ignition OPEL FRONTERA 1998 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1089 of 6000

6D2–4

IGNITION SYSTEM

Spark Plug

Removal

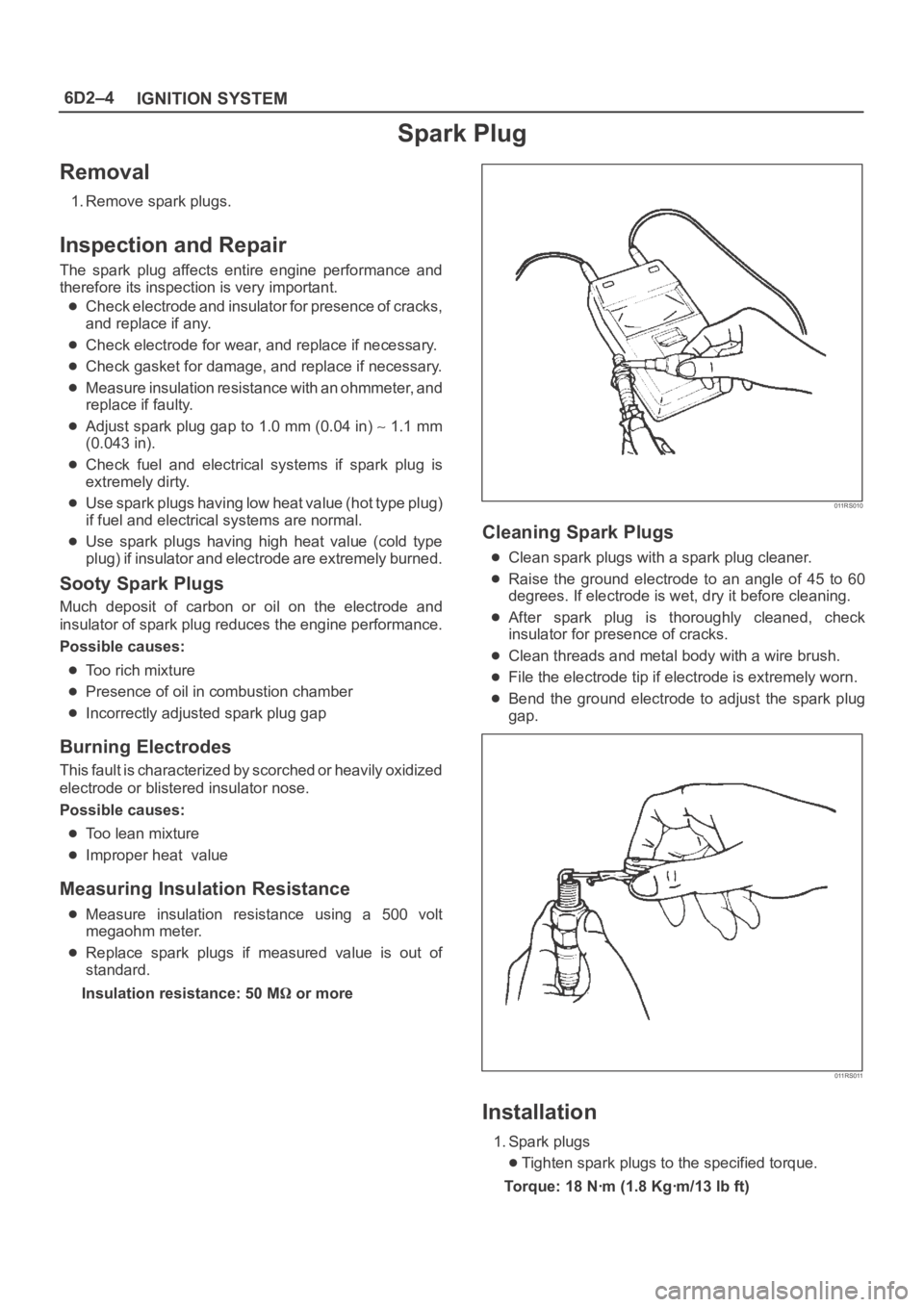

1. Remove spark plugs.

Inspection and Repair

The spark plug affects entire engine performance and

therefore its inspection is very important.

Check electrode and insulator for presence of cracks,

and replace if any.

Check electrode for wear, and replace if necessary.

Check gasket for damage, and replace if necessary.

Measure insulation resistance with an ohmmeter, and

replace if faulty.

Adjust spark plug gap to 1.0 mm (0.04 in) 1.1 mm

(0.043 in).

Check fuel and electrical systems if spark plug is

extremely dirty.

Use spark plugs having low heat value (hot type plug)

if fuel and electrical systems are normal.

Use spark plugs having high heat value (cold type

plug) if insulator and electrode are extremely burned.

Sooty Spark Plugs

Much deposit of carbon or oil on the electrode and

insulator of spark plug reduces the engine performance.

Possible causes:

Too rich mixture

Presence of oil in combustion chamber

Incorrectly adjusted spark plug gap

Burning Electrodes

This fault is characterized by scorched or heavily oxidized

electrode or blistered insulator nose.

Possible causes:

Too lean mixture

Improper heat value

Measuring Insulation Resistance

Measure insulation resistance using a 500 volt

megaohm meter.

Replace spark plugs if measured value is out of

standard.

Insulation resistance: 50 M

or more

011RS010

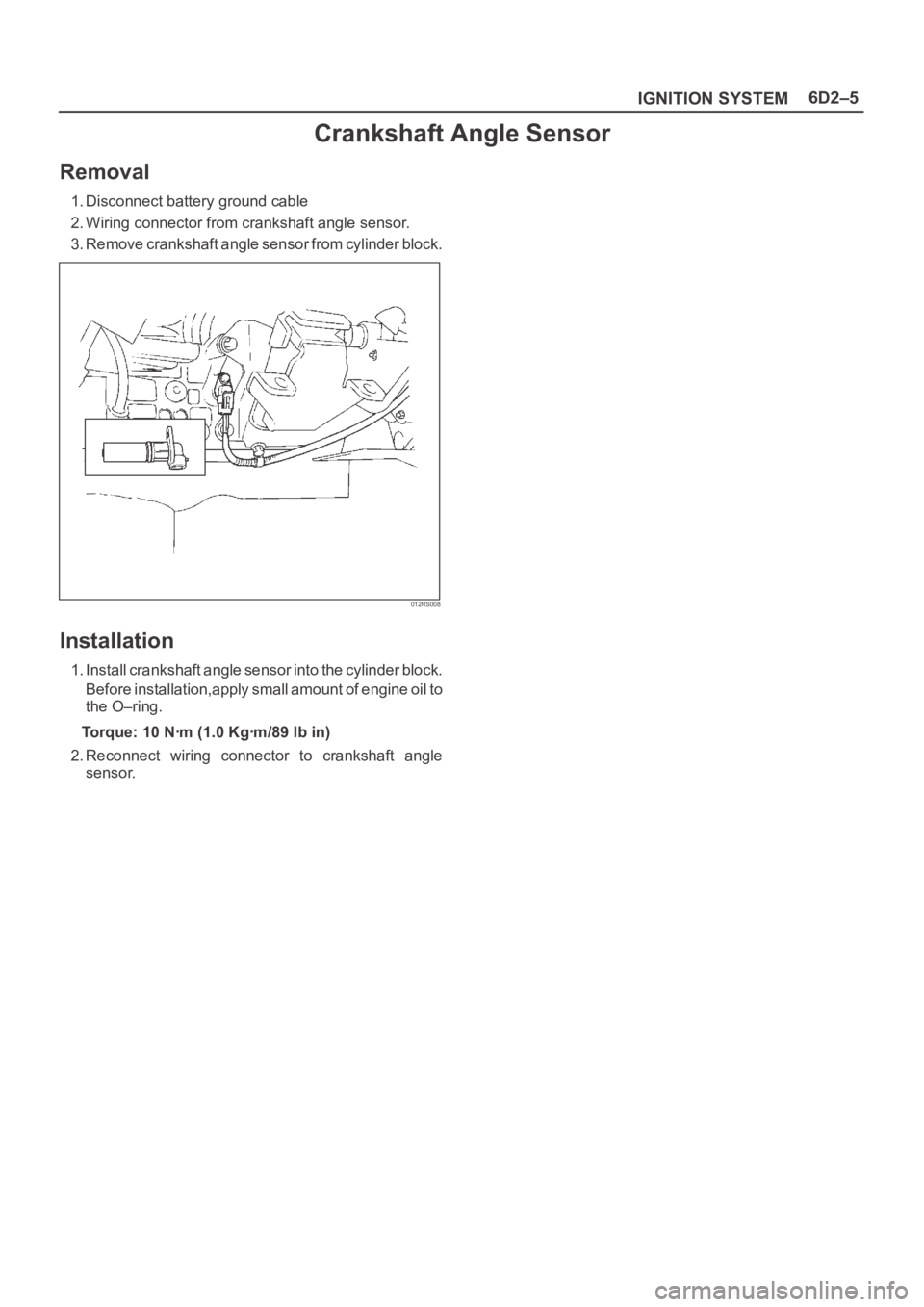

Cleaning Spark Plugs

Clean spark plugs with a spark plug cleaner.

Raise the ground electrode to an angle of 45 to 60

degrees. If electrode is wet, dry it before cleaning.

After spark plug is thoroughly cleaned, check

insulator for presence of cracks.

Clean threads and metal body with a wire brush.

File the electrode tip if electrode is extremely worn.

Bend the ground electrode to adjust the spark plug

gap.

011RS011

Installation

1. Spark plugs

Tighten spark plugs to the specified torque.

Torque: 18 Nꞏm (1.8 Kgꞏm/13 lb ft)

Page 1090 of 6000

6D2–5

IGNITION SYSTEM

Crankshaft Angle Sensor

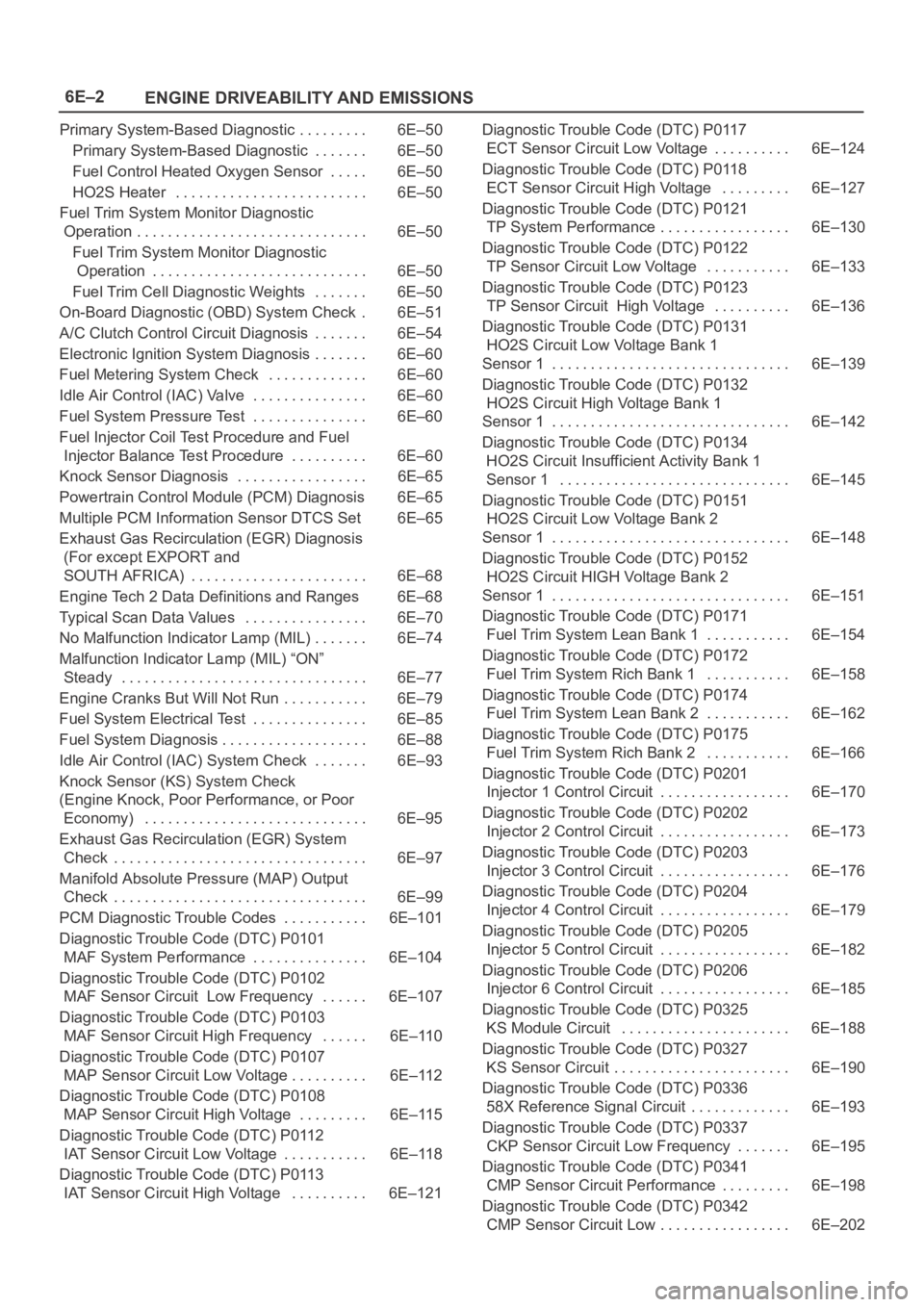

Removal

1. Disconnect battery ground cable

2. Wiring connector from crankshaft angle sensor.

3. Remove crankshaft angle sensor from cylinder block.

012RS008

Installation

1. Install crankshaft angle sensor into the cylinder block.

Before installation,apply small amount of engine oil to

the O–ring.

Torque: 10 Nꞏm (1.0 Kgꞏm/89 lb in)

2. Reconnect wiring connector to crankshaft angle

sensor.

Page 1091 of 6000

6D2–6

IGNITION SYSTEM

Main Data and Specifications

General Specifications

Ignition System

Ignition FormElectronic Ignition System (El system) with Crankshaft angle Sensor

Spark Plug

Ty p eK16PR–P11

RC10PYP4

PK16PR11

Plug gap1.0 mm (0.04 in) – 1.1 mm (0.043 in)

To r q u e18 Nꞏm (1.8 Kgꞏm/13 lb ft)

Torque Specifications

Nꞏm (Kgꞏm/lb ft)

E06RW038

Page 1119 of 6000

6E–2

ENGINE DRIVEABILITY AND EMISSIONS

Primary System-Based Diagnostic 6E–50. . . . . . . . .

Primary System-Based Diagnostic 6E–50. . . . . . .

Fuel Control Heated Oxygen Sensor 6E–50. . . . .

HO2S Heater 6E–50. . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Trim System Monitor Diagnostic

Operation 6E–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Trim System Monitor Diagnostic

Operation 6E–50. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Trim Cell Diagnostic Weights 6E–50. . . . . . .

On-Board Diagnostic (OBD) System Check 6E–51.

A/C Clutch Control Circuit Diagnosis 6E–54. . . . . . .

Electronic Ignition System Diagnosis 6E–60. . . . . . .

Fuel Metering System Check 6E–60. . . . . . . . . . . . .

Idle Air Control (IAC) Valve 6E–60. . . . . . . . . . . . . . .

Fuel System Pressure Test 6E–60. . . . . . . . . . . . . . .

Fuel Injector Coil Test Procedure and Fuel

Injector Balance Test Procedure 6E–60. . . . . . . . . .

Knock Sensor Diagnosis 6E–65. . . . . . . . . . . . . . . . .

Powertrain Control Module (PCM) Diagnosis 6E–65

Multiple PCM Information Sensor DTCS Set 6E–65

Exhaust Gas Recirculation (EGR) Diagnosis

(For except EXPORT and

SOUTH AFRICA) 6E–68. . . . . . . . . . . . . . . . . . . . . . .

Engine Tech 2 Data Definitions and Ranges 6E–68

Typical Scan Data Values 6E–70. . . . . . . . . . . . . . . .

No Malfunction Indicator Lamp (MIL) 6E–74. . . . . . .

Malfunction Indicator Lamp (MIL) “ON”

Steady 6E–77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Cranks But Will Not Run 6E–79. . . . . . . . . . .

Fuel System Electrical Test 6E–85. . . . . . . . . . . . . . .

Fuel System Diagnosis 6E–88. . . . . . . . . . . . . . . . . . .

Idle Air Control (IAC) System Check 6E–93. . . . . . .

Knock Sensor (KS) System Check

(Engine Knock, Poor Performance, or Poor

Economy) 6E–95. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Gas Recirculation (EGR) System

Check 6E–97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manifold Absolute Pressure (MAP) Output

Check 6E–99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Diagnostic Trouble Codes 6E–101. . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0101

MAF System Performance 6E–104. . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0102

MAF Sensor Circuit Low Frequency 6E–107. . . . . .

Diagnostic Trouble Code (DTC) P0103

MAF Sensor Circuit High Frequency 6E–110. . . . . .

Diagnostic Trouble Code (DTC) P0107

MAP Sensor Circuit Low Voltage 6E–112. . . . . . . . . .

Diagnostic Trouble Code (DTC) P0108

MAP Sensor Circuit High Voltage 6E–115. . . . . . . . .

Diagnostic Trouble Code (DTC) P0112

IAT Sensor Circuit Low Voltage 6E–118. . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0113

IAT Sensor Circuit High Voltage 6E–121. . . . . . . . . . Diagnostic Trouble Code (DTC) P0117

ECT Sensor Circuit Low Voltage 6E–124. . . . . . . . . .

Diagnostic Trouble Code (DTC) P0118

ECT Sensor Circuit High Voltage 6E–127. . . . . . . . .

Diagnostic Trouble Code (DTC) P0121

TP System Performance 6E–130. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0122

TP Sensor Circuit Low Voltage 6E–133. . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0123

TP Sensor Circuit High Voltage 6E–136. . . . . . . . . .

Diagnostic Trouble Code (DTC) P0131

HO2S Circuit Low Voltage Bank 1

Sensor 1 6E–139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0132

HO2S Circuit High Voltage Bank 1

Sensor 1 6E–142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0134

HO2S Circuit Insufficient Activity Bank 1

Sensor 1 6E–145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0151

HO2S Circuit Low Voltage Bank 2

Sensor 1 6E–148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0152

HO2S Circuit HIGH Voltage Bank 2

Sensor 1 6E–151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0171

Fuel Trim System Lean Bank 1 6E–154. . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0172

Fuel Trim System Rich Bank 1 6E–158. . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0174

Fuel Trim System Lean Bank 2 6E–162. . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0175

Fuel Trim System Rich Bank 2 6E–166. . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0201

Injector 1 Control Circuit 6E–170. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0202

Injector 2 Control Circuit 6E–173. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0203

Injector 3 Control Circuit 6E–176. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0204

Injector 4 Control Circuit 6E–179. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0205

Injector 5 Control Circuit 6E–182. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0206

Injector 6 Control Circuit 6E–185. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0325

KS Module Circuit 6E–188. . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0327

KS Sensor Circuit 6E–190. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0336

58X Reference Signal Circuit 6E–193. . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0337

CKP Sensor Circuit Low Frequency 6E–195. . . . . . .

Diagnostic Trouble Code (DTC) P0341

CMP Sensor Circuit Performance 6E–198. . . . . . . . .

Diagnostic Trouble Code (DTC) P0342

CMP Sensor Circuit Low 6E–202. . . . . . . . . . . . . . . . .

Page 1120 of 6000

6E–3 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0351

Ignition 1 Control Circuit 6E–206. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0352

Ignition 2 Control Circuit 6E–209. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0353

Ignition 3 Control Circuit 6E–212. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0354

Ignition 4 Control Circuit 6E–215. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0355

Ignition 5 Control Circuit 6E–218. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0356

Ignition 6 Control Circuit 6E–221. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0402

EGR Pintle Crank Error 6E–224. . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0404

EGR Open Stuck 6E–226. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0405

EGR Low Voltage 6E–228. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0406

EGR High Voltage 6E–231. . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0502

VSS Circuit Low Input 6E–234. . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0562

System Voltage Low 6E–237. . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0563

System Voltage High 6E–239. . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0601

PCM Memory 6E–240. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1154

HO2S Circuit Transition Time Ratio Bank 2

Sensor 1 6E–241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1171

Fuel System Lean During Acceleration 6E–245. . . .

Diagnostic Trouble Code (DTC) P1380

ABS Rough Road ABS System Fault 6E–248. . . . . .

Diagnostic Trouble Code (DTC) P1404

EGR Closed Stuck 6E–249. . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1508

IAC System Low RPM 6E–251. . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1509

IAC System High RPM 6E–254. . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1618

Serial Peripheral Interface (SPI) PCM

Interprocessor Communication Error 6E–257. . . . . .

Diagnostic Trouble Code (DTC) P1625

PCM Unexpected Reset 6E–258. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1640

Driver-1-Input High Voltage 6E–259. . . . . . . . . . . . . .

Symptom Diagnosis 6E–262. . . . . . . . . . . . . . . . . . . . .

Default Matrix Table 6E–288. . . . . . . . . . . . . . . . . . . . .

Camshaft Position (CMP) Sensor 6E–291. . . . . . . . . .

Crankshaft Position (CKP) Sensor 6E–292. . . . . . . . .

Engine Coolant Temperature (ECT) Sensor 6E–292.

Heated Oxygen Sensor (HO2S) 6E–293. . . . . . . . . . .

Intake Air Temperature (IAT) Sensor 6E–295. . . . . . .

Knock Sensor (KS) 6E–296. . . . . . . . . . . . . . . . . . . . . . Mass Air Flow (MAF) Sensor 6E–297. . . . . . . . . . . . .

Manifold Absolute Pressure (MAP) Sensor 6E–297.

Malfunction Indicator Lamp (MIL) 6E–298. . . . . . . . . .

Powertrain Control Module (PCM) 6E–298. . . . . . . . .

EEPROM 6E–300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Steering Pressure (PSP) Switch 6E–300

. . . .

Throttle Position (TP) Sensor 6E–301. . . . . . . . . . . . .

Vehicle Speed Sensor (VSS) 6E–302. . . . . . . . . . . . .

Air Cleaner/Air Filter 6E–303. . . . . . . . . . . . . . . . . . . . .

Idle Air Control (IAC) Valve 6E–304. . . . . . . . . . . . . . .

Common Chamber 6E–305. . . . . . . . . . . . . . . . . . . . . .

Accelerator Cable Assembly 6E–305. . . . . . . . . . . . . .

Accelerator Pedal Replacement 6E–308. . . . . . . . . . .

Fuel Filter Cap 6E–310. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter 6E–310. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge Unit 6E–313. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Injectors 6E–314. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pressure Regulator 6E–315. . . . . . . . . . . . . . . . .

Fuel Metering System 6E–317. . . . . . . . . . . . . . . . . . . .

Fuel Pump Assembly 6E–318. . . . . . . . . . . . . . . . . . . .

Fuel Pump Relay 6E–319. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Rail Assembly 6E–319. . . . . . . . . . . . . . . . . . . . . .

Fuel Tank 6E–321. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Throttle Body (TB) 6E–323. . . . . . . . . . . . . . . . . . . . . . .

Electronic Ignition System 6E–324. . . . . . . . . . . . . . . .

Catalytic Converter 6E–325. . . . . . . . . . . . . . . . . . . . . .

Air Conditioning Relay 6E–325. . . . . . . . . . . . . . . . . . .

EVAP Canister Hoses 6E–326. . . . . . . . . . . . . . . . . . . .

EVAP Canister 6E–326. . . . . . . . . . . . . . . . . . . . . . . . . .

EVAP Canister Purge Solenoid 6E–327. . . . . . . . . . . .

Fuel Tank Vent Valve 6E–328. . . . . . . . . . . . . . . . . . . .

Linear Exhaust Gas Recirculation

(EGR) Valve 6E–328. . . . . . . . . . . . . . . . . . . . . . . . . . .

Positive Crankcase Ventilation (PCV) Valve 6E–329.

Wiring and Connectors 6E–330. . . . . . . . . . . . . . . . . . .

PCM Connectors and Terminals 6E–330. . . . . . . . . . .

Wire Harness Repair: Twisted Shielded

Cable 6E–330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Twisted Leads 6E–331. . . . . . . . . . . . . . . . . . . . . . . . . .

Weather-Pack Connector 6E–332. . . . . . . . . . . . . . . . .

Com-Pack III 6E–333. . . . . . . . . . . . . . . . . . . . . . . . . . .

Metri-Pack 6E–333. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6E–335. . . . . . . . . . . . . . . . . . . . .

General Description (PCM and Sensors) 6E–335. . .

58X Reference PCM Input 6E–335. . . . . . . . . . . . . .

A/C Request Signal 6E–335. . . . . . . . . . . . . . . . . . . .

Crankshaft Position (CKP) Sensor 6E–335. . . . . . .

Camshaft Position (CMP) Sensor and

Signal 6E–335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Coolant Temperature (ECT) Sensor 6E–335

Electrically Erasable Programmable Read

Only Memory (EEPROM) 6E–336. . . . . . . . . . . . . .

Fuel Control Heated Oxygen Sensors 6E–336. . . .

Intake Air Temperature (IAT) Sensor 6E–336. . . . .

Page 1121 of 6000

6E–4

ENGINE DRIVEABILITY AND EMISSIONS

Knock Sensor 6E–337. . . . . . . . . . . . . . . . . . . . . . . . .

Linear Exhaust Gas Recirculation (EGR)

Control 6E–337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mass Air Flow (MAF) Sensor 6E–337. . . . . . . . . . . .

Manifold Absolute Pressure (MAP) Sensor 6E–338

Powertrain Control Module (PCM) 6E–338. . . . . . .

PCM Function 6E–338. . . . . . . . . . . . . . . . . . . . . . . . .

PCM Components 6E–339. . . . . . . . . . . . . . . . . . . . .

PCM Voltage Description 6E–339. . . . . . . . . . . . . . .

PCM Input/Outputs 6E–339. . . . . . . . . . . . . . . . . . . .

PCM Service Precautions 6E–339. . . . . . . . . . . . . .

Reprogramming The PCM 6E–339. . . . . . . . . . . . . .

Throttle Position (TP) Sensor 6E–339. . . . . . . . . . .

Transmission Fluid Temperature (TFT)

Sensor 6E–340. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Range Switch 6E–340. . . . . . . . . . . . .

Vehicle Speed Sensor (VSS) 6E–340. . . . . . . . . . . .

Use of Circuit Testing Tools 6E–340. . . . . . . . . . . . .

Aftermarket Electrical and Vacuum

Equipment 6E–340. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrostatic Discharge Damage 6E–341. . . . . . . . .

Upshift Lamp 6E–341. . . . . . . . . . . . . . . . . . . . . . . . .

General Description (Air Induction) 6E–341. . . . . . . .

Air Induction System 6E–341. . . . . . . . . . . . . . . . . . .

General Description (Fuel Metering) 6E–341. . . . . . .

Acceleration Mode 6E–341. . . . . . . . . . . . . . . . . . . . .

Accelerator Controls 6E–341. . . . . . . . . . . . . . . . . . .

Battery Voltage Correction Mode 6E–341. . . . . . . .

CMP Signal 6E–341. . . . . . . . . . . . . . . . . . . . . . . . . . .

Clear Flood Mode 6E–342. . . . . . . . . . . . . . . . . . . . .

Deceleration Mode 6E–342. . . . . . . . . . . . . . . . . . . .

Engine Speed/Vehicle Speed/Fuel

Disable Mode 6E–342. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Cutoff Mode 6E–342. . . . . . . . . . . . . . . . . . . . . .

Fuel Injector 6E–342. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Metering System Components 6E–342. . . . . . Fuel Metering System Purpose 6E–342. . . . . . . . . .

Fuel Pressure Regulator 6E–343. . . . . . . . . . . . . . . .

Fuel Pump Electrical Circuit 6E–343. . . . . . . . . . . . .

Fuel Rail 6E–343. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Idle Air Control (IAC) Valve 6E–343. . . . . . . . . . . . .

Run Mode 6E–344. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting Mode 6E–344. . . . . . . . . . . . . . . . . . . . . . . . .

Throttle Body Unit 6E–344. . . . . . . . . . . . . . . . . . . . .

General Description (Electronic Ignition

System) 6E–344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft Position (CMP) Sensor 6E–344. . . . . . . .

Crankshaft Position (CKP) Sensor 6E–345. . . . . . .

Electronic Ignition 6E–345. . . . . . . . . . . . . . . . . . . . .

Ignition Coils 6E–345. . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Control 6E–345. . . . . . . . . . . . . . . . . . . . . . . .

Ignition Control PCM Output 6E–347. . . . . . . . . . . .

Knock Sensor (KS) PCM Input 6E–347

. . . . . . . . . .

Powertrain Control Module (PCM) 6E–347. . . . . . .

Spark Plug 6E–347. . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/C Clutch Diagnosis 6E–349. . . . . . . . . . . . . . . . . . . .

A/C Clutch Circuit Operation 6E–349. . . . . . . . . . . .

A/C Clutch Circuit Purpose 6E–349. . . . . . . . . . . . .

A/C Request Signal 6E–349. . . . . . . . . . . . . . . . . . . .

General Description (Exhaust Gas

Recirculation (EGR) System) 6E–349. . . . . . . . . . . . .

EGR Purpose 6E–349. . . . . . . . . . . . . . . . . . . . . . . . .

Linear EGR Valve 6E–349. . . . . . . . . . . . . . . . . . . . .

Linear EGR Control 6E–349. . . . . . . . . . . . . . . . . . . .

Linear EGR Valve Operation and Results

of Incorrect Operation 6E–349. . . . . . . . . . . . . . . . .

EGR Pintle Position Sensor 6E–350. . . . . . . . . . . . .

General Description (Positive Crankcase

Ventilation (PCV) System) 6E–350. . . . . . . . . . . . . . .

Crankcase Ventilation System Purpose 6E–350. . .

Crankcase Ventilation System Operation 6E–350.

Page 1137 of 6000

6E–20

ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinout Table, 32-Way White Connector – Row “C” (For EC)

TS23345

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

C1Injector Cylinder #4GRN/REDB+B+General Description and

Operation, Fuel Injector

C2Shift “B” SolenoidBRN/BLK0.0 V0.0 VAutomatic Transmission

(4L30E)

C3Injector Cylinder #6GRN/YELB+B+General Description and

Operation, Fuel Injector

C4Ignition Control (IC)

Cylinder #1RED0.0 V0.1 VGeneral Description and

Operation, Fuel Injector

C5Crankshaft Position

Sensor, “A” CircuitYEL0.3 V to 5 V2.2 VGeneral Description and

Operation, Crankshaft

Position Sensor

C6Not Used————

C7PCM GroundYEL0.0 V0.0 VChassis Electrical

C8PCM GroundBLK/PNK0.0 V0.0 VChassis Electrical

C9PCM GroundBLK/BLU0.0 V0.0 VChassis Electrical

C10TachometerBLK/RED8.8 V10.0 V

(at idle)Chassis Electrical

C11Variable Intake ManifoldYEL/BLK0.0 VB+ (rpm

3600 over)Manual Transmission

C12Alternator Control GainWHT/BLU10.5 VB+Chassis Electrical

C13Fuel PWMBLU/PNKB+B+—

C14Bank 2 HO2S 1 HighPNK0.4 V0.1-0.9 VGeneral Description and

Operation, Fuel HO2S 1

C15Bank 2 HO2S 1 LowBLU0.0 V0.1 VGeneral Description and

Operation, Fuel HO2S 1

C16Not Used————

Page 1138 of 6000

6E–21 ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinout Table, 32-Way White Connector – Row “C” (For except EC)

TS23345

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

C1Injector Cylinder #4GRN/REDB+B+General Description and

Operation, Fuel Injector

C2Shift “B” SolenoidBRN/BLK0.0 V0.0 VAutomatic Transmission

(4L30E)

C3Injector Cylinder #6GRN/YELB+B+General Description and

Operation, Fuel Injector

C4Ignition Control (IC)

Cylinder #1RED0.0 V0.1 VGeneral Description and

Operation, Fuel Injector

C5Crankshaft Position

Sensor, “A” CircuitYEL0.3 V to 5 V2.2 VGeneral Description and

Operation, Crankshaft

Position Sensor

C6Not Used————

C7PCM GroundBLK/BLU0.0 V0.0 VChassis Electrical

C8PCM GroundBLK/PNK0.0 V0.0 VChassis Electrical

C9PCM GroundBLK/BLU0.0 V0.0 VChassis Electrical

C10TachometerBLK/RED8.8 V10.0 V

(at idle)Chassis Electrical

C11Variable Intake ManifoldYEL/BLK0.0 VB+ (rpm

3600 over)Manual Transmission

C12Not Used————

C13Not Used————

C14Not Used————

C15Not Used————

C16Not Used————

Page 1139 of 6000

6E–22

ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinout Table, 32-Way White Connector – Row “D”

(For except EXPORT and SOUTH AFRICA)

TS23345

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

D1Injector Cylinder #2GRN/ORNB+B+General Description and

Operation, Fuel Injector

D2Torque Converter Clutch

(TCC)BRN/BLU0.0 V0.0 VOn-Vehicle Service, Torque

Converter Clutch

D3Injector Cylinder #1GRN/WHTB+B+General Description and

Operation, Fuel Injector

D4Serial Data (8192)ORN5.0 V5.0 VChassis Electrical

D5Ignition Control, Cylinder

#5RED/YEL0.0 V0.1 VGeneral Description and

Operation, Ignition Coil

D6Ignition Control, Cylinder

#3RED/BLUE0.0 V0.0 VGeneral Description and

Operation, Ignition Coil

D7VSS Input / IMOB

ResponseWHT/BLK0.0 V0.1 V

(at rest)Chassis Electrical

D8Sensor Ground 5V

Reference A ReturnGRN0.0 V0.0 VAppropriate Sensor

D9Sensor Ground 5 V

Reference B ReturnGRY0.0 V0.0 VAppropriate Sensor

D10Mass Air Flow (MAF)YEL4.9 V4.2 VGeneral Description, Mass

Air Flow Sensor

D11Camshaft Position SensorWHT5.0 V or less

than 1.0 V4.6 VGeneral Description and

Operation, Camshaft

Position Sensor

D12Not Used————

D13Not Used————

D14Bank 1 HO2S 1 LowGRN0.0 V0.1 VGeneral Description and

Operation, Fuel HO2S 1

D15Bank 1 HO2S 1 SignalRED0.4 V0.1-0.9 VGeneral Description and

Operation, Fuel HO2S 1

D16Not Used————

Page 1140 of 6000

6E–23 ENGINE DRIVEABILITY AND EMISSIONS

PCM Pinout Table, 32-Way White Connector – Row “D”

(For EXPORT and SOUTH AFRICA)

TS23345

PINPIN FunctionWire ColorIGN ONENG RUNRefer To

D1Injector Cylinder #2GRN/ORNB+B+General Description and

Operation, Fuel Injector

D2Torque Converter Clutch

(TCC)BRN/BLU0.0 V0.0 VOn-Vehicle Service, Torque

Converter Clutch

D3Injector Cylinder #1GRN/WHTB+B+General Description and

Operation, Fuel Injector

D4Serial Data (8192)ORN5.0 V5.0 VChassis Electrical

D5Ignition Control, Cylinder

#5RED/YEL0.0 V0.1 VGeneral Description and

Operation, Ignition Coil

D6Ignition Control, Cylinder

#3RED/BLUE0.0 V0.0 VGeneral Description and

Operation, Ignition Coil

D7VSS Input / IMOB

ResponseLIGHT

GRN/WHT0.0 V0.1 V

(at rest)Chassis Electrical

D8Sensor Ground 5V

Reference A ReturnGRN0.0 V0.0 VAppropriate Sensor

D9Sensor Ground 5 V

Reference B ReturnGRY0.0 V0.0 VAppropriate Sensor

D10Mass Air Flow (MAF)YEL4.9 V4.2 VGeneral Description, Mass

Air Flow Sensor

D11Camshaft Position SensorWHT5.0 V or less

than 1.0 V4.6 VGeneral Description and

Operation, Camshaft

Position Sensor

D12Not Used————

D13Not Used————

D14Not Used————

D15Not Used————

D16Not Used————