ignition OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 819 of 6000

5A–9 BRAKE CONTROL SYSTEM

Getting Started

Before operating the Isuzu PCMCIA card with the

Tech 2, the following steps must be performed:

1. The Isuzu 98 System PCMCIA card (1) inserts into

the Tech 2 (4).

2. Connect the SAE 16/19 adapter (2) to the DLC cable

(3).

3. Connect the DLC cable to the Tech 2 (4).

4. Make sure the vehicle ignition is off.

5. Connect the Tech 2 SAE 16/19 adapter to the vehicle

DLC connector.

350RV014

6. The vehicle ignition turns on.

7. Power up the Tech 2.8. Verify the Tech 2 power up display.

060RW009

Page 822 of 6000

5A–12

BRAKE CONTROL SYSTEM

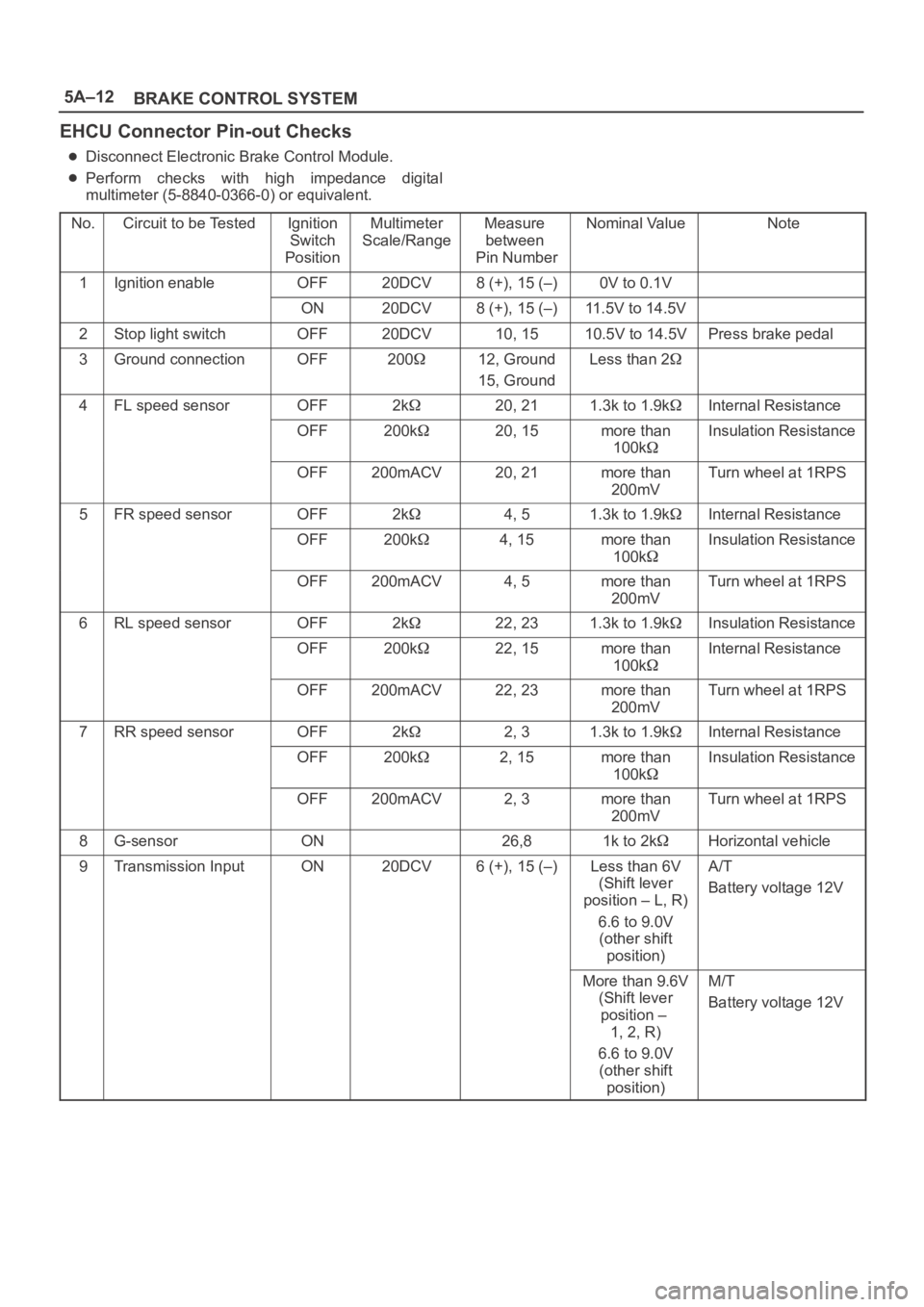

EHCU Connector Pin-out Checks

Disconnect Electronic Brake Control Module.

Perform checks with high impedance digital

multimeter (5-8840-0366-0) or equivalent.

No.

Circuit to be TestedIgnition

Switch

PositionMultimeter

Scale/RangeMeasure

between

Pin NumberNominal ValueNote

1Ignition enableOFF20DCV8 (+), 15 (–)0V to 0.1V

ON20DCV8 (+), 15 (–)11.5V to 14.5V

2Stop light switchOFF20DCV10, 1510.5V to 14.5VPress brake pedal

3Ground connectionOFF20012, Ground

15, GroundLess than 2

4FL speed sensorOFF2k20, 211.3k to 1.9kInternal Resistance

OFF200k20, 15more than

100kInsulation Resistance

OFF200mACV20, 21more than

200mVTurn wheel at 1RPS

5FR speed sensorOFF2k4, 51.3k to 1.9kInternal Resistance

OFF200k4, 15more than

100kInsulation Resistance

OFF200mACV4, 5more than

200mVTurn wheel at 1RPS

6RL speed sensorOFF2k22, 231.3k to 1.9kInsulation Resistance

OFF200k22, 15more than

100kInternal Resistance

OFF200mACV22, 23more than

200mVTurn wheel at 1RPS

7RR speed sensorOFF2k2, 31.3k to 1.9kInternal Resistance

OFF200k2, 15more than

100kInsulation Resistance

OFF200mACV2, 3more than

200mVTurn wheel at 1RPS

8G-sensorON26,81k to 2kHorizontal vehicle

9Transmission InputON20DCV6 (+), 15 (–)Less than 6V

(Shift lever

position – L, R)

6.6 to 9.0V

(other shift

position)A/T

Battery voltage 12V

More than 9.6V

(Shift lever

position –

1, 2, R)

6.6 to 9.0V

(other shift

position)M/T

Battery voltage 12V

Page 847 of 6000

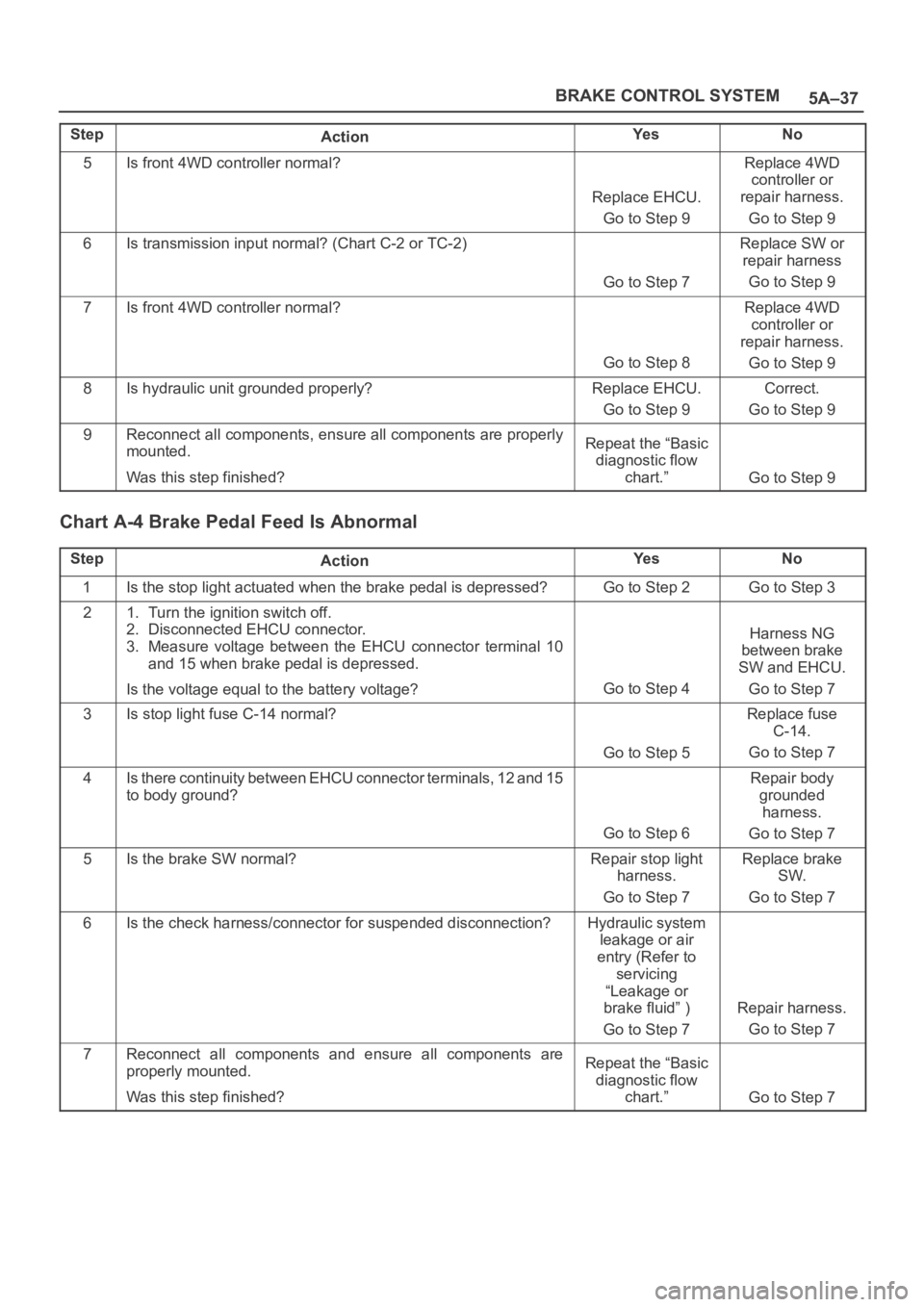

5A–37 BRAKE CONTROL SYSTEM

StepNo Ye s

Action

5Is front 4WD controller normal?

Replace EHCU.

Go to Step 9

Replace 4WD

controller or

repair harness.

Go to Step 9

6Is transmission input normal? (Chart C-2 or TC-2)

Go to Step 7

Replace SW or

repair harness

Go to Step 9

7Is front 4WD controller normal?

Go to Step 8

Replace 4WD

controller or

repair harness.

Go to Step 9

8Is hydraulic unit grounded properly?Replace EHCU.

Go to Step 9Correct.

Go to Step 9

9Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 9

Chart A-4 Brake Pedal Feed Is Abnormal

StepActionYe sNo

1Is the stop light actuated when the brake pedal is depressed?Go to Step 2Go to Step 3

21. Turn the ignition switch off.

2. Disconnected EHCU connector.

3. Measure voltage between the EHCU connector terminal 10

and 15 when brake pedal is depressed.

Is the voltage equal to the battery voltage?

Go to Step 4

Harness NG

between brake

SW and EHCU.

Go to Step 7

3Is stop light fuse C-14 normal?

Go to Step 5

Replace fuse

C-14.

Go to Step 7

4Is there continuity between EHCU connector terminals, 12 and 15

to body ground?

Go to Step 6

Repair body

grounded

harness.

Go to Step 7

5Is the brake SW normal?Repair stop light

harness.

Go to Step 7Replace brake

SW.

Go to Step 7

6Is the check harness/connector for suspended disconnection?Hydraulic system

leakage or air

entry (Refer to

servicing

“Leakage or

brake fluid” )

Go to Step 7

Repair harness.

Go to Step 7

7Reconnect all components and ensure all components are

properly mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 7

Page 853 of 6000

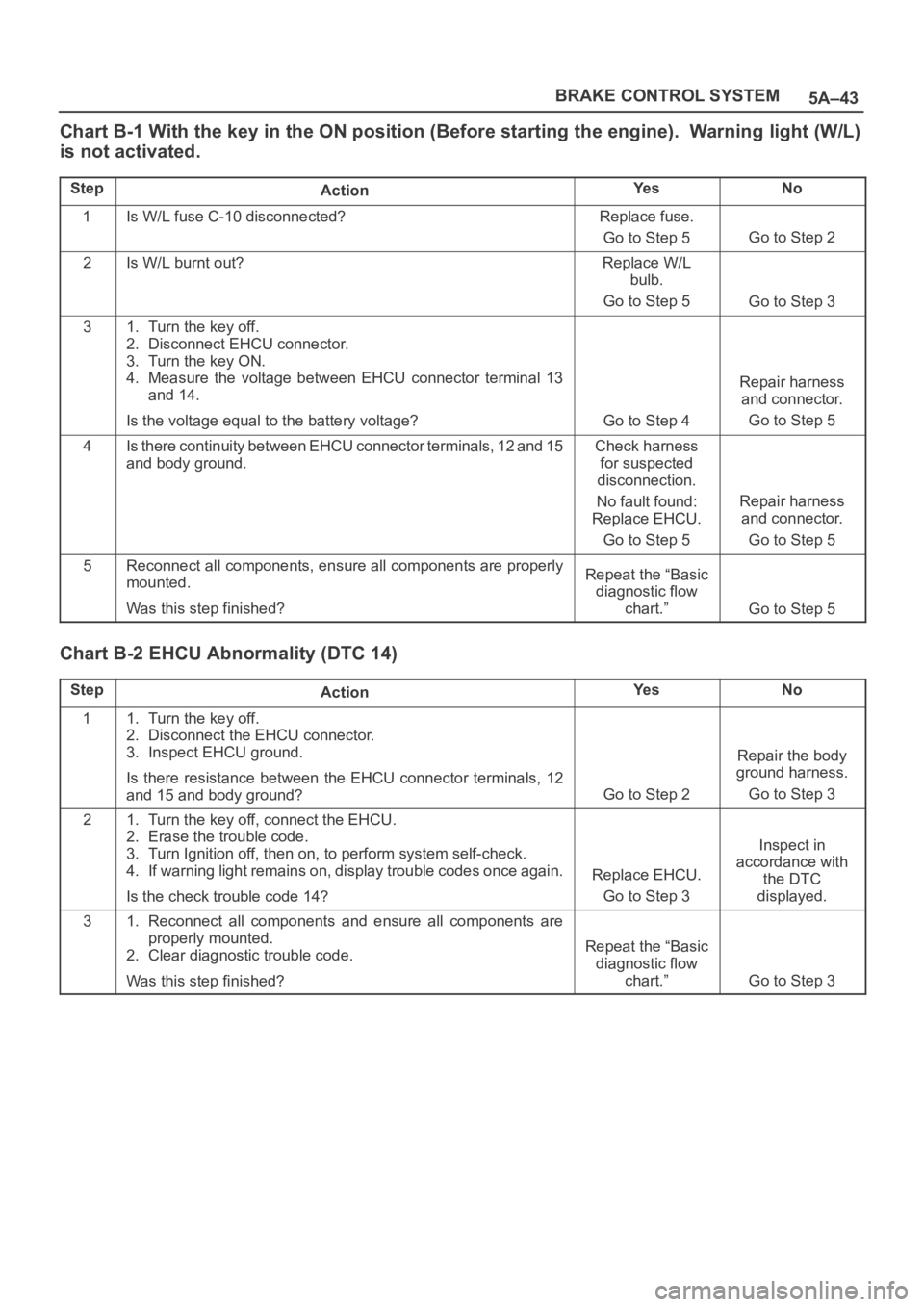

5A–43 BRAKE CONTROL SYSTEM

Chart B-1 With the key in the ON position (Before starting the engine). Warning light (W/L)

is not activated.

StepActionYe sNo

1Is W/L fuse C-10 disconnected?Replace fuse.

Go to Step 5

Go to Step 2

2Is W/L burnt out?Replace W/L

bulb.

Go to Step 5

Go to Step 3

31. Turn the key off.

2. Disconnect EHCU connector.

3. Turn the key ON.

4. Measure the voltage between EHCU connector terminal 13

and 14.

Is the voltage equal to the battery voltage?

Go to Step 4

Repair harness

and connector.

Go to Step 5

4Is there continuity between EHCU connector terminals, 12 and 15

and body ground.Check harness

for suspected

disconnection.

No fault found:

Replace EHCU.

Go to Step 5

Repair harness

and connector.

Go to Step 5

5Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the “Basic

diagnostic flow

chart.”

Go to Step 5

Chart B-2 EHCU Abnormality (DTC 14)

StepActionYe sNo

11. Turn the key off.

2. Disconnect the EHCU connector.

3. Inspect EHCU ground.

Is there resistance between the EHCU connector terminals, 12

and 15 and body ground?

Go to Step 2

Repair the body

ground harness.

Go to Step 3

21. Turn the key off, connect the EHCU.

2. Erase the trouble code.

3. Turn Ignition off, then on, to perform system self-check.

4. If warning light remains on, display trouble codes once again.

Is the check trouble code 14?

Replace EHCU.

Go to Step 3

Inspect in

accordance with

the DTC

displayed.

31. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Page 862 of 6000

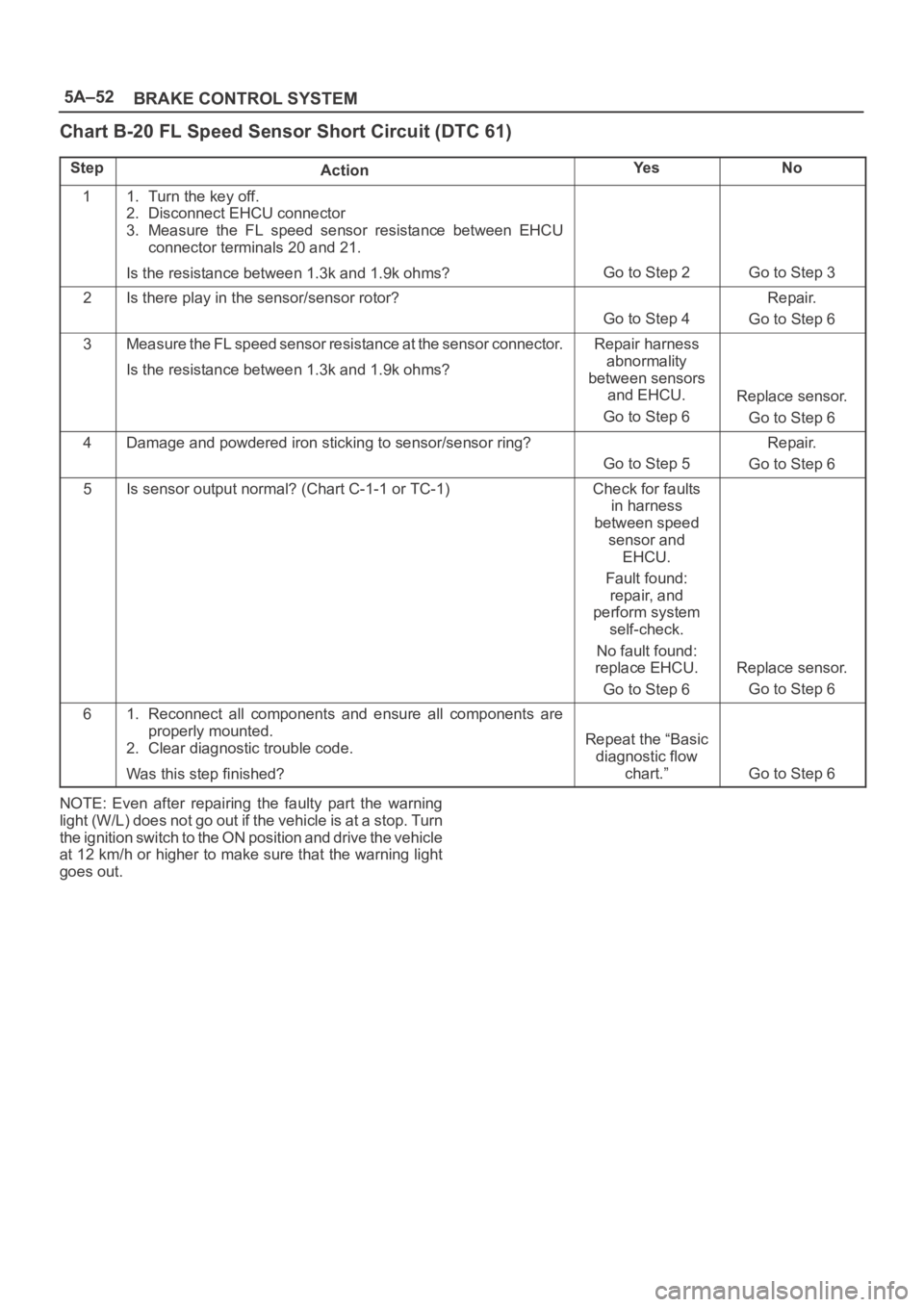

5A–52

BRAKE CONTROL SYSTEM

Chart B-20 FL Speed Sensor Short Circuit (DTC 61)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector

3. Measure the FL speed sensor resistance between EHCU

connector terminals 20 and 21.

Is the resistance between 1.3k and 1.9k ohms?

Go to Step 2Go to Step 3

2Is there play in the sensor/sensor rotor?

Go to Step 4

Repair.

Go to Step 6

3Measure the FL speed sensor resistance at the sensor connector.

Is the resistance between 1.3k and 1.9k ohms?Repair harness

abnormality

between sensors

and EHCU.

Go to Step 6

Replace sensor.

Go to Step 6

4Damage and powdered iron sticking to sensor/sensor ring?

Go to Step 5

Repair.

Go to Step 6

5Is sensor output normal? (Chart C-1-1 or TC-1)Check for faults

in harness

between speed

sensor and

EHCU.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 6

Replace sensor.

Go to Step 6

61. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h or higher to make sure that the warning light

goes out.

Page 863 of 6000

5A–53 BRAKE CONTROL SYSTEM

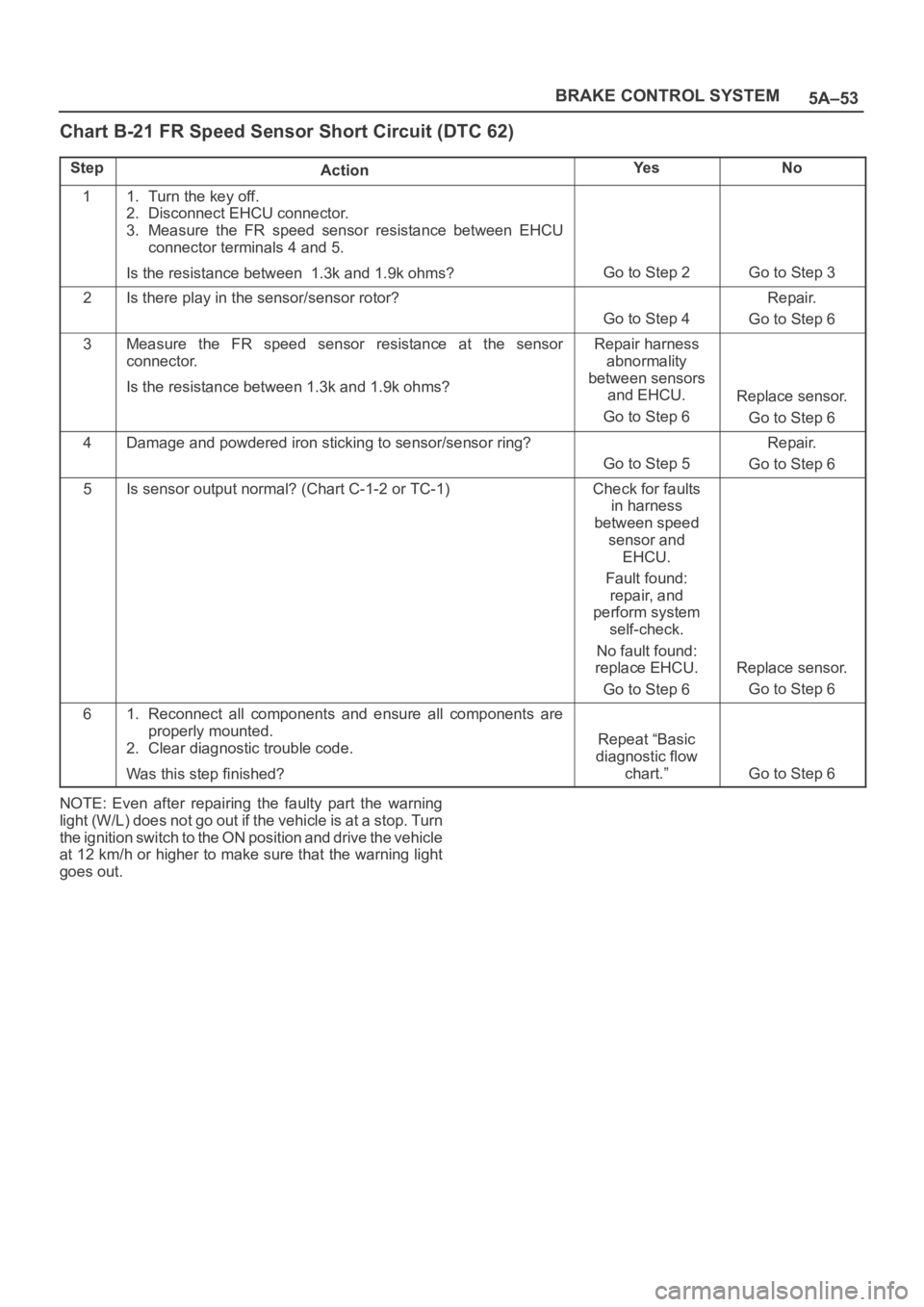

Chart B-21 FR Speed Sensor Short Circuit (DTC 62)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

3. Measure the FR speed sensor resistance between EHCU

connector terminals 4 and 5.

Is the resistance between 1.3k and 1.9k ohms?

Go to Step 2Go to Step 3

2Is there play in the sensor/sensor rotor?

Go to Step 4

Repair.

Go to Step 6

3Measure the FR speed sensor resistance at the sensor

connector.

Is the resistance between 1.3k and 1.9k ohms?Repair harness

abnormality

between sensors

and EHCU.

Go to Step 6

Replace sensor.

Go to Step 6

4Damage and powdered iron sticking to sensor/sensor ring?

Go to Step 5

Repair.

Go to Step 6

5Is sensor output normal? (Chart C-1-2 or TC-1)Check for faults

in harness

between speed

sensor and

EHCU.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 6

Replace sensor.

Go to Step 6

61. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat “Basic

diagnostic flow

chart.”

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h or higher to make sure that the warning light

goes out.

Page 864 of 6000

5A–54

BRAKE CONTROL SYSTEM

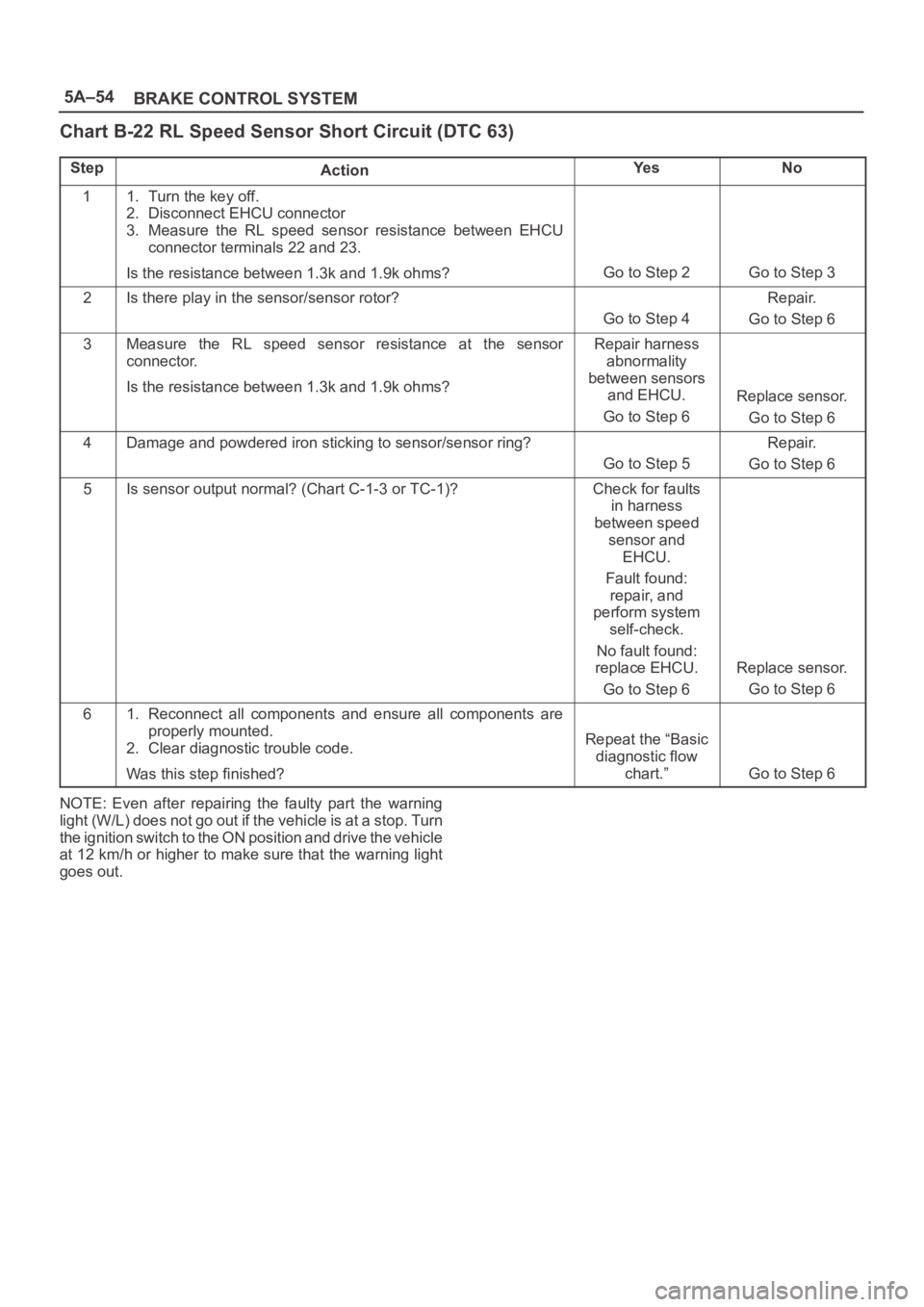

Chart B-22 RL Speed Sensor Short Circuit (DTC 63)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector

3. Measure the RL speed sensor resistance between EHCU

connector terminals 22 and 23.

Is the resistance between 1.3k and 1.9k ohms?

Go to Step 2Go to Step 3

2Is there play in the sensor/sensor rotor?

Go to Step 4

Repair.

Go to Step 6

3Measure the RL speed sensor resistance at the sensor

connector.

Is the resistance between 1.3k and 1.9k ohms?Repair harness

abnormality

between sensors

and EHCU.

Go to Step 6

Replace sensor.

Go to Step 6

4Damage and powdered iron sticking to sensor/sensor ring?

Go to Step 5

Repair.

Go to Step 6

5Is sensor output normal? (Chart C-1-3 or TC-1)?Check for faults

in harness

between speed

sensor and

EHCU.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 6

Replace sensor.

Go to Step 6

61. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h or higher to make sure that the warning light

goes out.

Page 865 of 6000

5A–55 BRAKE CONTROL SYSTEM

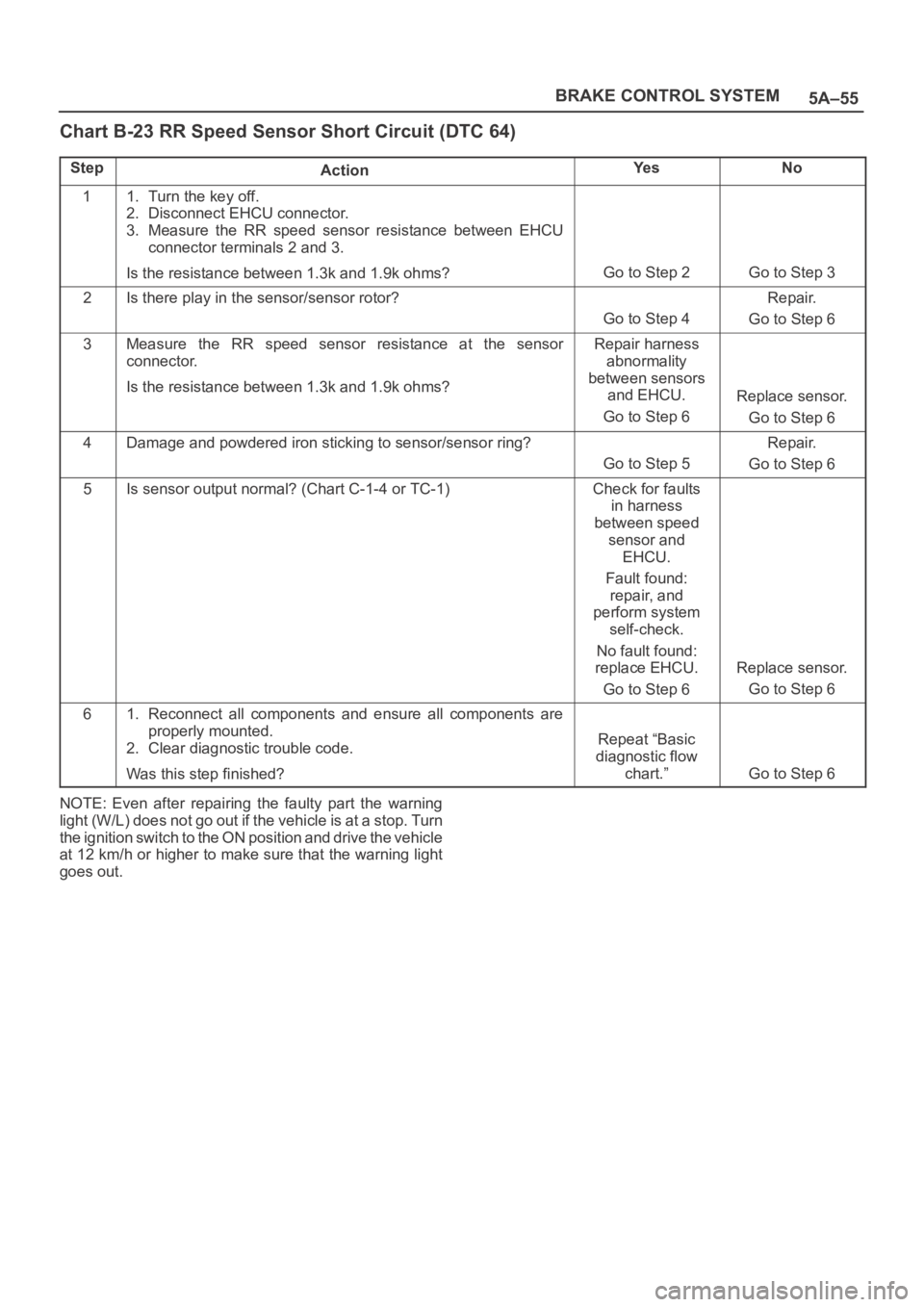

Chart B-23 RR Speed Sensor Short Circuit (DTC 64)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

3. Measure the RR speed sensor resistance between EHCU

connector terminals 2 and 3.

Is the resistance between 1.3k and 1.9k ohms?

Go to Step 2Go to Step 3

2Is there play in the sensor/sensor rotor?

Go to Step 4

Repair.

Go to Step 6

3Measure the RR speed sensor resistance at the sensor

connector.

Is the resistance between 1.3k and 1.9k ohms?Repair harness

abnormality

between sensors

and EHCU.

Go to Step 6

Replace sensor.

Go to Step 6

4Damage and powdered iron sticking to sensor/sensor ring?

Go to Step 5

Repair.

Go to Step 6

5Is sensor output normal? (Chart C-1-4 or TC-1)Check for faults

in harness

between speed

sensor and

EHCU.

Fault found:

repair, and

perform system

self-check.

No fault found:

replace EHCU.

Go to Step 6

Replace sensor.

Go to Step 6

61. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat “Basic

diagnostic flow

chart.”

Go to Step 6

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop. Turn

the ignition switch to the ON position and drive the vehicle

at 12 km/h or higher to make sure that the warning light

goes out.

Page 866 of 6000

5A–56

BRAKE CONTROL SYSTEM

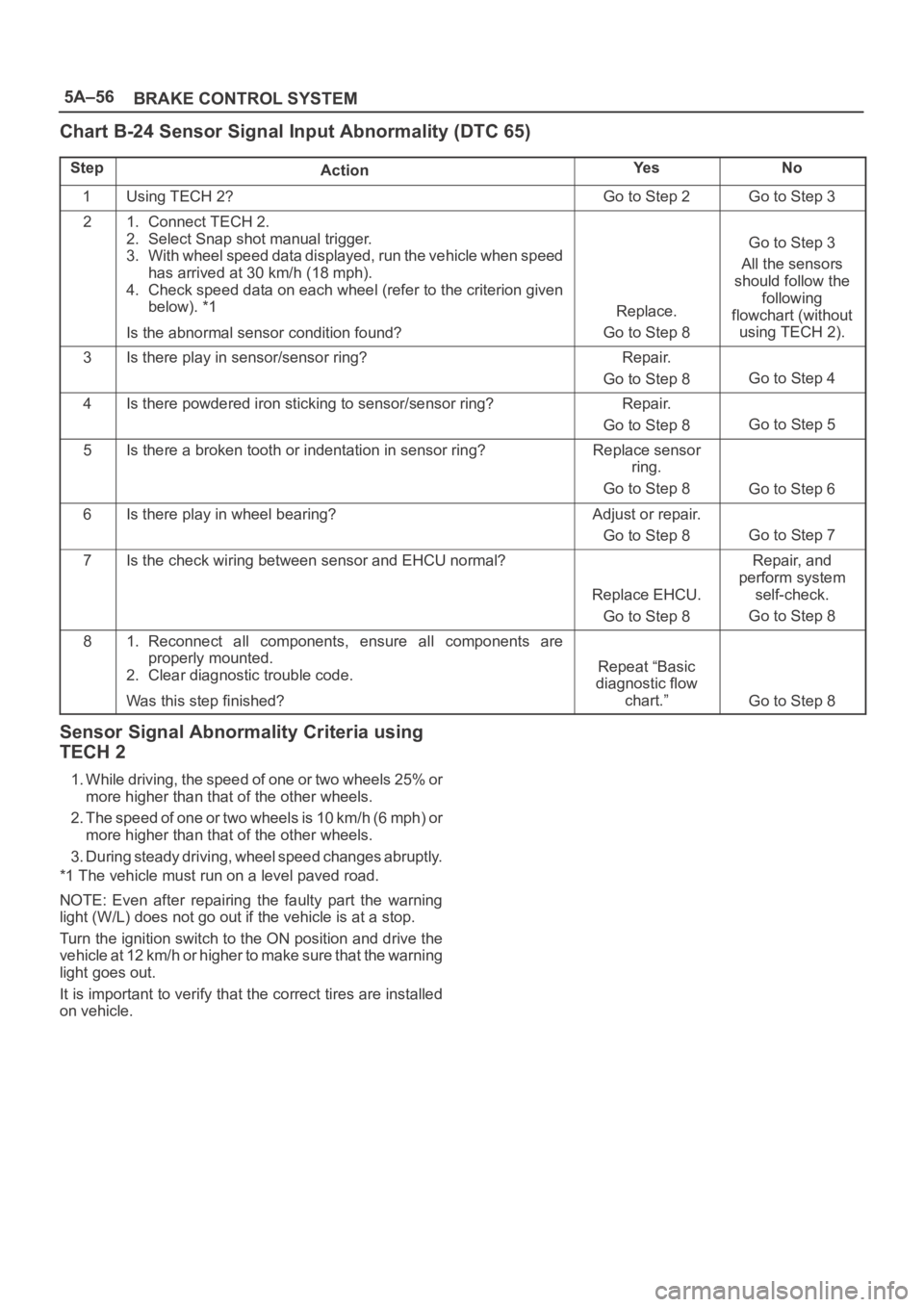

Chart B-24 Sensor Signal Input Abnormality (DTC 65)

StepActionYe sNo

1Using TECH 2?Go to Step 2Go to Step 3

21. Connect TECH 2.

2. Select Snap shot manual trigger.

3. With wheel speed data displayed, run the vehicle when speed

has arrived at 30 km/h (18 mph).

4. Check speed data on each wheel (refer to the criterion given

below). *1

Is the abnormal sensor condition found?

Replace.

Go to Step 8

Go to Step 3

All the sensors

should follow the

following

flowchart (without

using TECH 2).

3Is there play in sensor/sensor ring?Repair.

Go to Step 8

Go to Step 4

4Is there powdered iron sticking to sensor/sensor ring?Repair.

Go to Step 8

Go to Step 5

5Is there a broken tooth or indentation in sensor ring?Replace sensor

ring.

Go to Step 8

Go to Step 6

6Is there play in wheel bearing?Adjust or repair.

Go to Step 8

Go to Step 7

7Is the check wiring between sensor and EHCU normal?

Replace EHCU.

Go to Step 8

Repair, and

perform system

self-check.

Go to Step 8

81. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat “Basic

diagnostic flow

chart.”

Go to Step 8

Sensor Signal Abnormality Criteria using

TECH 2

1. While driving, the speed of one or two wheels 25% or

more higher than that of the other wheels.

2. The speed of one or two wheels is 10 km/h (6 mph) or

more higher than that of the other wheels.

3. During steady driving, wheel speed changes abruptly.

*1 The vehicle must run on a level paved road.

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop.

Turn the ignition switch to the ON position and drive the

vehicle at 12 km/h or higher to make sure that the warning

light goes out.

It is important to verify that the correct tires are installed

on vehicle.

Page 957 of 6000

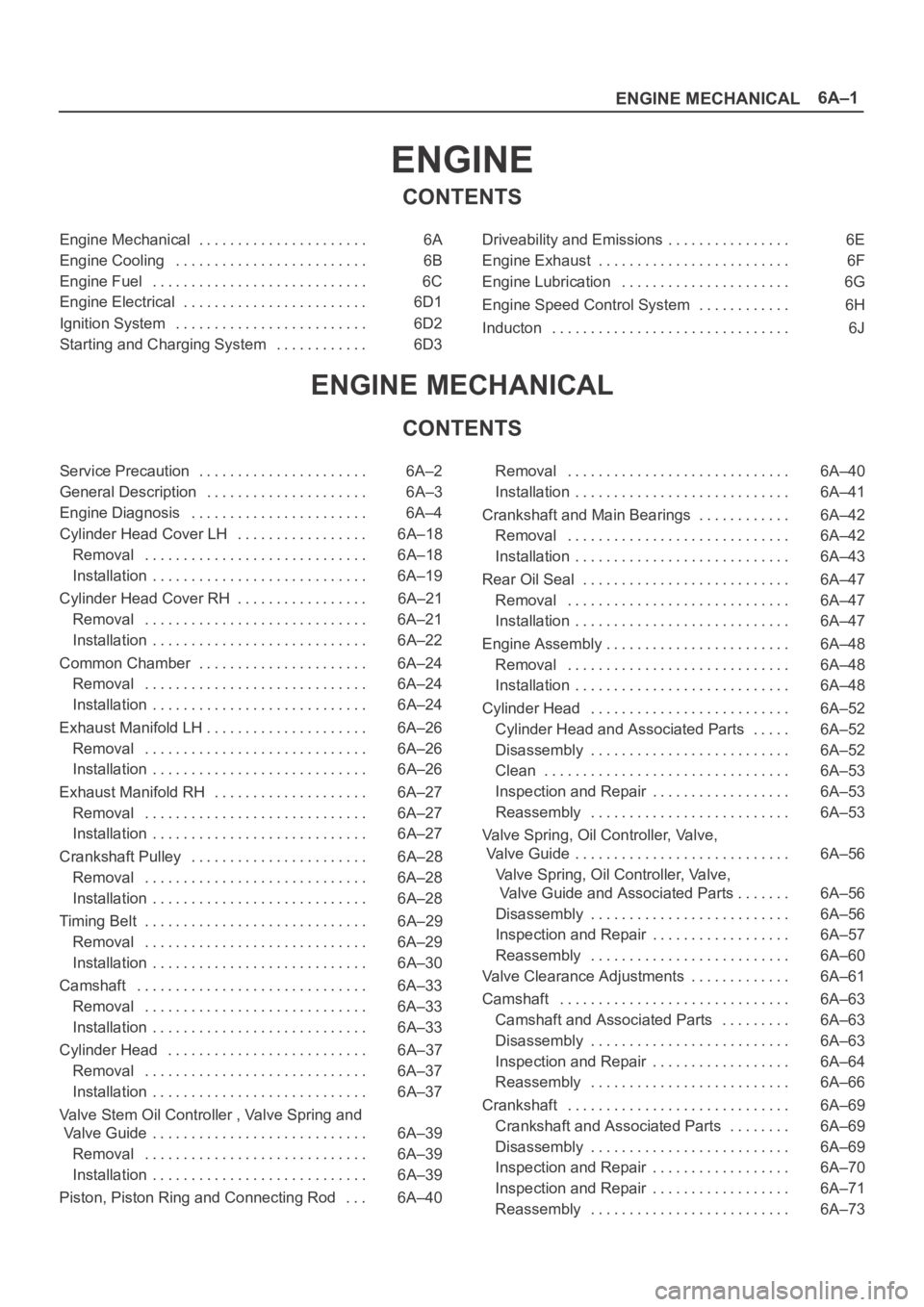

6A–1

ENGINE MECHANICAL

ENGINE

CONTENTS

Engine Mechanical 6A. . . . . . . . . . . . . . . . . . . . . .

Engine Cooling 6B. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Fuel 6C. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Electrical 6D1. . . . . . . . . . . . . . . . . . . . . . . .

Ignition System 6D2. . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Charging System 6D3. . . . . . . . . . . . Driveability and Emissions 6E. . . . . . . . . . . . . . . .

Engine Exhaust 6F. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Lubrication 6G. . . . . . . . . . . . . . . . . . . . . .

Engine Speed Control System 6H. . . . . . . . . . . .

Inducton 6J. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE MECHANICAL

CONTENTS

Service Precaution 6A–2. . . . . . . . . . . . . . . . . . . . . .

General Description 6A–3. . . . . . . . . . . . . . . . . . . . .

Engine Diagnosis 6A–4. . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Cover LH 6A–18. . . . . . . . . . . . . . . . .

Removal 6A–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Cover RH 6A–21. . . . . . . . . . . . . . . . .

Removal 6A–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Chamber 6A–24. . . . . . . . . . . . . . . . . . . . . .

Removal 6A–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold LH 6A–26. . . . . . . . . . . . . . . . . . . . .

Removal 6A–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold RH 6A–27. . . . . . . . . . . . . . . . . . . .

Removal 6A–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Pulley 6A–28. . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Belt 6A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 6A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 6A–37. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Stem Oil Controller , Valve Spring and

Valve Guide 6A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston, Piston Ring and Connecting Rod 6A–40. . . Removal 6A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Main Bearings 6A–42. . . . . . . . . . . .

Removal 6A–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal 6A–47. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Assembly 6A–48. . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–48. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 6A–52. . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Associated Parts 6A–52. . . . .

Disassembly 6A–52. . . . . . . . . . . . . . . . . . . . . . . . . .

Clean 6A–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–53

. . . . . . . . . . . . . . . . . .

Reassembly 6A–53. . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Spring, Oil Controller, Valve,

Valve Guide 6A–56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Spring, Oil Controller, Valve,

Valve Guide and Associated Parts 6A–56. . . . . . .

Disassembly 6A–56. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–57. . . . . . . . . . . . . . . . . .

Reassembly 6A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Clearance Adjustments 6A–61. . . . . . . . . . . . .

Camshaft 6A–63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft and Associated Parts 6A–63. . . . . . . . .

Disassembly 6A–63. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–64. . . . . . . . . . . . . . . . . .

Reassembly 6A–66. . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft 6A–69. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Associated Parts 6A–69. . . . . . . .

Disassembly 6A–69. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–70. . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–71. . . . . . . . . . . . . . . . . .

Reassembly 6A–73. . . . . . . . . . . . . . . . . . . . . . . . . .