraulic Diagnosis Check Trans

Indicator Chart 7A–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical / Hydraulic Diagnosis Symptoms

Index 7A–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stall Test 7A–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Pressure Test 7A–23. . . . . . . . . . . . . . . . . . . . . .

Shift Speed Chart 7A–24. . . . . . . . . . . . . . . . . . . . . . .

Lockup Speed Chart 7A–26. . . . . . . . . . . . . . . . . . . . .

Changing Transmission Fluid 7A–27. . . . . . . . . . . . .

Selector Lever 7A–27. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 7A–27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission (With Transfer Case) 7A–31. . . . . . . .

Transmission And Associated Parts 7A–31. . . . . .

Removal 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid (Main Case Valve Body) 7A–36. . . . . . . . .

Removal 7A–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–36. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid (Adapter Case Valve Body) 7A–37. . . . . . .

Removal 7A–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body Assembly (Main Case) 7A–38. . . . . . . .

Removal 7A–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body Assembly (Adapter Case) 7A–40. . . . . .

Removal 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powertrain Control Module (PCM) 7A–40. . . . . . . . . Removal 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Sensor (Extension Housing) 7A–41. . . . . . . .

Removal 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Oil Temperature Sensor

(Adapter Case) 7A–41. . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–42. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Oil Seal (Converter Housing) 7A–42. . . . . . . .

Removal 7A–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–42. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal (Extension Housing) 7A–43. . . . . . . . .

Removal 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission (4L30–E) 7A–43. . . . . . . . . . . . . . . . . .

Disassembly 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 7A–47. . . . . . . . . . . . . . . . . . . . . . . . . .

Converter Housing And Oil Pump Assembly 7A–57

Disassembled View 7A–57. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–57. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–57. . . . . . . . . . . . . . . . . .

Reassembly 7A–57. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 7A–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 7A–58. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–58. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–58. . . . . . . . . . . . . . . . . .

Reassembly 7A–58. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Case Valve Body 7A–59. . . . . . . . . . . . . . . . . . .

Disassembled View 7A–59. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–59. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–60. . . . . . . . . . . . . . . . . .

Reassembly 7A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Adapter Case Valve Body 7A–61. . . . . . . . . . . . . . . .

Disassembled View 7A–61. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–61. . . . . . . . . . . . . . . . . .

Reassembly 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Third Clutch And Sprag Unit 7A–63. . . . . . . . . . . . . .

Disassembled View 7A–63. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–63. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–64. . . . . . . . . . . . . . . . . .

Reassembly 7A–64. . . . . . . . . . . . . . . . . . . . . . . . . .

Third Clutch 7A–65. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2156 of 6000

7A–2

AUTOMATIC TRANSMISSION (4L30–E)

Disassembled View 7A–65. . . . . . . . . . . . . . . . . . . .

Disassemble 7A–65. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–65. . . . . . . . . . . . . . . . . .

Reassembly 7A–65. . . . . . . . . . . . . . . . . . . . . . . . . .

Sprag Unit 7A–67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 7A–67. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–67. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–67. . . . . . . . . . . . . . . . . .

Reassembly 7A–67. . . . . . . . . . . . . . . . . . . . . . . . . .

Second Clutch 7A–68. . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 7A–68. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–68. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–69. . . . . . . . . . . . . . . . . .

Reassembly 7A–69. . . . . . . . . . . . . . . . . . . . . . . . . .

3–4 Accumulator Piston 7A–70. . . . . . . . . . . . . . . . . .

Disassembled View 7A–70. . . . . . . . . . . . . . . . . . . . Disassembly 7A–70. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–70. . . . . . . . . . . . . . . . . .

Reassembly 7A–71. . . . . . . . . . . . . . . . . . . . . . . . . .

Reverse Clutch Piston And Center Support 7A–72.

Disassembled View 7A–72. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–72. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–73. . . . . . . . . . . . . . . . . .

Reassembly 7A–73. . . . . . . . . . . . . . . . . . . . . . . . . .

Overrun Clutch And Turbine Shaft 7A–74. . . . . . . . .

Disassembled View 7A–74. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–74. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–75. . . . . . . . . . . . . . . . . .

Reassembly 7A–75. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data And Specification 7A–77. . . . . . . . . . . . . .

Special Tools 7A–81. . . . . . . . . . . . . . . . . . . . . . . . . . .

4L30–E Parts List 7A–84. . . . . . . . . . . . . . . . . . . . . . .

Page 2157 of 6000

7A–3 AUTOMATIC TRANSMISSION (4L30–E)

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Construction

A07RS001

Legend

(1) Torque Converter Clutch (TCC)

(2) Fourth Clutch (C4)

(3) Overrun Clutch (OC)

(4) Overdrive Unit

(5) Reverse Clutch (RC)

(6) Second Clutch (C2)(7) Third Clutch (C3)

(8) Ravigneaux Planetary Gear Set

(9) Brake Band (B)

(10) Overdrive Free Wheel (One Way Clutch)

(OFW)

(11) Sprag Free Wheel (One Way Clutch) (PFW)

Page 2158 of 6000

7A–4

AUTOMATIC TRANSMISSION (4L30–E)

Range Reference Chart

C07RT010

Page 2159 of 6000

7A–5 AUTOMATIC TRANSMISSION (4L30–E)

Normal Operation Of 1998 4L30–E

Tr a n s m i s s i o n

Torque Converter Clutch (TCC)

Application Conditions:

The TCC is normally applied in 2nd, 3rd and 4th gears

only when all of the following conditions exist:

— The engine coolant temperature is above 70

C

(158

F).

— The brake pedal is released.

— The shift pattern requests TCC apply.

Moreover, TCC is always applied in 2nd, 3rd and 4th

gears when the transmission oil temperature is above

135

C (275F).

This mode should be canceled at 125

C (257F).

ATF Warning Lamp

The ATF warning lamp will be constantly on (not flashing)

if the transmission oil temperature is above 140

C

(284

F).

The ATF warning lamp goes off again when the

transmission oil temperature is below 130

C (266F).

Special Shift Pattern When The Engine Is

Cold:

A special shift pattern is activated when the engine

coolant temperature is below 70

C (158F). (3–4 shifts,

for example, are delayed for small throttle openings and

will occur a few MPH higher.)

Diagnosis

Introduction

The systematic troubleshooting information covered by

this Section offers a practical and systematic approach to

diagnosing 4L30–E transmission, using information that

can be obtained from road tests, electrical diagnosis, oil

pressure checks or noise evaluation.

The key to correcting a complaint is to make use of all of

the available symptoms and logically letting them direct

you to the cause.

When dealing with automatic transmission complaints, it

is best to gather as many symptoms as possible before

making the decision to remove the transmission from the

vehicle.

Frequently, the correction of the complaint does not

require removal of the transmission from the vehicle.

Driver Information

To analyze the problem fill out a complete description of

the owner’s complaint.

Please draw a circle around the right information and

complete the following form. (The next page is an

example of a completed form). You can draw a circle

around many numbers if you are not sure.

Page 2160 of 6000

7A–6

AUTOMATIC TRANSMISSION (4L30–E)

F07RT036

Example of form completed.