check oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2002 of 6000

6E–109 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1217 (Flash DTC 36)

High Oil Temp Warning

060RW129

Circuit Description

The engine oil temperature (OT) sensor is a thermistor

mounted on a oil manifold. The Engine Control Module

ECM applies a voltage (about 5 volts) through a pull-up

resistor to the OT signal circuit. When the engine oil is

cold, the sensor (thermistor) resistance is high, therefore

the ECM will measure a high signal voltage. As the

engine oil warms, the sensor resistance becomes lower,

and the OT signal voltage measured at the ECM drops.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1217 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage.

High Oil Temperature Warning may sometimes be

given due to High Coolant Temp Warning. On this

occasion, recognize DTC P0217 and give priority to

High Coolant Temp Warning.

Page 2003 of 6000

6E–110

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P1217 – High Oil Temp Warning

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Observe the “Eng Cool Temp” display on the Tech 2.

Is the “Eng Cool Temp” below the specified value?

139C

(282

F)Go to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Using a Tech 2, monitor “ DTC” info for DTC P0217.

Does the Tech 2 indicate DTC P0217 failed this

ignition?

—Go to Step 4

Refer to

Diagnostic

Aids

41. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “ DTC” info for DTC P1217.

Does the Tech 2 indicate DTC P1217 failed this

ignition?

—Go to Step 5

Refer to

Diagnostic

Aids

51. Measure the engine oil quantity by oil level gage.

2. If the engine oil is shortage, fill up it as necessary.

Was the engine oil is shortaged?

—Verify repairGo to Step 6

6Replace the oil temp sensor.

Is the action complete?

—Verify repairGo to Step 7

7Replace the oil cooler.

Is the action complete?

—Verify repair—

Page 2010 of 6000

6E–117 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0337 – CKP Sensor No Signal

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Attempt to start the engine.

Does the engine start?

—Go to Step 3Go to Chart 3

31. Review and record Failure Records information.

2. Clear DTC P0337.

3. Start the engine and idle for 1 minute.

4. Observe DTCs.

Is DTC P0337 set?

—Go to Step 4

Refer to

Diagnostic

Aid

41. Disconnect the CKP sensor.

2. Ignition “ON.”

3. Using a DVM, verify that 5 V reference and ground

are being supplied at the sensor connector (ECM

side).

Are 4-6 volts and ground available at the sensor?

—Go to Step 7Go to Step 5

51. Ignition “ON.”

2. With a DVM, backprobe the ECM connector 5 V

reference and ground connections.

Are 5 V reference and ground available at the ECM?

—Go to Step 6Go to Step 11

6Check 5 V reference or ground between the CKP

sensor and ECM and repair the open circuit, short to

ground or short to voltage.

Is the action complete?

—Verify repair—

71. Ignition “OFF.”

2. Disconnect the ECM and CKP sensor.

3. Check for an open or a short to ground in the CKP

reference circuit between the CKP sensor

connector and the ECM harness connector.

4. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

81. Reconnect the ECM and CKP sensor.

2. Connect a DVM to measure voltage on the CKP

reference circuit at the ECM connector.

3. Observe the voltage while cranking the engine.

Is the voltage near the specified value?

2.5 VGo to Step 11Go to Step 9

9Check the connections at the CKP sensor and replace

the terminals if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 10

10Replace the CKP sensor. Use caution and avoid hot oil

that may drip out.

Is the action complete?

—Verify repair—

Page 2070 of 6000

6E–177 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

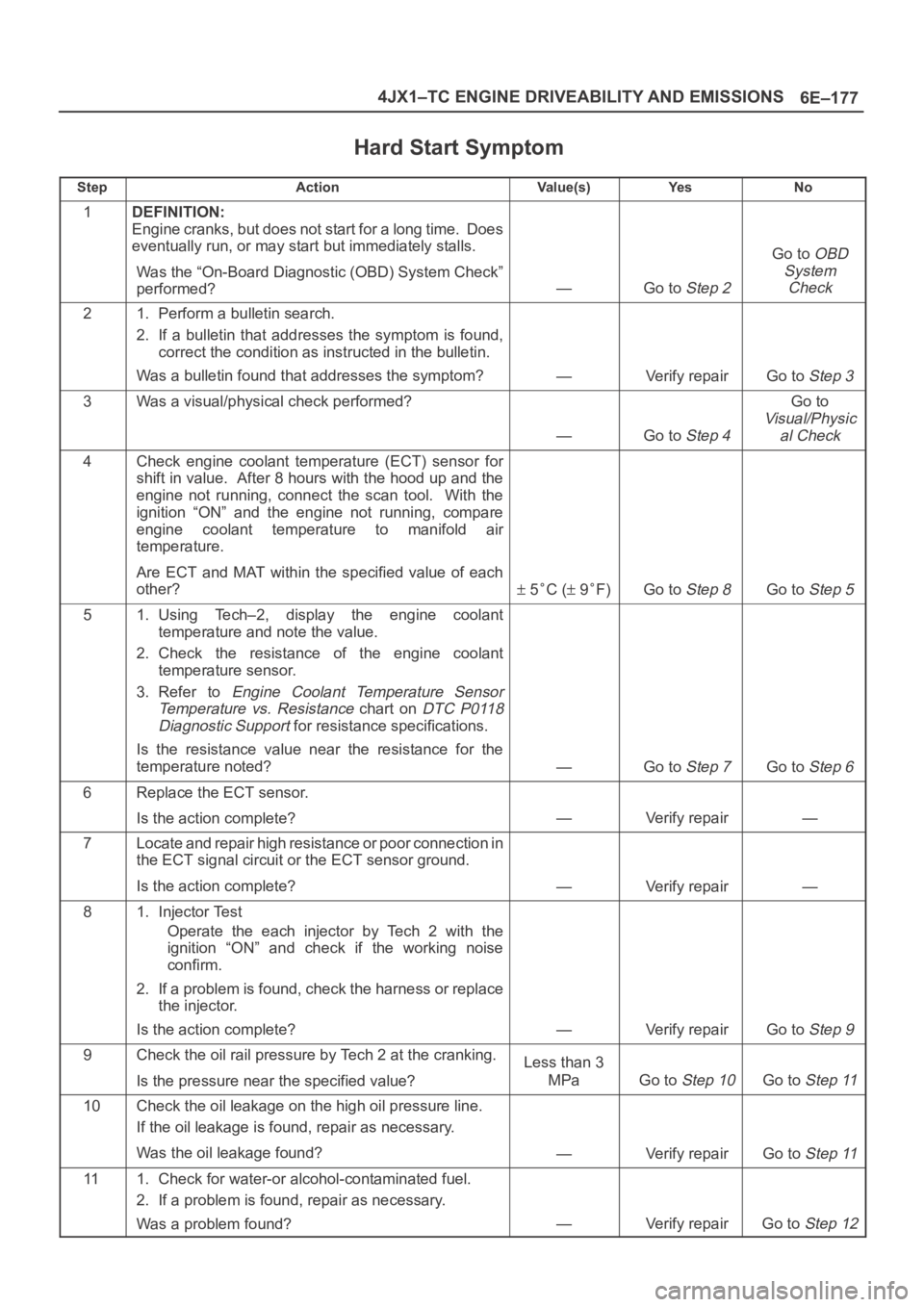

Hard Start Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Engine cranks, but does not start for a long time. Does

eventually run, or may start but immediately stalls.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to

Visual/Physic

al Check

4Check engine coolant temperature (ECT) sensor for

shift in value. After 8 hours with the hood up and the

engine not running, connect the scan tool. With the

ignition “ON” and the engine not running, compare

engine coolant temperature to manifold air

temperature.

Are ECT and MAT within the specified value of each

other?

5C ( 9F)Go to Step 8Go to Step 5

51. Using Tech–2, display the engine coolant

temperature and note the value.

2. Check the resistance of the engine coolant

temperature sensor.

3. Refer to

Engine Coolant Temperature Sensor

Temperature vs. Resistance

chart on DTC P0118

Diagnostic Support

for resistance specifications.

Is the resistance value near the resistance for the

temperature noted?

—Go to Step 7Go to Step 6

6Replace the ECT sensor.

Is the action complete?

—Verify repair—

7Locate and repair high resistance or poor connection in

the ECT signal circuit or the ECT sensor ground.

Is the action complete?

—Verify repair—

81. Injector Test

Operate the each injector by Tech 2 with the

ignition “ON” and check if the working noise

confirm.

2. If a problem is found, check the harness or replace

the injector.

Is the action complete?

—Verify repairGo to Step 9

9Check the oil rail pressure by Tech 2 at the cranking.

Is the pressure near the specified value?Less than 3

MPa

Go to Step 10Go to Step 11

10Check the oil leakage on the high oil pressure line.

If the oil leakage is found, repair as necessary.

Was the oil leakage found?

—Verify repairGo to Step 11

111. Check for water-or alcohol-contaminated fuel.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 12

Page 2078 of 6000

6E–185 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

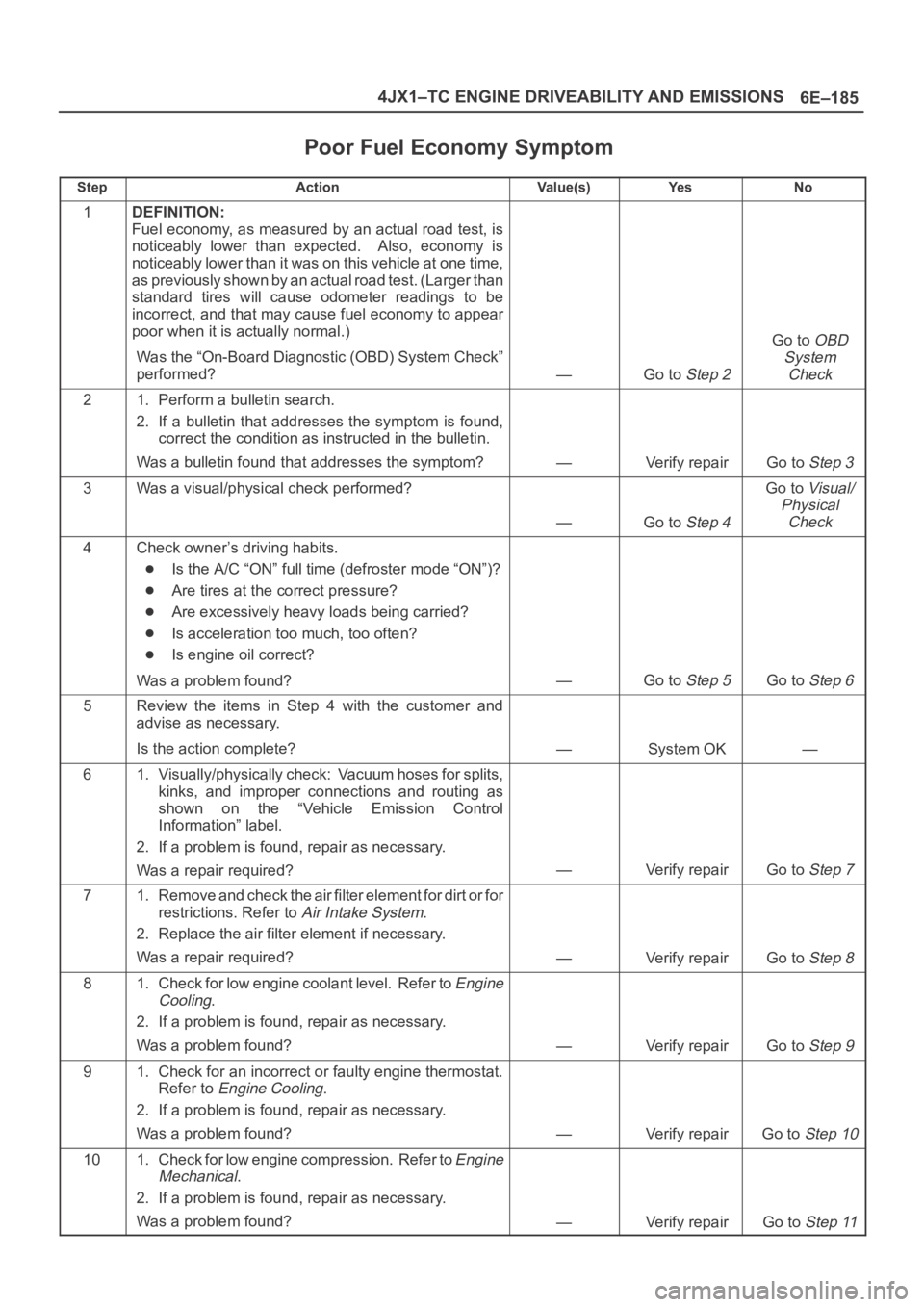

Poor Fuel Economy Symptom

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Fuel economy, as measured by an actual road test, is

noticeably lower than expected. Also, economy is

noticeably lower than it was on this vehicle at one time,

as previously shown by an actual road test. (Larger than

standard tires will cause odometer readings to be

incorrect, and that may cause fuel economy to appear

poor when it is actually normal.)

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—Verify repairGo to Step 3

3Was a visual/physical check performed?

—Go to Step 4

Go to Visual/

Physical

Check

4Check owner’s driving habits.

Is the A/C “ON” full time (defroster mode “ON”)?

Are tires at the correct pressure?

Are excessively heavy loads being carried?

Is acceleration too much, too often?

Is engine oil correct?

Was a problem found?

—Go to Step 5Go to Step 6

5Review the items in Step 4 with the customer and

advise as necessary.

Is the action complete?

—System OK—

61. Visually/physically check: Vacuum hoses for splits,

kinks, and improper connections and routing as

shown on the “Vehicle Emission Control

Information” label.

2. If a problem is found, repair as necessary.

Was a repair required?

—Verify repairGo to Step 7

71. Remove and check the air filter element for dirt or for

restrictions. Refer to

Air Intake System.

2. Replace the air filter element if necessary.

Was a repair required?

—Verify repairGo to Step 8

81. Check for low engine coolant level. Refer to Engine

Cooling

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Check for an incorrect or faulty engine thermostat.

Refer to

Engine Cooling.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

101. Check for low engine compression. Refer to Engine

Mechanical

.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 11

Page 2087 of 6000

6E–194

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Lubrication System Trouble

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

In road tests oil pressure doesn’t rise, or oil is foul to

excess.

Was OBD System check performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin research.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found?

—Verify repairGo to Step 3

31. Check if a correct engine oil is used.

2. If a problem is found, change engine oil.

Was a problem found?

—Verify repairGo to Step 4

41. Check the oil pressure meter for damage.

2. Check the oil unit harness and connector for

damage.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 5

51. Check oil pipe connections for leakage.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 6

61. Check oil filter for clogging.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

71. Check valve clearance.

2. If a problem is found, adjust as necessary.

Was a problem found?

—Verify repairGo to Step 8

81. Check camshaft bearing for wear.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Check crankshaft & connecting rod bearings for

wear.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

101. Check oil pump for damage.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 11

Page 2091 of 6000

6E–198

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Excess Engine Oil Consumption

StepActionVa l u e ( s )Ye sNo

1DEFINITION:

Oil consumption measured in road tests is higher than

expected.

Was OBD System check performed?

—Go to Step 2

Go to OBD

System

Check

21. Perform a bulletin research.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found?

—Verify repairGo to Step 3

31. Check if a correct engine oil is used.

2. If a problem is found, change engine oil.

Was a problem found?

—Verify repairGo to Step 4

41. Check oil pipe connections for leakage.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 5

51. Check oil seals and gaskets for leakage.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 6

61. Connect Tech 2 to the vehicle.

2. Perform RPCV test to check its function.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 7

71. Check piston ring for damage & groove wear.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

81. Check valve stem, valve guide and oil controller for

wear.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 9

91. Check camshaft carrier & cylinder head gaskets for

blow-by.

2. If a problem is found, repair or replace as

necessary.

Was a problem found?

—Verify repairGo to Step 10

101. Review all the diagnostic procedures in this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

Visual/physical check

Tech 2 data list

Freeze Frame data

All electrical connections in suspected circuits

& systems

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repair

Contact

Te c h n i c a l

Assistance

Page 2103 of 6000

6E–210

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

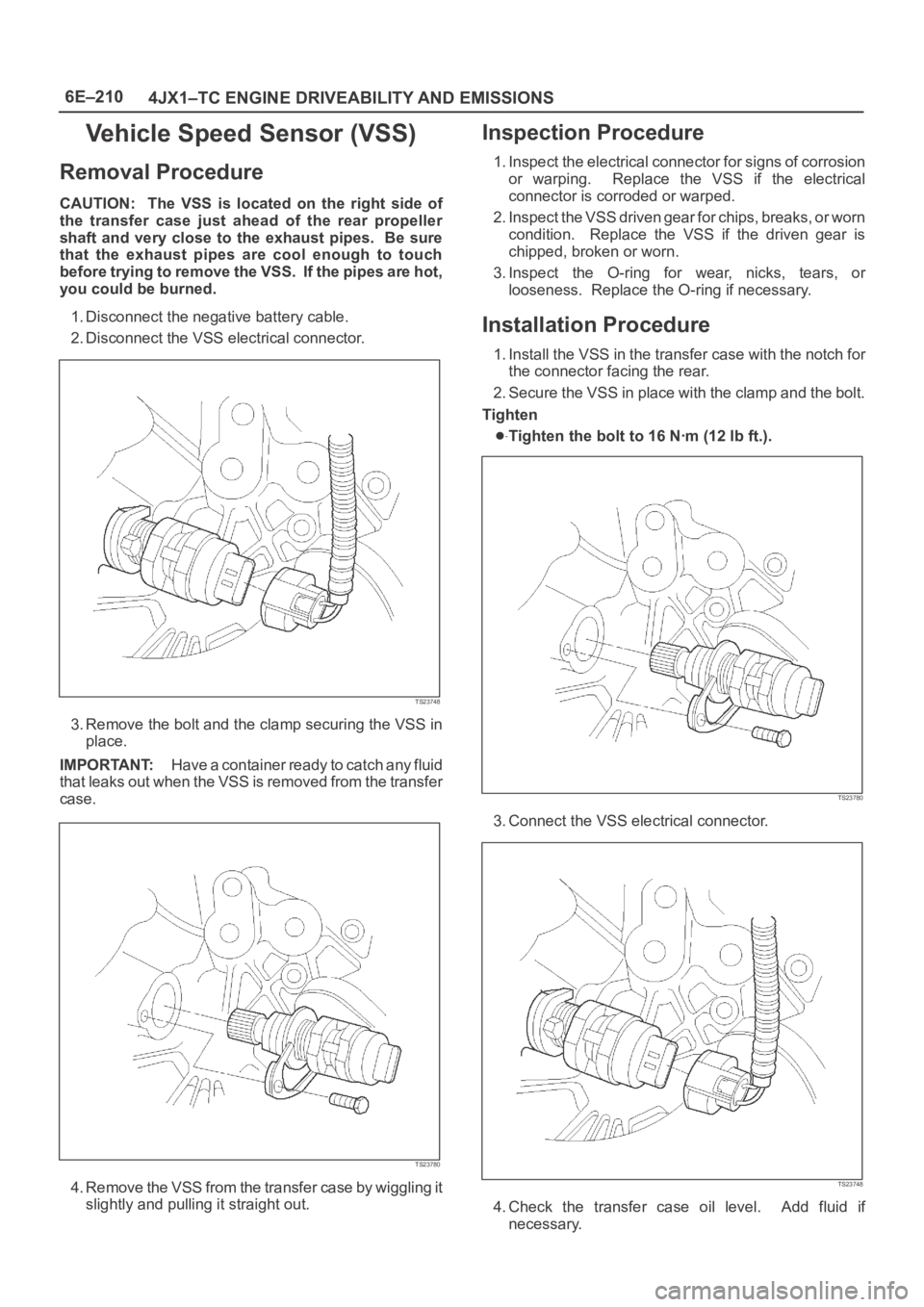

Vehicle Speed Sensor (VSS)

Removal Procedure

CAUTION: The VSS is located on the right side of

the transfer case just ahead of the rear propeller

shaft and very close to the exhaust pipes. Be sure

that the exhaust pipes are cool enough to touch

before trying to remove the VSS. If the pipes are hot,

you could be burned.

1. Disconnect the negative battery cable.

2. Disconnect the VSS electrical connector.

TS23748

3. Remove the bolt and the clamp securing the VSS in

place.

IMPORTANT:H a v e a c o n t a i n e r r e a d y t o c a t c h a n y f l u i d

that leaks out when the VSS is removed from the transfer

case.

TS23780

4. Remove the VSS from the transfer case by wiggling it

slightly and pulling it straight out.

Inspection Procedure

1. Inspect the electrical connector for signs of corrosion

or warping. Replace the VSS if the electrical

connector is corroded or warped.

2. Inspect the VSS driven gear for chips, breaks, or worn

condition. Replace the VSS if the driven gear is

chipped, broken or worn.

3. Inspect the O-ring for wear, nicks, tears, or

looseness. Replace the O-ring if necessary.

Installation Procedure

1. Install the VSS in the transfer case with the notch for

the connector facing the rear.

2. Secure the VSS in place with the clamp and the bolt.

Tighten

Tighten the bolt to 16 Nꞏm (12 lb ft.).

TS23780

3. Connect the VSS electrical connector.

TS23748

4. Check the transfer case oil level. Add fluid if

necessary.

Page 2133 of 6000

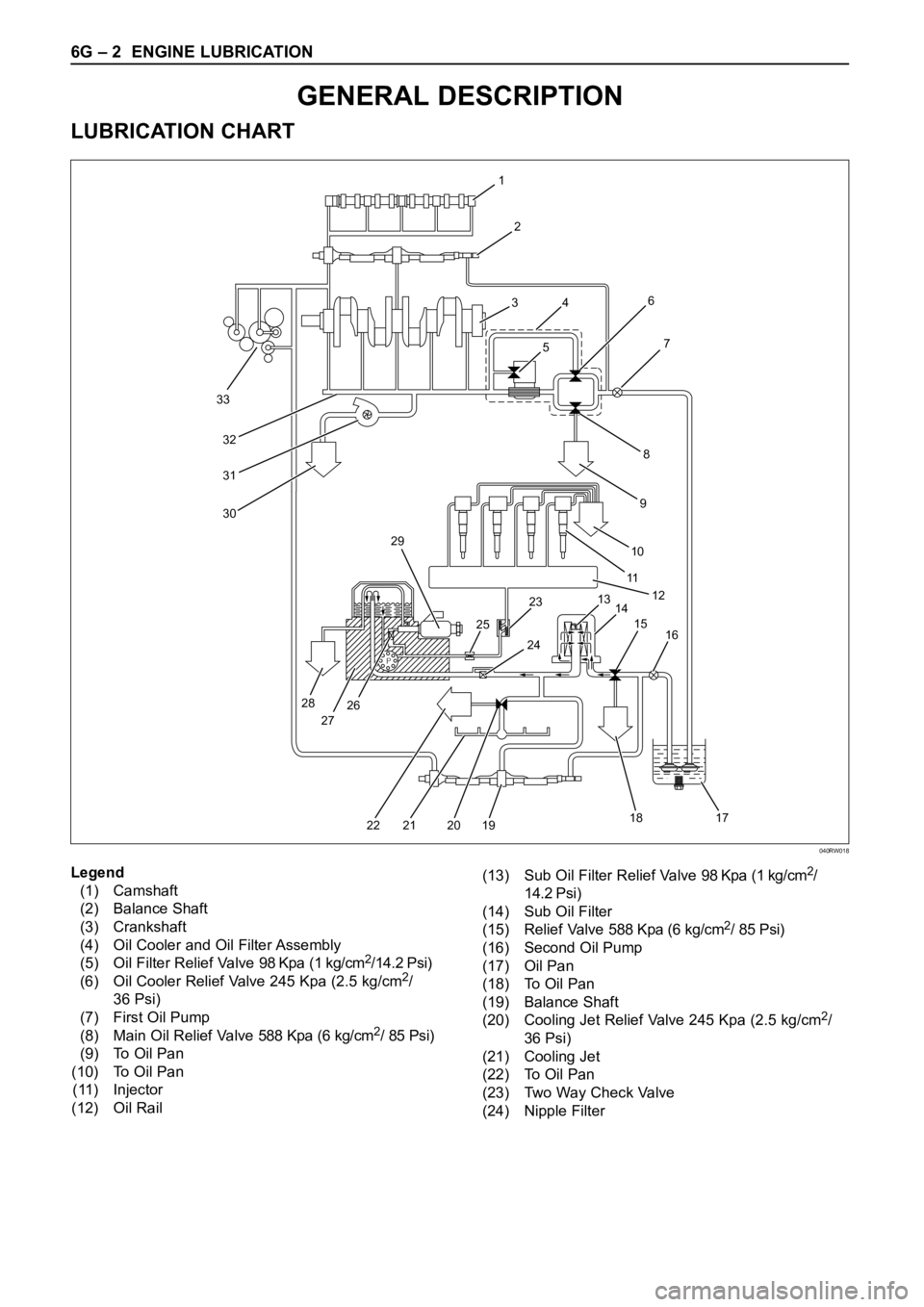

6G – 2 ENGINE LUBRICATION

GENERAL DESCRIPTION

LUBRICATION CHART

P

33

32

31

30

1

2

3

4

56

8

97

10

11

12

13

14 23 29

25

28

27262415

16

17 18

19 20 21 22

Legend

(1) Camshaft

(2) Balance Shaft

(3) Crankshaft

(4) Oil Cooler and Oil Filter Assembly

(5) Oil Filter Relief Valve 98 Kpa (1 kg/cm

2/14.2 Psi)

(6) Oil Cooler Relief Valve 245 Kpa (2.5 kg/cm2/

36 Psi)

(7) First Oil Pump

(8) Main Oil Relief Valve 588 Kpa (6 kg/cm

2/ 85 Psi)

(9) To Oil Pan

(10) To Oil Pan

(11) Injector

(12) Oil Rail(13) Sub Oil Filter Relief Valve 98 Kpa (1 kg/cm

2/

14.2 Psi)

(14) Sub Oil Filter

(15) Relief Valve 588 Kpa (6 kg/cm

2/ 85 Psi)

(16) Second Oil Pump

(17) Oil Pan

(18) To Oil Pan

(19) Balance Shaft

(20) Cooling Jet Relief Valve 245 Kpa (2.5 kg/cm

2/

36 Psi)

(21) Cooling Jet

(22) To Oil Pan

(23) Two Way Check Valve

(24) Nipple Filter

040RW018

Page 2135 of 6000

6G – 4 ENGINE LUBRICATION

SUB OIL FILTER SPECIFICATIONS

The sub oil filter requires no servicing until the

replacement interval is reached.

The element is designed to provide special filtering

efficiency until it becomes due for replacement.

It is recommended to check and replace the sub filter

when the engine is being overhauled or if it is broken

inside the engine.

442RW004