check oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 264 of 6000

Inspection and Repair

Drive Plate

If the frictional surface shows signs of damage due to

excessive heat, the drive plate and pulley should be

replaced.

Pulley Assembly

Check the appearance of the pulley assembly. If the

frictional surface of the pulley shows signs of excessive

grooving due to slippage, both the pulley and drive

plate should be replaced. The frictional surfaces of the

pulley assembly should be cleaned with a suitable

solvent before reinstallation.

Coil

Check coil for loose connector or cracked insulation.

Installation

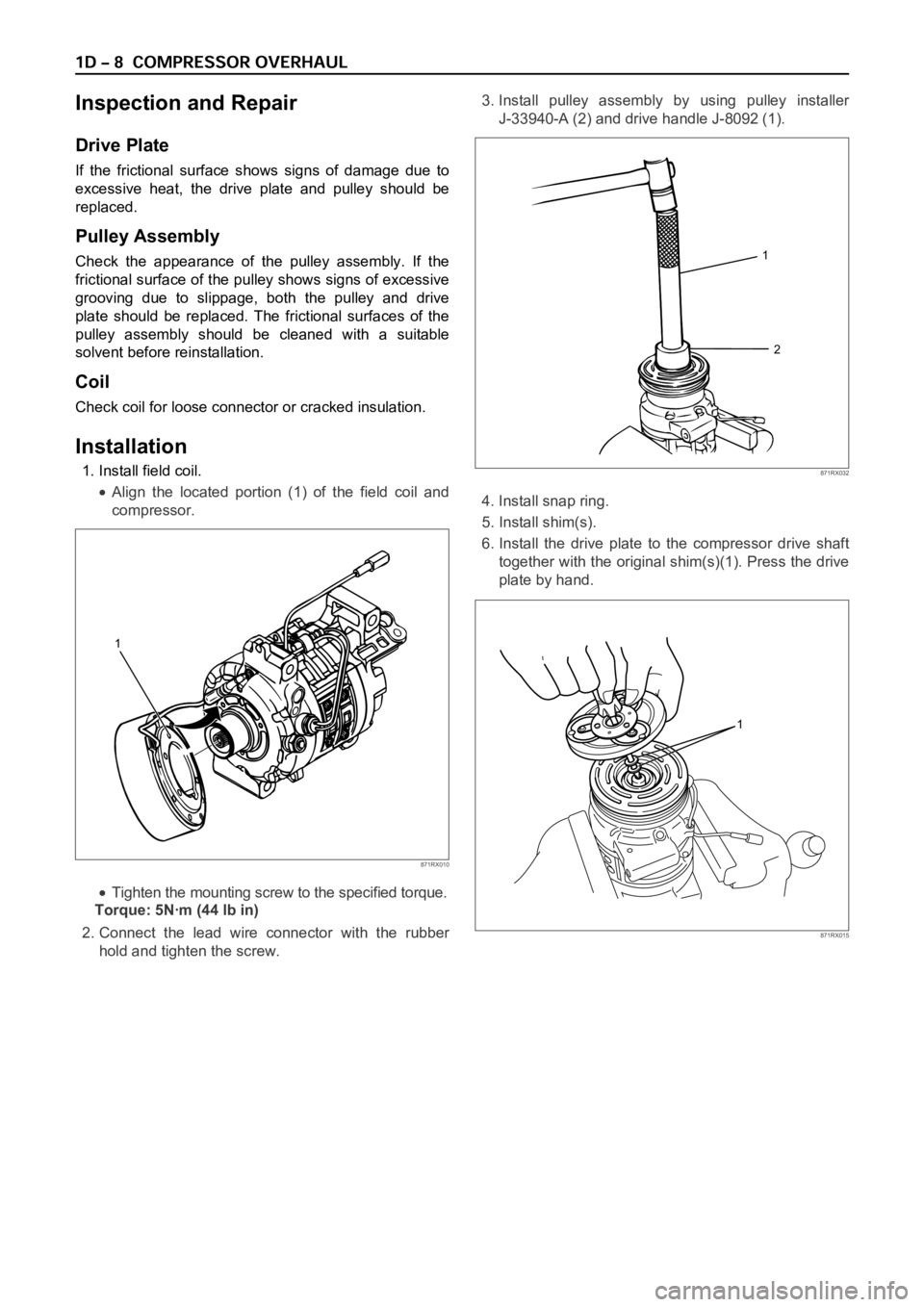

1. Install field coil.

Align the located portion (1) of the field coil and

compressor.

Tighten the mounting screw to the specified torque.

Torque: 5Nꞏm (44 lb in)

2. Connect the lead wire connector with the rubber

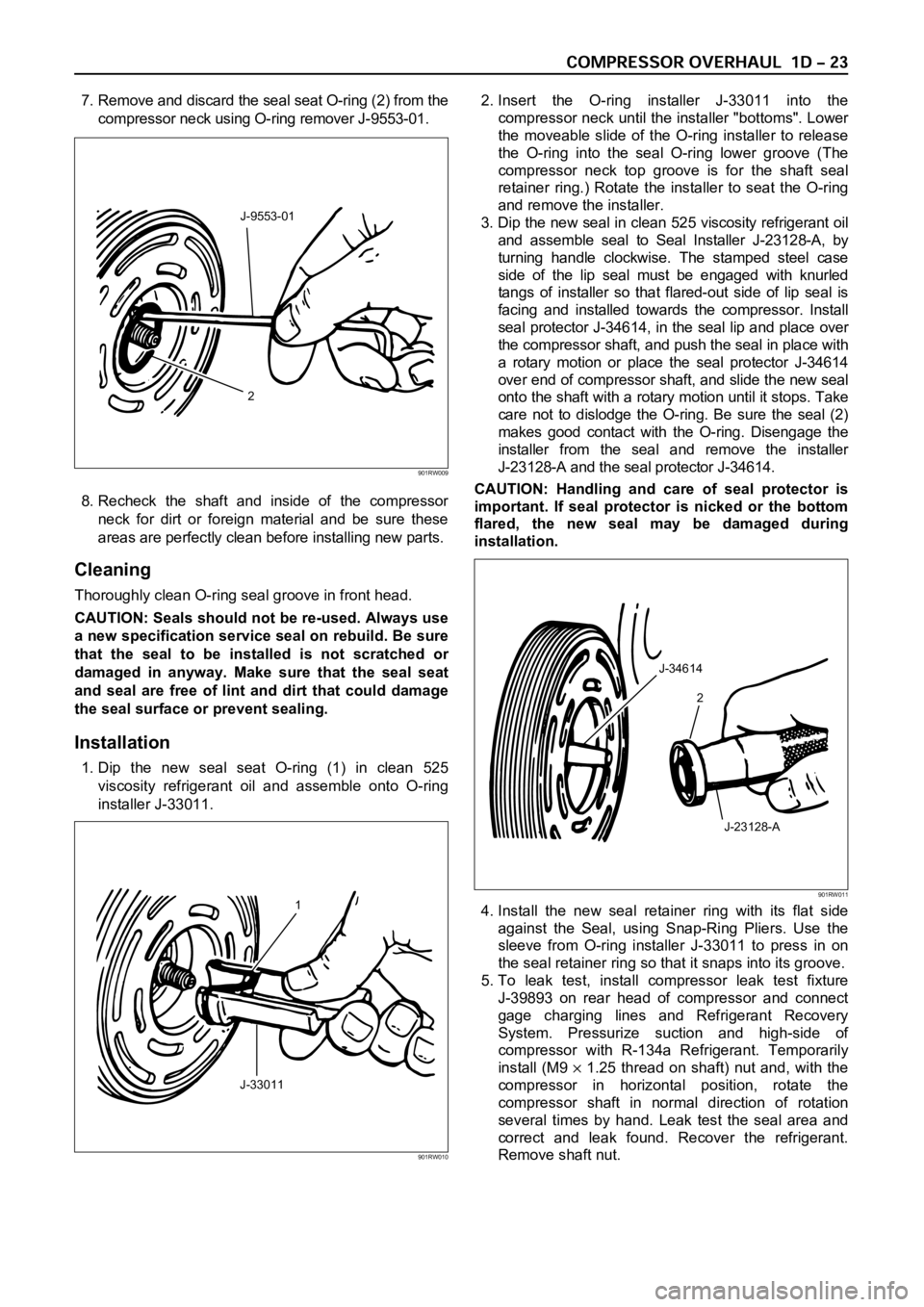

hold and tighten the screw.3. Install pulley assembly by using pulley installer

J-33940-A (2) and drive handle J-8092 (1).

4. Install snap ring.

5. Install shim(s).

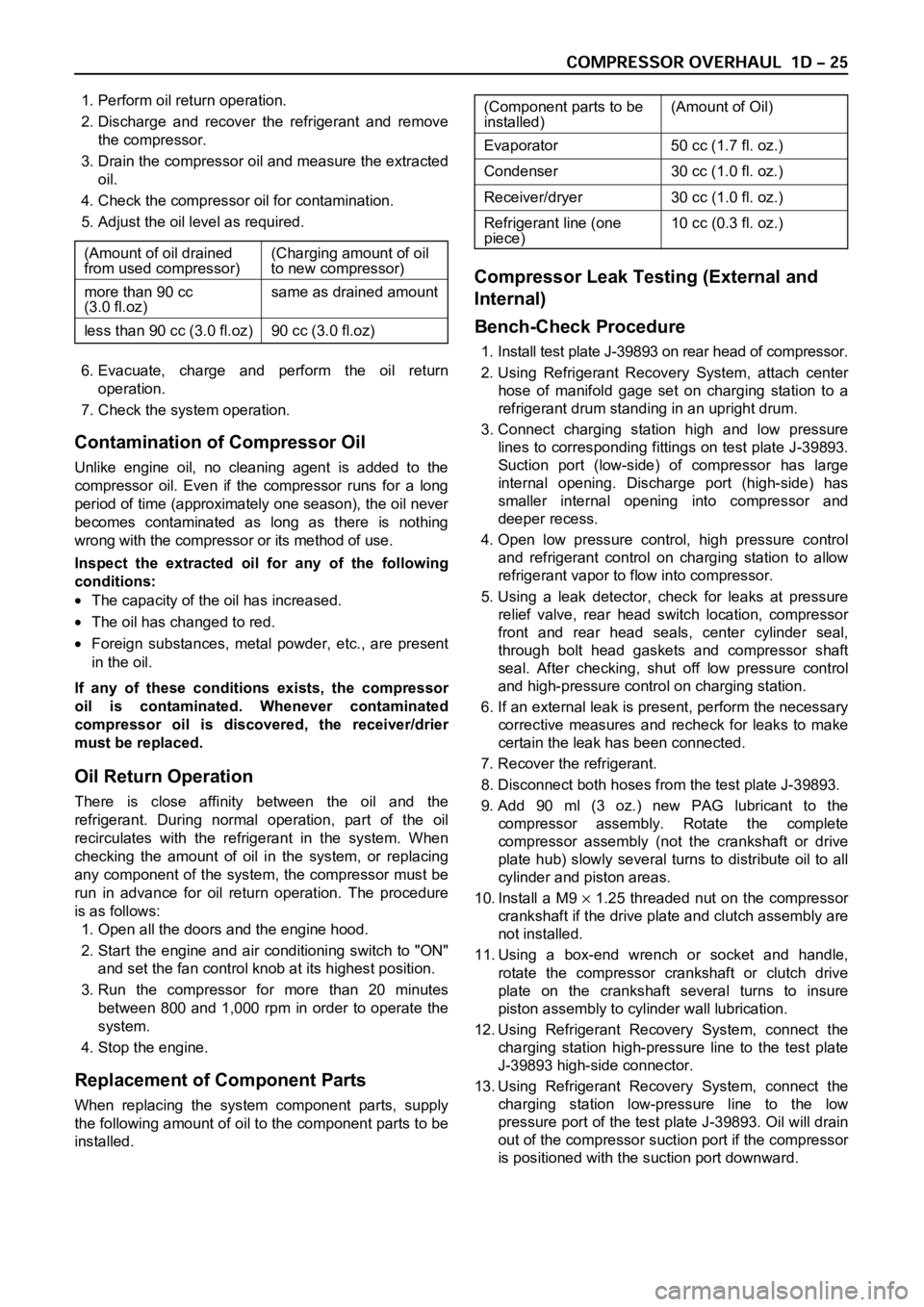

6. Install the drive plate to the compressor drive shaft

together with the original shim(s)(1). Press the drive

plate by hand.

1

2

871RX032

1

871RX010

1

871RX015

Page 279 of 6000

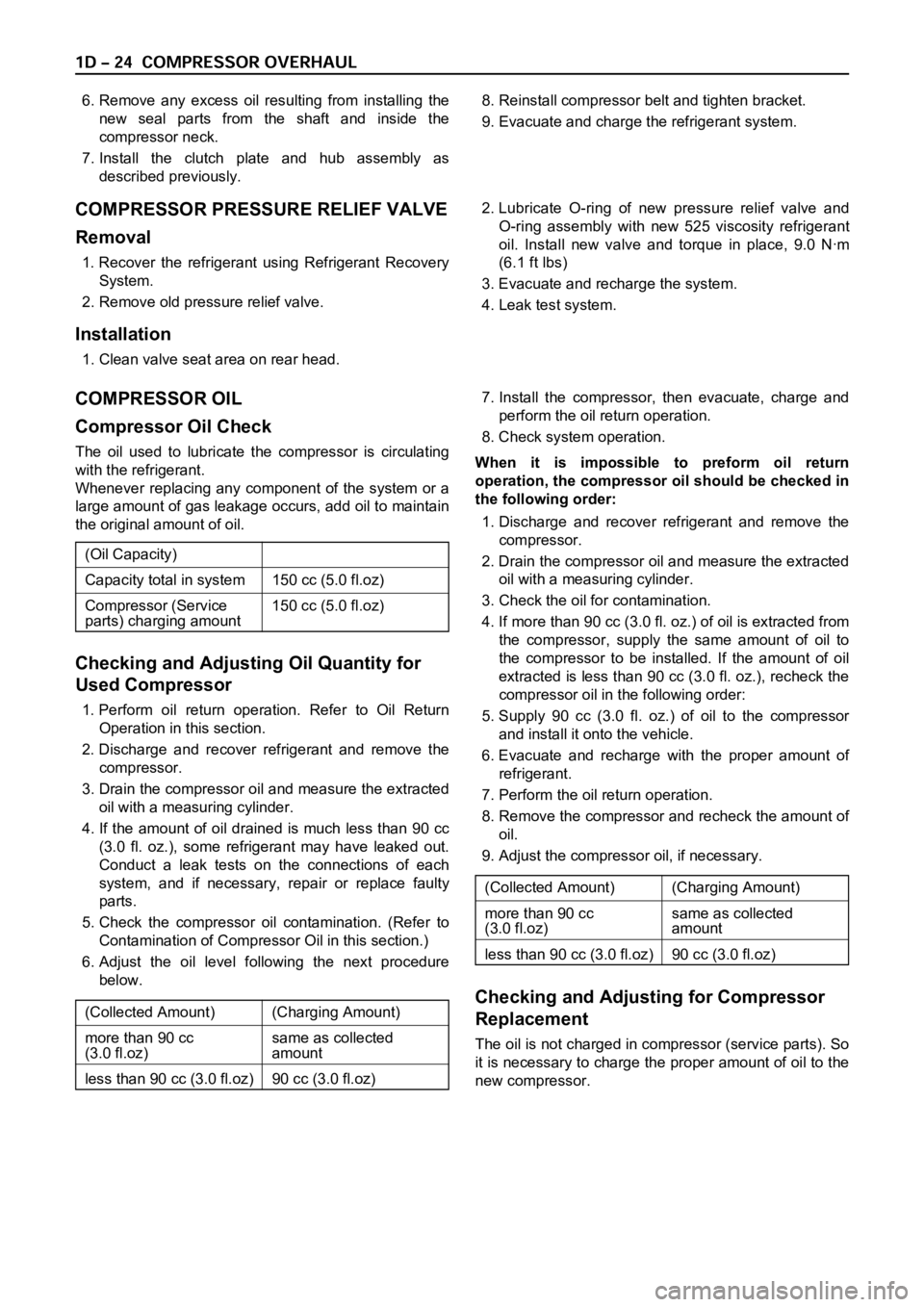

7. Remove and discard the seal seat O-ring (2) from the

compressor neck using O-ring remover J-9553-01.

8. Recheck the shaft and inside of the compressor

neck for dirt or foreign material and be sure these

areas are perfectly clean before installing new parts.

Cleaning

Thoroughly clean O-ring seal groove in front head.

CAUTION: Seals should not be re-used. Always use

a new specification service seal on rebuild. Be sure

that the seal to be installed is not scratched or

damaged in anyway. Make sure that the seal seat

and seal are free of lint and dirt that could damage

the seal surface or prevent sealing.

Installation

1. Dip the new seal seat O-ring (1) in clean 525

viscosity refrigerant oil and assemble onto O-ring

installer J-33011.2. Insert the O-ring installer J-33011 into the

compressor neck until the installer "bottoms". Lower

the moveable slide of the O-ring installer to release

the O-ring into the seal O-ring lower groove (The

compressor neck top groove is for the shaft seal

retainer ring.) Rotate the installer to seat the O-ring

and remove the installer.

3. Dip the new seal in clean 525 viscosity refrigerant oil

and assemble seal to Seal Installer J-23128-A, by

turning handle clockwise. The stamped steel case

side of the lip seal must be engaged with knurled

tangs of installer so that flared-out side of lip seal is

facing and installed towards the compressor. Install

seal protector J-34614, in the seal lip and place over

the compressor shaft, and push the seal in place with

a rotary motion or place the seal protector J-34614

over end of compressor shaft, and slide the new seal

onto the shaft with a rotary motion until it stops. Take

care not to dislodge the O-ring. Be sure the seal (2)

makes good contact with the O-ring. Disengage the

installer from the seal and remove the installer

J-23128-A and the seal protector J-34614.

CAUTION: Handling and care of seal protector is

important. If seal protector is nicked or the bottom

flared, the new seal may be damaged during

installation.

4. Install the new seal retainer ring with its flat side

against the Seal, using Snap-Ring Pliers. Use the

sleeve from O-ring installer J-33011 to press in on

the seal retainer ring so that it snaps into its groove.

5. To leak test, install compressor leak test fixture

J-39893 on rear head of compressor and connect

gage charging lines and Refrigerant Recovery

System. Pressurize suction and high-side of

compressor with R-134a Refrigerant. Temporarily

install (M9

1.25 thread on shaft) nut and, with the

compressor in horizontal position, rotate the

compressor shaft in normal direction of rotation

several times by hand. Leak test the seal area and

correct and leak found. Recover the refrigerant.

Remove shaft nut.

2 J-9553-01

901RW009

1

J-33011

901RW010

J-34614

2

J-23128-A

901RW011

Page 280 of 6000

6. Remove any excess oil resulting from installing the

new seal parts from the shaft and inside the

compressor neck.

7. Install the clutch plate and hub assembly as

described previously.8. Reinstall compressor belt and tighten bracket.

9. Evacuate and charge the refrigerant system.

COMPRESSOR PRESSURE RELIEF VALVE

Removal

1. Recover the refrigerant using Refrigerant Recovery

System.

2. Remove old pressure relief valve.

Installation

1. Clean valve seat area on rear head.2. Lubricate O-ring of new pressure relief valve and

O-ring assembly with new 525 viscosity refrigerant

oil. Install new valve and torque in place, 9.0 Nꞏm

(6.1 ft lbs)

3. Evacuate and recharge the system.

4. Leak test system.

COMPRESSOR OIL

Compressor Oil Check

The oil used to lubricate the compressor is circulating

with the refrigerant.

Whenever replacing any component of the system or a

large amount of gas leakage occurs, add oil to maintain

the original amount of oil.

Checking and Adjusting Oil Quantity for

Used Compressor

1. Perform oil return operation. Refer to Oil Return

Operation in this section.

2. Discharge and recover refrigerant and remove the

compressor.

3. Drain the compressor oil and measure the extracted

oil with a measuring cylinder.

4. If the amount of oil drained is much less than 90 cc

(3.0 fl. oz.), some refrigerant may have leaked out.

Conduct a leak tests on the connections of each

system, and if necessary, repair or replace faulty

parts.

5. Check the compressor oil contamination. (Refer to

Contamination of Compressor Oil in this section.)

6. Adjust the oil level following the next procedure

below.7. Install the compressor, then evacuate, charge and

perform the oil return operation.

8. Check system operation.

When it is impossible to preform oil return

operation, the compressor oil should be checked in

the following order:

1. Discharge and recover refrigerant and remove the

compressor.

2. Drain the compressor oil and measure the extracted

oil with a measuring cylinder.

3. Check the oil for contamination.

4. If more than 90 cc (3.0 fl. oz.) of oil is extracted from

the compressor, supply the same amount of oil to

the compressor to be installed. If the amount of oil

extracted is less than 90 cc (3.0 fl. oz.), recheck the

compressor oil in the following order:

5. Supply 90 cc (3.0 fl. oz.) of oil to the compressor

and install it onto the vehicle.

6. Evacuate and recharge with the proper amount of

refrigerant.

7. Perform the oil return operation.

8. Remove the compressor and recheck the amount of

oil.

9. Adjust the compressor oil, if necessary.

Checking and Adjusting for Compressor

Replacement

The oil is not charged in compressor (service parts). So

it is necessary to charge the proper amount of oil to the

new compressor. (Oil Capacity)

Capacity total in system 150 cc (5.0 fl.oz)

Compressor (Service 150 cc (5.0 fl.oz)

parts) charging amount

(Collected Amount) (Charging Amount)

more than 90 cc same as collected

(3.0 fl.oz) amount

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

(Collected Amount) (Charging Amount)

more than 90 cc same as collected

(3.0 fl.oz) amount

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

Page 281 of 6000

1. Perform oil return operation.

2. Discharge and recover the refrigerant and remove

the compressor.

3. Drain the compressor oil and measure the extracted

oil.

4. Check the compressor oil for contamination.

5. Adjust the oil level as required.

6. Evacuate, charge and perform the oil return

operation.

7. Check the system operation.

Contamination of Compressor Oil

Unlike engine oil, no cleaning agent is added to the

compressor oil. Even if the compressor runs for a long

period of time (approximately one season), the oil never

becomes contaminated as long as there is nothing

wrong with the compressor or its method of use.

Inspect the extracted oil for any of the following

conditions:

The capacity of the oil has increased.

The oil has changed to red.

Foreign substances, metal powder, etc., are present

in the oil.

If any of these conditions exists, the compressor

oil is contaminated. Whenever contaminated

compressor oil is discovered, the receiver/drier

must be replaced.

Oil Return Operation

There is close affinity between the oil and the

refrigerant. During normal operation, part of the oil

recirculates with the refrigerant in the system. When

checking the amount of oil in the system, or replacing

any component of the system, the compressor must be

run in advance for oil return operation. The procedure

is as follows:

1. Open all the doors and the engine hood.

2. Start the engine and air conditioning switch to "ON"

and set the fan control knob at its highest position.

3. Run the compressor for more than 20 minutes

between 800 and 1,000 rpm in order to operate the

system.

4. Stop the engine.

Replacement of Component Parts

When replacing the system component parts, supply

the following amount of oil to the component parts to be

installed.

Compressor Leak Testing (External and

Internal)

Bench-Check Procedure

1. Install test plate J-39893 on rear head of compressor.

2. Using Refrigerant Recovery System, attach center

hose of manifold gage set on charging station to a

refrigerant drum standing in an upright drum.

3. Connect charging station high and low pressure

lines to corresponding fittings on test plate J-39893.

Suction port (low-side) of compressor has large

internal opening. Discharge port (high-side) has

smaller internal opening into compressor and

deeper recess.

4. Open low pressure control, high pressure control

and refrigerant control on charging station to allow

refrigerant vapor to flow into compressor.

5. Using a leak detector, check for leaks at pressure

relief valve, rear head switch location, compressor

front and rear head seals, center cylinder seal,

through bolt head gaskets and compressor shaft

seal. After checking, shut off low pressure control

and high-pressure control on charging station.

6. If an external leak is present, perform the necessary

corrective measures and recheck for leaks to make

certain the leak has been connected.

7. Recover the refrigerant.

8. Disconnect both hoses from the test plate J-39893.

9. Add 90 ml (3 oz.) new PAG lubricant to the

compressor assembly. Rotate the complete

compressor assembly (not the crankshaft or drive

plate hub) slowly several turns to distribute oil to all

cylinder and piston areas.

10. Install a M9

1.25 threaded nut on the compressor

crankshaft if the drive plate and clutch assembly are

not installed.

11. Using a box-end wrench or socket and handle,

rotate the compressor crankshaft or clutch drive

plate on the crankshaft several turns to insure

piston assembly to cylinder wall lubrication.

12. Using Refrigerant Recovery System, connect the

charging station high-pressure line to the test plate

J-39893 high-side connector.

13. Using Refrigerant Recovery System, connect the

charging station low-pressure line to the low

pressure port of the test plate J-39893. Oil will drain

out of the compressor suction port if the compressor

is positioned with the suction port downward. (Component parts to be (Amount of Oil)

installed)

Evaporator 50 cc (1.7 fl. oz.)

Condenser 30 cc (1.0 fl. oz.)

Receiver/dryer 30 cc (1.0 fl. oz.)

Refrigerant line (one 10 cc (0.3 fl. oz.)

piece)

(Amount of oil drained (Charging amount of oil

from used compressor) to new compressor)

more than 90 cc same as drained amount

(3.0 fl.oz)

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

Page 282 of 6000

14. Attach the compressor to the J-34992 holding

fixture and mount the compressor in a vise so that

the compressor will be in a horizontal position and

the shaft can be turned with a wrench.

15. Using a wrench, rotate the compressor crankshaft

or drive plate hub ten complete revolutions at a

speed of approximately one-revolution per second

turning the compressor at less than one-revolution

per second can result in a lower pump-up pressure

and disqualify a good pumping compressor.

16. Observe the reading on high-pressure gauge at the

completion of the tenth revolution of the

compressor. The pressure reading for a good

pumping compressor should be 690 kPa (100 psi)

or above. A pressure reading of less than 620 kPa

(90 psi) would indicate one or more suction and/or

discharge valves leaking an internal leak, or an

inoperative valve, and the refrigerant must be

recovered and the compressor disassembled and

checked for cause of leak. Repair as needed,

reassemble and repeat the pump-up test. Externally

leak test.

17. When the pressure pump-up test is completed,

recover the refrigerant from the high-side and

remove the test plate J-39893.

18. Tilt the compressor so that the compressor suction

and discharge ports are down. Drain the PAG

lubricant from the compressor.

19. Allow the compressor to drain for 10 minutes, then

refill with the proper amount of PAG lubricant, per

oil balance procedure described previously. The

PAG lubricant may be poured into the suction port.

If further assembly or processing is required, a

shipping plate or test plate J-39893 should be

installed to keep out air, dirt and moisture until the

compressor is installed.

Page 441 of 6000

DIFFERENTIAL (FRONT) 4A1–4

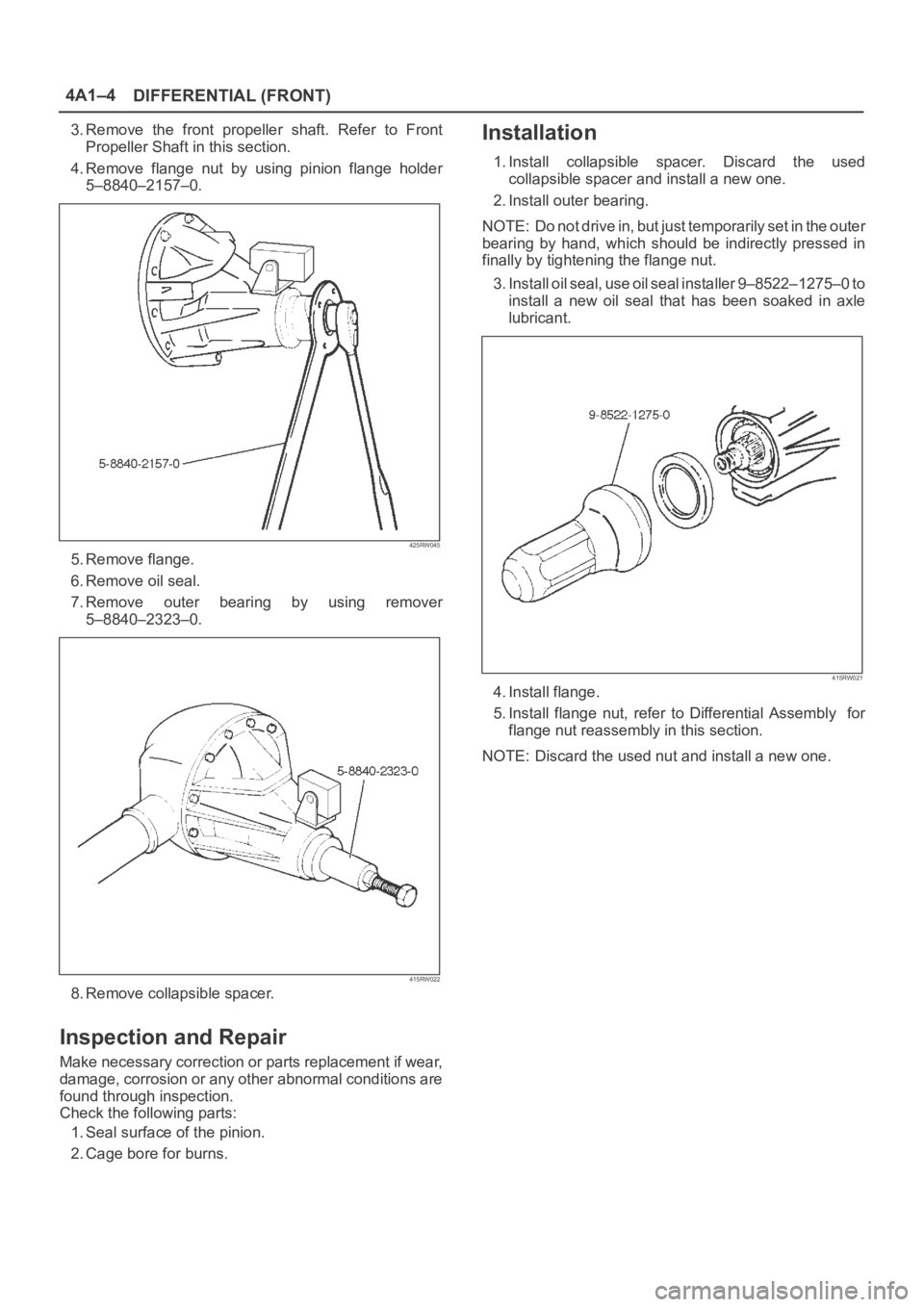

3. Remove the front propeller shaft. Refer to Front

Propeller Shaft in this section.

4. Remove flange nut by using pinion flange holder

5–8840–2157–0.

425RW045

5. Remove flange.

6. Remove oil seal.

7. Remove outer bearing by using remover

5–8840–2323–0.

415RW022

8. Remove collapsible spacer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

1. Seal surface of the pinion.

2. Cage bore for burns.

Installation

1. Install collapsible spacer. Discard the used

collapsible spacer and install a new one.

2. Install outer bearing.

NOTE: Do not drive in, but just temporarily set in the outer

bearing by hand, which should be indirectly pressed in

finally by tightening the flange nut.

3. Install oil seal, use oil seal installer 9–8522–1275–0 to

install a new oil seal that has been soaked in axle

lubricant.

415RW021

4. Install flange.

5. Install flange nut, refer to Differential Assembly for

flange nut reassembly in this section.

NOTE: Discard the used nut and install a new one.

Page 459 of 6000

DIFFERENTIAL (FRONT) 4A1–22

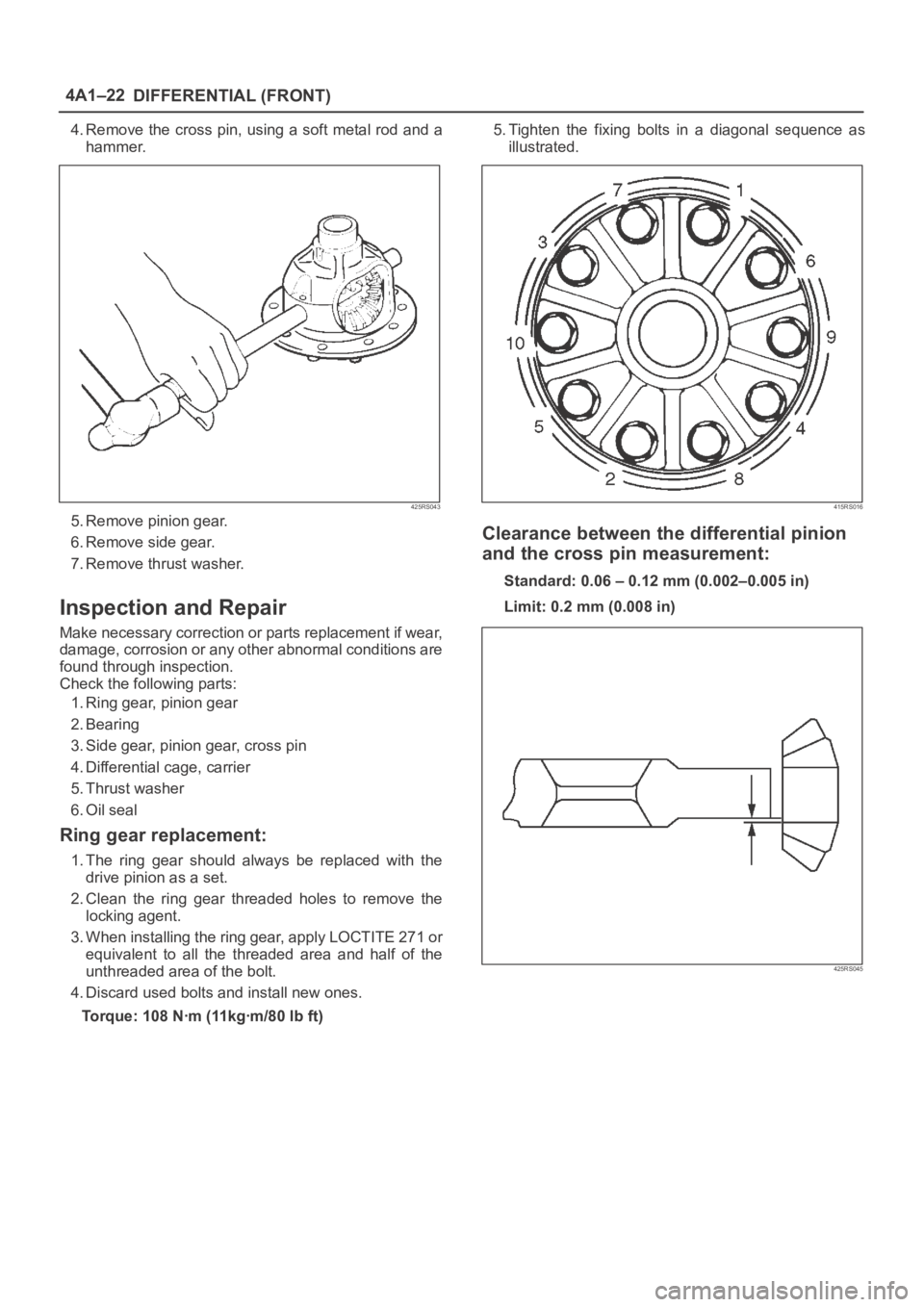

4. Remove the cross pin, using a soft metal rod and a

hammer.

425RS043

5. Remove pinion gear.

6. Remove side gear.

7. Remove thrust washer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

1. Ring gear, pinion gear

2. Bearing

3. Side gear, pinion gear, cross pin

4. Differential cage, carrier

5. Thrust washer

6. Oil seal

Ring gear replacement:

1. The ring gear should always be replaced with the

drive pinion as a set.

2. Clean the ring gear threaded holes to remove the

locking agent.

3. When installing the ring gear, apply LOCTITE 271 or

equivalent to all the threaded area and half of the

unthreaded area of the bolt.

4. Discard used bolts and install new ones.

Torque: 108 Nꞏm (11kgꞏm/80 lb ft)5. Tighten the fixing bolts in a diagonal sequence as

illustrated.

415RS016

Clearance between the differential pinion

and the cross pin measurement:

Standard: 0.06 – 0.12 mm (0.002–0.005 in)

Limit: 0.2 mm (0.008 in)

425RS045

Page 474 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–7

3. Remove flange nut and washer by using pinion flange

holder 5–8840–2157–0 after raising up its staked

parts completely.

415RW028

4. Remove flange.

5. Remove oil seal.

6. Remove outer bearing by using remover

5–8840–2323–0.

425RW066

7. Remove collapsible spacer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

1. Seal surface of the pinion.

2. Cage bore for burns.

Installation

1. Install collapsible spacer, discard the used collapsible

spacer and install a new one.

2. Install outer bearing.

NOTE: Do not drive in, but just temporarily set in the outer

bearing by hand, which should be indirectly pressed in

finally by tightening the flange nut.

3. By using the seal installer 5–8840–2165–0, install a

new oil seal (1) that has grease on seal lip.

425RW050

4. Install flange.

5. Install flange nut and washer. Refer to Differential

Assembly in this section for flange nut reassembly.

NOTE: Discard the used nut and install a new one.

Page 489 of 6000

4A2A–22

DIFFERENTIAL (REAR 220mm)

4. Remove the cross pin, using a soft metal rod and a

hammer.

425RS043

5. Remove pinion gear.

6. Remove side gear.

7. Remove thrust washer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

1. Ring gear, pinion gear

2. Bearing

3. Side gear, pinion gear, cross pin

4. Differential cage, carrier

5. Thrust washer

6. Oil seal

Ring gear replacement:

1. The ring gear should always be replaced with the

drive pinion as a set.

2. Clean the ring gear threaded holes to remove the

locking agent.

3. When installing the ring gear, apply LOCTITE 271 or

equivalent to all the threaded area and half of the

unthreaded area of the bolt.

4. Discard used bolts and install new ones.

Torque: 108 Nꞏm (11.0kgꞏm/80 lb ft)5. Tighten the fixing bolts in a diagonal sequence as

illustrated.

415RW036

Clearance between the differential pinion

and the cross pin measurement:

Standard: 0.06 – 0.12 mm (0.002–0.005 in)

Limit: 0.2 mm (0.008 in)

425RS045

Page 510 of 6000

DIFFERENTIAL (REAR 244mm)

4A2B–7

3. Remove flange nut and washer by using pinion flange

holder 5–8840–0133–0 after raising up its staked

parts completely.

415RW040

4. Remove flange.

5. Remove oil seal.

6. Remove outer bearing by using remover

5–8840–2323–0.

425RW066

7. Remove collapsible spacer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

1. Seal surface of the pinion.

2. Cage bore for burns.

Installation

1. Install collapsible spacer, discard the used collapsible

spacer and install a new one.

2. Install outer bearing.

NOTE: Do not drive in, but just temporarily set in the outer

bearing by hand, which should be indirectly pressed in

finally by tightening the flange nut.

3. By using the seal installer 5–8840–2165–0, install a

new oil seal (1) that has grease on seal lip.

425RW050

4. Install flange.

5. Install flange nut and washer. Refer to Differential

Assembly in this section for flange nut reassembly.

NOTE: Discard the used nut and install a new one.