engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5365 of 6000

6A – 92 ENGINE MECHANICAL

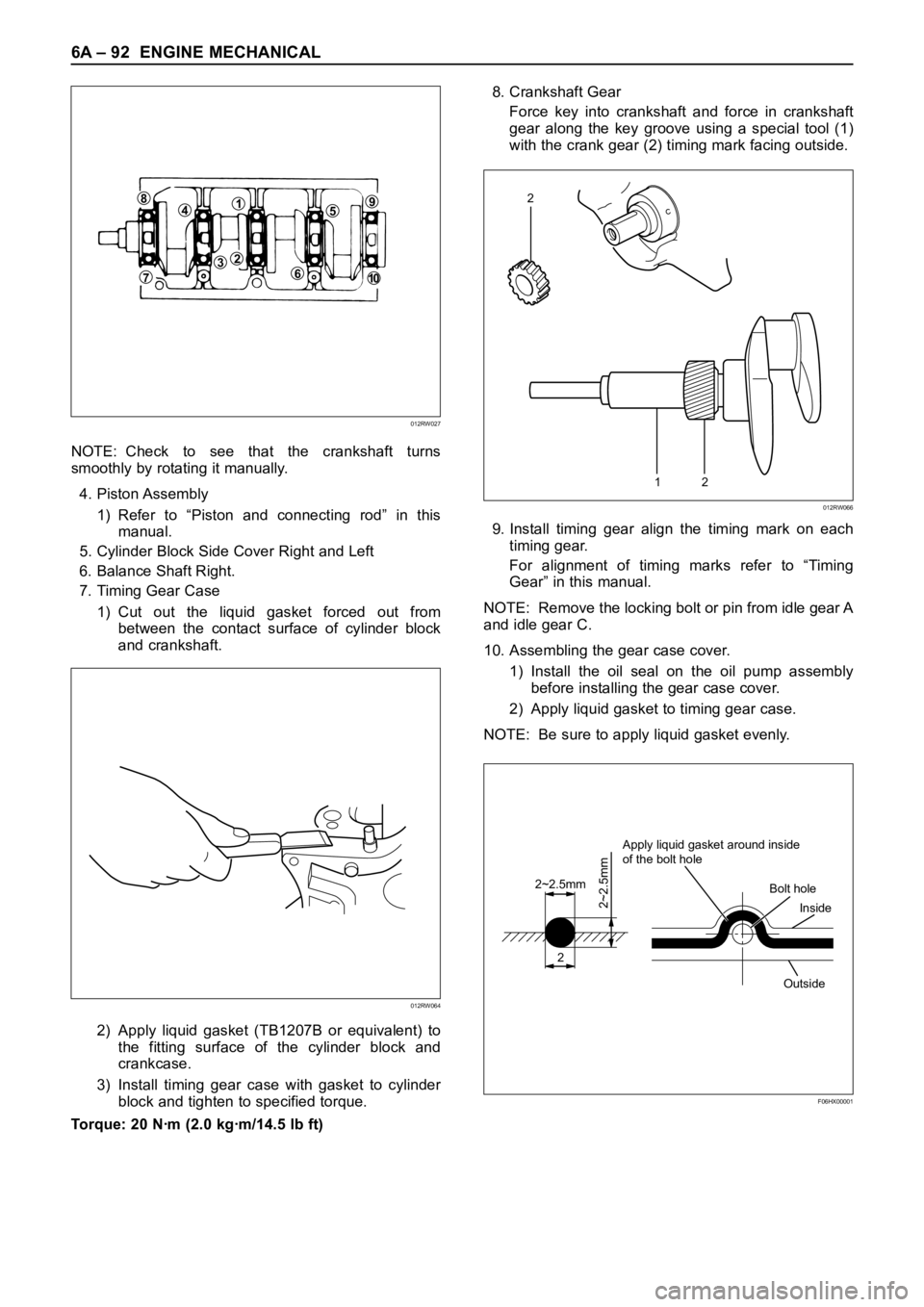

NOTE: Check to see that the crankshaft turns

smoothly by rotating it manually.

4. Piston Assembly

1) Refer to “Piston and connecting rod” in this

manual.

5. Cylinder Block Side Cover Right and Left

6. Balance Shaft Right.

7. Timing Gear Case

1) Cut out the liquid gasket forced out from

between the contact surface of cylinder block

and crankshaft.

2) Apply liquid gasket (TB1207B or equivalent) to

the fitting surface of the cylinder block and

crankcase.

3) Install timing gear case with gasket to cylinder

block and tighten to specified torque.

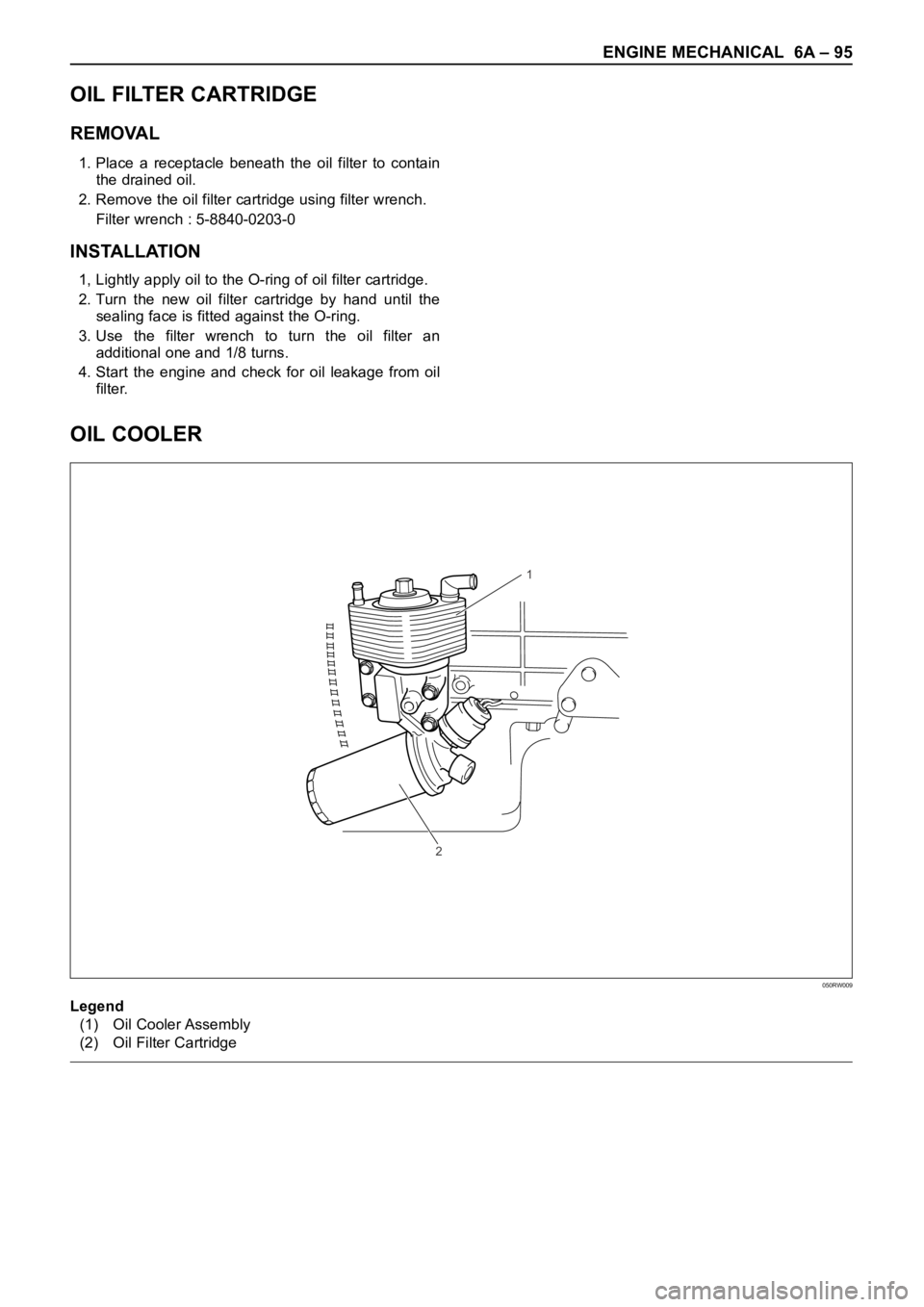

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)8. Crankshaft Gear

Force key into crankshaft and force in crankshaft

gear along the key groove using a special tool (1)

with the crank gear (2) timing mark facing outside.

9. Install timing gear align the timing mark on each

timing gear.

For alignment of timing marks refer to “Timing

Gear” in this manual.

NOTE: Remove the locking bolt or pin from idle gear A

and idle gear C.

10. Assembling the gear case cover.

1) Install the oil seal on the oil pump assembly

before installing the gear case cover.

2) Apply liquid gasket to timing gear case.

NOTE: Be sure to apply liquid gasket evenly.

84159

610

237

012RW027

012RW064

12

2

012RW066

2

2~2.5mm

2~2.5mm

Apply liquid gasket around inside

of the bolt hole

Bolt hole

Inside

Outside

F06HX00001

Page 5366 of 6000

ENGINE MECHANICAL 6A – 93

11. Use the special tool to install the crankshaft front oil

seal to timing gear case.

Front Oil Seal Installer: 5-8840-2061-0

1) Check fit-of the oil seal and gear case cover at

the front end.

Standard: 0.5 – 2.5 mm (0.0197 – 0.0984 in)

NOTE: Apply engine oil to oil seal lip before installation

of the seal.

12. Install the oil pan assembly to original position and

tighten to specified torque.

Torque: 22 Nꞏm (2.2 kgꞏm/15.9 lb ft)

13. Crankshaft Rear Oil Seal

1) Tighten the adapter to the crankshaft rear end

with 2 bolts.

2) Insert the oil seal into the adapter.

3) Insert the sleeve into the adapter and tighten it

with a bolt (M12 x 1.75L = 70) until the adapter

hits the sleeve.

4) Remove the adapter and the sleeve.

5) With the seal pressed in, check the dimension of

the oil seal outside end and crankshaft end.

Standard Dimension = 12.5 ± 0.3 mm

Oil Seal Installer: 5-8840-2359-014. Cylinder Block Rear Plate (A/T Model)

1) Tighten the cylinder block rear plate fixing bolts

to the specified torque.

Torque: 97 Nꞏm (9.9 kgꞏm/72 lb ft)

15. Flywheel Housing (M/T Model)

1) Install flywheel housing aligned with the dowel

pin on the cylinder block.

2) Tighten the flywheel housing fixing bolts to the

specified torque.

Torque: 97 Nꞏm (9.9 kgꞏm/72 lb ft)

16. Flywheel

1) Refer to “Crankshaft” in this manual.

17. Cylinder Head Assembly

1) Refer to “Cylinder Head” in this manual.

015RW074

12.5 + 0.3–

012RW067

Page 5367 of 6000

6A – 94 ENGINE MECHANICAL

OIL PUMP ASSEMBLY

2

1

5

6

3

4

012RW097

Legend

(1) Flywheel

(2) Rear Plate (A/T)

(3) First Oil Pump Assembly(4) Second Oil Pump Assembly

(5) O-Ring (For first oil pump)

(6) O-Ring (For second oil pump)

REMOVAL

1. Disconnect battery ground cable

2. Lift up car

3. Drain engine oil

NOTE: Install drain plug with new gasket.

4. Flywheel

5. Rear Plate (A/T) or Flywheel Housing (M/T)

6. First Oil Pump Assembly and Second Oil Pump

Assembly

1) Remove oil pump assembly from cylinder block

and crankcase.

INSTALLATION

1. First oil pump assembly

1) Set O-ring to oil pump.

2) Install oil pump drive gear to the rear end of the

balance shaft RH.

3) Apply engine oil to pump gear, install pump gear

to rear end of cylinder block with specified

torque.Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

2. Second oil pump assembly

1) Set O-ring to oil pump.

2) Install oil pump drive gear to the rear end of the

balance shaft LH.

3) Apply engine oil to pump gear, install pump gear

to rear end of crank case with specified torque.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

3. Install rear plate (A/T) or flywheel housing (M/T)

Torque: 97 Nꞏm (9.9 kgꞏm/72 lb ft)

4. Install flywheel

1) Apply engine oil to bolt and tighten with angular

tightening method.

First step: 59 Nꞏm (6.0 kgꞏm/43 lb ft)

Second step: 60° to 90°

Page 5368 of 6000

ENGINE MECHANICAL 6A – 95

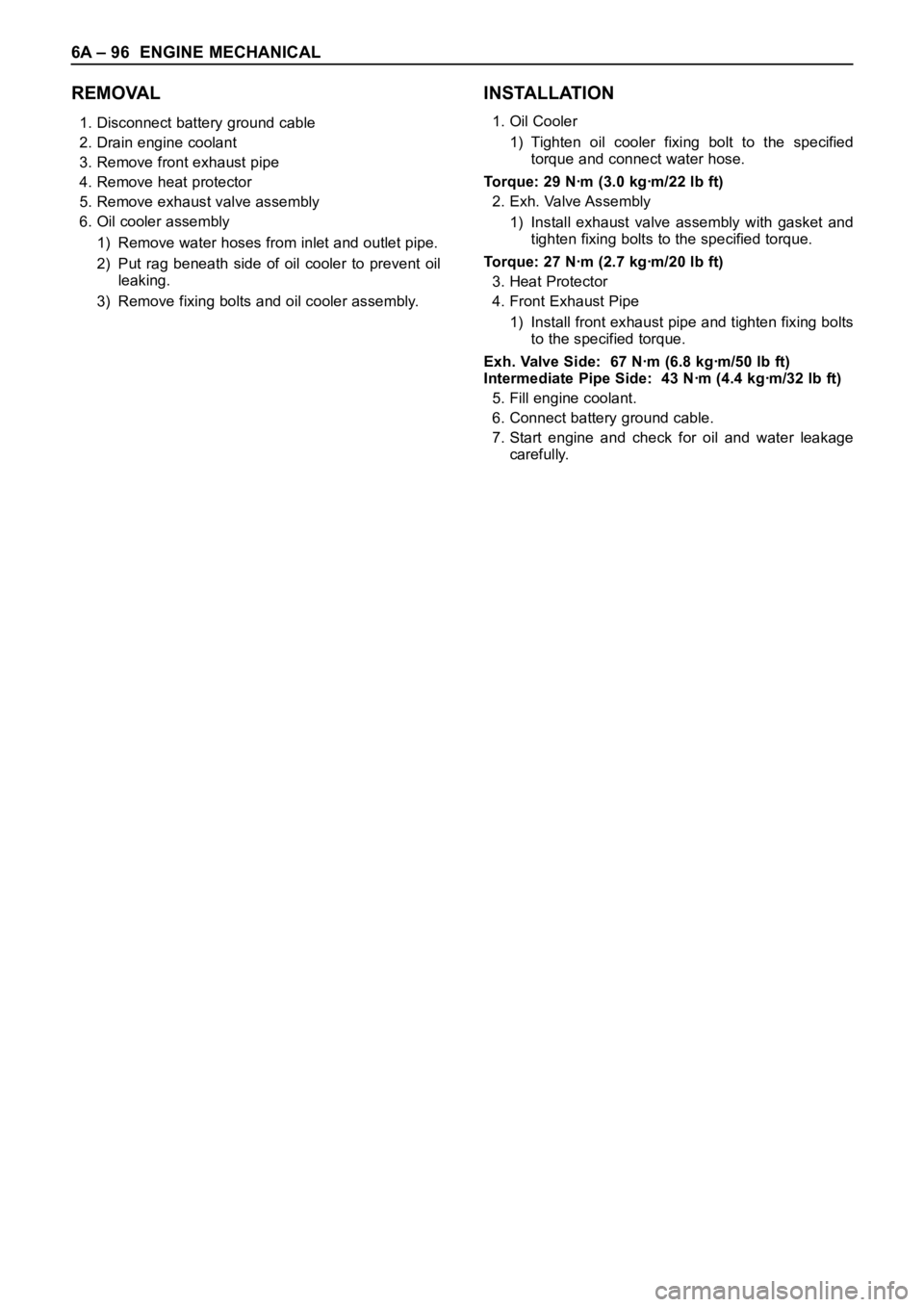

OIL COOLER

1

2

050RW009

Legend

(1) Oil Cooler Assembly

(2) Oil Filter Cartridge

OIL FILTER CARTRIDGE

REMOVAL

1. Place a receptacle beneath the oil filter to contain

the drained oil.

2. Remove the oil filter cartridge using filter wrench.

Filter wrench : 5-8840-0203-0

INSTALLATION

1, Lightly apply oil to the O-ring of oil filter cartridge.

2. Turn the new oil filter cartridge by hand until the

sealing face is fitted against the O-ring.

3. Use the filter wrench to turn the oil filter an

additional one and 1/8 turns.

4. Start the engine and check for oil leakage from oil

filter.

Page 5369 of 6000

6A – 96 ENGINE MECHANICAL

REMOVAL

1. Disconnect battery ground cable

2. Drain engine coolant

3. Remove front exhaust pipe

4. Remove heat protector

5. Remove exhaust valve assembly

6. Oil cooler assembly

1) Remove water hoses from inlet and outlet pipe.

2) Put rag beneath side of oil cooler to prevent oil

leaking.

3) Remove fixing bolts and oil cooler assembly.

INSTALLATION

1. Oil Cooler

1) Tighten oil cooler fixing bolt to the specified

torque and connect water hose.

Torque: 29 Nꞏm (3.0 kgꞏm/22 lb ft)

2. Exh. Valve Assembly

1) Install exhaust valve assembly with gasket and

tighten fixing bolts to the specified torque.

Torque: 27 Nꞏm (2.7 kgꞏm/20 lb ft)

3. Heat Protector

4. Front Exhaust Pipe

1) Install front exhaust pipe and tighten fixing bolts

to the specified torque.

Exh. Valve Side: 67 Nꞏm (6.8 kgꞏm/50 lb ft)

Intermediate Pipe Side: 43 Nꞏm (4.4 kgꞏm/32 lb ft)

5. Fill engine coolant.

6. Connect battery ground cable.

7. Start engine and check for oil and water leakage

carefully.

Page 5370 of 6000

ENGINE COOLING 6B – 1

ENGINE COOLING

CONTENTS

General Description . . . . . . . . . . . . . . . . . . 6B–2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . 6B–6

Water Pump . . . . . . . . . . . . . . . . . . . . . . 6B–6Thermostat . . . . . . . . . . . . . . . . . . . . . . . 6B–7

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . 6B–9

Drive Belt Adjustment . . . . . . . . . . . . . . . 6B–11

Page 5371 of 6000

6B – 2 ENGINE COOLING

Legend

(1) Turbocharger

(2) Thermostat

(3) Reservoir Tank

(4) Radiator

(5) Bypass(6) Oil Cooler

(7) Cooling fan

(8) Water Pump

(9) Thermo Valve

(10) Car Heater

GENERAL DESCRIPTION

COOLANT FLOW

1

6

9

10

8

4

325

7

032RW001

The cooling system is a pressurized coolant forced

circulation type which consists of water pump,

thermostat, cooling fan, radiator and other components. The circulating coolant cools the lubricating oil in the oil

cooler and turbocharger.

Page 5372 of 6000

ENGINE COOLING 6B – 3

WAT E R P U M P

The coolant pump is a centrifugal impeller type and is

driven by V type drive belt.

Legend

(1) Roller Bearing

(2) Ball Bearing

(3) Seal Unit

THERMOSTAT

The thermostat is a wax pellet type with a jiggle valve

and is installed in the thermostat housing.

Legend

(1) Bolt

(2) Thermostat Housing

(3) Thermostat

(4) Intake Manifold

RADIATOR

The radiator is a tube type with corrugated fins. In order

to raise the boiling point of coolant, the radiator is fitted

with a cap in which the valve is operated under the

pressure.

1

3 2

PCD 60

A06RW024

1

2

3

4

032RW002

110RS001

Page 5373 of 6000

6B – 4 ENGINE COOLING

ANTI-FREEZE SOLUTION

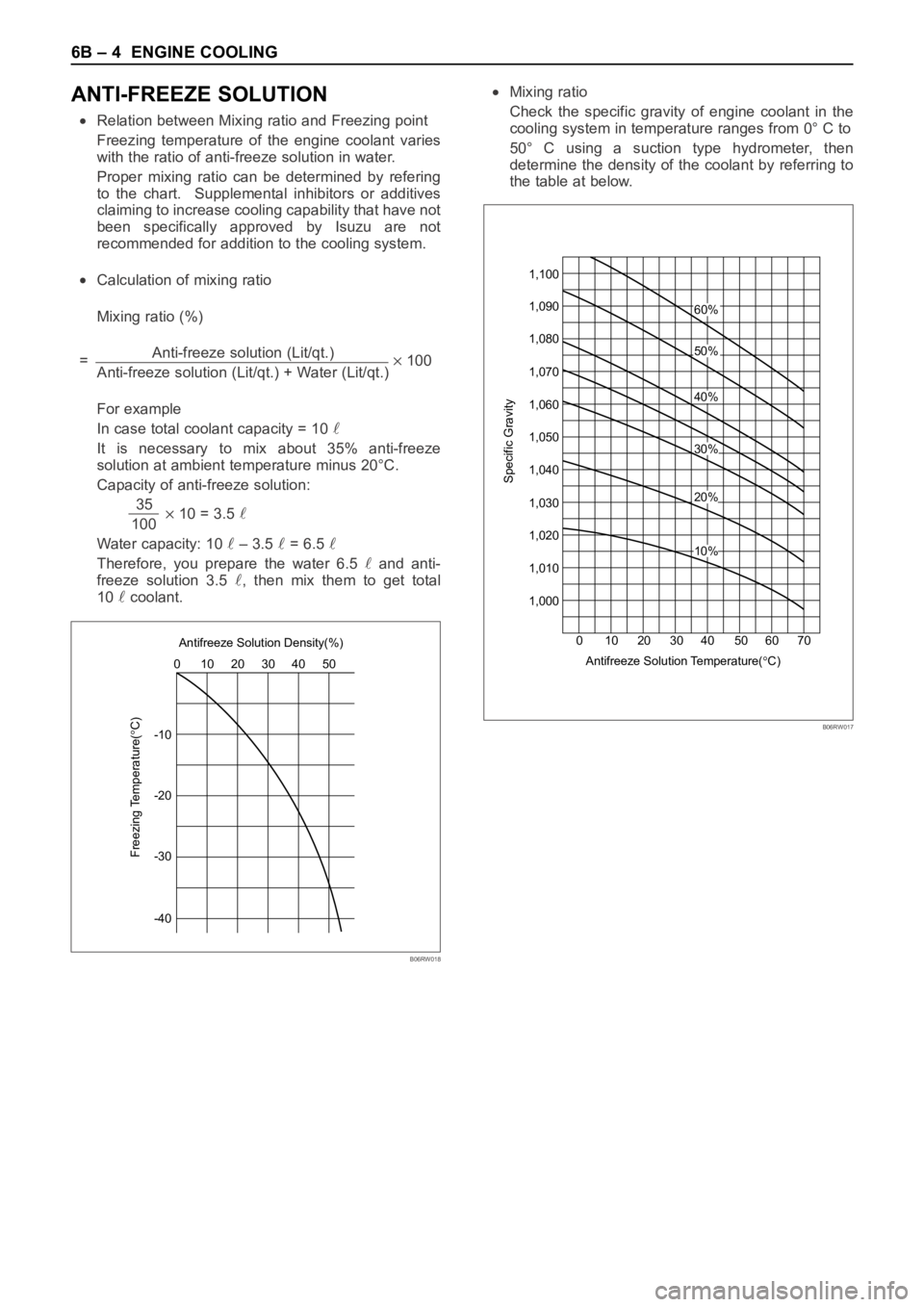

Relation between Mixing ratio and Freezing point

Freezing temperature of the engine coolant varies

with the ratio of anti-freeze solution in water.

Proper mixing ratio can be determined by refering

to the chart. Supplemental inhibitors or additives

claiming to increase cooling capability that have not

been specifically approved by Isuzu are not

recommended for addition to the cooling system.

Calculation of mixing ratio

Mixing ratio (%)

=Anti-freeze solution (Lit/qt.)

100

Anti-freeze solution (Lit/qt.) + Water (Lit/qt.)

For example

In case total coolant capacity = 10

It is necessary to mix about 35% anti-freeze

solution at ambient temperature minus 20°C.

Capacity of anti-freeze solution:

35

10 = 3.5 100

Water capacity: 10

– 3.5 = 6.5

Therefore, you prepare the water 6.5 and anti-

freeze solution 3.5

, then mix them to get total

10

coolant.

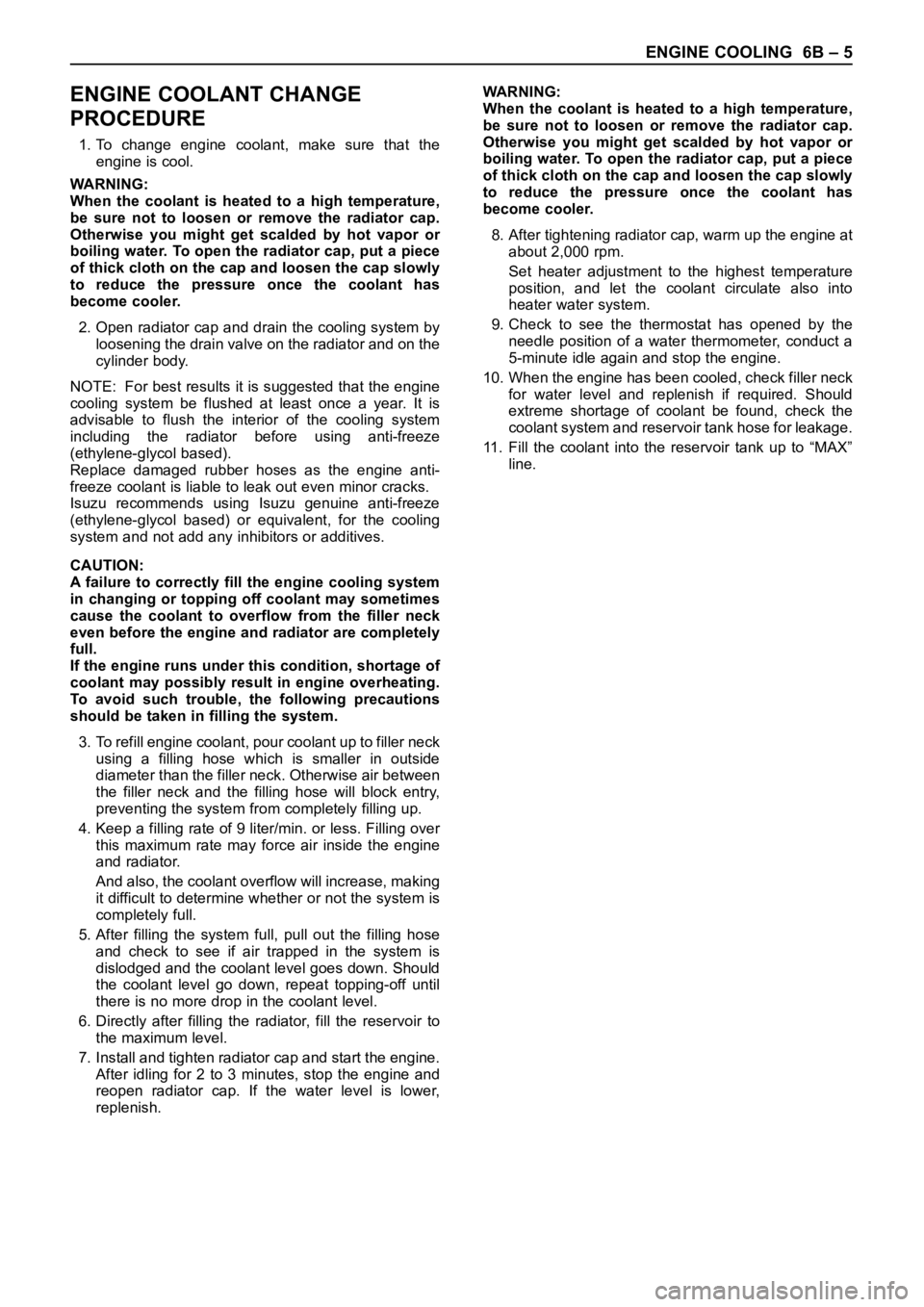

Mixing ratio

Check the specific gravity of engine coolant in the

cooling system in temperature ranges from 0° C to

50° C using a suction type hydrometer, then

determine the density of the coolant by referring to

the table at below.

-1010 0

Freezing Temperature(

C)

20 30 Antifreeze Solution Density(%)

40 50

-20

-30

-40

B06RW018

1,100

20 10 30 4060%

50%

40%

20%

10%

30%

Antifreeze Solution Temperature(

C) 50 60 70 0

Specific Gravity

1,090

1,080

1,070

1,060

1,050

1,040

1,030

1,020

1,010

1,000

B06RW017

Page 5374 of 6000

ENGINE COOLING 6B – 5

ENGINE COOLANT CHANGE

PROCEDURE

1. To change engine coolant, make sure that the

engine is cool.

WARNING:

When the coolant is heated to a high temperature,

be sure not to loosen or remove the radiator cap.

Otherwise you might get scalded by hot vapor or

boiling water. To open the radiator cap, put a piece

of thick cloth on the cap and loosen the cap slowly

to reduce the pressure once the coolant has

become cooler.

2. Open radiator cap and drain the cooling system by

loosening the drain valve on the radiator and on the

cylinder body.

NOTE: For best results it is suggested that the engine

cooling system be flushed at least once a year. It is

advisable to flush the interior of the cooling system

including the radiator before using anti-freeze

(ethylene-glycol based).

Replace damaged rubber hoses as the engine anti-

freeze coolant is liable to leak out even minor cracks.

Isuzu recommends using Isuzu genuine anti-freeze

(ethylene-glycol based) or equivalent, for the cooling

system and not add any inhibitors or additives.

CAUTION:

A failure to correctly fill the engine cooling system

in changing or topping off coolant may sometimes

cause the coolant to overflow from the filler neck

even before the engine and radiator are completely

full.

If the engine runs under this condition, shortage of

coolant may possibly result in engine overheating.

To avoid such trouble, the following precautions

should be taken in filling the system.

3. To refill engine coolant, pour coolant up to filler neck

using a filling hose which is smaller in outside

diameter than the filler neck. Otherwise air between

the filler neck and the filling hose will block entry,

preventing the system from completely filling up.

4. Keep a filling rate of 9 liter/min. or less. Filling over

this maximum rate may force air inside the engine

and radiator.

And also, the coolant overflow will increase, making

it difficult to determine whether or not the system is

completely full.

5. After filling the system full, pull out the filling hose

and check to see if air trapped in the system is

dislodged and the coolant level goes down. Should

the coolant level go down, repeat topping-off until

there is no more drop in the coolant level.

6. Directly after filling the radiator, fill the reservoir to

the maximum level.

7. Install and tighten radiator cap and start the engine.

After idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.WARNING:

When the coolant is heated to a high temperature,

be sure not to loosen or remove the radiator cap.

Otherwise you might get scalded by hot vapor or

boiling water. To open the radiator cap, put a piece

of thick cloth on the cap and loosen the cap slowly

to reduce the pressure once the coolant has

become cooler.

8. After tightening radiator cap, warm up the engine at

about 2,000 rpm.

Set heater adjustment to the highest temperature

position, and let the coolant circulate also into

heater water system.

9. Check to see the thermostat has opened by the

needle position of a water thermometer, conduct a

5-minute idle again and stop the engine.

10. When the engine has been cooled, check filler neck

for water level and replenish if required. Should

extreme shortage of coolant be found, check the

coolant system and reservoir tank hose for leakage.

11. Fill the coolant into the reservoir tank up to “MAX”

line.