ECO mode OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 215 of 6000

4.512

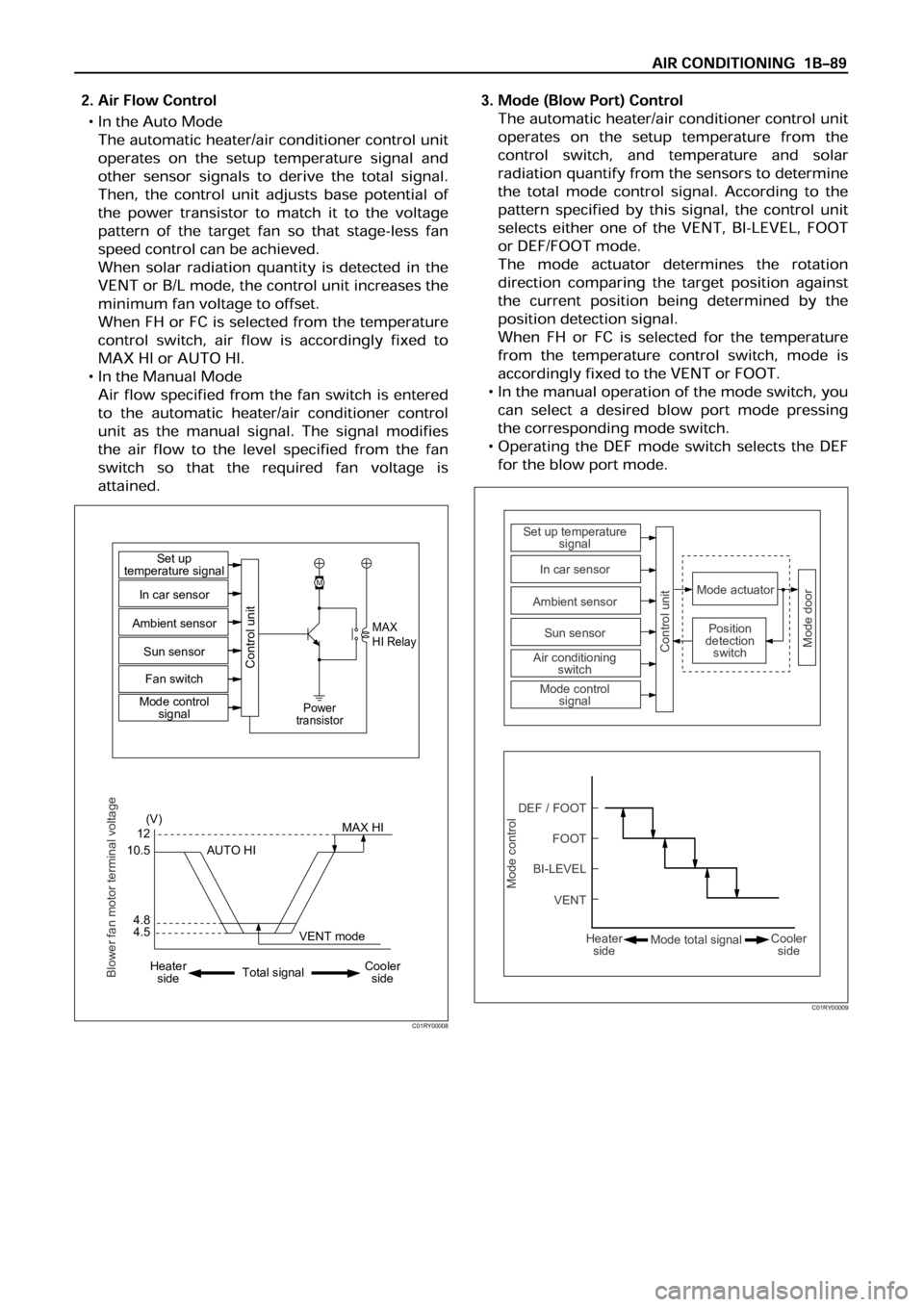

(V)

M

MAX

HI Relay

Power

transistor

4.8 10.5MAX HI Set up

temperature signal

Control unit

In car sensor

Ambient sensor

Sun sensor

Mode control

signal Fan switch

AUTO HI

Heater

sideCooler

side Total signalVENT mode

Blower fan motor terminal voltage

C01RY00008

Mode control

DEF / FOOTSet up temperature

signal

Mode actuator

Mode doorPosition

detection

switch

Control unit

In car sensor

Sun sensor

Air conditioning

switch

Mode control

signal Ambient sensor

FOOT

BI-LEVEL

VENT

Heater

sideCooler

side Mode total signal

C01RY00009

Page 216 of 6000

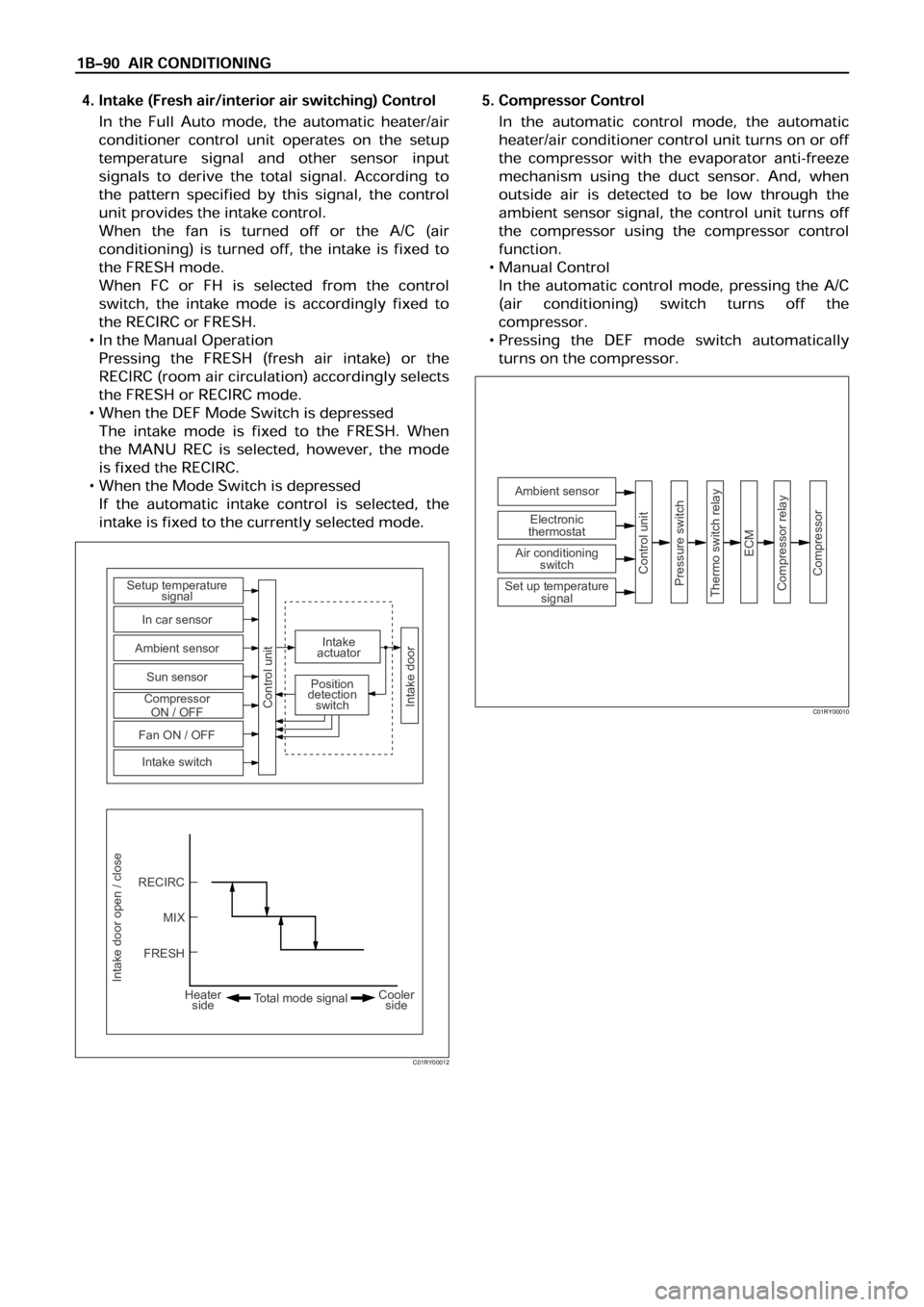

Intake door open / close

RECIRC Setup temperature

signal

Intake

actuator

Position

detection

switch

In car sensor

Ambient sensor

Sun sensor

Compressor

ON / OFF

Fan ON / OFF

Intake switch

Control unit

Intake door

MIX

FRESH

Heater

sideCooler

side Total mode signal

C01RY00012

Ambient sensor

Control unit

Pressure switch

Thermo switch relay

ECM

Compressor relay

Compressor

Electronic

thermostat

Air conditioning

switch

Set up temperature

signal

C01RY00010

Page 224 of 6000

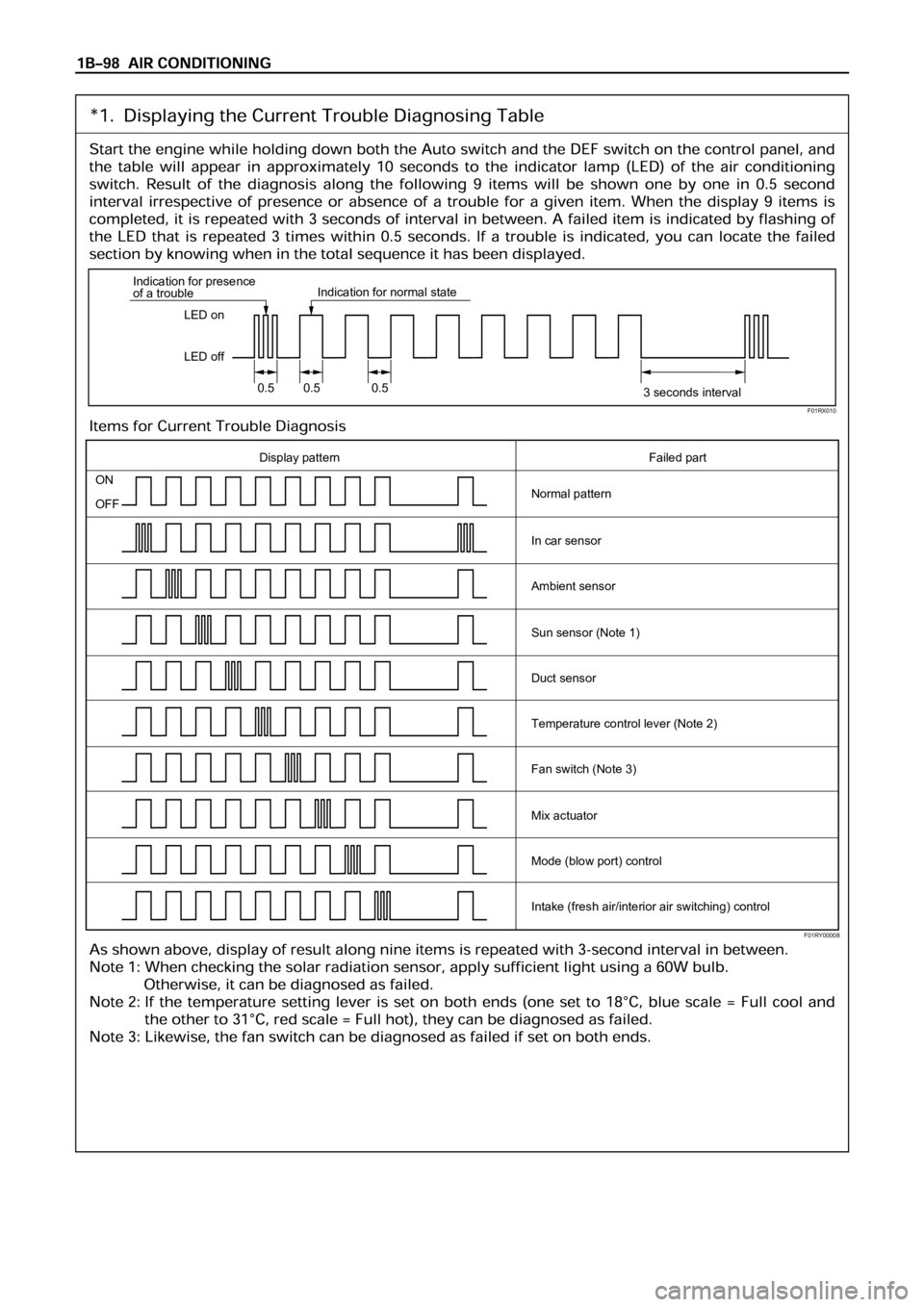

LED on

LED off Indication for presence

of a troubleIndication for normal state

0.5 0.5 0.5

3 seconds interval

ON

OFF

Display pattern Failed part

Normal pattern

In car sensor

Ambient sensor

Sun sensor (Note 1)

Duct sensor

Temperature control lever (Note 2)

Fan switch (Note 3)

Mix actuator

Mode (blow port) control

Intake (fresh air/interior air switching) control

F01RX010

F01RY00008

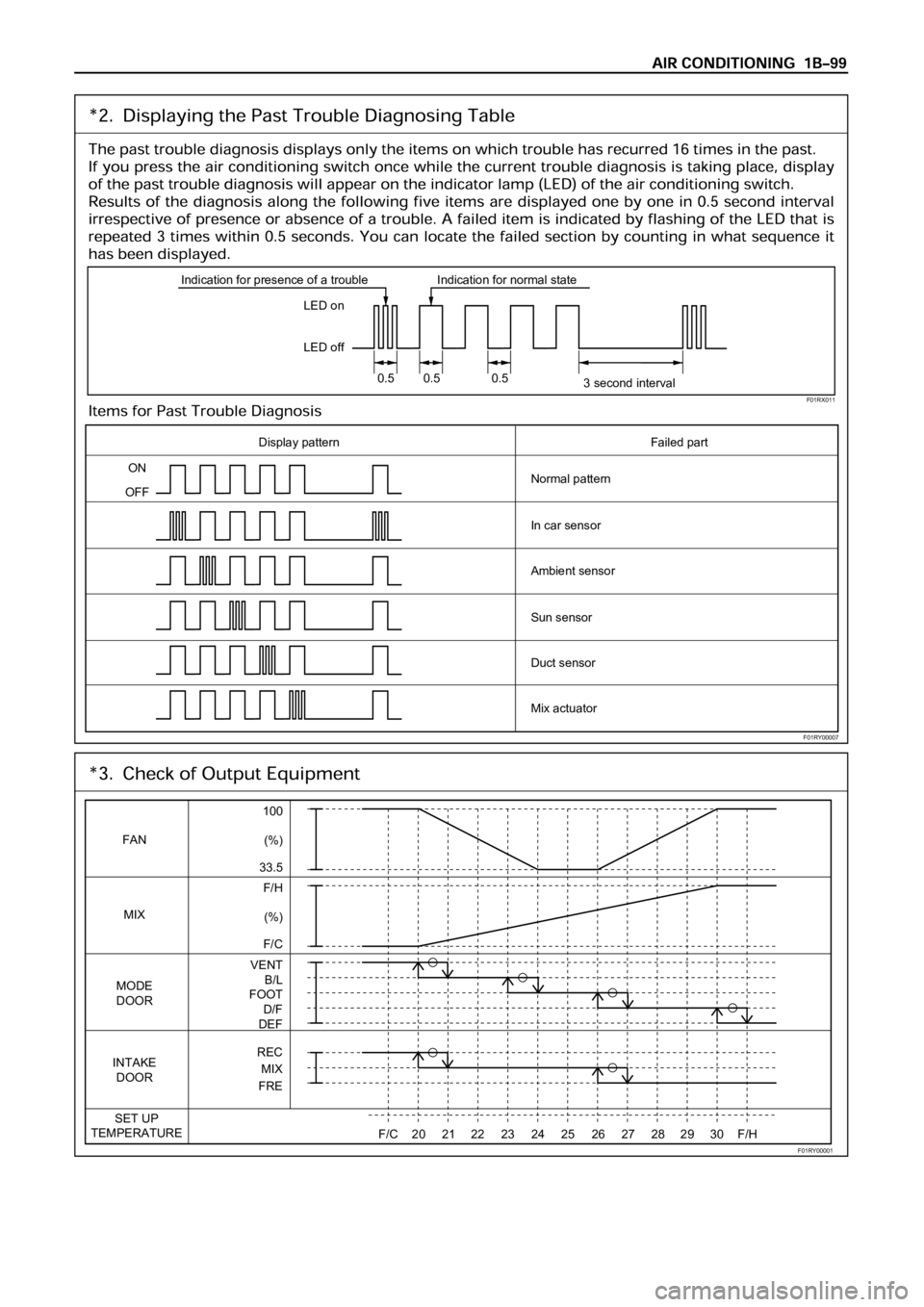

Page 225 of 6000

LED on

LED off Indication for presence of a trouble Indication for normal state

0.5 0.5 0.5

3 second interval

Display pattern

ON

OFFNormal pattern

In car sensor

Ambient sensor

Sun sensor

Duct sensor

Mix actuatorFailed part

F01RX011

F01RY00007

FAN

MIX

MODE

DOOR

INTAKE

DOOR

SET UP

TEMPERATURE

100

(%)

33.5

F/H

VENT

B/L

FOOT

D/F

DEF

REC

MIX

FRE

F/C2021222324252627282930F/H (%)

F/C

F01RY00001

Page 544 of 6000

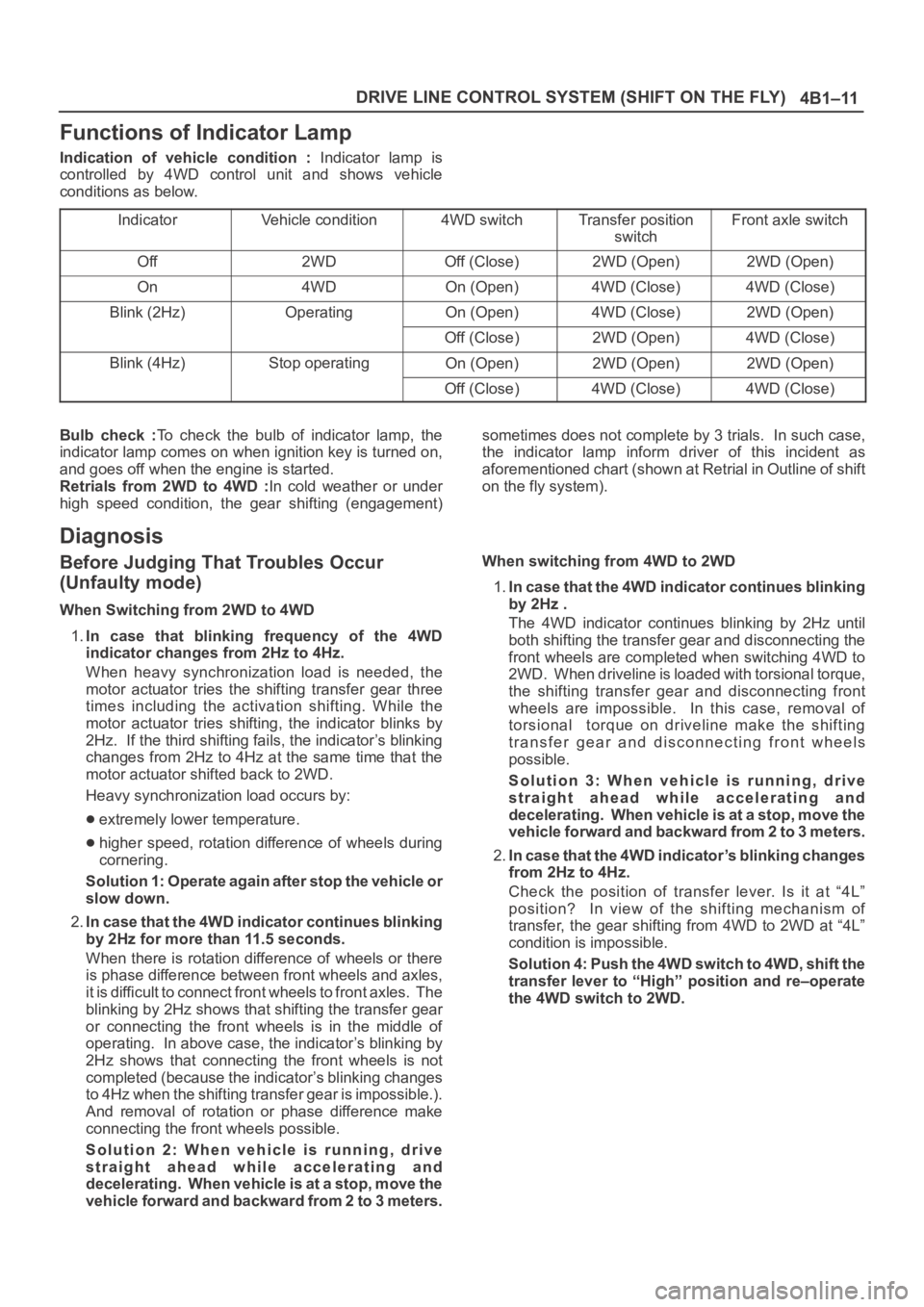

4B1–11 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

Functions of Indicator Lamp

Indication of vehicle condition : Indicator lamp is

controlled by 4WD control unit and shows vehicle

conditions as below.

Indicator

Vehicle condition4WD switchTransfer position

switchFront axle switch

Off2WDOff (Close)2WD (Open)2WD (Open)

On4WDOn (Open)4WD (Close)4WD (Close)

Blink (2Hz)OperatingOn (Open)4WD (Close)2WD (Open)

Off (Close)2WD (Open)4WD (Close)

Blink (4Hz)Stop operatingOn (Open)2WD (Open)2WD (Open)

Off (Close)4WD (Close)4WD (Close)

Bulb check :To check the bulb of indicator lamp, the

indicator lamp comes on when ignition key is turned on,

and goes off when the engine is started.

Retrials from 2WD to 4WD :In cold weather or under

high speed condition, the gear shifting (engagement)sometimes does not complete by 3 trials. In such case,

the indicator lamp inform driver of this incident as

aforementioned chart (shown at Retrial in Outline of shift

on the fly system).

Diagnosis

Before Judging That Troubles Occur

(Unfaulty mode)

When Switching from 2WD to 4WD

1.In case that blinking frequency of the 4WD

indicator changes from 2Hz to 4Hz.

When heavy synchronization load is needed, the

motor actuator tries the shifting transfer gear three

times including the activation shifting. While the

motor actuator tries shifting, the indicator blinks by

2Hz. If the third shifting fails, the indicator’s blinking

changes from 2Hz to 4Hz at the same time that the

motor actuator shifted back to 2WD.

Heavy synchronization load occurs by:

extremely lower temperature.

higher speed, rotation difference of wheels during

cornering.

Solution 1: Operate again after stop the vehicle or

slow down.

2.In case that the 4WD indicator continues blinking

by 2Hz for more than 11.5 seconds.

When there is rotation difference of wheels or there

is phase difference between front wheels and axles,

it is difficult to connect front wheels to front axles. The

blinking by 2Hz shows that shifting the transfer gear

or connecting the front wheels is in the middle of

operating. In above case, the indicator’s blinking by

2Hz shows that connecting the front wheels is not

completed (because the indicator’s blinking changes

to 4Hz when the shifting transfer gear is impossible.).

And removal of rotation or phase difference make

connecting the front wheels possible.

Solution 2: When vehicle is running, drive

straight ahead while accelerating and

decelerating. When vehicle is at a stop, move the

vehicle forward and backward from 2 to 3 meters.When switching from 4WD to 2WD

1.In case that the 4WD indicator continues blinking

by 2Hz .

The 4WD indicator continues blinking by 2Hz until

both shifting the transfer gear and disconnecting the

front wheels are completed when switching 4WD to

2WD. When driveline is loaded with torsional torque,

the shifting transfer gear and disconnecting front

wheels are impossible. In this case, removal of

torsional torque on driveline make the shifting

transfer gear and disconnecting front wheels

possible.

Solution 3: When vehicle is running, drive

straight ahead while accelerating and

decelerating. When vehicle is at a stop, move the

vehicle forward and backward from 2 to 3 meters.

2.In case that the 4WD indicator’s blinking changes

from 2Hz to 4Hz.

Check the position of transfer lever. Is it at “4L”

position? In view of the shifting mechanism of

transfer, the gear shifting from 4WD to 2WD at “4L”

condition is impossible.

Solution 4: Push the 4WD switch to 4WD, shift the

transfer lever to “High” position and re–operate

the 4WD switch to 2WD.

Page 574 of 6000

4B2–3 DRIVE LINE CONTROL SYSTEM (TOD)

detects the slip condition, determines the optimum torque

based on the feedback control logic, and increases the

torque to the front wheels.

The control unit uses the signal from the throttle position

sensor to predict the future vehicle condition and the

intention of the driver with respect to acceleration and

deceleration, and determines the initial torque distribution

using these data and the information from the speed

sensors.

In case of small circle turning in the parking lot, for

example, the control unit minimizes the clutch pressing

force restrict a braking phenomenon. When the ABS

becomes active, the control unit optimizes the clutch

pressing force to ensure stable braking.

TOD Indicator Control

The TOD indicator on the instrument panel informs the

driver of the current working status of the transfer unit.

The information consists of two items: the drive mode

(2H, TOD, 4L, transition) and the torque split status of the

TOD (torque distribution level). The indicator can display

occasional errors and corresponding error codes.

Page 582 of 6000

4B2–11 DRIVE LINE CONTROL SYSTEM (TOD)

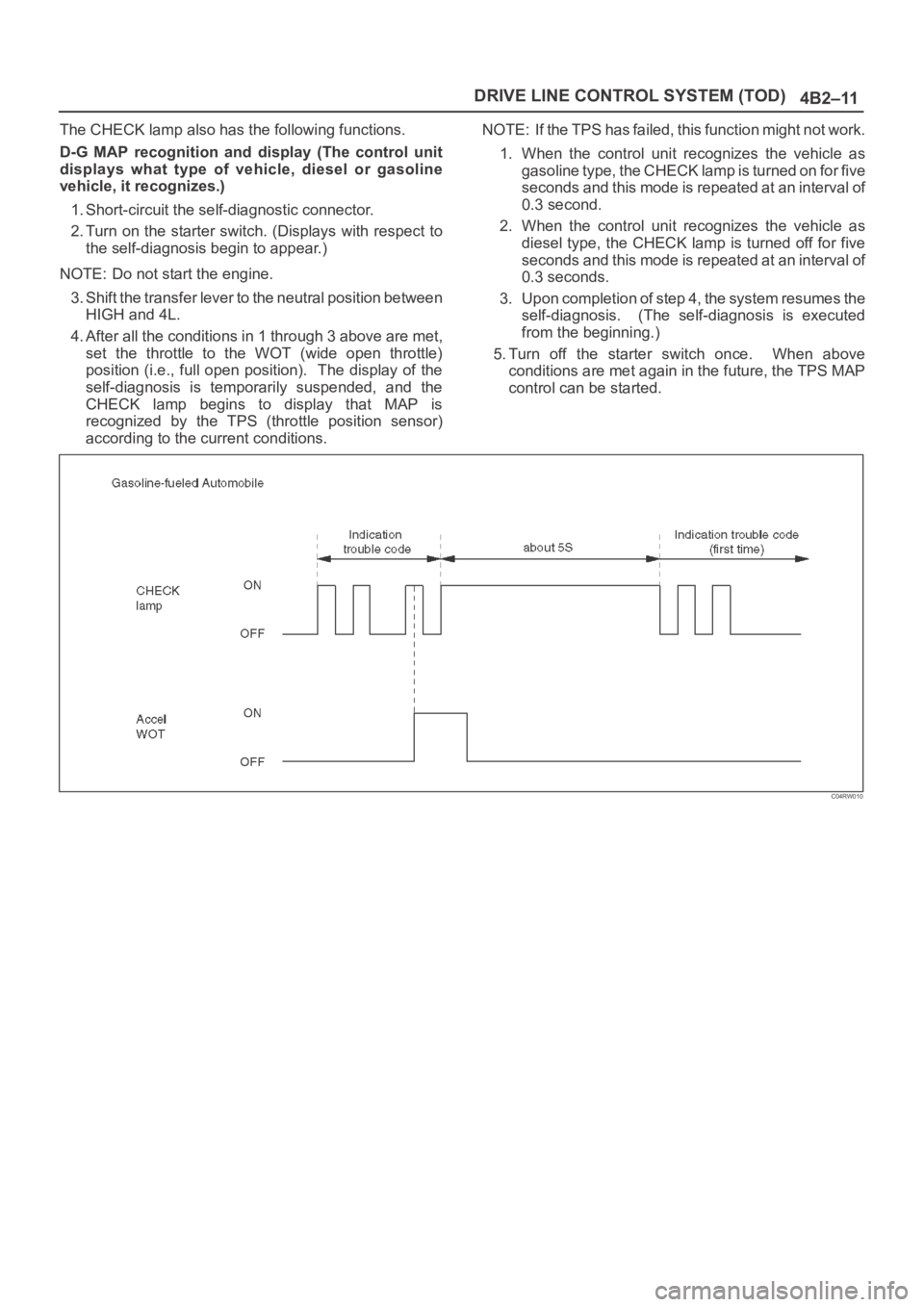

The CHECK lamp also has the following functions.

D-G MAP recognition and display (The control unit

displays what type of vehicle, diesel or gasoline

vehicle, it recognizes.)

1. Short-circuit the self-diagnostic connector.

2. Turn on the starter switch. (Displays with respect to

the self-diagnosis begin to appear.)

NOTE: Do not start the engine.

3. Shift the transfer lever to the neutral position between

HIGH and 4L.

4. After all the conditions in 1 through 3 above are met,

set the throttle to the WOT (wide open throttle)

position (i.e., full open position). The display of the

self-diagnosis is temporarily suspended, and the

CHECK lamp begins to display that MAP is

recognized by the TPS (throttle position sensor)

according to the current conditions.NOTE: If the TPS has failed, this function might not work.

1. When the control unit recognizes the vehicle as

gasoline type, the CHECK lamp is turned on for five

seconds and this mode is repeated at an interval of

0.3 second.

2. When the control unit recognizes the vehicle as

diesel type, the CHECK lamp is turned off for five

seconds and this mode is repeated at an interval of

0.3 seconds.

3. Upon completion of step 4, the system resumes the

self-diagnosis. (The self-diagnosis is executed

from the beginning.)

5. Turn off the starter switch once. When above

conditions are met again in the future, the TPS MAP

control can be started.

C04RW010

Page 585 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–14

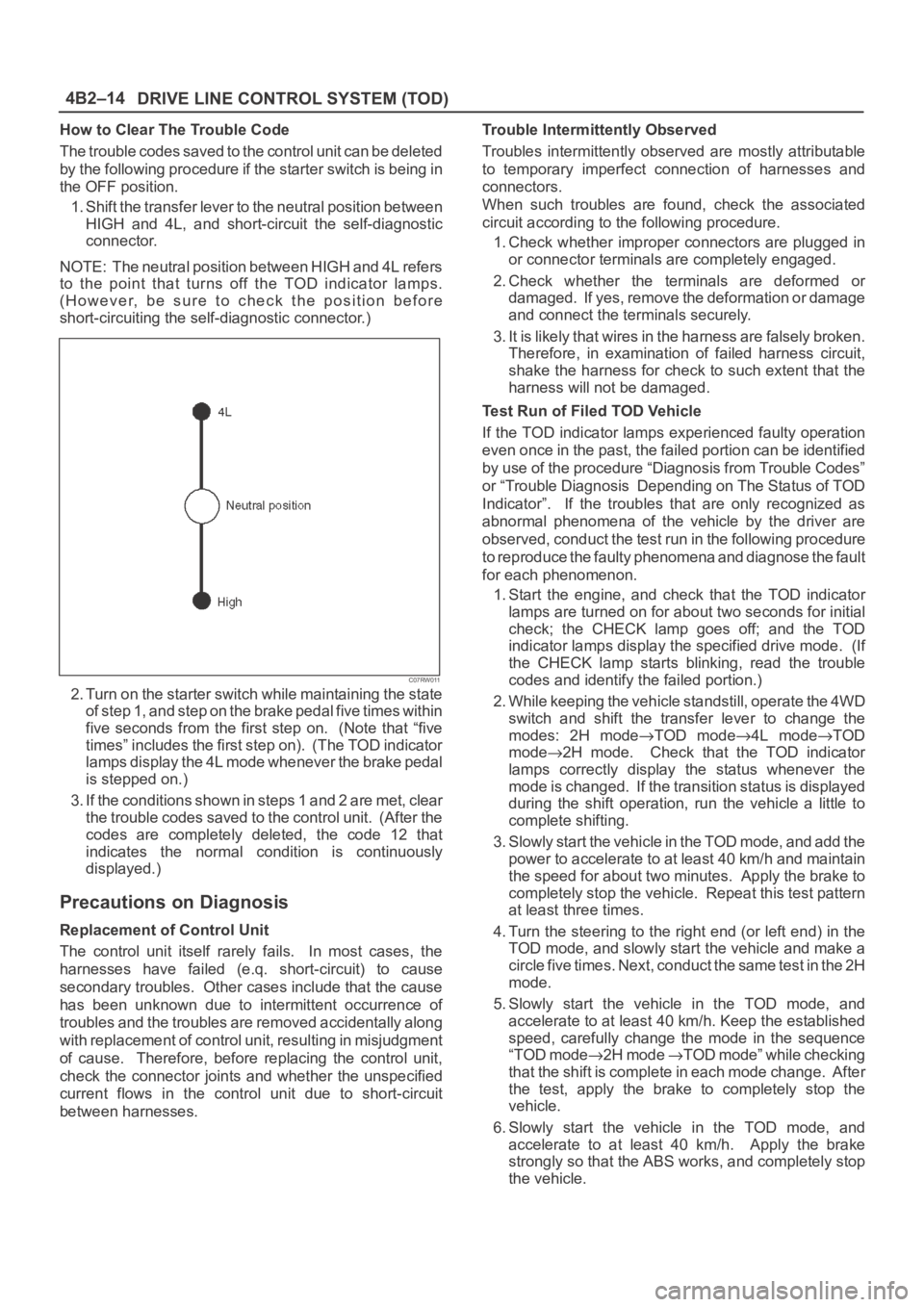

How to Clear The Trouble Code

The trouble codes saved to the control unit can be deleted

by the following procedure if the starter switch is being in

the OFF position.

1. Shift the transfer lever to the neutral position between

HIGH and 4L, and short-circuit the self-diagnostic

connector.

NOTE: The neutral position between HIGH and 4L refers

to the point that turns off the TOD indicator lamps.

(However, be sure to check the position before

short-circuiting the self-diagnostic connector.)

C07RW011

2. Turn on the starter switch while maintaining the state

of step 1, and step on the brake pedal five times within

five seconds from the first step on. (Note that “five

times” includes the first step on). (The TOD indicator

lamps display the 4L mode whenever the brake pedal

is stepped on.)

3. If the conditions shown in steps 1 and 2 are met, clear

the trouble codes saved to the control unit. (After the

codes are completely deleted, the code 12 that

indicates the normal condition is continuously

displayed.)

Precautions on Diagnosis

Replacement of Control Unit

The control unit itself rarely fails. In most cases, the

harnesses have failed (e.q. short-circuit) to cause

secondary troubles. Other cases include that the cause

has been unknown due to intermittent occurrence of

troubles and the troubles are removed accidentally along

with replacement of control unit, resulting in misjudgment

of cause. Therefore, before replacing the control unit,

check the connector joints and whether the unspecified

current flows in the control unit due to short-circuit

between harnesses.Trouble Intermittently Observed

Troubles intermittently observed are mostly attributable

to temporary imperfect connection of harnesses and

connectors.

When such troubles are found, check the associated

circuit according to the following procedure.

1. Check whether improper connectors are plugged in

or connector terminals are completely engaged.

2. Check whether the terminals are deformed or

damaged. If yes, remove the deformation or damage

and connect the terminals securely.

3. It is likely that wires in the harness are falsely broken.

Therefore, in examination of failed harness circuit,

shake the harness for check to such extent that the

harness will not be damaged.

Test Run of Filed TOD Vehicle

If the TOD indicator lamps experienced faulty operation

even once in the past, the failed portion can be identified

by use of the procedure “Diagnosis from Trouble Codes”

or “Trouble Diagnosis Depending on The Status of TOD

Indicator”. If the troubles that are only recognized as

abnormal phenomena of the vehicle by the driver are

observed, conduct the test run in the following procedure

to reproduce the faulty phenomena and diagnose the fault

for each phenomenon.

1. Start the engine, and check that the TOD indicator

lamps are turned on for about two seconds for initial

check; the CHECK lamp goes off; and the TOD

indicator lamps display the specified drive mode. (If

the CHECK lamp starts blinking, read the trouble

codes and identify the failed portion.)

2. While keeping the vehicle standstill, operate the 4WD

switch and shift the transfer lever to change the

modes: 2H mode

TOD mode4L modeTOD

mode

2H mode. Check that the TOD indicator

lamps correctly display the status whenever the

mode is changed. If the transition status is displayed

during the shift operation, run the vehicle a little to

complete shifting.

3. Slowly start the vehicle in the TOD mode, and add the

power to accelerate to at least 40 km/h and maintain

the speed for about two minutes. Apply the brake to

completely stop the vehicle. Repeat this test pattern

at least three times.

4. Turn the steering to the right end (or left end) in the

TOD mode, and slowly start the vehicle and make a

c i r c l e f i v e t i m e s . N e x t , c o n d u c t t h e s a m e t e s t i n t h e 2 H

mode.

5. Slowly start the vehicle in the TOD mode, and

accelerate to at least 40 km/h. Keep the established

speed, carefully change the mode in the sequence

“TOD mode

2H mode TOD mode” while checking

that the shift is complete in each mode change. After

the test, apply the brake to completely stop the

vehicle.

6. Slowly start the vehicle in the TOD mode, and

accelerate to at least 40 km/h. Apply the brake

strongly so that the ABS works, and completely stop

the vehicle.

Page 625 of 6000

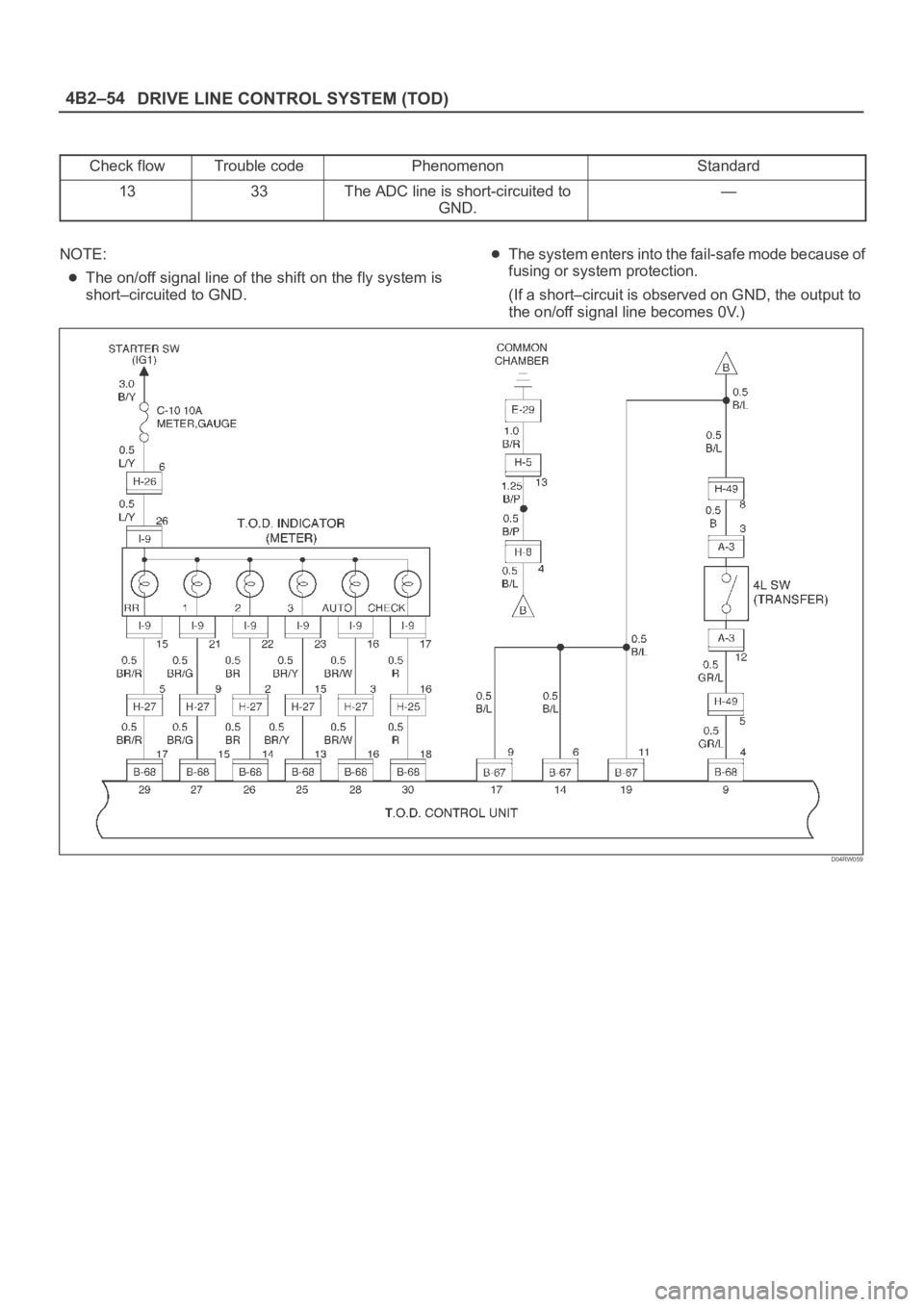

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–54

Check flowTrouble codePhenomenonStandard

1333The ADC line is short-circuited to

GND.—

NOTE:

The on/off signal line of the shift on the fly system is

short–circuited to GND.

The system enters into the fail-safe mode because of

fusing or system protection.

(If a short–circuit is observed on GND, the output to

the on/off signal line becomes 0V.)

D04RW059

Page 648 of 6000

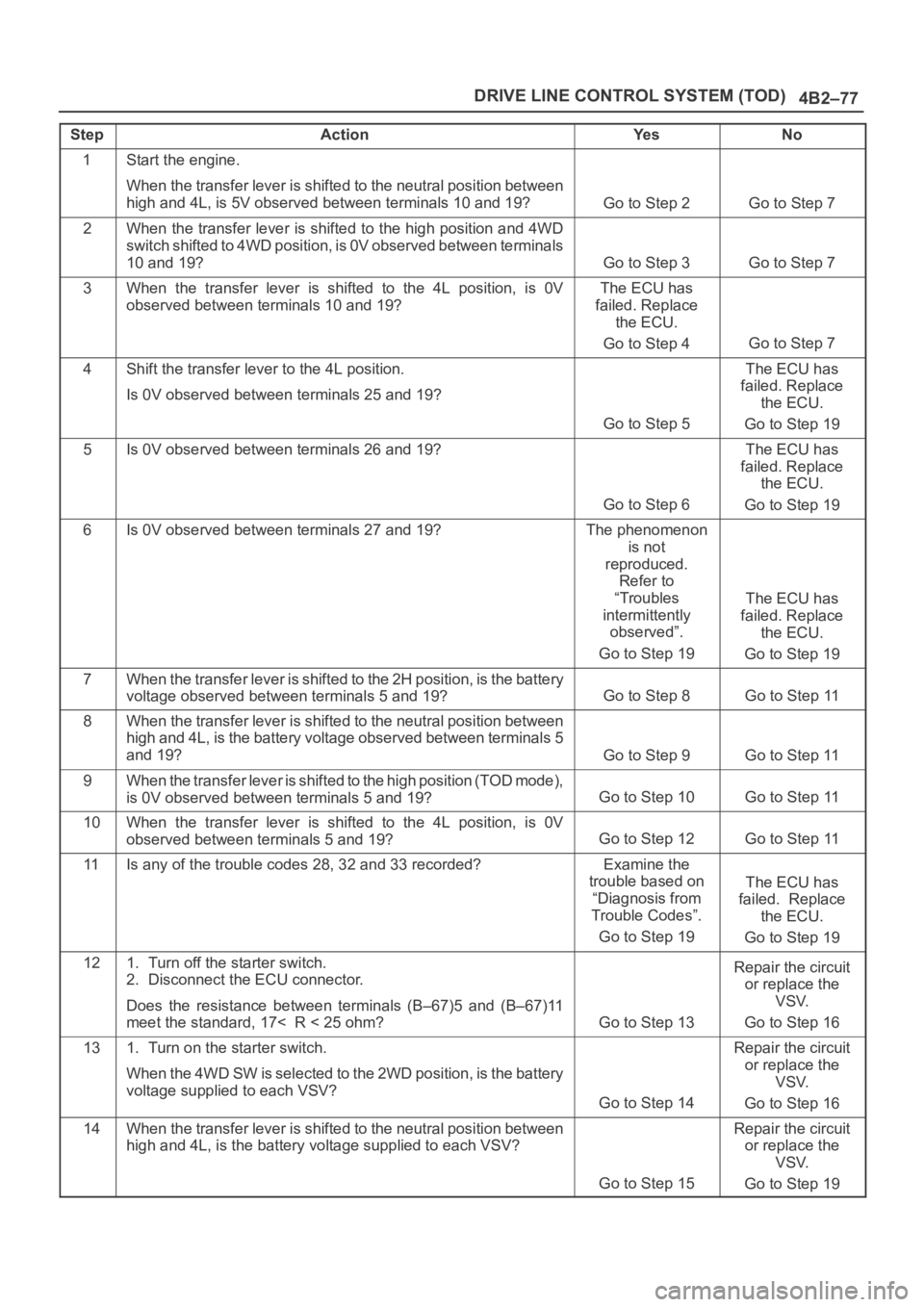

4B2–77 DRIVE LINE CONTROL SYSTEM (TOD)

StepActionYe sNo

1Start the engine.

When the transfer lever is shifted to the neutral position between

high and 4L, is 5V observed between terminals 10 and 19?

Go to Step 2Go to Step 7

2When the transfer lever is shifted to the high position and 4WD

switch shifted to 4WD position, is 0V observed between terminals

10 and 19?

Go to Step 3Go to Step 7

3When the transfer lever is shifted to the 4L position, is 0V

observed between terminals 10 and 19?The ECU has

failed. Replace

the ECU.

Go to Step 4

Go to Step 7

4Shift the transfer lever to the 4L position.

Is 0V observed between terminals 25 and 19?

Go to Step 5

The ECU has

failed. Replace

the ECU.

Go to Step 19

5Is 0V observed between terminals 26 and 19?

Go to Step 6

The ECU has

failed. Replace

the ECU.

Go to Step 19

6Is 0V observed between terminals 27 and 19?The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”.

Go to Step 19

The ECU has

failed. Replace

the ECU.

Go to Step 19

7When the transfer lever is shifted to the 2H position, is the battery

voltage observed between terminals 5 and 19?

Go to Step 8Go to Step 11

8When the transfer lever is shifted to the neutral position between

high and 4L, is the battery voltage observed between terminals 5

and 19?

Go to Step 9Go to Step 11

9When the transfer lever is shifted to the high position (TOD mode),

is 0V observed between terminals 5 and 19?

Go to Step 10Go to Step 11

10When the transfer lever is shifted to the 4L position, is 0V

observed between terminals 5 and 19?

Go to Step 12Go to Step 11

11Is any of the trouble codes 28, 32 and 33 recorded?Examine the

trouble based on

“Diagnosis from

Trouble Codes”.

Go to Step 19

The ECU has

failed. Replace

the ECU.

Go to Step 19

121. Turn off the starter switch.

2. Disconnect the ECU connector.

Does the resistance between terminals (B–67)5 and (B–67)11

meet the standard, 17< R < 25 ohm?

Go to Step 13

Repair the circuit

or replace the

VSV.

Go to Step 16

131. Turn on the starter switch.

When the 4WD SW is selected to the 2WD position, is the battery

voltage supplied to each VSV?

Go to Step 14

Repair the circuit

or replace the

VSV.

Go to Step 16

14When the transfer lever is shifted to the neutral position between

high and 4L, is the battery voltage supplied to each VSV?

Go to Step 15

Repair the circuit

or replace the

VSV.

Go to Step 19