4WD OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 741 of 6000

4D1–20

TRANSFER CASE (STANDARD TYPE)

Removal

1. Remove the speedometer sensor.

2. Remove the plate.

3. Remove the speedometer driven gear bushing and

driven gear.

NOTE: Apply a reference mark to the driven gear bushing

before removal.

4. Remove the front companion flange and the rear

companion flange, using the flange companion holder

5–8840–0133–0 (J–8614–11) to remove the end

nuts.

262RW067

NOTE: Use a universal puller to remove the rear

companion flange.

5. Disconnect the transfer breather hose from the

control box.

6. Remove the control box assembly.

7. Remove the transfer rear cover assembly from the

transfer case assembly.

Installation

1. Apply the recommended liquid gasket (LOCTITE

17430) or its equivalent to the transfer rear cover

fitting faces.

220RS017

2. Install the transfer rear cover assembly to the transfer

case assembly.

3. Perform the following steps before fitting the transfer

rear case:

1. Shift the high–low shift rod to the 4H side.

2. Turn the select rod counterclockwise so that the

select block projection may enter into the

2WD–4WD shift block.

3. The cut–away portion of the select rod head (9)

should align with that of the rear case hole’s

stopper (10).

230RW004

4. Tighten the transfer rear case bolts to the specified

torque.

Torque: 37 Nꞏm (3.8kgꞏm/27 lb ft)

Page 747 of 6000

4D1–26

TRANSFER CASE (STANDARD TYPE)

Detent, Shift Arm, and Interlock Pin

Disassembled View

262RW074

Legend

(1) Detent Ball, Spring and Plug

(2) Spring Pin and Bridge

(3) Spring Pin

(4) Spring

(5) 2WD–4WD Shift Rod

(6) Shift Arm

(7) Shift Block

(8) 4WD Indicator Switch(9) Interlock Pin

(10) Spring

(11) Select Rod Assembly

(12) Spring Pin

(13) High–Low Shift Rod

(14) Shift Arm

(15) Shift Block

(16) Transfer Case

(17) Spring (Except Shift On The Fly Model)

Disassembly

1. Remove the detent ball, spring and plug (1).

Page 748 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–27

2. Use a spring pin remover to remove the spring pin (2)

from the bridge (2).

262RW011

3. Remove the spring (4).

4. Engage the 2WD–4WD sleeve with the front output

gear. Remove the spring pin (3) from the block (7).

Remove the 2WD–4WD shift rod (5).

262RW022

5. Remove the shift arm (6).

6. Remove the shift block (7).

7. Remove the 4WD indicator switch (8).8. Use a magnetic tool to remove the interlock pin (9)

and spring (10) from the transfer case (16).

262RS005

9. Remove the select rod assembly (11).

10. Use a spring pin remover to remove the shift arm

spring pins (12) from the shift arm (14) and shift block

(15). Remove the high–low shift rod (13) from the

transfer case (16).

262RS006

11. Remove the shift arm (14).

12.Remove the shift block (15) from the transfer case

(16).

Page 749 of 6000

4D1–28

TRANSFER CASE (STANDARD TYPE)

Inspection and Repair

Refer to “TRANSFER CASE ASSEMBLY” in this section

for inspection and repair.

Reassembly

1. Place the shift block (15) in the transfer case (16).

2. Set the shift arm (14) on the High–Low sleeve.

3. Push the High–Low shift rod (13) through the shift

arm (14) and block (14).

4. Engage the High–Low sleeve with the 4H (1) side.

5. Install the spring pins (12) to the shift block (15) and

shift arm (14).

262RW012

6 . I n s t a l l t h e s e l e c t r o d a s s e m b l y ( 11 ) , j o i n i n g i t s l e v e r t o

the shift block groove.

7. Engage the High–Low sleeve with the 4H side and

install the the interlock pin (9) and spring (10) in the

proper direction.

8. Place the 2WD–4WD shift block (7) in the transfer

case (16).

9. Set the 2WD–4WD shift arm (6) on the 2WD–4WD

sleeve.

10. Push the 2WD–4WD shift rod (5) through the

2WD–4WD shift arm (6) and 2WD–4WD shift block

(7).

11. Install the 2WD–4WD shift rod (5) with the interlock

pin pushed in.

262RW035

Legend

(18) 2WD–4WD

(19) 4H Side

(20) Interlock pin

(21) 2WD

(22) 4WD

(23) Rod: 2–4

(24) Rod: H–L

(25) 4H

(26) 4L

(27) 4

2

(28) 4

4

12. Install the 4WD indicator switch and gasket (8).

Tighten to the specified torque.

Torque: 39 Nꞏm (4.0kgꞏm/29 lb ft)

13. Install the spring (4).

Page 750 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–29

14. Engage the 2WD–4WD sleeve with the 4WD side and

install the spring pin (3).

262RW022

15. Install the spring pin and bridge (2).

16. Install the detent ball, spring and plug and tighten the

plug (1) to the specified torque.

Torque: 25 Nꞏm (2.5kgꞏm/18 lb ft)

Page 751 of 6000

4D1–30

TRANSFER CASE (STANDARD TYPE)

Transfer Case Assembly

Disassembled View

226RW132

Legend

(1) Transfer Case (with oil seal)

(2) Bearing Snap Ring

(3) Front Output Gear Assembly

(4) Ball Bearing

(5) Front Output Shaft

(6) Stopper Plate (Shift On The Fly model)

(7) 2WD–4WD Clutch Hub and Sleeve Assembly

(8) Block Ring (Shift On The Fly model)

(9) Outside Ring (Shift On The Fly model)

(10) Inside Ring (Shift On The Fly model)

(11) Front Output Gear

(12) Needle Bearing

(13) Sub–Gear (anti–lash plate) (M/T)

(14) Belleville Spring (M/T)

(15) Spacer (M/T)

(16) Sub–Gear Snap Ring (M/T)

(17) Bearing Collar

(18) Ball Bearing

(19) Bearing Snap Ring

(20) Snap Ring

(21) Ball Bearing(22) Counter Gear

(23) Sub–Gear (anti–lash plate)

(24) Belleville Spring

(25) Spacer

(26) Ball Bearing

(27) Snap Ring

(28) Counter Gear Assembly

(29) Bearing Snap Ring

(30) Input Shaft Assembly

(31) Input Shaft

(32) Ball Bearing

(33) Snap Ring

(34) Plate

(35) Ball

(36) Bearing Collar

(37) Needle Bearing

(38) Transfer Input Gear

(39) High–Low Clutch Hub and Sleeve Assembly

(40) Lock Nut

(41) Ball Bearing

(42) Bearing Snap Ring

Page 753 of 6000

4D1–32

TRANSFER CASE (STANDARD TYPE)

10. Remove the bearing collar (36).

226RS071

11. Remove the ball (35).

12. Remove the plate (34).

13. Use a bench press and the ball bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (32) from input shaft (31).

265RW013

14. Remove the bearing snap ring (2) from the transfer

case, using a pair of snap ring pliers.15. Use a plastic hammer to tap the front output gear

assembly (3) free.

262RS009

16. Remove the bearing snap ring (19). Remove the ball

bearing (18) and bearing collar (17) together with

front output gear assembly: including following parts.

17. Use a bench press and the bearing remover

5–8840–0015–0 (J–22912–01) to remove the

following parts.

18. Remove the sub–gear snap ring (16), spacer (15),

belleville spring (14), and sub–gear (anti–lash plate)

(13).(M/T)

19. Remove the front output gear (11) and needle bearing

(12).

262RW070

20. Remove the inside ring (10). (Shift On The Fly model)

2 1 . R e m o v e t h e o u t s i d e r i n g ( 9 ) . ( S h i f t O n T h e F l y m o d e l )

22. Remove the block ring (8). (Shift On The Fly model)

23. Use a bench press and bearing remover

5–8840–0015–0 (J–22912–01) to remove the

2WD–4WD clutch hub and sleeve assembly (7) and

stopper plate (6). (Shift On The Fly model)

Page 754 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–33

NOTE: Do not reuse the stopper plate. (Shift On The Fly

model)

24. Disassemble the 2WD–4WD clutch hub and sleeve

assembly.

Springs (1) (Shift On The Fly model)

Inserts (2) (Shift On The Fly model)

Clutch Hub (3)

Sleeve (4)

226RW133

25. Use a bench press and the ball bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (4) from front output shaft (5).

262RW071

26. Remove bearing snap ring (29) from transfer case.

27. Remove the counter gear assembly (28) from the

transfer case (1).

28. Use a pair of snap ring pliers to remove the snap ring

(20).29. Use a bench press and the bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (21).

30. Use a pair of snap ring pliers to remove the snap ring

(27).

31. Use a bench press and the bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (26).

226RW191

32. Remove the spacer (25).

33. Remove the belleville spring (24).

34. Remove the sub–gear (anti–lash plate) (23) from the

counter gear (22).

Inspection and Repair

1. Make the necessary repair or parts replacement if

wear, damage or any other abnormal conditions are

found during inspection.

2. Wash all parts thoroughly in clean solvent. Be sure all

old lubricant, metallic particles, dirt, or foreign

material are removed from the surfaces of every part.

Apply compressed air to each oil feed port and

channel in each case half to remove any obstructions

or cleaning solvent residue.

Gears

1. Inspect all the gear teeth for signs of excessive wear

or damage and check all the gear splines for burrs,

nicks, wear or damage. Remove the minor nicks or

scratches on an oil stone. Replace any part exhibiting

excessive wear or damage.

Front Output Gear Inside Diameter

1. Use an inside dial indicator to measure the gear inside

diameter.

Page 756 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–35

Limit : 3.0 mm (0.118 in)

226RS037

2WD–4WD 3–Cone Synchronizer (Shift On

The Fly model)

1. Use a thickness gauge to measure the clearance

between the block ring and the dog teeth.

2. If the measured value exceeds the specified limit, the

2WD–4WD synchronizer assembly must be

replaced.

Block ring and insert clearance

Standard : 1.5 mm (0.059 in)

Limit : 0.8 mm (0.031 in)

226RW142

Clutch Hub and Insert Clearance

1. Use a thickness gauge to measure the clearance

between the clutch hub and the insert.

2. If the measured value exceeds the specified limit, the

clutch hub and the insert must be replaced.

Clutch hub and insert clearance

Standard : 0.01–0.19 mm (0.0004–0.0075 in)

Limit : 0.3 mm (0.012 in)

226RS038

Detent Springs

1. Inspect the springs for distortion, cracks or wear.

Replace if these conditions are present.

Detent Spring Free Length

1. Use a vernier caliper to measure the detent spring

free length.

Page 760 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–39

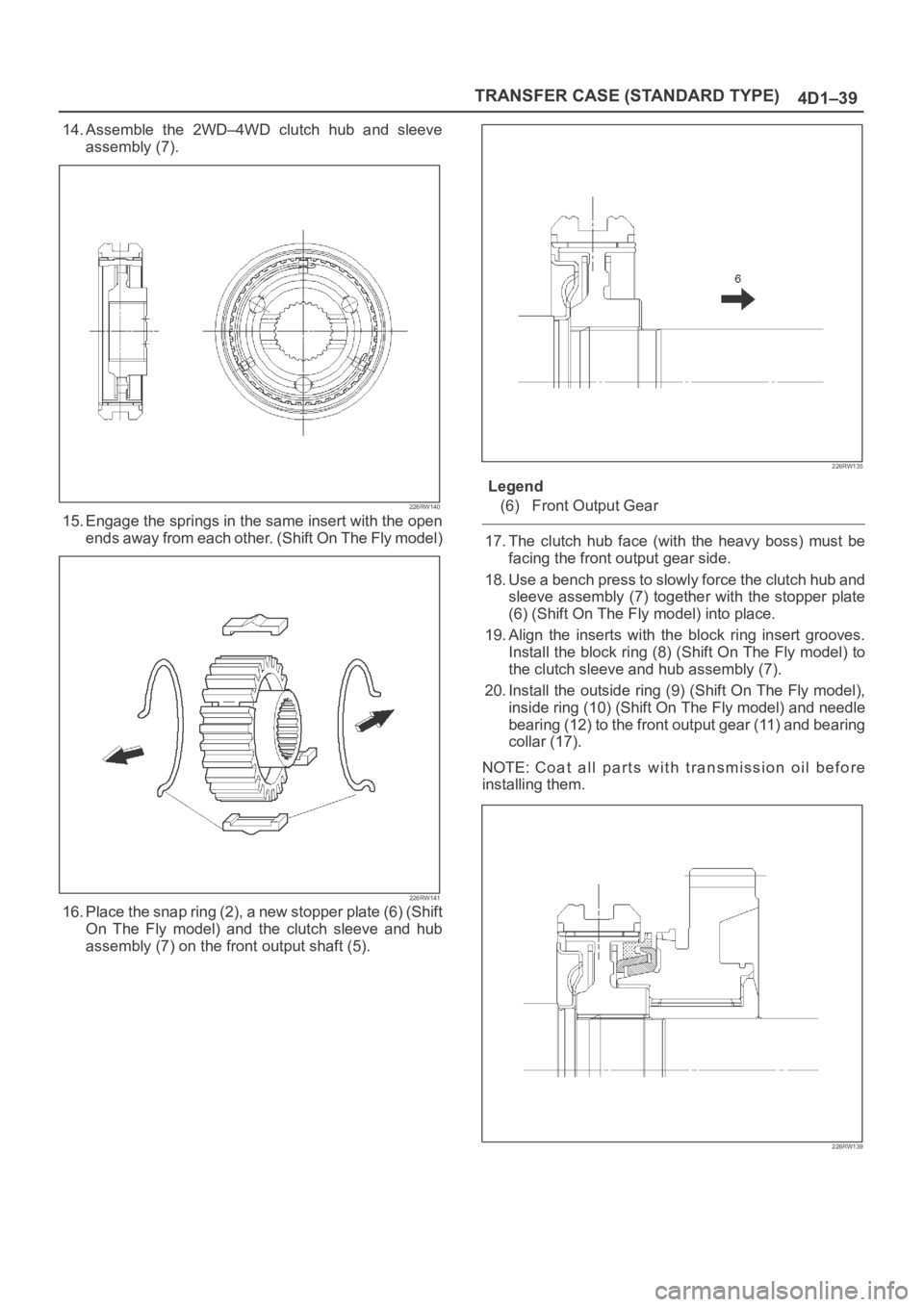

14. Assemble the 2WD–4WD clutch hub and sleeve

assembly (7).

226RW140

15. Engage the springs in the same insert with the open

ends away from each other. (Shift On The Fly model)

226RW141

16. Place the snap ring (2), a new stopper plate (6) (Shift

On The Fly model) and the clutch sleeve and hub

assembly (7) on the front output shaft (5).

226RW135

Legend

(6) Front Output Gear

17. The clutch hub face (with the heavy boss) must be

facing the front output gear side.

18. Use a bench press to slowly force the clutch hub and

sleeve assembly (7) together with the stopper plate

(6) (Shift On The Fly model) into place.

19. Align the inserts with the block ring insert grooves.

Install the block ring (8) (Shift On The Fly model) to

the clutch sleeve and hub assembly (7).

20. Install the outside ring (9) (Shift On The Fly model),

inside ring (10) (Shift On The Fly model) and needle

bearing (12) to the front output gear (11) and bearing

collar (17).

NOTE: Coat all parts with transmission oil before

installing them.

226RW139