4WD OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 561 of 6000

4B1–28

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

2.Case that indicator keeps 2Hz blinking after

aforementioned Solution 3 is carried out.

Step

ActionYe sNo

1Check the air pressure and wear of all tires.

Were problems found?Try Solution 3

after adjust the

air pressure and

replace worn

tires.

Go to Step 2

2

Can the transfer lever be operated from High to 4L or vice versa?

Faults on the

harness wiring of

motor actuator.

Trace this chart

from the start

after repair or

replace.

Internal faults on

transfer case.

Disassemble the

transfer case for

check. Trace this

chart from the

start after repair

or replace.

Faults on the

motor actuator.

Trace this chart

from the start

after or replace.

Go to Step 3

3Pull out the hoses from vacuum actuator and operate 4WD

switch.

Is there negative pressure on either of hoses?

Go to Step 4

Faults on the

transfer position

switch or its

harness. Trace

this chart from

the start after

repair or replace.

Faults on the

VSV main body,

its harness or

vacuuming

system. Trace

the front axle

diagnosis chart in

this section.

After that, trace

this chart from

the start.

4Check the axle switch.

Were problems found?Internal faults on

axle switch.

Trace this chart

from the start

after replace.

Faults on Front

Axle ASM. Trace

the front axle

diagnosis chart in

this section.

After that, trace

this chart from

the start.

Short circuit

(body short) or

disconnection of

the axle harness.

Trace this chart

from the start

after repair or

replace.

Page 562 of 6000

4B1–29 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

3.Case that indicator’s blinking changes to 4Hz

after aforementioned Solution 4 is carried out.

Step

ActionYe sNo

1

Can the transfer lever be operated from High to 4L or vice versa?

Faults on the

harness wiring of

motor actuator.

Trace this chart

from the start

after repair or

replace.

Faults on the

motor actuator.

Trace this chart

from the start

after replace.

Internal faults on

transfer case.

Disassemble the

transfer case for

check. Trace this

chart from the

start after repair

or replace.

Faults on the

4WD control unit.

Trace this chart

from the start

after replace.

Page 563 of 6000

4B1–30

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Front Axle Diagnosis

When the 4WD switch is operated from 4H to 2H,

indicator light does not go out.

Step

ActionYe sNo

1Drive slow 100 — 200m after a few minutes” idling.

Has indicator light gone out?

All right.Go to Step 2

2Jack up front tires.

Does the right side of front wheel rotate when the left side of f r o n t

wheel is rotated?

Go to Step 4Go to Step 3

31. Check the actuator switch.

2. Check the circuit to indicator.

Was a problem found?

Trace this chart

from the start

after repair or

replace.

Disassemble axle

ASM for check.

Trace this chart

from the start

after repair or

replace.

41. Check the VSV valve.

2. Check the circuit to VSV valve.

Was a problem found?Trace this chart

from the start

after repair or

replace.

Go to Step 5

5I s v a c u u m p i p i n g a l l r i g h t ? ( t a n k , h o s e , & p i p e d a m a g e o r t r o u ble)

Go to Step 6

Trace this chart

from the start

after repair or

replace.

6Does actuator work all right?

Trace this chart

from the start.

Disassemble axle

ASM for check.

Trace this chart

from the start

after repair or

replace.

Page 564 of 6000

4B1–31 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

When the 4WD switch is operated from 2H to 4H,

indicator light is not actuated.

Step

ActionYe sNo

1Drive slow 100 — 200m after a few minutes” idling.

Has indicator light actuated?

All right.Go to Step 2

2Jack up front tires.

Does not the right side of front wheel rotate when the left side of

front wheel is rotated?

Go to Step 4Go to Step 3

31. Check the actuator switch.

2. Check the circuit to indicator.

Was a problem found?

Trace this chart

from the start

after repair or

replace.

Disassemble axle

ASM for check.

Trace this chart

from the start

after repair or

replace.

41. Check the VSV valve.

2. Check the circuit to VSV valve.

Was a problem found?Trace this chart

from the start

after repair or

replace.

Go to Step 5

5I s v a c u u m p i p i n g a l l r i g h t ? ( t a n k , h o s e , & p i p e d a m a g e o r t r o u ble)

Go to Step 6

Trace this chart

from the start

after repair or

replace.

6Does actuator work all right?

Trace this chart

from the start.

Disassemble axle

ASM for check.

Trace this chart

from the start

after repair or

replace.

Page 568 of 6000

4B1–35 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

1. Disassemble the motor actuator from transfer rear

case.

412RW037

Legend

(3) Shift Rod

(4) Connector

2. Connect the terminals as shown in figure.

Shift rod of the motor actuator moves and stops

at 4WD position.

412RW038

Legend

(1) 2WD

(2) 4WD

(3) Shift Rod

(4) Connector

3. Connect the terminals as shown in figure.Shift rod of the motor actuator moves and stops

at 2WD position.

412RW039

Legend

(1) 2WD

(2) 4WD

(3) Shift Rod

(4) Connector

4. If 2) and 3) fail, replace with a new motor actuator.

Transfer Position Switch

412RW040

Legend

(1) Ball

1. With ball being free.

A–B : There is continuity.

2. With ball forced into the switch.

A–B : No continuity.

3. If 1) and 2) fail, replace with a new switch.

Page 569 of 6000

4B1–36

DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

4WD Control Unit (For Push Button Type)

4WD Control Unit Associated Parts

412RW044

Legend

(1) Lower Cluster Assembly

(2) Front Console Assembly(3) Harness Connector

(4) Nut

(5) 4WD Control Unit

Page 570 of 6000

4B1–37 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Removal

1. Remove lower cluster assembly and front console

assembly.

Refer to Interior Trim in Body and Accessories

section.

2. Remove nut.

3. Remove 4WD control unit.

4. Disconnect harness connector (1).

412RW045

Legend

(1) Harness Connector

Installation

1. Connect harness connector, then install 4WD control

unit.

2. Install lower cluster assembly and front console

assembly.

Page 573 of 6000

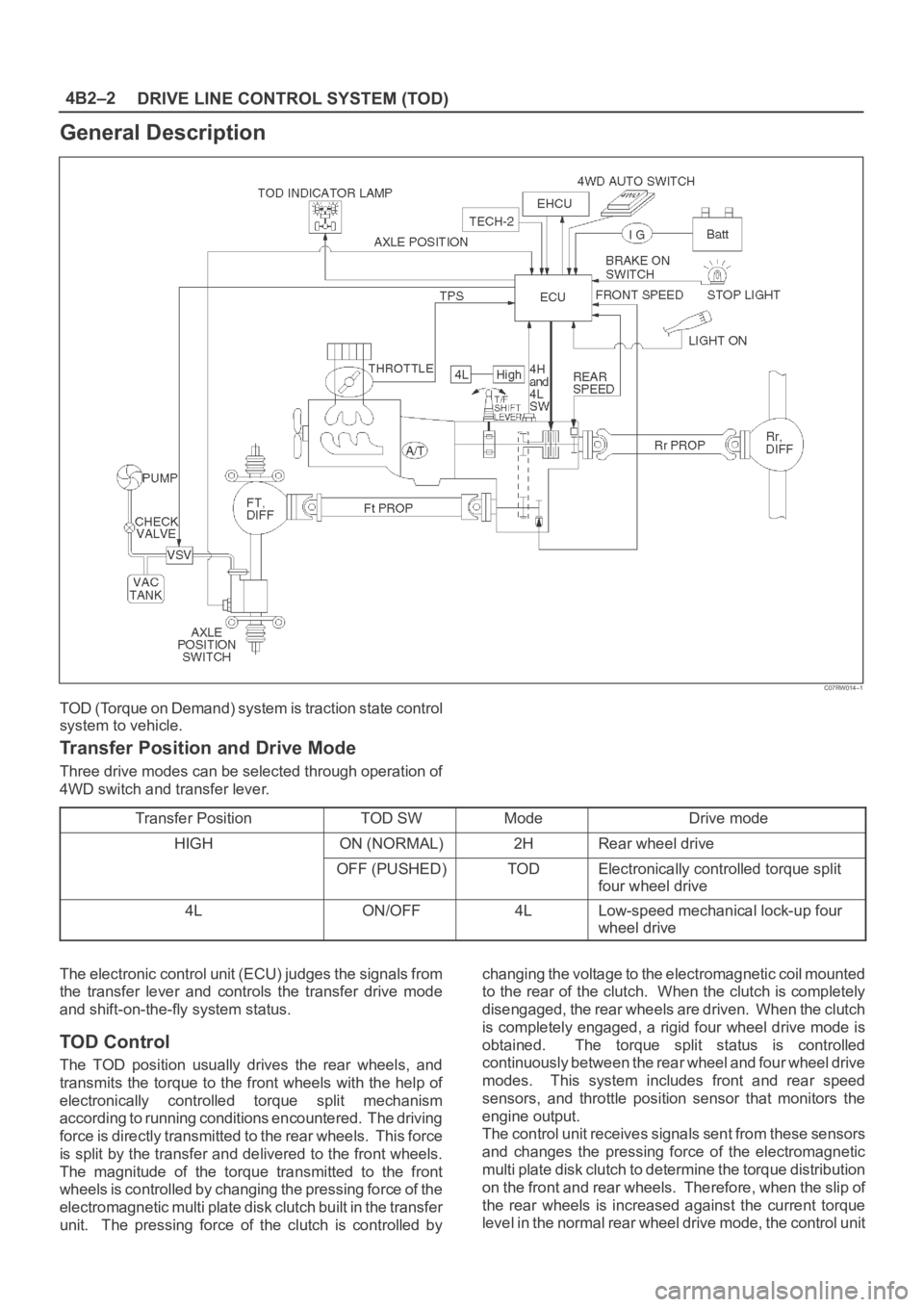

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–2

General Description

C07RW014–1

TOD (Torque on Demand) system is traction state control

system to vehicle.

Transfer Position and Drive Mode

Three drive modes can be selected through operation of

4WD switch and transfer lever.

Transfer Position

TOD SWModeDrive mode

HIGHON (NORMAL)2HRear wheel drive

OFF (PUSHED)TODElectronically controlled torque split

four wheel drive

4LON/OFF4LLow-speed mechanical lock-up four

wheel drive

The electronic control unit (ECU) judges the signals from

the transfer lever and controls the transfer drive mode

and shift-on-the-fly system status.

TOD Control

The TOD position usually drives the rear wheels, and

transmits the torque to the front wheels with the help of

electronically controlled torque split mechanism

according to running conditions encountered. The driving

force is directly transmitted to the rear wheels. This force

is split by the transfer and delivered to the front wheels.

The magnitude of the torque transmitted to the front

wheels is controlled by changing the pressing force of the

electromagnetic multi plate disk clutch built in the transfer

unit. The pressing force of the clutch is controlled bychanging the voltage to the electromagnetic coil mounted

to the rear of the clutch. When the clutch is completely

disengaged, the rear wheels are driven. When the clutch

is completely engaged, a rigid four wheel drive mode is

obtained. The torque split status is controlled

continuously between the rear wheel and four wheel drive

modes. This system includes front and rear speed

sensors, and throttle position sensor that monitors the

engine output.

The control unit receives signals sent from these sensors

and changes the pressing force of the electromagnetic

multi plate disk clutch to determine the torque distribution

on the front and rear wheels. Therefore, when the slip of

the rear wheels is increased against the current torque

level in the normal rear wheel drive mode, the control unit

Page 585 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–14

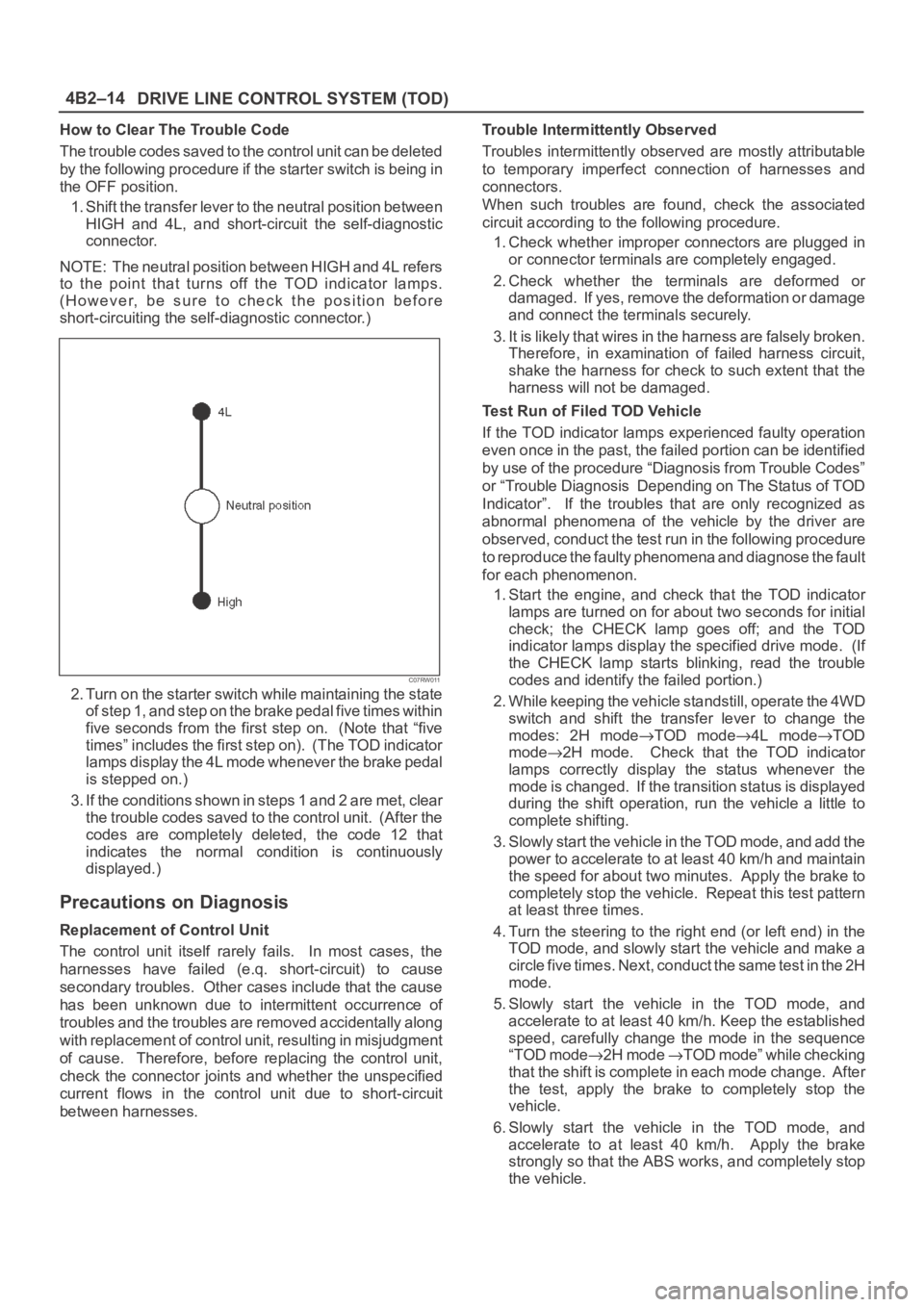

How to Clear The Trouble Code

The trouble codes saved to the control unit can be deleted

by the following procedure if the starter switch is being in

the OFF position.

1. Shift the transfer lever to the neutral position between

HIGH and 4L, and short-circuit the self-diagnostic

connector.

NOTE: The neutral position between HIGH and 4L refers

to the point that turns off the TOD indicator lamps.

(However, be sure to check the position before

short-circuiting the self-diagnostic connector.)

C07RW011

2. Turn on the starter switch while maintaining the state

of step 1, and step on the brake pedal five times within

five seconds from the first step on. (Note that “five

times” includes the first step on). (The TOD indicator

lamps display the 4L mode whenever the brake pedal

is stepped on.)

3. If the conditions shown in steps 1 and 2 are met, clear

the trouble codes saved to the control unit. (After the

codes are completely deleted, the code 12 that

indicates the normal condition is continuously

displayed.)

Precautions on Diagnosis

Replacement of Control Unit

The control unit itself rarely fails. In most cases, the

harnesses have failed (e.q. short-circuit) to cause

secondary troubles. Other cases include that the cause

has been unknown due to intermittent occurrence of

troubles and the troubles are removed accidentally along

with replacement of control unit, resulting in misjudgment

of cause. Therefore, before replacing the control unit,

check the connector joints and whether the unspecified

current flows in the control unit due to short-circuit

between harnesses.Trouble Intermittently Observed

Troubles intermittently observed are mostly attributable

to temporary imperfect connection of harnesses and

connectors.

When such troubles are found, check the associated

circuit according to the following procedure.

1. Check whether improper connectors are plugged in

or connector terminals are completely engaged.

2. Check whether the terminals are deformed or

damaged. If yes, remove the deformation or damage

and connect the terminals securely.

3. It is likely that wires in the harness are falsely broken.

Therefore, in examination of failed harness circuit,

shake the harness for check to such extent that the

harness will not be damaged.

Test Run of Filed TOD Vehicle

If the TOD indicator lamps experienced faulty operation

even once in the past, the failed portion can be identified

by use of the procedure “Diagnosis from Trouble Codes”

or “Trouble Diagnosis Depending on The Status of TOD

Indicator”. If the troubles that are only recognized as

abnormal phenomena of the vehicle by the driver are

observed, conduct the test run in the following procedure

to reproduce the faulty phenomena and diagnose the fault

for each phenomenon.

1. Start the engine, and check that the TOD indicator

lamps are turned on for about two seconds for initial

check; the CHECK lamp goes off; and the TOD

indicator lamps display the specified drive mode. (If

the CHECK lamp starts blinking, read the trouble

codes and identify the failed portion.)

2. While keeping the vehicle standstill, operate the 4WD

switch and shift the transfer lever to change the

modes: 2H mode

TOD mode4L modeTOD

mode

2H mode. Check that the TOD indicator

lamps correctly display the status whenever the

mode is changed. If the transition status is displayed

during the shift operation, run the vehicle a little to

complete shifting.

3. Slowly start the vehicle in the TOD mode, and add the

power to accelerate to at least 40 km/h and maintain

the speed for about two minutes. Apply the brake to

completely stop the vehicle. Repeat this test pattern

at least three times.

4. Turn the steering to the right end (or left end) in the

TOD mode, and slowly start the vehicle and make a

c i r c l e f i v e t i m e s . N e x t , c o n d u c t t h e s a m e t e s t i n t h e 2 H

mode.

5. Slowly start the vehicle in the TOD mode, and

accelerate to at least 40 km/h. Keep the established

speed, carefully change the mode in the sequence

“TOD mode

2H mode TOD mode” while checking

that the shift is complete in each mode change. After

the test, apply the brake to completely stop the

vehicle.

6. Slowly start the vehicle in the TOD mode, and

accelerate to at least 40 km/h. Apply the brake

strongly so that the ABS works, and completely stop

the vehicle.

Page 595 of 6000

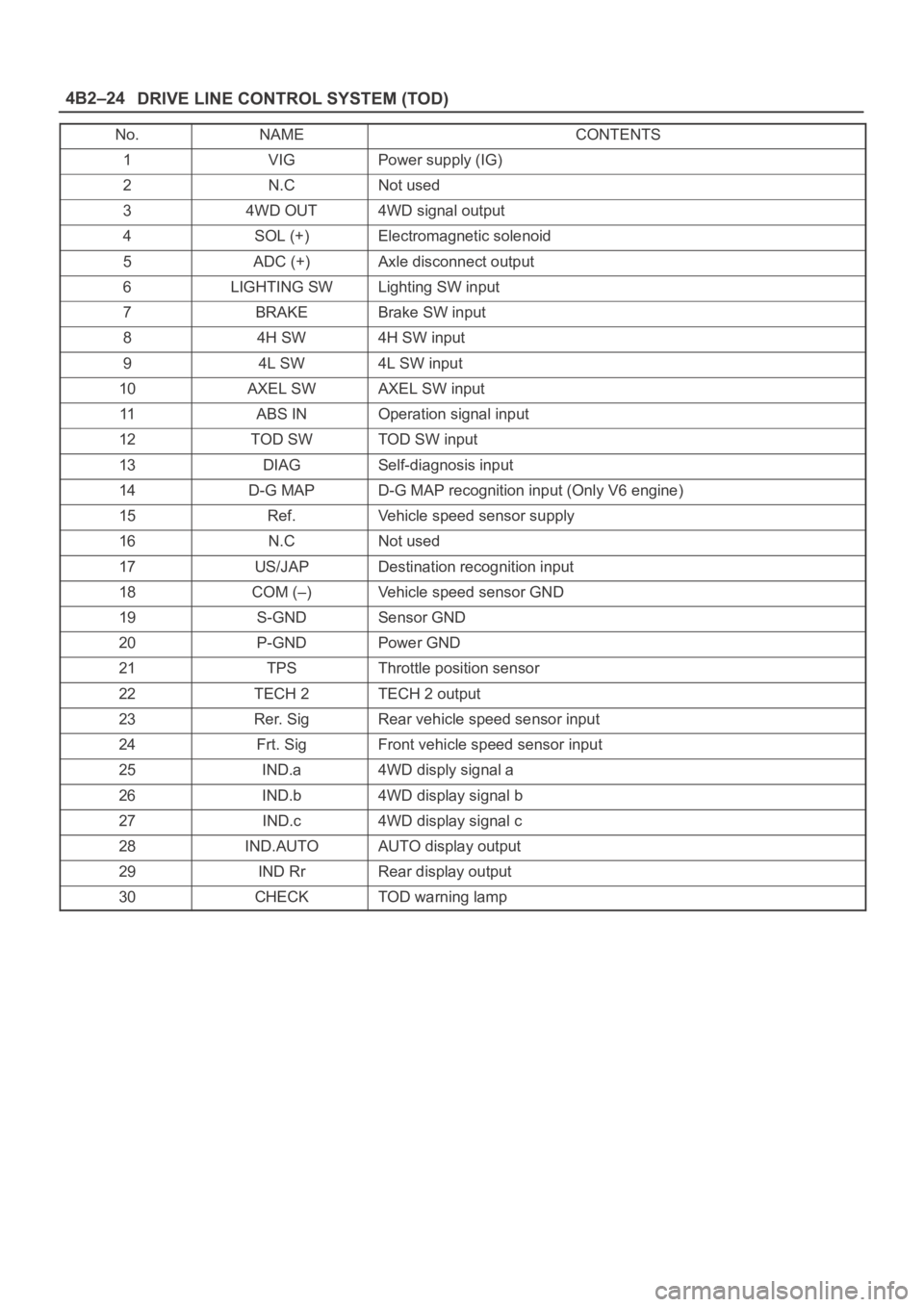

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–24

No.NAMECONTENTS

1VIGPower supply (IG)

2N.CNot used

34WD OUT4WD signal output

4SOL (+)Electromagnetic solenoid

5ADC (+)Axle disconnect output

6LIGHTING SWLighting SW input

7BRAKEBrake SW input

84H SW4H SW input

94L SW4L SW input

10AXEL SWAXEL SW input

11ABS INOperation signal input

12TOD SWTOD SW input

13DIAGSelf-diagnosis input

14D-G MAPD-G MAP recognition input (Only V6 engine)

15Ref.Vehicle speed sensor supply

16N.CNot used

17US/JAPDestination recognition input

18COM (–)Vehicle speed sensor GND

19S-GNDSensor GND

20P-GNDPower GND

21TPSThrottle position sensor

22TECH 2TECH 2 output

23Rer. SigRear vehicle speed sensor input

24Frt. SigFront vehicle speed sensor input

25IND.a4WD disply signal a

26IND.b4WD display signal b

27IND.c4WD display signal c

28IND.AUTOAUTO display output

29IND RrRear display output

30CHECKTOD warning lamp