ECO mode OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 657 of 6000

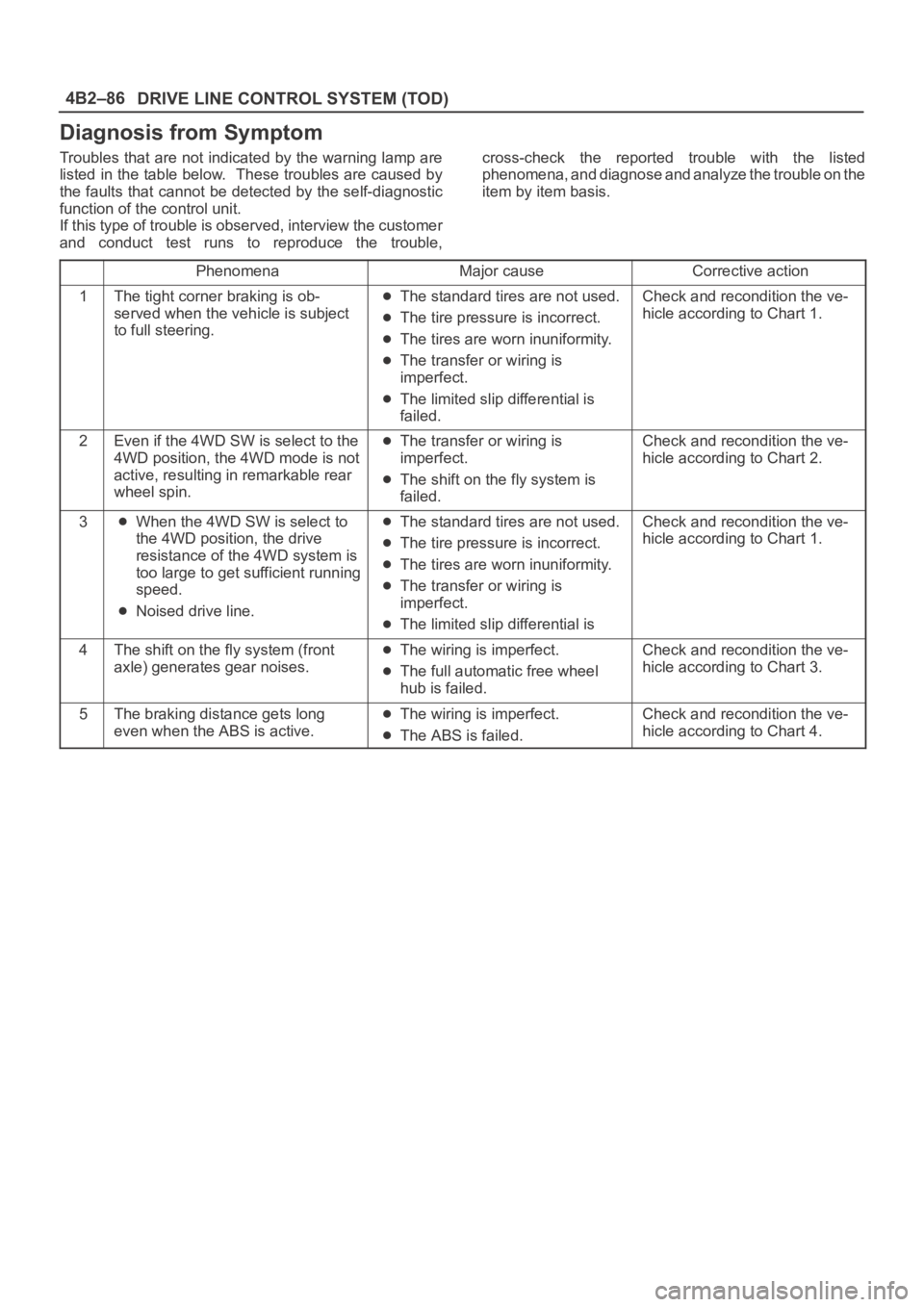

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–86

Diagnosis from Symptom

Troubles that are not indicated by the warning lamp are

listed in the table below. These troubles are caused by

the faults that cannot be detected by the self-diagnostic

function of the control unit.

If this type of trouble is observed, interview the customer

and conduct test runs to reproduce the trouble,cross-check the reported trouble with the listed

phenomena, and diagnose and analyze the trouble on the

item by item basis.

PhenomenaMajor causeCorrective action

1The tight corner braking is ob-

served when the vehicle is subject

to full steering.The standard tires are not used.

The tire pressure is incorrect.

The tires are worn inuniformity.

The transfer or wiring is

imperfect.

The limited slip differential is

failed.

Check and recondition the ve-

hicle according to Chart 1.

2Even if the 4WD SW is select to the

4WD position, the 4WD mode is not

active, resulting in remarkable rear

wheel spin.The transfer or wiring is

imperfect.

The shift on the fly system is

failed.

Check and recondition the ve-

hicle according to Chart 2.

3When the 4WD SW is select to

the 4WD position, the drive

resistance of the 4WD system is

too large to get sufficient running

speed.

Noised drive line.

The standard tires are not used.

The tire pressure is incorrect.

The tires are worn inuniformity.

The transfer or wiring is

imperfect.

The limited slip differential is

Check and recondition the ve-

hicle according to Chart 1.

4The shift on the fly system (front

axle) generates gear noises.The wiring is imperfect.

The full automatic free wheel

hub is failed.

Check and recondition the ve-

hicle according to Chart 3.

5The braking distance gets long

even when the ABS is active.The wiring is imperfect.

The ABS is failed.

Check and recondition the ve-

hicle according to Chart 4.

Page 663 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–92

Chart 3The shift on the fly system generates gear noises.

(The fuel economy is bad in the 2H mode.)

Function of circuit—

Fail conditionWhen the vehicle is run in the 2H mode, the shift on the fly system generates gear

noises or the front wheel gears are engaged to generate a shock.

D04RW055

Page 728 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–7

A/T, WO/Shift On The Fly, WO/4WD Switch, model

A07RW055

The transfer case is used to provide a means of providing

power flow to the front axle. The transfer case also

provides a means of disconnecting the front axle,

providing better fuel economy and quieter operation when

the vehicle is driven on improved roads where four wheel

drive is not required. In addition, the transfer case

provides an additional gear reduction when placed in low

range, which is useful when difficult off–road conditions

are encountered.

A floor mounted shift lever is used to select the high–low

range. When four wheel drive switch has been turned on,

the four wheel drive indicator light is designed to come on

when the front axle has been engaged.

Page 734 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–13

10. Offset the actuator assembly.

220RW028

11. Remove the actuator assembly.

220RW029

Legend

(7) Position: 4WD

(8) Mode: 2WD

12. Remove the transfer rear cover assembly from the

transfer case assembly.

Installation

1. Apply the recommended liquid gasket (LOCTITE

17430) or its equivalent to the transfer rear cover

fitting faces.

220RS017

2. Install the transfer rear cover assembly to the transfer

case assembly.

3. Perform the following steps before fitting the transfer

rear case:

1. Shift the high–low shift rod to the 4H side.

2. The cut–away portion of the select rod head (9)

should align with that of the rear case hole’s

stopper (10).

230RW004

4. Tighten the transfer rear case bolts to the specified

torque.

Torque: 37 Nꞏm (3.8kgꞏm/27 lb ft)

5. Shift the 2WD–4WD shift rod (11) to the 4WD side.

Page 816 of 6000

5A–6

BRAKE CONTROL SYSTEM

Test Driving ABS Complaint Vehicles

In case that there has been an malfunction in the lighting

pattern of “ABS” warning light, the fault can be located in

accordance with the “DIAGNOSIS BY “ABS” WARNING

LIGHT ILLUMINATION PATTERN” . In case of such

trouble as can be detected by the driver as a vehicle

symptom, however, it is necessary to give a test drive

following the test procedure mentioned below, thereby

reproducing the symptom for trouble diagnosis on a

symptom basis:

1. Start the engine and make sure that the “ABS” W/L

goes OFF. If the W/L remains ON, it means that the

Diagnostic Trouble Code (DTC) is stored. Therefore,

read the code and locate the fault.

2. Start the vehicle and accelerate to about 30 km/h (19

mph) or more.

3. Slowly brake and stop the vehicle completely.

4. Then restart the vehicle and accelerate to about 40

km/h (25 mph) or more.

5. Brake at a time so as to actuate the ABS and stop the

vehicle.

6. Be cautious of abnormality during the test. If the W/L

is actuated while driving, read the DTC and locate the

fault.

7. If the abnormality is not reproduced by the test, make

best efforts to reproduce the situation reported by the

customer.

8. If the abnormality has been detected, repair in

accordance with the “SYMPTOM DIAGNOSIS” .NOTE:Be sure to give a test drive on a wide, even road with

little traffic.

If an abnormality is detected, be sure to suspend the

test and start trouble diagnosis at once.

“ABS” Warning Light

When ABS trouble occurs and actuates when possible

the “ABS” warning light, the trouble code corresponding

to the trouble is stored in the EHCU. Only the ordinary

brake system is available when the ABS is turned off.

When the “ABS” warning light is actuated, if the starter

switch is set ON after setting it OFF once, the EHCU

checks up on the entire system and, if there is no

abnormality, judges ABS to work currently and the

warning light works normally even though the trouble

code is stored.

NOTE: Illumination of the “ABS” warning light indicates

that anti-lock braking is no longer available. Power

assisted braking without anti-lock control is still available.

Normal Operation

“ABS” Warning Light

W h e n t h e i g n i t i o n i s f i r s t m o v e d f r o m “ O F F ” t o “ R U N ” , t h e

amber “ABS” warning light will turn “ON” . The “ABS”

warning light will turn “ON” during engine starting and will

usually stay “ON” for approximately three seconds after

the ignition switch is returned to the “ON” position. The

warning light should remain “OFF” at all other times.

Basic Diagnostic Flow Chart

StepActionYe sNo

11. Customer complaint.

2. Questioning to customer.

3. Basic inspection (Refer to “Basic inspection procedure”)

Using TECH 2?

Go to Step 2Go to Step 4

2Make sure of DTC by mode “F0: Diagnostic Trouble Codes”.

Is EHCU including DTC?

Go to Step 3Go to Step 5

31. Repair of faulty part.

2. Elimination of DTC.

3. Inspection of “ABS” W/L Illumination pattern with ignition SW

“ON”.

4. Test drive.

Does repeat trouble?

Repeat the

diagnosis it the

symptom or DTC

appears again Go

to Step 1

Go to Step 5

4Check if the DTC is stored.

Is EHCU including DTC?

Go to Step 3

Trouble diagnosis

based on

symptom (Refer

to “SYMPTOM

DIAGNOSIS”) Go

to Step 3

51. Reconnect all components and ensure all component are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

FinishedGo to Step 5

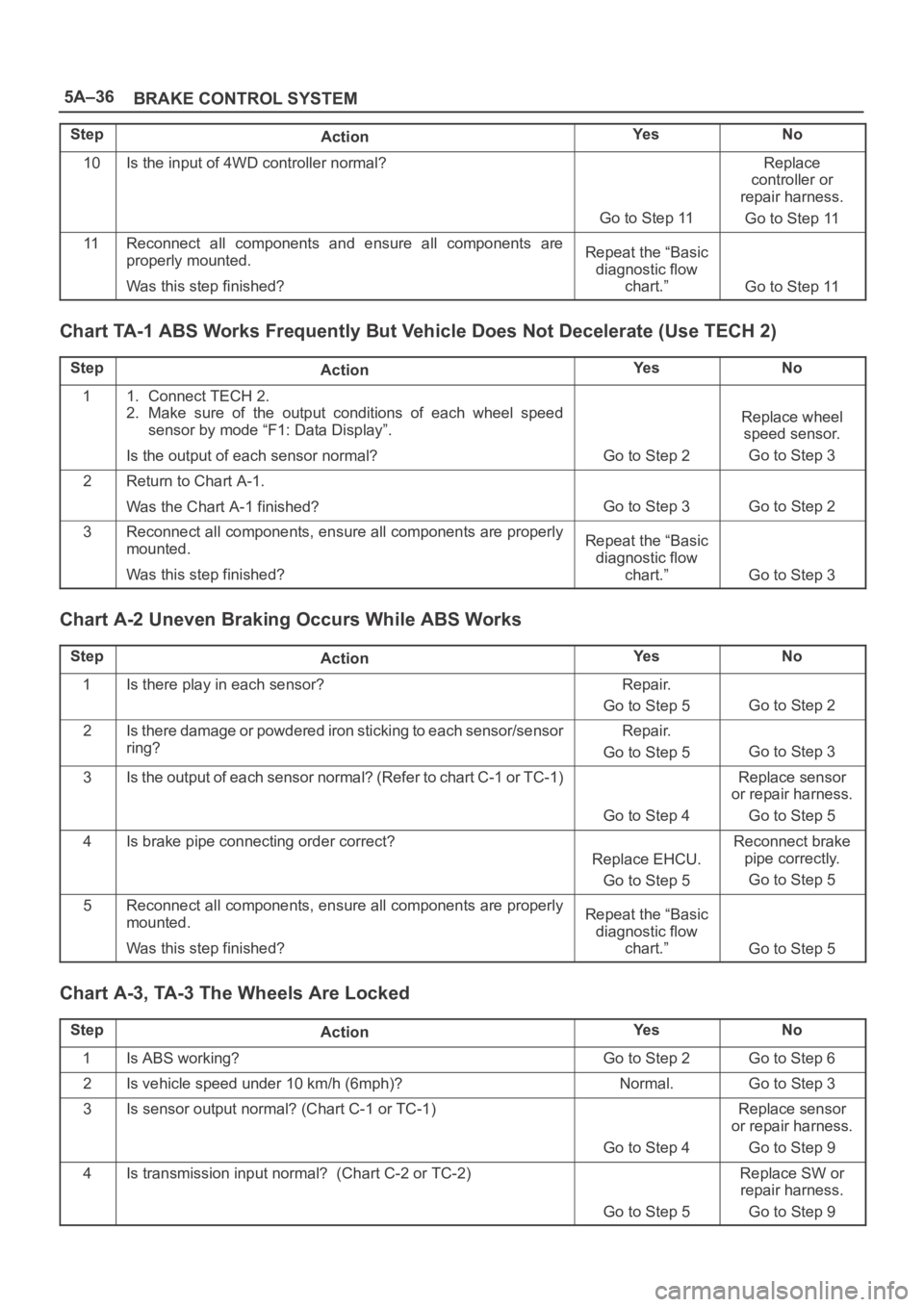

Page 846 of 6000

5A–36

BRAKE CONTROL SYSTEM

StepNo Ye s

Action

10Is the input of 4WD controller normal?

Go to Step 11

Replace

controller or

repair harness.

Go to Step 11

11Reconnect all components and ensure all components are

properly mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 11

Chart TA-1 ABS Works Frequently But Vehicle Does Not Decelerate (Use TECH 2)

StepActionYe sNo

11. Connect TECH 2.

2. Make sure of the output conditions of each wheel speed

sensor by mode “F1: Data Display”.

Is the output of each sensor normal?

Go to Step 2

Replace wheel

speed sensor.

Go to Step 3

2Return to Chart A-1.

Was the Chart A-1 finished?

Go to Step 3Go to Step 2

3Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart A-2 Uneven Braking Occurs While ABS Works

StepActionYe sNo

1Is there play in each sensor?Repair.

Go to Step 5

Go to Step 2

2Is there damage or powdered iron sticking to each sensor/sensor

ring?Repair.

Go to Step 5

Go to Step 3

3Is the output of each sensor normal? (Refer to chart C-1 or TC-1)

Go to Step 4

Replace sensor

or repair harness.

Go to Step 5

4Is brake pipe connecting order correct?

Replace EHCU.

Go to Step 5

Reconnect brake

pipe correctly.

Go to Step 5

5Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 5

Chart A-3, TA-3 The Wheels Are Locked

StepActionYe sNo

1Is ABS working?Go to Step 2Go to Step 6

2Is vehicle speed under 10 km/h (6mph)?Normal.Go to Step 3

3Is sensor output normal? (Chart C-1 or TC-1)

Go to Step 4

Replace sensor

or repair harness.

Go to Step 9

4Is transmission input normal? (Chart C-2 or TC-2)

Go to Step 5

Replace SW or

repair harness.

Go to Step 9

Page 856 of 6000

5A–46

BRAKE CONTROL SYSTEM

Chart B-6 Abnormal Transmission Input (DTC 23)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

Is there continuity between EHCU connector terminal 6 to 15

(Gear position-P(A/T), N(M/T))?Shorted switch

harness.

Repair switch or

harness.

Go to Step 6

Go to Step 2

2Is the vehicle an A/T model?Go to Step 3Go to Step 4

3Turn the key on and measure the voltage between EHCU

connector terminal 6 and 15.

Is the 6V under when the gear position is L, and R(Battery voltage

12V)?

Go to Step 5

Transmission SW

trouble.

Disconnected

harness.

Repair SW and

harness.

Go to Step 6

4Turn the key on and measure the voltage between EHCU

connector terminal 6 and 15.

Is the 9.6V over when the gear position is 1, 2, R(Battery voltage

12V)?

Go to Step 5

Transmission SW

trouble.

Disconnected

harness.

Repair SW and

harness.

Go to Step 6

5Is there 6.6 to 9.0V when the gear position is 3, 4, 5 and N(M/T) or

2,3,D,N and P(A/T)(Battery voltage 12V)?Suspected

harness/

connector short

power

source/GND.

Suspected

shorted

transmission SW.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 6

Transmission SW

trouble.

Disconnected

harness.

Repair SW and

harness.

Go to Step 6

61. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 6

Page 870 of 6000

5A–60

BRAKE CONTROL SYSTEM

Chart C-2 Transmission Input Inspection Procedure

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

Is there continuity between EHCU connector terminals 6 and 15

(Gear position-P(A/T), N(M/T))?Shorted switch

harness.

Repair switch or

harness.

Go to Step 6

Go to Step 2

2Is the vehicle an A/T model?Go to Step 3Go to Step 5

3Turn the key on and measure voltage between EHCU connector

terminals 6 and 15.

Is there less than 6V when the gear position is L, and R(Battery

voltage 12V)?

Go to Step 5

Transmission SW

trouble.

Disconnected

harness.

Repair SW and

harness.

Go to Step 6

4Turn the key on and measure the voltage between EHCU

connector terminal 6 and 15.

Is there more than 9.6V when the gear position is 1, 2, R(Battery

voltage 12V)?

Go to Step 5

Transmission SW

trouble.

Disconnected

harness.

Repair SW and

harness.

Go to Step 6

5Measure the voltage between EHCU connector terminals 6 and

15.

Is there 6.6 to 9.0V when the gear position is 3, 4, 5 and N(M/T) or

2,3,D,N and P(A/T)(Battery voltage 12V)?

Go to Step 6

Transmission SW

trouble.

Disconnected

harness.

Repair SW and

harness.

Go to Step 6

61. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 6

Page 871 of 6000

5A–61 BRAKE CONTROL SYSTEM

Chart TC-2 Transmission Input Inspection Procedure (Use TECH 2)

StepActionYe sNo

11. Connect TECH 2.

2. Select Data List.

Is this vehicle an A/T model ?

Go to Step 2Go to Step 4

2Is “Off-Road Switch(Transmission Input): Active” when the shift

lever is the L and R?

Go to Step 3Go to Step 6

3Is “Off-Road Switch(Transmission Input): Inactive” when the shift

lever is other than the L and R?

Go to Step 7Go to Step 6

4Is “Off-Road Switch(Transmission Input): Active” when the shift

lever is in 1, 2 and R?

Go to Step 5Go to Step 6

5Is “Off-Road Switch(Transmission Input): Inactive” when the shift

lever is other than the 1, 2 and R?

Go to Step 7Go to Step 6

61. Abnormal T/M SW, inhibitor SW, or harness.

2. Repair T/M SW, inhibitor SW, or harness.

Is the T/M SW, inhibitor SW, or harness repaired?

Go to Step 7Go to Step 6

7Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 7

Page 1154 of 6000

6E–37 ENGINE DRIVEABILITY AND EMISSIONS

Diagnosis

Strategy-Based Diagnostics

Strategy-Based Diagnostics

The strategy-based diagnostic is a uniform approach to

repair all Electrical/Electronic (E/E) systems. The

diagnostic flow can always be used to resolve an E/E

system problem and is a starting point when repairs are

necessary. The following steps will instruct the technician

how to proceed with a diagnosis:

1. Verify the customer complaint.

To verify the customer complaint, the technician

should know the normal operation of the system.

2. Perform preliminary checks.

Conduct a thorough visual inspection.

Review the service history.

Detect unusual sounds or odors.

Gather diagnostic trouble code information to

achieve an effective repair.

3. Check bulletins and other service information.

This includes videos, newsletters, etc.

4. Refer to service information (manual) system

check(s).

“System checks” contain information on a system

that may not be supported by one or more DTCs.

System checks verify proper operation of the

system. This will lead the technician in an

organized approach to diagnostics.

5. Refer to service diagnostics.

DTC Stored

Follow the designated DTC chart exactly to make an

effective repair.

No DTC

Select the symptom from the symptom tables. Follow the

diagnostic paths or suggestions to complete the repair.

You may refer to the applicable component/system check

in the system checks.

No Matching Symptom

1. Analyze the complaint.

2. Develop a plan for diagnostics.

3. Utilize the wiring diagrams and the theory of

operation.

Call technical assistance for similar cases where repair

history may be available. Combine technician knowledge

with efficient use of the available service information.

Intermittents

Conditions that are not always present are called

intermittents. To resolve intermittents, perform the

following steps:

1. Observe history DTCs, DTC modes, and freezeframe

data.

2. Evaluate the symptoms and the conditions described

by the customer.3. Use a check sheet or other method to identify the

circuit or electrical system component.

4. Follow the suggestions for intermittent diagnosis

found in the service documentation.

Most Tech 2s, such as the Tech II and the

5–8840–0285–0 (Fluke model 87 DVOM), have

data-capturing capabilities that can assist in detecting

intermittents.

No Trouble Found

This condition exists when the vehicle is found to operate

normally. The condition described by the customer may

be normal. Verify the customer complaint against another

vehicle that is operating normally. The condition may be

intermittent. Verify the complaint under the conditions

described by the customer before releasing the vehicle.

1. Re-examine the complaint.

When the Complaint cannot be successfully found or

isolated, a re-evaluation is necessary. The complaint

should be re-verified and could be intermittent as

defined in

Intermittents, or could be normal.

2. Repair and verify.

After isolating the cause, the repairs should be made.

Validate for proper operation and verify that the

symptom has been corrected. This may involve road

testing or other methods to verify that the complaint

has been resolved under the following conditions:

Conditions noted by the customer.

If a DTC was diagnosed, verify a repair by

duplicating conditions present when the DTC was

set as noted in the Failure Records or Freeze

Frame data.

Verifying Vehicle Repair

Verification of the vehicle repair will be more

comprehensive for vehicles with OBD system

diagnostics. Following a repair, the technician should

perform the following steps:

IMPORTANT:Follow the steps below when you verify

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

1. Review and record the Failure Records and the

Freeze Frame data for the DTC which has been

diagnosed (Freeze Frame data will only be stored for

an A or B type diagnostic and only if the MIL(”Check

Engine” lamp) has been requested).

2. Clear the DTC(S).

3. Operate the vehicle within conditions noted in the

Failure Records and Freeze Frame data.

4. Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnostic

test associated with that DTC runs.