check oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1813 of 6000

6A – 80 ENGINE MECHANICAL

3. Piston and Connecting Rod Assembly

1) Apply engine oil to the cylinder bores, the

connecting rod bearings and the crankshaft pins

and each piston ring and piston.

2) Align the front mark (2) of piston and front mark

(3) of connecting rod then assemble them.

3) The N mark of the piston ring is faced toward the

top, check to see that the piston ring end gap is

correctly positioned.

Legend

(1) 1st piston ring end gap

(2) 2nd piston ring end gap

(3) Oil ring end gap4) Insert the piston/connecting rod assemblies into

each cylinder with the piston ring compressor.

The front marks must be facing the front of the

engine.

Piston Ring Compressor: 5-8840-9018-0

5) Match the numbered caps with the numbers on

the connecting rods. Align the punched marks

on the connecting rods and caps.

6) Apply engine oil to the threads and seating faces

of the nuts.

7) Tighten the cap nuts in 2 steps, using angular

tightening method as shown in the following

specifications.

1st step: 29 Nꞏm (3.0 kgꞏm/22 lb ft)

2nd step: 45°– 60°

After tightening the cap nuts, check to see that

the crankshaft rotates smoothly

4. Piston Cooling Oil Pipe

If the piston cooling oil pipe is forcibly assembled,

the end of the oil jet may bend. It could make it

impossible to supply oil to the piston cooling holes,

which will sometimes cause piston seizure.

Sufficient care should be taken to pipe assembly

work.

1) Tighten the bolt and oil jet plug to the specified

torque.

Torque:

M6: 8 Nꞏm (0.8 kgꞏm/6 lb ft)

M8: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

Oiling Jet Plug: 30 Nꞏm (3.1 kgꞏm/22 lb ft)

5. Crank case

1) Refer to “Crank case” in this manual.

6. Apply liquid gasket (TB-1207C or equivalent) to

retainer then install it to rear end of cylinder block

within 5 minutes.

7. Crankshaft Rear Oil Seal

1) Tighten the adapter to the crankshaft rear and

section with 2 bolts.

2) Insert the oil seal into the peripheral section of

the adapter.

3) Insert the sleeve into the adapter and tighten it

with a bolt (M12 x 1.75L = 70) until the adapter

hits the sleeve.

4) Remove the adapter and the sleeve.

5) Check the dimension of the oil seal setting from

rear end of crankshaft.

Standard Dimension = 12.5 ± 0.3 mm

Oil Seal Installer: 5-8840-2359-0

2

3

1

015RW051

3

1

2

015RW083

Page 1816 of 6000

15. Crankshaft Front Oil Seal

1) Set oil seal with special tool.

2) Install front oil seal to timing gear case cover.

Crankshaft Front Oil Seal Installer: 5-8840-2061-0

3) Remove special tool and check oil seal position

from front surface of timing gear case.

Oil Seal Position: 0.5 – 2.5 mm (0.0197 – 0.0984 in)

16. Cylinder Head

1) Refer to “Cylinder head” in this manual.

ENGINE MECHANICAL 6A – 83

015RW074

Page 1821 of 6000

6A – 88 ENGINE MECHANICAL

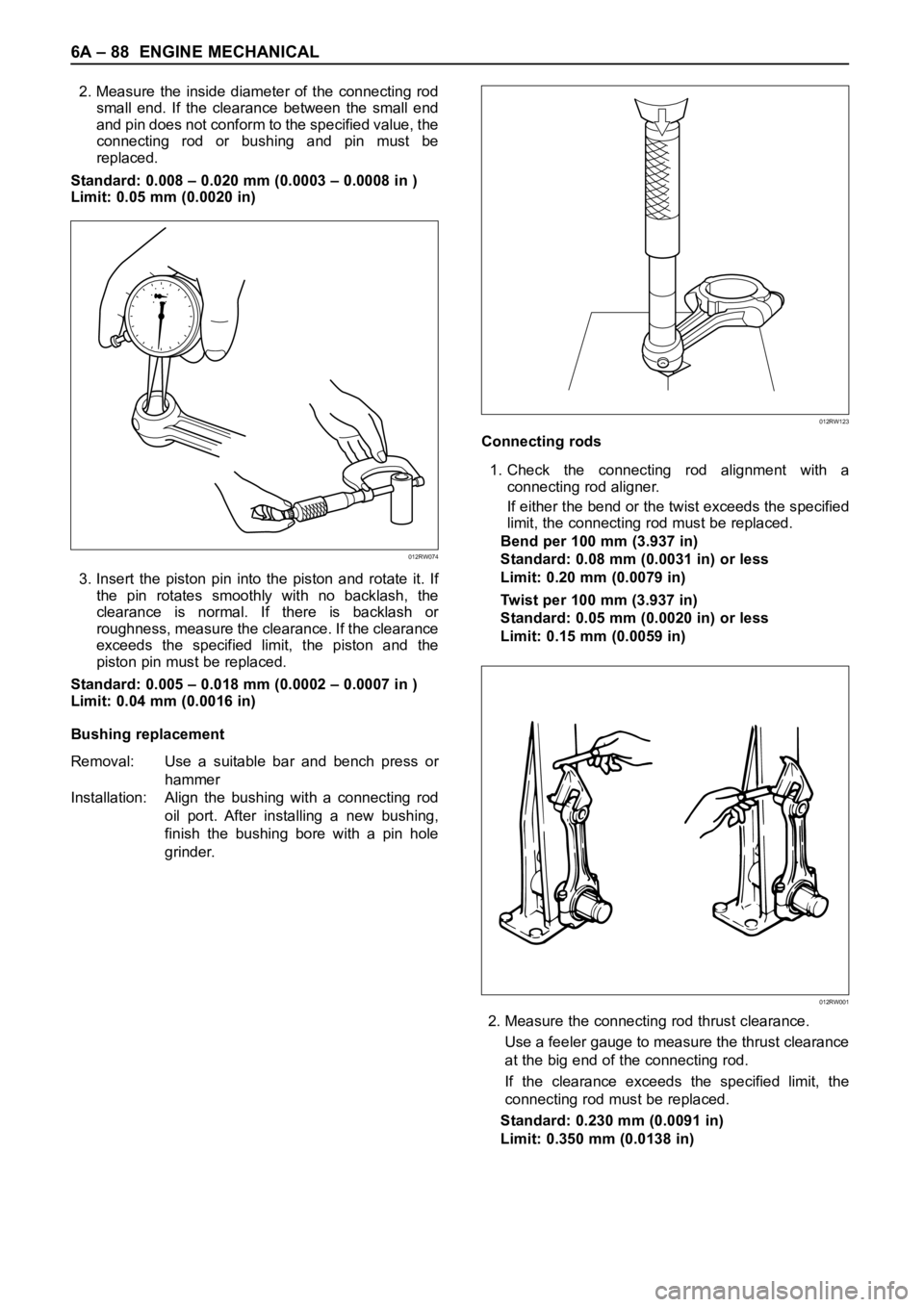

2. Measure the inside diameter of the connecting rod

small end. If the clearance between the small end

and pin does not conform to the specified value, the

connecting rod or bushing and pin must be

replaced.

Standard: 0.008 – 0.020 mm (0.0003 – 0.0008 in )

Limit: 0.05 mm (0.0020 in)

3. Insert the piston pin into the piston and rotate it. If

the pin rotates smoothly with no backlash, the

clearance is normal. If there is backlash or

roughness, measure the clearance. If the clearance

exceeds the specified limit, the piston and the

piston pin must be replaced.

Standard: 0.005 – 0.018 mm (0.0002 – 0.0007 in )

Limit: 0.04 mm (0.0016 in)

Bushing replacement

Removal: Use a suitable bar and bench press or

hammer

Installation: Align the bushing with a connecting rod

oil port. After installing a new bushing,

finish the bushing bore with a pin hole

grinder.Connecting rods

1. Check the connecting rod alignment with a

connecting rod aligner.

If either the bend or the twist exceeds the specified

limit, the connecting rod must be replaced.

Bend per 100 mm (3.937 in)

Standard: 0.08 mm (0.0031 in) or less

Limit: 0.20 mm (0.0079 in)

Twist per 100 mm (3.937 in)

Standard: 0.05 mm (0.0020 in) or less

Limit: 0.15 mm (0.0059 in)

2. Measure the connecting rod thrust clearance.

Use a feeler gauge to measure the thrust clearance

at the big end of the connecting rod.

If the clearance exceeds the specified limit, the

connecting rod must be replaced.

Standard: 0.230 mm (0.0091 in)

Limit: 0.350 mm (0.0138 in)

012RW074

012RW123

012RW001

Page 1822 of 6000

ENGINE MECHANICAL 6A – 89

3. Measure the oil clearance between the connecting

rod and the crankshaft.

1) Remove the connecting rod cap nuts and the

rod caps.

Arrange the removed rod caps in the cylinder

number order.

2) Clean the rod bearings and the crankshaft pins.

3) Carefully check the rod bearings.

If even one bearing is found to be damaged or

badly worn, the entire bearing assembly must be

replaced as a set. Reinstall the bearings in their

original positions.

Apply plastigage to the crank pin.

4) Reinstall the rod caps to their original positions.

5) Tighten the cap nuts in 2 steps, using angular

tightening method as shown in the following

specifications.

1st step: 29 Nꞏm (3.0 kgꞏm/22 lb ft)

2nd step: 45°– 60°NOTE: Do not allow the crankshaft to rotate

6) Remove the rod caps.

7) Measure the smallest width of the plastigage

and determine the oil clearance. If the oil

clearance exceeds the limit, replace the rod

bearings as a set.

8) Clean the plastigage from the bearings and the

crankshaft pins

Standard: 0.022 – 0.042 mm (0.0009 – 0.0017 in)

Limit: 0.100 mm (0.0039 in)

REASSEMBLY

1. Connecting Rod

2. Piston

3. Piston Pin

1) Apply a coat of engine oil to the piston pin and

the piston pin hole.

4. Piston Pin Snap Ring

1) Try to insert the piston pin into the piston pin

hole with normal finger pressure.

2) Weight each piston and connecting rod

assembly.

3) Select piston and connecting rod combinations

so that the weight variation of the different four

assemblies is held within the specified limits.

Variance in weight after assembly: Less than 3g

(0.1058 oz)

NOTE: When changing piston/connecting rod

combinations, do not change the piston/piston pin

combination.

4) Attach the piston to the connecting rod with the

piston front mark (2) and the connecting rod

front mark (3) on the same side.

014RW055

012RW075

014RW077

Page 1823 of 6000

6A – 90 ENGINE MECHANICAL

5. Piston Ring

1) Install the piston rings with the piston ring

expander.

The compression ring must be set with the 1N,

2N mark facing up.

2) Discerning mark is stamped as shown in the

illustration (1).

Marked 1N: 1st compression ring

Marked 2N: 2nd compression ring

3) Install piston rings in the following sequence.

1) Oil ring

(1) After installing the expander ring then assemble

the oil ring.

2) 2nd compression ring3) 1st compression ring

1) The compression ring must be set with the 1N or

2N mark facing up.

2) 1st compression ring:1N

3) 2nd compression ring: 2N

4) After installation, apply engine oil to the entire

circumference of the piston rings.

Check to see that all the rings rotate smoothly.

5) Insert the bearings into the connecting rods and

caps.

Apply new engine oil to the bearing faces.

Cap side bearings have no oil hole.

Connecting rod side bearing’s oil hole should be

aligned with oil hole on the connecting rod.

6. Piston and Connecting Rod

1) Apply engine oil to the cylinder bores, the

connecting rod bearings and the crankshaft

pins.

2) Check to see that the piston ring end gaps are

correctly positioned.

N

012RW037

2

3

1

015RW051

3

2

11

012RW058

Page 1824 of 6000

ENGINE MECHANICAL 6A – 91

Legend

(1) 1st compressor ring gap

(2) 2nd compressor ring gap

(3) Oil ring gap

3) Insert the piston/connecting rod assemblies into

each cylinder with the piston ring compressor.

4) The front marks must be facing the front of the

engine.

Piston Ring Compressor : 5-8840-9018-0

7. Connecting Rod Bearing Cap

1) Apply engine oil to thread and seat of bearing

cap bolts.

2) Tighten the cap bolts in 2 steps, using angular

tightening method as shown in the following

specifications.

1st step: 29 Nꞏm (3.0 kgꞏm/22 lb ft)

2nd step: 45°– 60°

After tightening the cap bolts, check to see that

the crankshaft rotates smoothly.

8. Crank Case Assembly

1) Refer to “Crank Case” in this manual.

9. Cylinder Head Assembly

1) Refer to “Cylinder head” in this manual.

3

1

2

015RW083

Page 1826 of 6000

ENGINE MECHANICAL 6A – 93

DISASSEMBLY

1. Cylinder Head Assembly

Refer to “Cylinder Head” in this manual.

2. Cylinder Head Gasket.

3. Flywheel

4. Cylinder Block Rear Plate (A/T), or Flywheel

housing (M/T).

5. Crankshaft Rear Oil Seal.

Install the special tool as shown in the illustration

and remove the oil seal.

Oil Seal Remover: 5-8840-2360-0

6. Retainer

7. Timing Gear Case Cover

8. Crankshaft Front Oil Seal

1) Use a plastic hammer and a screwdriver to tap

around the oil seal to free it from the gear case

cover.

9. Timing Gears

Refer to “Timing Gear” in this manual.

10. Timing gear case

11. Gasket

12. Balance shaft right

13. Crank case assembly

14. Piston cooling oil pipe

15. Piston assembly

16. Main bearing cap

17. Crankshaft assembly

18. Cylinder block side cover right and left

19. Cylinder block

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

1. Remove the cylinder head gasket and any other

material adhering to the upper surface of the

cylinder block.

Be very careful not to allow any material to

accidentally drop into the cylinder block.

Be very careful not to scratch the cylinder block.

2. Carefully remove liquid gasket, which was used

when assembled, from gear case, rear oil seal

retainer and crank case.

3. Wipe the cylinder block clean and visually check it.

4. Use a straight edge and a feeler gauge to measure

the four sides and the two diagonals of the cylinder

block upper face.

If the measured values exceed the limit, the cylinder

block must be replaced.

Limit: 0.20 mm (0.0079 in)

015RV002

012RW122

Page 1828 of 6000

ENGINE MECHANICAL 6A – 95

Oil pipe fixing bolts

M8: 20 Nꞏm (2.0 kgꞏm/14 lb ft)

M6: 8 Nꞏm (0.8 kgꞏm/69 lb in)

Relief valve fixing bolts : 30 Nꞏm (3.1 kgꞏm/22 lb ft)

CAUTION: After installing the piston assembly,

check and see that there is appropriate clearance

between pistons and oil jet pipes by rotating

crankshaft slowly.

3. Crankshaft

1) Install the main bearings to the cylinder body

and the main bearing caps.

2) Be sure that they are positioned correctly.

3) Apply new engine oil to the upper and lower

main bearing faces.

4) Carefully mount the crankshaft.5) Apply engine oil to the thrust washer.

6) Assemble the thrust washer to the No. 3

bearing journal. The oil grooves must face the

crankshaft.

4. Main Bearing Cap Assembly

1) Install the bearing caps with the bearing cap

head arrow mark facing the front of the engine.

2) Apply engine oil to the crankshaft bearing cap

bolts.

3) Tighten the crankshaft bearing cap bolts to the

specified torque a little at a time in the sequence

shown in the illustration.

Torque: 167 Nꞏm (17.0 kgꞏm/123 lb ft)

321

012RW076

012RW038

012RW047

12345

012RW025

Page 1829 of 6000

6A – 96 ENGINE MECHANICAL

NOTE: Check to see that the crankshaft turns

smoothly by rotating it manually.

4. Piston Assembly

1) Refer to “Piston and connecting rod” in this

manual.

5. Cylinder Block Side Cover Right and Left

6. Balance Shaft Right.

7. Timing Gear Case

1) Cut out the liquid gasket forced out from

between the contact surface of cylinder block

and crankshaft.

2) Apply liquid gasket (TB1207B or equivalent) to

the fitting surface of the cylinder block and

crankcase.

3) Install timing gear case with gasket to cylinder

block and tighten to specified torque.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)8. Crankshaft Gear

Force key into crankshaft and force in crankshaft

gear along the key groove using a special tool (1)

with the crank gear (2) timing mark facing outside.

9. Install timing gear align the timing mark on each

timing gear.

For alignment of timing marks refer to “Timing

Gear” in this manual.

NOTE: Remove the locking bolt or pin from idle gear A

and idle gear C.

10. Assembling the gear case cover.

1) Install the oil seal on the oil pump assembly

before installing the gear case cover.

2) Apply liquid gasket to timing gear case.

NOTE: Be sure to apply liquid gasket evenly.

84159

610

237

012RW027

012RW064

12

2

012RW066

2

2~2.5mm

2~2.5mm

Apply liquid gasket around inside

of the bolt hole

Bolt hole

Inside

Outside

F06HX00001

Page 1830 of 6000

ENGINE MECHANICAL 6A – 97

11. Use the special tool to install the crankshaft front oil

seal to timing gear case.

Front Oil Seal Installer: 5-8840-2061-0

1) Check fit-of the oil seal and gear case cover at

the front end.

Standard: 0.5 – 2.5 mm (0.0197 – 0.0984 in)

NOTE: Apply engine oil to oil seal lip before installation

of the seal.

12. Install the oil pan assembly to original position and

tighten to specified torque.

Torque: 22 Nꞏm (2.2 kgꞏm/15.9 lb ft)

13. Crankshaft Rear Oil Seal

1) Tighten the adapter to the crankshaft rear end

with 2 bolts.

2) Insert the oil seal into the adapter.

3) Insert the sleeve into the adapter and tighten it

with a bolt (M12 x 1.75L = 70) until the adapter

hits the sleeve.

4) Remove the adapter and the sleeve.

5) With the seal pressed in, check the dimension of

the oil seal outside end and crankshaft end.

Standard Dimension = 12.5 ± 0.3 mm

Oil Seal Installer: 5-8840-2359-014. Cylinder Block Rear Plate (A/T Model)

1) Tighten the cylinder block rear plate fixing bolts

to the specified torque.

Torque: 97 Nꞏm (9.9 kgꞏm/72 lb ft)

15. Flywheel Housing (M/T Model)

1) Install flywheel housing aligned with the dowel

pin on the cylinder block.

2) Tighten the flywheel housing fixing bolts to the

specified torque.

Torque: 97 Nꞏm (9.9 kgꞏm/72 lb ft)

16. Flywheel

1) Refer to “Crankshaft” in this manual.

17. Cylinder Head Assembly

1) Refer to “Cylinder Head” in this manual.

015RW074

12.5 + 0.3–

012RW067