check oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2212 of 6000

7A–58

AUTOMATIC TRANSMISSION (4L30–E)

Oil Pump

Disassembled View

241RS014

Legend

(1) Oil Pump Drive Gear

(2) Oil Pump Driven Gear

(3) Pin

(4) Plug

(5) Spring

(6) Converter Clutch Control Valve

(7) Snap Ring

(8) Spring Seat

(9) Spring(10) Throttle Signal Accumulator Piston

(11) Sleeve Pin

(12) Sleeve

(13) Boost Valve

(14) Spring Seat

(15) Valve Spring

(16) Spring Seat

(17) Pressure Regulator valve

(18) Oil Pump Assembly

Disassembly

1. Remove oil pump drive gear (1) and driven gear (2).

2. Remove pin (3) from oil pump assembly (18).

3. Remove plug (4), spring (5), and converter clutch

control valve (6).

4. Remove snap ring (7) from oil pump assembly (18).

5. Remove spring seat (8), spring (9), and throttle signal

accumulator piston (10).

6. Remove sleeve pin (11) from oil pump assembly (18).

7. Remove sleeve (12), boost valve (13), spring seat

(14), valve spring (15), spring seat (16), and pressure

regulator valve (17).

Inspection And Repair

Visual Check:

If any damage, deformation or wear is found, replace the

damaged part.

Reassembly

1. Lubricate and preinstall pressure regulator spring

seat (16) on valve (17), with the flat side against

shoulder.

2. Install pressure regulator valve (17) and spring seat

(16) assembly, valve spring (15), and spring seat (14)

with the flat side away from spring to oil pump

assembly (18).

3. Assemble boost valve (13) into sleeve (12).

4. Install boost valve and sleeve assembly, and sleeve

pin (11) to oil pump assembly (18).

5. Install throttle signal accumulator piston (10), spring

(9), and spring seat (8), with the flat side away from

the spring, and snap ring (7) to oil pump assembly

(18).

6. Install converter clutch control valve (6), spring (5),

plug (4), and pin (3) to oil pump assembly (18).

7. Install oil pump driven gear (2) and drive gear (1).

Page 2214 of 6000

7A–60

AUTOMATIC TRANSMISSION (4L30–E)

10. Remove retainer (13), 2–3 shift valve (14), and spring

(15).

11. Remove spring pin (16), plug (17), spring (18), and

low pressure control valve (19).

12. Remove spring pin (20), plug (21), and band control

screen assembly (22).

13. Remove spring pin (23), plug (24), 1–2 accumulator

valve (25), and 1–2 accumulator control valve (26).

14. Remove check ball (27) from valve body (28).

Inspection And Repair

Inspect for the following, and replace any damaged or

worn parts:

1. Damage or wear to each valve.

2. Damage in oil passeges.

3. Cracks or damage to valve body.

4. Valve operations.

5. Spring fatigue.

Reassembly

1. Install 1–2 accumulator control valve (26), 1–2

accumulator valve (25), plug (24), and spring pin (23).

2. Install band control screen assembly (22), plug (21),

and spring pin (20).

3. Install low pressure control valve (19), spring (18),

plug (17), and spring pin (16).

4. Install spring (15), 2–3 shift valve (14), retainer (13),

solenoid B (12), and spring pin (11).

5. Install spring (10), 1–2/3–4 shift valve (9), retainer (8),

solenoid A (7), and spring pin (6).

6. Install waved washer (5), band control solenoid (3),

and pin (4).

7. Install manual valve (2).

8. Install check ball (27) to valve body (28).

9. Install gasket (valve body/transfer plate) and transfer

plate using two 5–8840–2270–0 (J–3387–2) guide

pins.

Install two 11mm bolts.

Torque: 13 N

m (1.3 kgꞏm/113 lb in)

244RW004

Install gasket (transfer plate/main case).

Page 2239 of 6000

7A–85 AUTOMATIC TRANSMISSION (4L30–E)

(38) Seal, O–Ring

(39) Reservoir

(42) Gasket, Extension Case

(43) Extension Assembly

(44) Seal, O–Ring/Speed Sensor

(45) Sensor Assembly, Speed

(46) Screw, Speed Sensor

(50) Seal, Extension Assembly

(52) Screw, Extension/Main Case

(53) Spring, Parking Pawl Lock

(54) Pawl, Parking Lock

(55) Connector, Electrical/Main Case

(56) Actuator Assembly, Parking Lock

(57) Nut, Parking Lock Lever

(58) Link, Manual Valve

(59) Pin, Spring

(60) Lever, Parking Lock and Range Selector

(61) Shaft, Selector

(62) Seal, Selector Shaft

(63) Mode Switch Assembly

(64) Screw and Conical Washer Assembly

(65) Shield, Mode Switch

(67) Pan, Bottom/Adapter Case

(68) Gasket, Bottom Pan/Adapter Case

(69) Harness Assembly, Adapter Case

(70) Screw, Valve Body

(71) Valve Body Assembly, Adapter Case

(72) Gasket, Adapter Valve Body

(73) Plate, Adapter Valve Body/Transfer

(74) Pan, Bottom/Main Case(75) Gasket, Bottom Pan/Main Case

(76) Gasket, Oil Drain or Overfill Screw

(77) Screw, Oil Drain or Overfill

(78) Magnet, Chip Collector

(79) Filter Oil

(80) Harness Assembly, Main Case

(82) Roller and Spring Assembly, Manual Detent

(84) Valve Body Assembly, Main Case

(85) Ball, Check

(86) Gasket, Main V.B./Transfer Plate

(87) Plate, Main V.B./Transfer

(88) Gasket, Transfer/Main Case

(89) Screw, Transfer Plate on V.B.

(90) Screw, Servo Cover

(91) Cover, Servo Piston

(92) Gasket, Cover/Servo Piston

(93) Ring, Retaining Servo Piston

(94) Clip, Servo Piston

(95) Nut, Servo Screw

(96) Screw, Servo Piston

(97) Piston, Servo

(98) Seal, Ring/Servo Piston

(99) Spring, Cushion/Servo Piston

(100) Seat, Cushion Spring

(101) Sleeve, Servo Piston Adjust

(102) Rod, Apply/Servo Piston

(103) Spring, Return/Servo Piston

(104) Gasket, Adapter Case/Transfer Plate

(105) Powertrain Control Module

(106) Servo Piston Assembly

Page 2243 of 6000

7A–89 AUTOMATIC TRANSMISSION (4L30–E)

Overdrive Internal Components

252RW003

Legend

(501) Retainer, 4th Clutch

(502) Plate, 4th Clutch (Steel)

(503) Plate Assembly, 4th Clutch (Lined)

(504) Retainer And Ball Assembly, Check Valve

(505) Seal, O–Ring/Turbine Shaft

(506) Shaft, Turbine

(508) Ring, Oil Seal/Turbine Shaft

(510) Housing, Overrun Clutch

(513) Piston, Overrun Clutch

(514) Spring, Overrun Clutch Release

(515) Retainer, Release Spring/Overrun Clutch

(516) Roller Assembly, Overdrive Clutch

(517) Cam, Overdrive Roller Clutch

(518) Ring, Snap/Overrun Clutch Hub

(519) Gear, Overdrive Sun(520) Plate, Waved/Overrun Clutch

(521) Plate, Overrun Clutch (Steel)

(522) Plate Assembly, Overrun Clutch (Lined)

(523) Plate, Backing/Overrun Clutch

(524) Ring, Snap/Overrun Clutch Housing

(525) Carrier Assembly, Overdrive Complete

(526) Ring, Snap/Turbine Shaft/Carrier

(527) Bearing Assembly, Thrust

(528) Gear, Overdrive Internal

(529) Washer, Thrust/Internal Gear/Support

(530) Ring, Snap/Adapter/4th Clutch Spring

(531) Retainer and spring assembly, 4th clutch

(532) Piston, 4th Clutch

(533) Seal, 4th Clutch Piston (Inner)

(534) Seal, 4th Clutch Piston (outer)

Page 2254 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–9

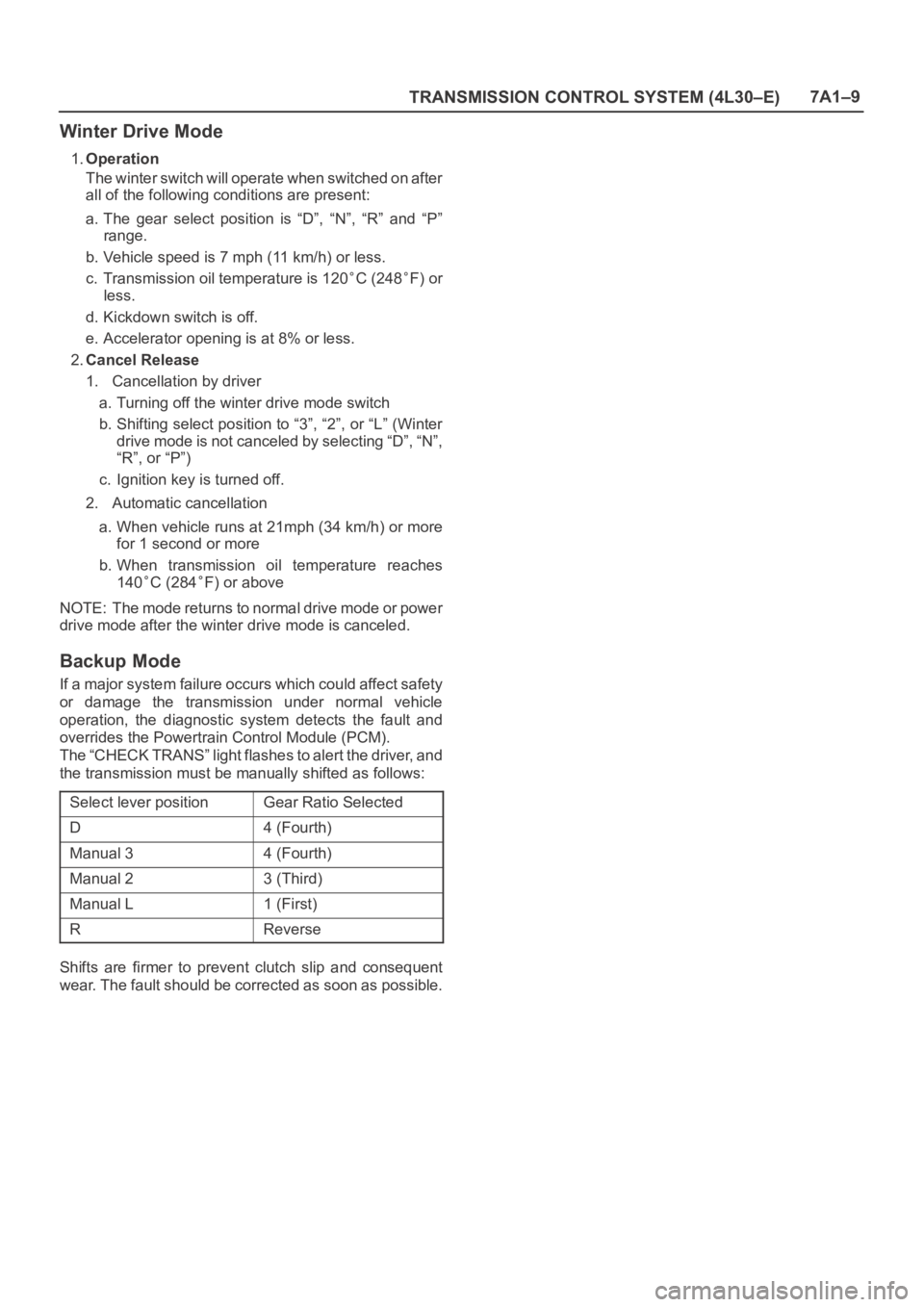

Winter Drive Mode

1.Operation

The winter switch will operate when switched on after

all of the following conditions are present:

a. The gear select position is “D”, “N”, “R” and “P”

range.

b. Vehicle speed is 7 mph (11 km/h) or less.

c. Transmission oil temperature is 120

C (248F) or

less.

d. Kickdown switch is off.

e. Accelerator opening is at 8% or less.

2.Cancel Release

1. Cancellation by driver

a. Turning off the winter drive mode switch

b. Shifting select position to “3”, “2”, or “L” (Winter

drive mode is not canceled by selecting “D”, “N”,

“R”, or “P”)

c. Ignition key is turned off.

2. Automatic cancellation

a. When vehicle runs at 21mph (34 km/h) or more

for 1 second or more

b. When transmission oil temperature reaches

140

C (284F) or above

NOTE: The mode returns to normal drive mode or power

drive mode after the winter drive mode is canceled.

Backup Mode

If a major system failure occurs which could affect safety

or damage the transmission under normal vehicle

operation, the diagnostic system detects the fault and

overrides the Powertrain Control Module (PCM).

The “CHECK TRANS” light flashes to alert the driver, and

the transmission must be manually shifted as follows:

Select lever position

Gear Ratio Selected

D4 (Fourth)

Manual 34 (Fourth)

Manual 23 (Third)

Manual L1 (First)

RReverse

Shifts are firmer to prevent clutch slip and consequent

wear. The fault should be corrected as soon as possible.

Page 2255 of 6000

7A1–10

TRANSMISSION CONTROL SYSTEM (4L30–E)

Functions of Input / Output Components

ComponentsFunction

Speed sensor

(fixed to transmission

(T/M))Senses rotation of output shaft and feeds the data to Powertrain Control Module

(PCM).

Throttle position sensor

(TPS)

(fixed to engine)Senses the extent of throttle valve opening and the speed of the throttle valve

lever motion to open the valve. Feeds the data to PCM.

I

N

Brake Switch (SW)

(fixed to brake pedal)Senses whether the driver has pressed the brake pedal or not and feeds the

information to PCM.

N-

P

U

Kickdown SW

(fixed to accelerator pedal)Senses whether the driver has pushed the accelerator pedal fully or not, and

feeds the information to PCM.

U

TMode SW (fixed to T/M)Senses the select lever position, and feeds the information to PCM.

S

I

Power drive SW

(fixed to front console)Senses whether the driver has selected the power mode, and feeds the informa-

tion to PCM.

I

G-T/M oil temp. sensorSenses the T/M oil temperature and feeds the data to PCM

N

A

L

Engine coolant tempera-

ture sensorSenses the engine coolant temperature, and feeds the data to PCM.

LEngine speed signalFeeds the signals monitoring engine speed to PCM from crank angle sensor.

Air conditioning informationSenses whether the air conditioner has been switched on or not, and feeds the

information to PCM.

Winter switch (fixed to front

console)Senses whether the driver has selected the winter mode, and feeds the informa-

tion to PCM.

Cruise controller * (Over-

drive OFF signal)Downshift takes place when Overdrive OFF signal is received from auto cruise

control unit.

S

Shift solenoid A, BSelects shift point and gear position suited to the vehicle running condition on

the basis of PCM output.

O

S

O-

L

Band apply solenoidControls oil flow suited to the vehicle running condition on the basis of PCM out-

put.

O

U

T-

P

E-

N

O

Torque Converter

Clutch solenoidControls clutch engagement/disengagement suited to the vehicle running condi-

tion on the basis of PCM output.

P

U

T

O

I

DForce motor

(Pressure regulator

valve)Adjusts the oil pump delivery pressure to line pressure suited to the vehicle run-

ning condition on the basis of PCM output.

S

I

Power drive mode lampInforms the driver whether the vehicle is in power mode or not.

I

G-Winter drive mode lampInforms the driver whether the vehicle is in winter mode or not.G

N

A

L

T/M monitor lamp

(“CHECK TRANS”)Informs the driver of failure in the system.

LATF warning lampLights when ATF oil temperature rises.

ABS signal *When the select lever is at “Reverse” or “L” range, sends a signal to the ABS

controller as one of the ABS control conditions.

* If equipped

Page 2267 of 6000

7A1–22

TRANSMISSION CONTROL SYSTEM (4L30–E)

connection or loose wiring. Terminals and grounds should

always be the prime suspect. Intermittents rarely occur

inside sophisticated electronic components such as the

PCM.

Use the DTC information to understand which wires and

sensors are involved.

When an intermittent problem is encountered, check

suspect circuits for:

1. Poor terminal to wire connection.

2. Terminals not fully seated in the connector body

(backed out).

3. Improperly formed or damaged terminals.

4. Loose, dirty, or corroded ground connections:

HINT: Any time you have an intermittent in more than

one circuit, check whether the circuits share a

common ground connection.

5. Pinched or damaged wires.

6. Electro–Magnetic Interference (EMI):

HINT: Check that all wires are properly routed away

from spark plug wires, distributor wires, coil, and

generator. Also check for improperly installed

electrical options, such as lights, 2–way radios, etc.Use the F3 SNAPSHOT mode of the Tech2 to help isolate

the cause of an intermittent fault. The snapshot mode will

record information before and after the problem occurs.

Set the snapshot to “trigger” on the suspect DTC. If you

notice the reported symptom during the test drive, trigger

the snapshot manually.

After the snapshot has been triggered, command the

Tech2 to play back the flow of data recorded from each of

the various sensors. Signs of an intermittent fault in a

sensor circuit are sudden unexplainable jump in data

values out of the normal range.

Transmission And PCM Identification

The chart below contains a list of all important information

concerning rear axle ratio, Powertrain Control Module

(PCM), and transmission identification.

VEHICLE

Rr axlePCMTRANSMISSION

Ty p eEngine

Rr axle

RatioISUZU Parts No.Calibration

CodeIsuzu Part No.Model Code

Isuzu /

Trooper3.2L V64.555

8–16254–949–0

8–16254–749–0

8–16253–989–0

G208–96018–272–3FP (4X4)

Page 2282 of 6000

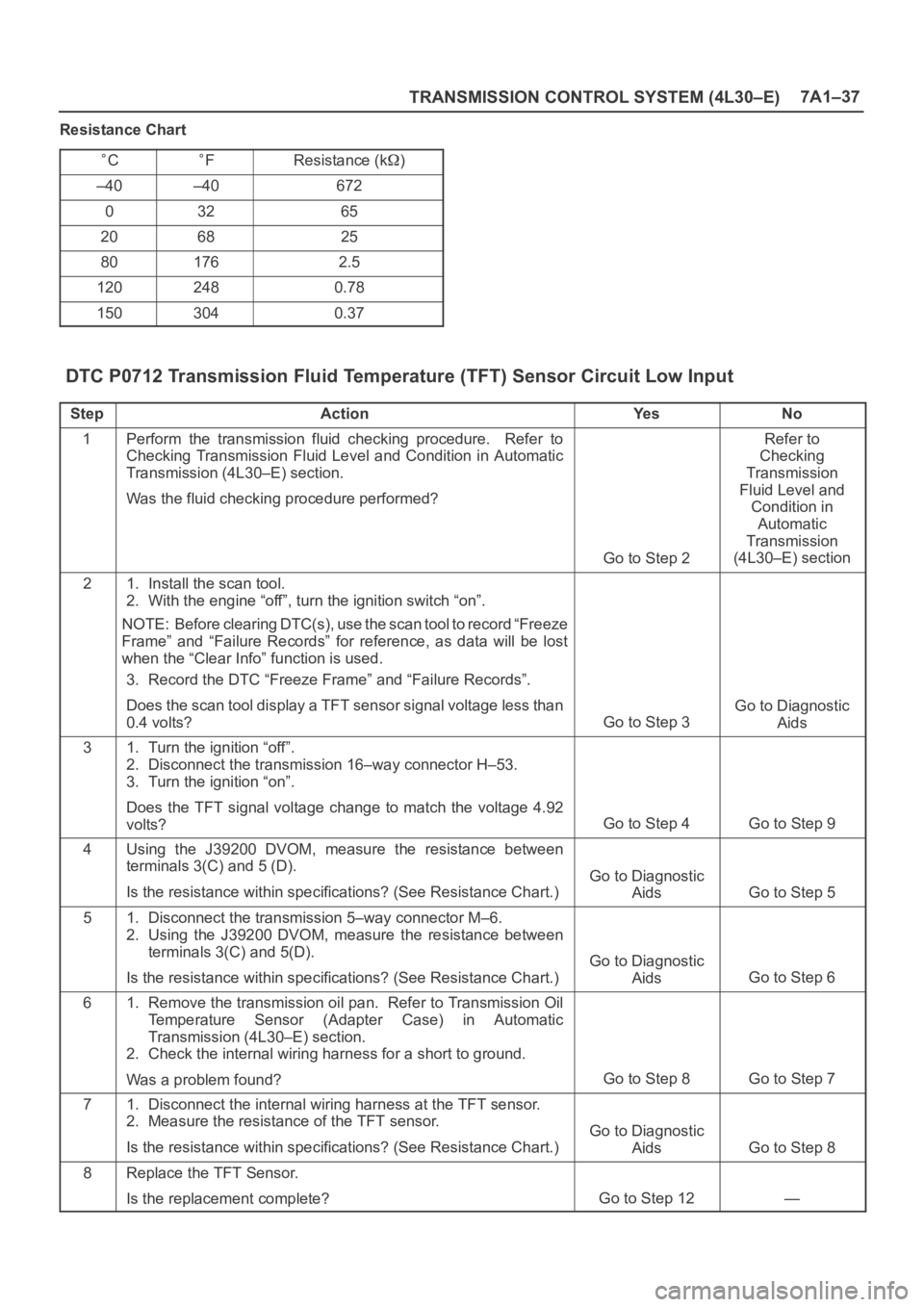

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–37

Resistance Chart

CFResistance (k)

–40–40672

03265

206825

801762.5

1202480.78

1503040.37

DTC P0712 Transmission Fluid Temperature (TFT) Sensor Circuit Low Input

StepActionYe sNo

1Perform the transmission fluid checking procedure. Refer to

Checking Transmission Fluid Level and Condition in Automatic

Transmission (4L30–E) section.

Was the fluid checking procedure performed?

Go to Step 2

Refer to

Checking

Transmission

Fluid Level and

Condition in

Automatic

Transmission

(4L30–E) section

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Freeze

Frame” and “Failure Records” for reference, as data will be lost

when the “Clear Info” function is used.

3. Record the DTC “Freeze Frame” and “Failure Records”.

Does the scan tool display a TFT sensor signal voltage less than

0.4 volts?

Go to Step 3

Go to Diagnostic

Aids

31. Turn the ignition “off”.

2. Disconnect the transmission 16–way connector H–53.

3. Turn the ignition “on”.

Does the TFT signal voltage change to match the voltage 4.92

volts?

Go to Step 4Go to Step 9

4Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5 (D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 5

51. Disconnect the transmission 5–way connector M–6.

2. Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5(D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 6

61. Remove the transmission oil pan. Refer to Transmission Oil

Temperature Sensor (Adapter Case) in Automatic

Transmission (4L30–E) section.

2. Check the internal wiring harness for a short to ground.

Was a problem found?

Go to Step 8Go to Step 7

71. Disconnect the internal wiring harness at the TFT sensor.

2. Measure the resistance of the TFT sensor.

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 8

8Replace the TFT Sensor.

Is the replacement complete?

Go to Step 12—

Page 2285 of 6000

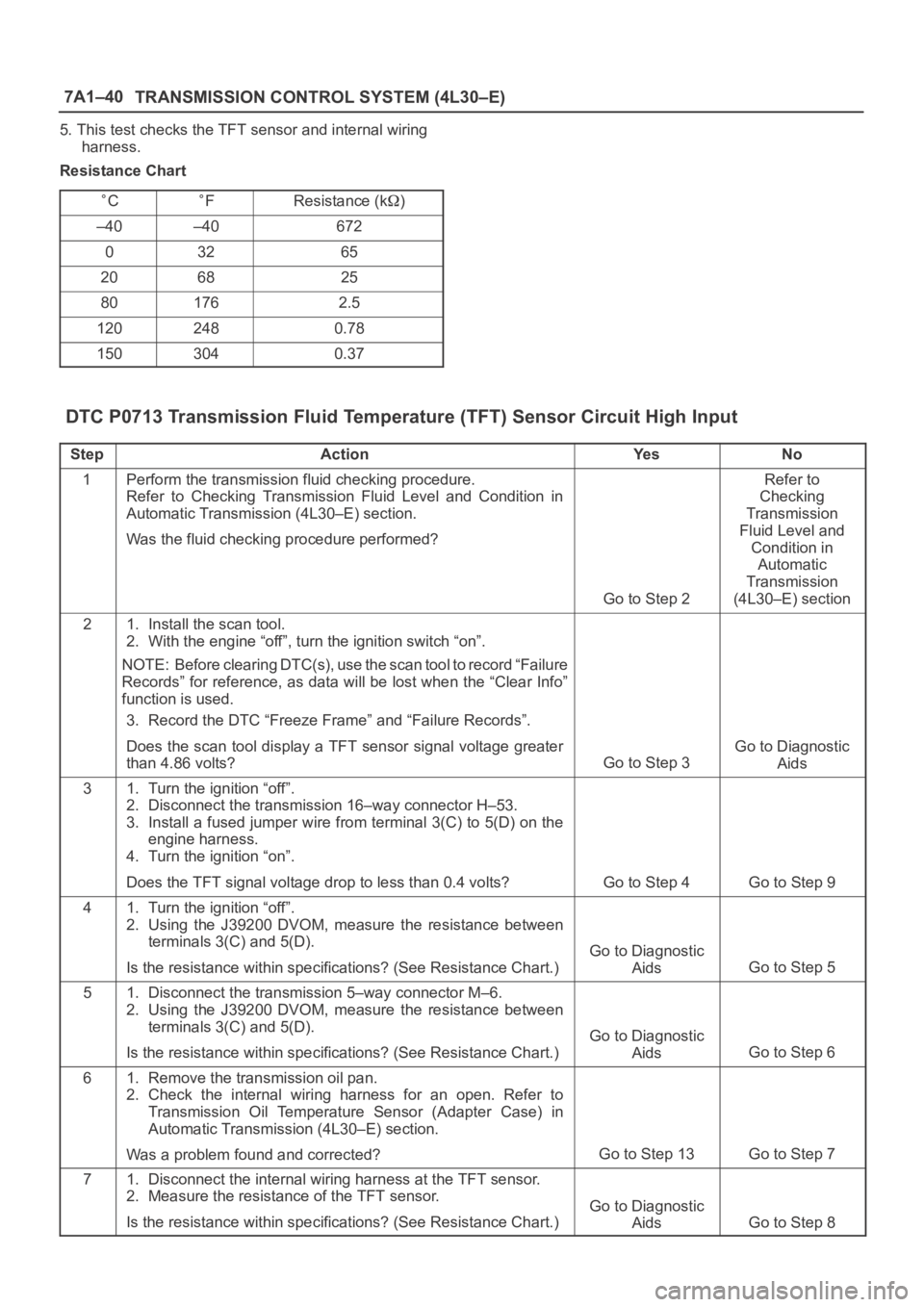

7A1–40

TRANSMISSION CONTROL SYSTEM (4L30–E)

5. This test checks the TFT sensor and internal wiring

harness.

Resistance Chart

CFResistance (k)

–40–40672

03265

206825

801762.5

1202480.78

1503040.37

DTC P0713 Transmission Fluid Temperature (TFT) Sensor Circuit High Input

StepActionYe sNo

1Perform the transmission fluid checking procedure.

Refer to Checking Transmission Fluid Level and Condition in

Automatic Transmission (4L30–E) section.

Was the fluid checking procedure performed?

Go to Step 2

Refer to

Checking

Transmission

Fluid Level and

Condition in

Automatic

Transmission

(4L30–E) section

21. Install the scan tool.

2. With the engine “off”, turn the ignition switch “on”.

NOTE: Before clearing DTC(s), use the scan tool to record “Failure

Records” for reference, as data will be lost when the “Clear Info”

function is used.

3. Record the DTC “Freeze Frame” and “Failure Records”.

Does the scan tool display a TFT sensor signal voltage greater

than 4.86 volts?

Go to Step 3

Go to Diagnostic

Aids

31. Turn the ignition “off”.

2. Disconnect the transmission 16–way connector H–53.

3. Install a fused jumper wire from terminal 3(C) to 5(D) on the

engine harness.

4. Turn the ignition “on”.

Does the TFT signal voltage drop to less than 0.4 volts?

Go to Step 4Go to Step 9

41. Turn the ignition “off”.

2. Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5(D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 5

51. Disconnect the transmission 5–way connector M–6.

2. Using the J39200 DVOM, measure the resistance between

terminals 3(C) and 5(D).

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 6

61. Remove the transmission oil pan.

2. Check the internal wiring harness for an open. Refer to

Transmission Oil Temperature Sensor (Adapter Case) in

Automatic Transmission (4L30–E) section.

Was a problem found and corrected?

Go to Step 13Go to Step 7

71. Disconnect the internal wiring harness at the TFT sensor.

2. Measure the resistance of the TFT sensor.

Is the resistance within specifications? (See Resistance Chart.)

Go to Diagnostic

Aids

Go to Step 8

Page 2286 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–41

DTC P0713 Transmission Fluid Temperature (TFT) Sensor Circuit High Input (Cont’d)

StepNo Ye s Action

8Replace TFT sensor. Refer to Transmission Oil Temperature

Sensor (Adapter Case) in Automatic Transmission (4L30–E)

section.

Is the replacement complete?

Go to Step 13—

9Check circuit RED/BLK–GRN/RED for an open or short to B+.

Was a problem found?

Go to Step 13Go to Step 10

10Check circuit GRY–GRN for an open.

Was a problem found?

Go to Step 13Go to Step 11

11Check the PCM for faulty or intermittent connections.

Was a problem found?

Go to Step 13Go to Step 12

12Replace the PCM. Refer to Powertrain Control Module (PCM) in

Automatic Transmission (4L30–E) section.

Is the replacement complete?

Go to Step 13—

131. After the repair is complete, use the scan tool to select “DTC”,

then “Clear Info” function and ensure the following conditions

are met:

2. TFT sensor indicates a voltage less than 4.92 volts for 2

seconds.

3. Review the scan tool “DTC Info”.

Has the last test failed or is the current DTC displayed?

Begin diagnosis

again

Go to Step 1

Repair verified

Exit DTC table