oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 795 of 6000

4D2–28

TRANSFER CASE (TOD)

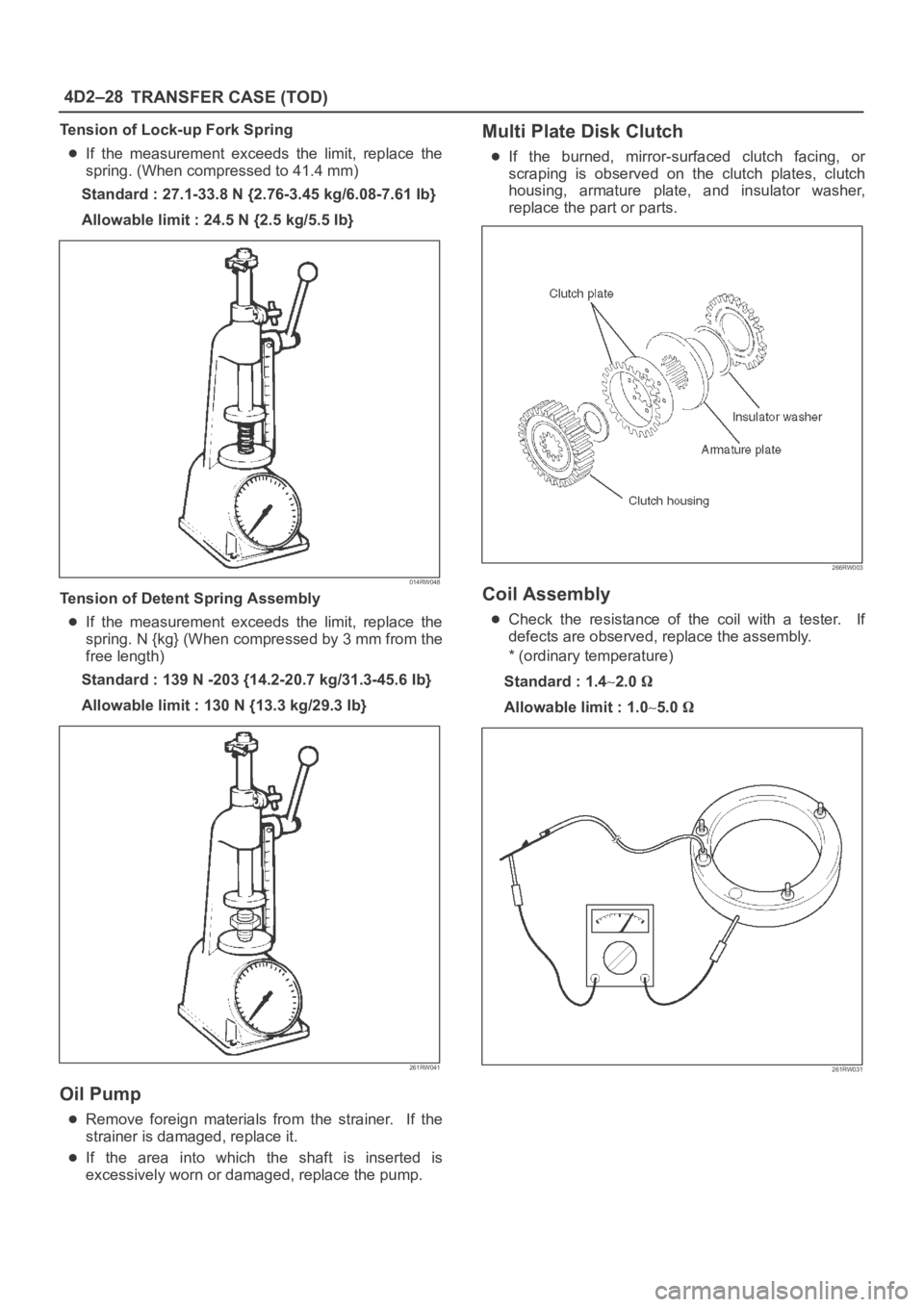

Tension of Lock-up Fork Spring

If the measurement exceeds the limit, replace the

spring. (When compressed to 41.4 mm)

Standard : 27.1-33.8 N {2.76-3.45 kg/6.08-7.61 Ib}

Allowable limit : 24.5 N {2.5 kg/5.5 Ib}

014RW048

Tension of Detent Spring Assembly

If the measurement exceeds the limit, replace the

spring. N {kg} (When compressed by 3 mm from the

free length)

Standard : 139 N -203 {14.2-20.7 kg/31.3-45.6 Ib}

Allowable limit : 130 N {13.3 kg/29.3 Ib}

261RW041

Oil Pump

Remove foreign materials from the strainer. If the

strainer is damaged, replace it.

If the area into which the shaft is inserted is

excessively worn or damaged, replace the pump.

Multi Plate Disk Clutch

If the burned, mirror-surfaced clutch facing, or

scraping is observed on the clutch plates, clutch

housing, armature plate, and insulator washer,

replace the part or parts.

266RW003

Coil Assembly

Check the resistance of the coil with a tester. If

defects are observed, replace the assembly.

* (ordinary temperature)

Standard : 1.4

2.0

Allowable limit : 1.05.0

261RW031

Page 796 of 6000

4D2–29 TRANSFER CASE (TOD)

Cam Pulley, Cam Ball, and Cam&Coil

Housing

Check the cam balls and cam for excessive wear or

damage. If defective, replace the parts. 4H and 4L

switches.

266RW016

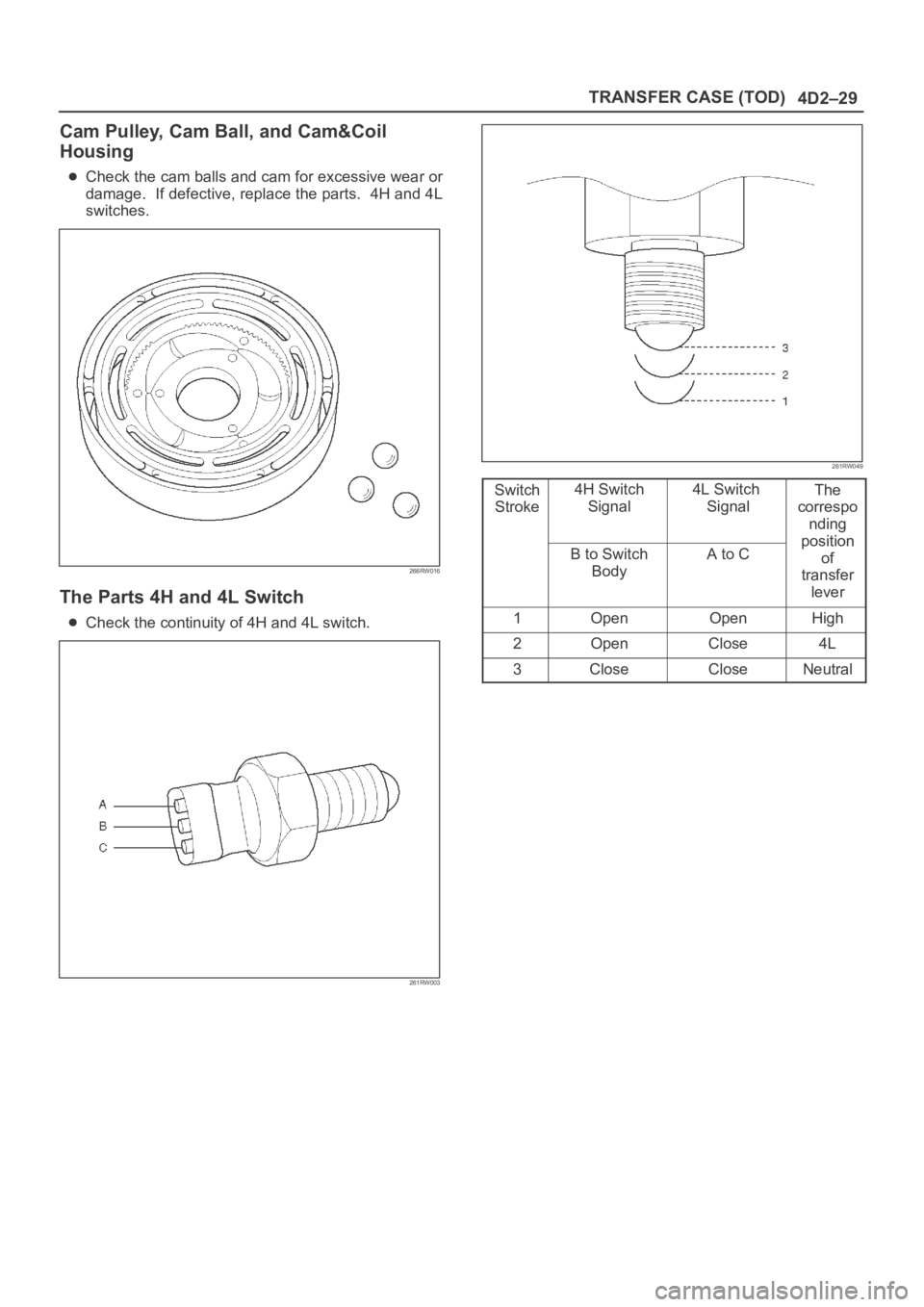

The Parts 4H and 4L Switch

Check the continuity of 4H and 4L switch.

261RW003

261RW049

Switch

Stroke4H Switch

Signal4L Switch

SignalThe

correspo

nding

p

ositionB to Switch

BodyA to Cosition

of

transfer

lever

1OpenOpenHigh

2OpenClose4L

3CloseCloseNeutral

Page 797 of 6000

4D2–30

TRANSFER CASE (TOD)

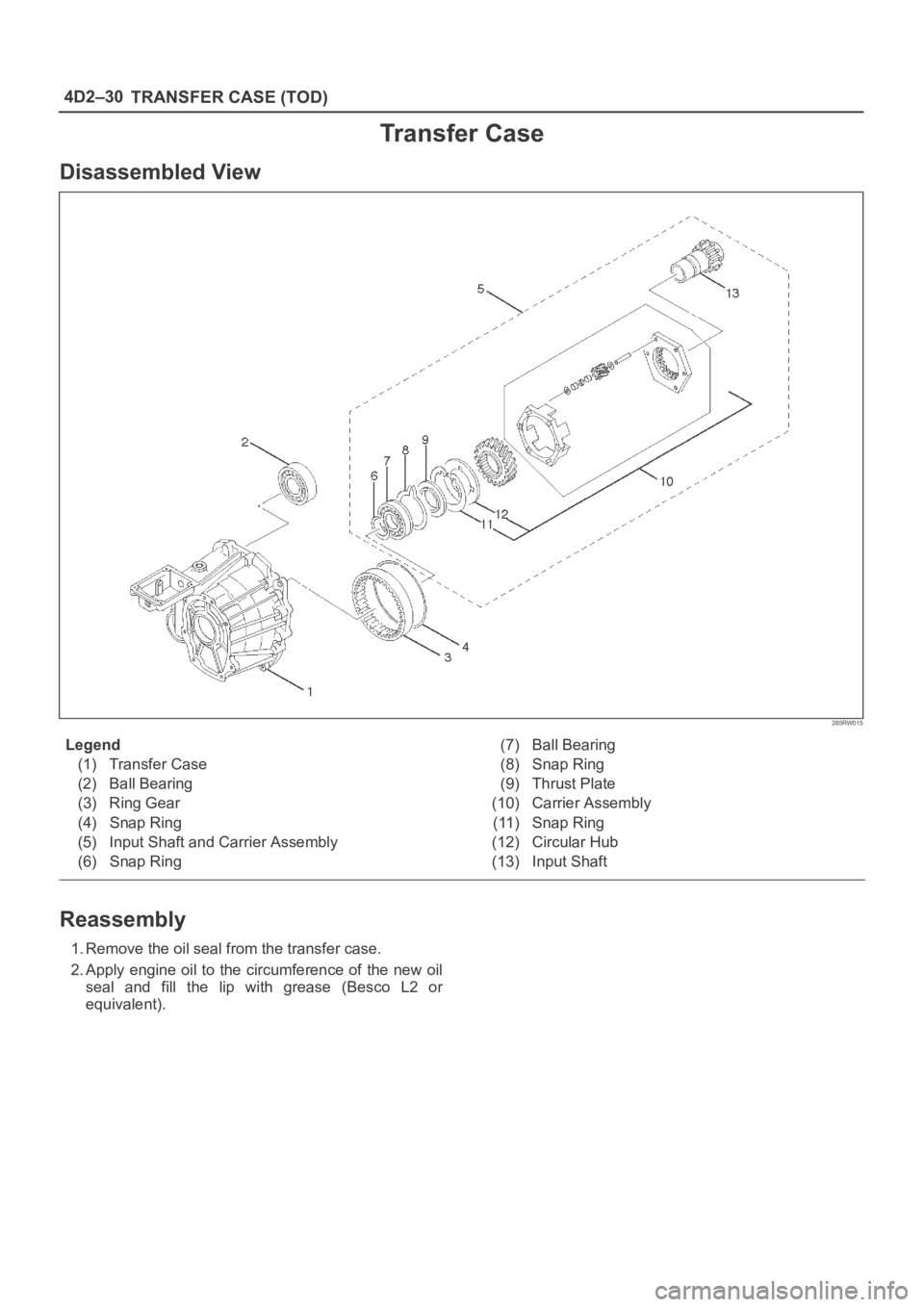

Transfer Case

Disassembled View

265RW015

Legend

(1) Transfer Case

(2) Ball Bearing

(3) Ring Gear

(4) Snap Ring

(5) Input Shaft and Carrier Assembly

(6) Snap Ring(7) Ball Bearing

(8) Snap Ring

(9) Thrust Plate

(10) Carrier Assembly

(11) Snap Ring

(12) Circular Hub

(13) Input Shaft

Reassembly

1. Remove the oil seal from the transfer case.

2. Apply engine oil to the circumference of the new oil

seal and fill the lip with grease (Besco L2 or

equivalent).

Page 798 of 6000

4D2–31 TRANSFER CASE (TOD)

3. Using the front output shaft oil seal installer

5-8840-2410-0 (J-42807), install the oil seal to the

transfer case.

261RW053

Front Output Shaft Oil Seal

Distance between the transfer case end and oil seal.

NOTE: When installing the oil seal to the specified

dimension, be careful not to damage it.

Distance : 0.93 — 1.43mm (0.037 — 0.056 in)

A04RW003

4. Using the input shaft (main) oil seal installer

5-8840-2411-0 (J-42808), install the oil seal to the

transfer case.

261RW055

Input Shaft Oil Seal

Distance between the transfer case end and oil seal.

NOTE: When installing the oil seal to the specified

dimension, be careful not to damage it.

Distance : 3.25 — 3.75mm (0.13 — 0.15 in)

A04RW002

Page 804 of 6000

4D2–37 TRANSFER CASE (TOD)

Sprocket and Mechanical Lock

Disassembled View

266RW008

Legend

(1) Strainer

(2) Hose

(3) Oil Pump Assembly

(4) Thrust Washer

(5) Mechanical Lock Hub

(6) Lock-up Sleeve(7) Lock-up Fork

(8) Chain

(9) Lower Drive Sprocket

(10) Front Tone Wheel

(11) Drive Sprocket

(12) Sprocket Spacer

Reassembly

1. Connect the hose and strainer to the oil pump

assembly.

2. Install the oil pump assembly to the output shaft and

set the magnet to the strainer position.

3. Install the thrust washer.

4. Install the spring to the lock-up fork.

Page 806 of 6000

4D2–39 TRANSFER CASE (TOD)

Clutch Pack and Clutch Cam

Disassembled View

266RW006

Legend

(1) Clutch Pack Assembly

(2) Insulator Washer

(3) Armature Plate

(4) Snap Ring(5) Wave Spring

(6) Cam Pulley

(7) Cam Ball

(8) Cam and Coil Housing

(9) Thrust Bearing

Reassembly

1. Mount the clutch pack assembly to which the multi

plate disk clutch is already installed to the output

shaft.

NOTE: Mount the clutch pack assembly while adjusting

the phase of both the clutch housing and drive sprocket.

2. Install the insulator washer.

3. Install the armature plate.

Page 807 of 6000

4D2–40

TRANSFER CASE (TOD)

4. Using snap ring pliers, install the snap ring.

266RW009

5. Install the wave spring.

6. Install the cam pulley.

7. Place a ball on each groove of the cam pulley.

266RW013

8. Install the cam and coil housing.

9. Install the thrust bearing.

Page 808 of 6000

4D2–41 TRANSFER CASE (TOD)

Main Data and Specifications

Leading Particulars

Ty p eTransfer case with low range reduction mechanism

2H Rear wheel drive

TOD Electronically controlled torque split four wheel drive

4L Low-speed mechanical lock-up four wheel drive

Control systemFloor direct control

Gear ratioH1.000

L2.480

Oil quantity, Lit1.9

OilAT F D E X R O N-IIE or ATF DEXRON-III

Torque Specifications

E04RW012

Page 810 of 6000

4D2–43 TRANSFER CASE (TOD)

Special Tools

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–0133–0

(J–8614–11)

Flange Holder

5–8840–2412–0

(J–42804)

Rear Oil Seal Installer

5–8840–2293–0

(J–39209)

Punch

5–8840–2409–0

(J–42805)

Bearing Remover

5–8840–0084–0

(J–2619–01)

Slide Hammer

5–8840–0015–0

(J–22912–01)

Bearing Remover

ILLUSTRATIONTOOL NO.

TOOL NAME

5–8840–2413–0

(J–42806)

Ring Gear Replacer

5–8840–2410–0

(J–42807)

Front Out Oil Seal

Installer

5–8840–2411–0

(J–42808)

Input Shaft Oil Seal

Installer

5–8840–2416–0

(J–42809)

Ring Gear Installer

Page 814 of 6000

5A–4

BRAKE CONTROL SYSTEM

normal braking when a malfunction has occurred in the

ABS.

The EHCU has a self-diagnosing function which can

indicate faulty circuits during diagnosis.

The EHCU is mounted on the engine compartment front

right side. It consists of a Motor, Plunger Pump, Solenoid

Valves and Check Valve.

On the outside, the relay box containing a motor relay and

a valve relay is installed.

Solenoid Valves: Reduces or holds the caliper fluid

pressure for each front disc brake or both rear disc brakes

according to the signal sent from the EHCU.

Reservoir: Temporarily holds the brake fluid that returns

from the front and rear disc brake caliper so that pressure

of front disc brake caliper can be reduced smoothly.

Plunger Pump: Feeds the brake fluid held in the reservoir

to the master cylinder.

Motor: Drives the pump according to the signal from

EHCU.

Check Valve: Controls the brake fluid flow.

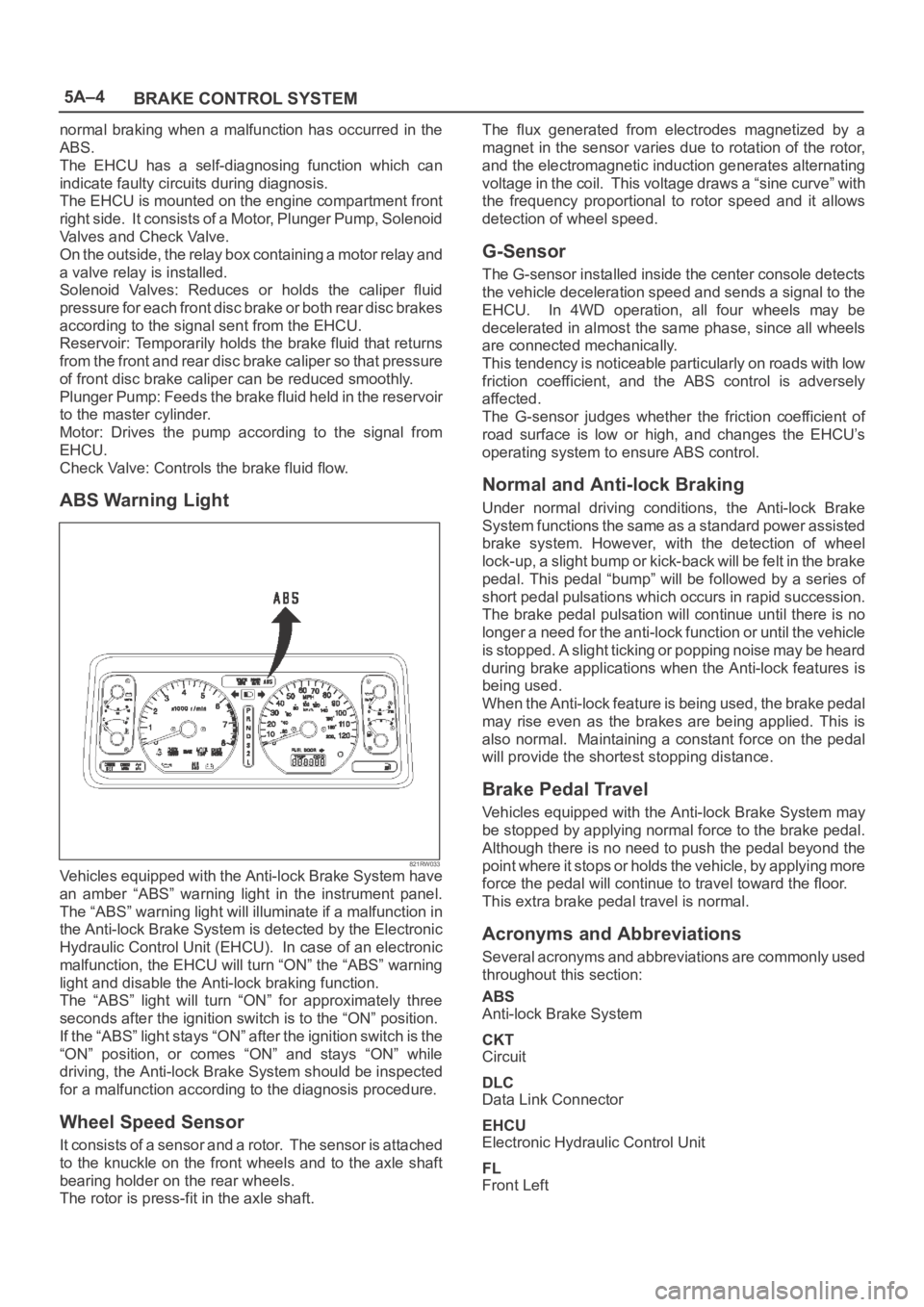

ABS Warning Light

821RW033Vehicles equipped with the Anti-lock Brake System have

an amber “ABS” warning light in the instrument panel.

The “ABS” warning light will illuminate if a malfunction in

the Anti-lock Brake System is detected by the Electronic

Hydraulic Control Unit (EHCU). In case of an electronic

malfunction, the EHCU will turn “ON” the “ABS” warning

light and disable the Anti-lock braking function.

The “ABS” light will turn “ON” for approximately three

seconds after the ignition switch is to the “ON” position.

If the “ABS” light stays “ON” after the ignition switch is the

“ON” position, or comes “ON” and stays “ON” while

driving, the Anti-lock Brake System should be inspected

for a malfunction according to the diagnosis procedure.

Wheel Speed Sensor

It consists of a sensor and a rotor. The sensor is attached

to the knuckle on the front wheels and to the axle shaft

bearing holder on the rear wheels.

The rotor is press-fit in the axle shaft.The flux generated from electrodes magnetized by a

magnet in the sensor varies due to rotation of the rotor,

and the electromagnetic induction generates alternating

voltage in the coil. This voltage draws a “sine curve” with

the frequency proportional to rotor speed and it allows

detection of wheel speed.

G-Sensor

The G-sensor installed inside the center console detects

the vehicle deceleration speed and sends a signal to the

EHCU. In 4WD operation, all four wheels may be

decelerated in almost the same phase, since all wheels

are connected mechanically.

This tendency is noticeable particularly on roads with low

friction coefficient, and the ABS control is adversely

affected.

The G-sensor judges whether the friction coefficient of

road surface is low or high, and changes the EHCU’s

operating system to ensure ABS control.

Normal and Anti-lock Braking

Under normal driving conditions, the Anti-lock Brake

System functions the same as a standard power assisted

brake system. However, with the detection of wheel

lock-up, a slight bump or kick-back will be felt in the brake

pedal. This pedal “bump” will be followed by a series of

short pedal pulsations which occurs in rapid succession.

The brake pedal pulsation will continue until there is no

longer a need for the anti-lock function or until the vehicle

is stopped. A slight ticking or popping noise may be heard

during brake applications when the Anti-lock features is

being used.

When the Anti-lock feature is being used, the brake pedal

may rise even as the brakes are being applied. This is

also normal. Maintaining a constant force on the pedal

will provide the shortest stopping distance.

Brake Pedal Travel

Vehicles equipped with the Anti-lock Brake System may

be stopped by applying normal force to the brake pedal.

Although there is no need to push the pedal beyond the

point where it stops or holds the vehicle, by applying more

force the pedal will continue to travel toward the floor.

This extra brake pedal travel is normal.

Acronyms and Abbreviations

Several acronyms and abbreviations are commonly used

throughout this section:

ABS

Anti-lock Brake System

CKT

Circuit

DLC

Data Link Connector

EHCU

Electronic Hydraulic Control Unit

FL

Front Left