service OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 468 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–1

DRIVELINE/AXLE

DIFFERENTIAL (Rear 220mm)

CONTENTS

Service Precaution 4A2A–1. . . . . . . . . . . . . . . . . . . . . .

General Description 4A2A–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 4A2A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Housing 4A2A–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Housing and Associated Parts 4A2A–4. . . . . .

Removal 4A2A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Seal Replacement 4A2A–5. . . . . . . . . . . . . . . . . .

Installation 4A2A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Oil Seal 4A2A–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Oil Seal and Associated Parts 4A2A–6. . . . .

Removal 4A2A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2A–7. . . . . . . . . . . . . . . . . .

Installation 4A2A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Assembly 4A2A–8. . . . . . . . . . . . . . . . . . . .

Differential Assembly and Associated Parts 4A2A–8

Removal 4A2A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 4A2A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 4A2A–10. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2A–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4A2A–13. . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Cage Assembly 4A2A–21. . . . . . . . . . . . . . .

Disassembled View 4A2A–21. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2A–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2A–22. . . . . . . . . . . . . . . . . .

Reassembly 4A2A–23. . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Slip Differential 4A2A–25. . . . . . . . . . . . . . . . . . .

Disassembled View 4A2A–25. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2A–26. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2A–26. . . . . . . . . . . . . . . . . .

Reassembly 4A2A–28. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4A2A–32. . . . . . . . . . .

Special Tools 4A2A–34. . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE REFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally,such coatings

adversely affect the fastener torque and the joint

c l a m p i n g f o r c e , a n d m a y d a m a g e t h e f a s t e n e r. W h e n

you install fasteners, use the correct tightening

sequence and specification. Following these

instructions can help you avoid damage to parts and

systems.

Page 504 of 6000

DIFFERENTIAL (REAR 244mm)

4A2B–1

DRIVELINE/AXLE

DIFFERENTIAL (REAR 244mm)

CONTENTS

Service Precaution 4A2B–1. . . . . . . . . . . . . . . . . . . . . .

General Description 4A2B–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 4A2B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Housing 4A2B–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Axle Housing and Associated Parts 4A2B–4. . . . . .

Removal 4A2B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Seal Replacement 4A2B–5. . . . . . . . . . . . . . . . . .

Installation 4A2B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Oil Seal 4A2B–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion Oil Seal and Associated Parts 4A2B–6. . . . .

Removal 4A2B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2B–7. . . . . . . . . . . . . . . . . .

Installation 4A2B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Assembly 4A2B–8. . . . . . . . . . . . . . . . . . . .

Differential Assembly and Associated Parts 4A2B–8

Removal 4A2B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 4A2B–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 4A2B–10. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2B–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4A2B–13. . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Cage Assembly 4A2B–20. . . . . . . . . . . . . . .

Disassembled View 4A2B–20. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2B–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2B–21. . . . . . . . . . . . . . . . . .

Reassembly 4A2B–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Locking Differential Assembly 4A2B–23. . . . . . . . . . . . .

Disassembled View 4A2B–23. . . . . . . . . . . . . . . . . . . .

Disassembly 4A2B–23. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4A2B–25. . . . . . . . . . . . . . . . . .

Reassembly 4A2B–25. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4A2B–27. . . . . . . . . . . . .

Special Tools 4A2B–29. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE REFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally,such coatings

adversely affect the fastener torque and the joint

c l a m p i n g f o r c e , a n d m a y d a m a g e t h e f a s t e n e r. W h e n

you install fasteners, use the correct tightening

sequence and specification. Following these

instructions can help you avoid damage to parts and

systems.

Page 534 of 6000

4B1–1 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

DRIVELINE/AXLE

DRIVELINE CONTROL SYSTEM (SHIFT ON THE FLY)

CONTENTS

Service Precaution 4B1–1. . . . . . . . . . . . . . . . . . . . . .

Shift on the Fly System (Lever Type) 4B1–2. . . . . . .

Outline of Shift on the Fly System

(Lever Type) 4B1–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Shift on the Fly Vacuum Piping and Electric

Equipment (For Lever Control Type) 4B1–3. . . . . .

Vacuum Piping Diagram 4B1–3. . . . . . . . . . . . . . . .

Inspection and Repair 4B1–4. . . . . . . . . . . . . . . . . .

Shift on the Fly System (Push Button Type) 4B1–7.

Outline of Shift on the Fly System

(Push Button Type) 4B1–7. . . . . . . . . . . . . . . . . . . . Functions of Indicator Lamp 4B1–11. . . . . . . . . . . . . . .

Diagnosis 4B1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Axle Diagnosis 4B1–30. . . . . . . . . . . . . . . . . . .

Shift on the Fly Vacuum Piping and Electric

Equipment (For Push Button Type) 4B1–32. . . . . . . .

Vacuum Piping Diagram 4B1–32. . . . . . . . . . . . . . . .

Inspection and Repair 4B1–33. . . . . . . . . . . . . . . . . .

4WD Control Unit (For Push Button Type) 4B1–36. .

4WD Control Unit Associated Parts 4B1–36. . . . . .

Removal 4B1–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4B1–37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 572 of 6000

4B2–1 DRIVE LINE CONTROL SYSTEM (TOD)

DRIVELINE/AXLE

DRIVELINE CONTROL SYSTEM (TOD)

CONTENTS

Service Precaution 4B2–1. . . . . . . . . . . . . . . . . . . . . .

General Description 4B2–2. . . . . . . . . . . . . . . . . . . . .

System Components 4B2–4. . . . . . . . . . . . . . . . . . . .

Parts Location 4B2–4. . . . . . . . . . . . . . . . . . . . . . . .

Functions of Indicator Lamp 4B2–8. . . . . . . . . . . . . .

Diagnosis 4B2–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Diagnostic Flow Chart 4B2–16. . . . . . . . . . . . . .

Parts Location 4B2–17. . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram 4B2–18. . . . . . . . . . . . . . . . . . . . . . . . . Connector List 4B2–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Failed Pin 4B2–23. . . . . . . . . . . . . . . . . . . . .

Checking Failed TOD Control Unit Pin 4B2–26. . . . .

Diagnostic Trouble Codes 4B2–30. . . . . . . . . . . . . . . .

Diagnosis from Trouble Codes 4B2–31. . . . . . . . . . . .

Trouble Diagnosis Depending on The Status

of TOD Indicator 4B2–58. . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis from Symptom 4B2–86. . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 598 of 6000

4B2–27 DRIVE LINE CONTROL SYSTEM (TOD)

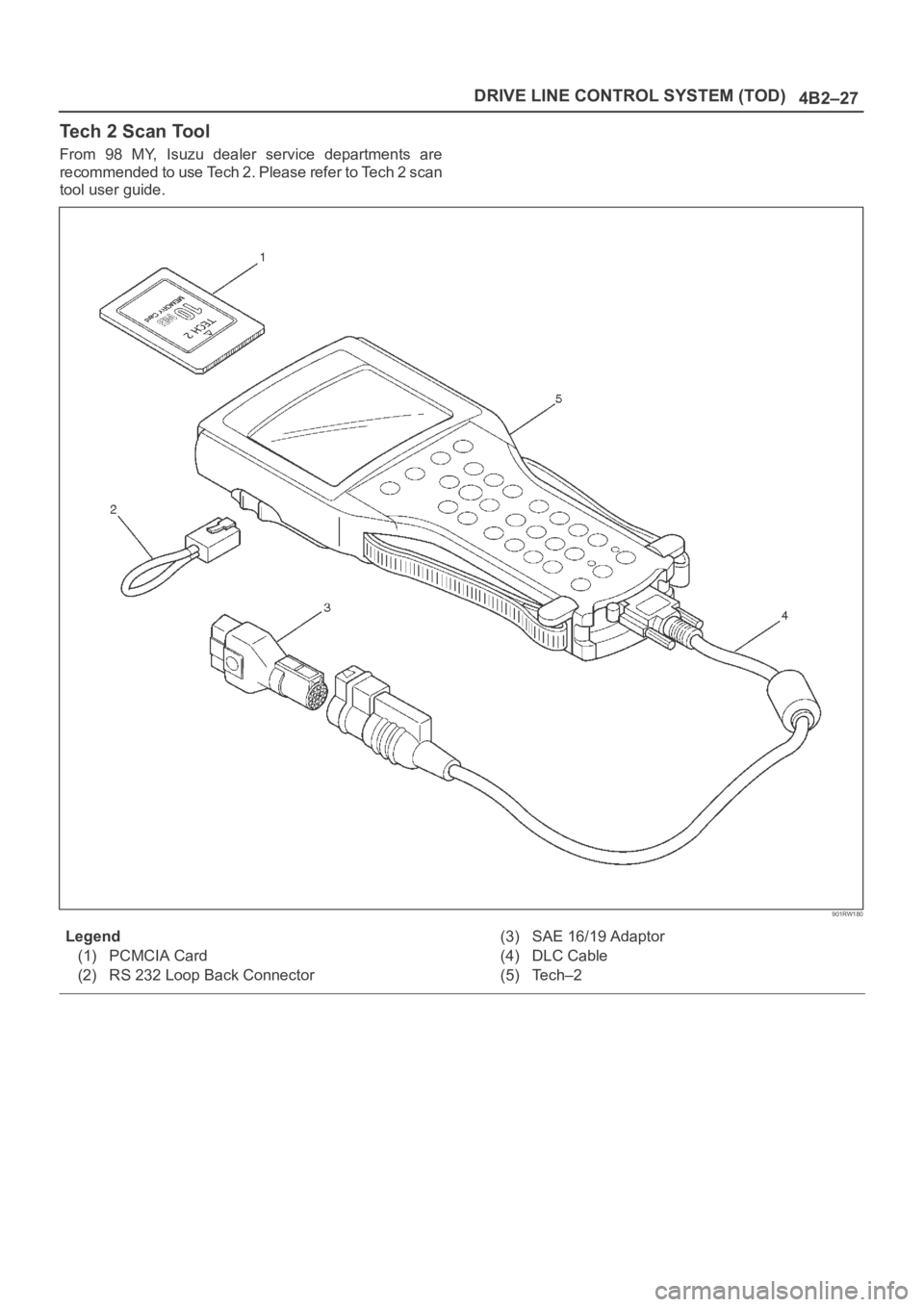

Tech 2 Scan Tool

From 98 MY, Isuzu dealer service departments are

recommended to use Tech 2. Please refer to Tech 2 scan

tool user guide.

901RW180

Legend

(1) PCMCIA Card

(2) RS 232 Loop Back Connector(3) SAE 16/19 Adaptor

(4) DLC Cable

(5) Tech–2

Page 659 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–88

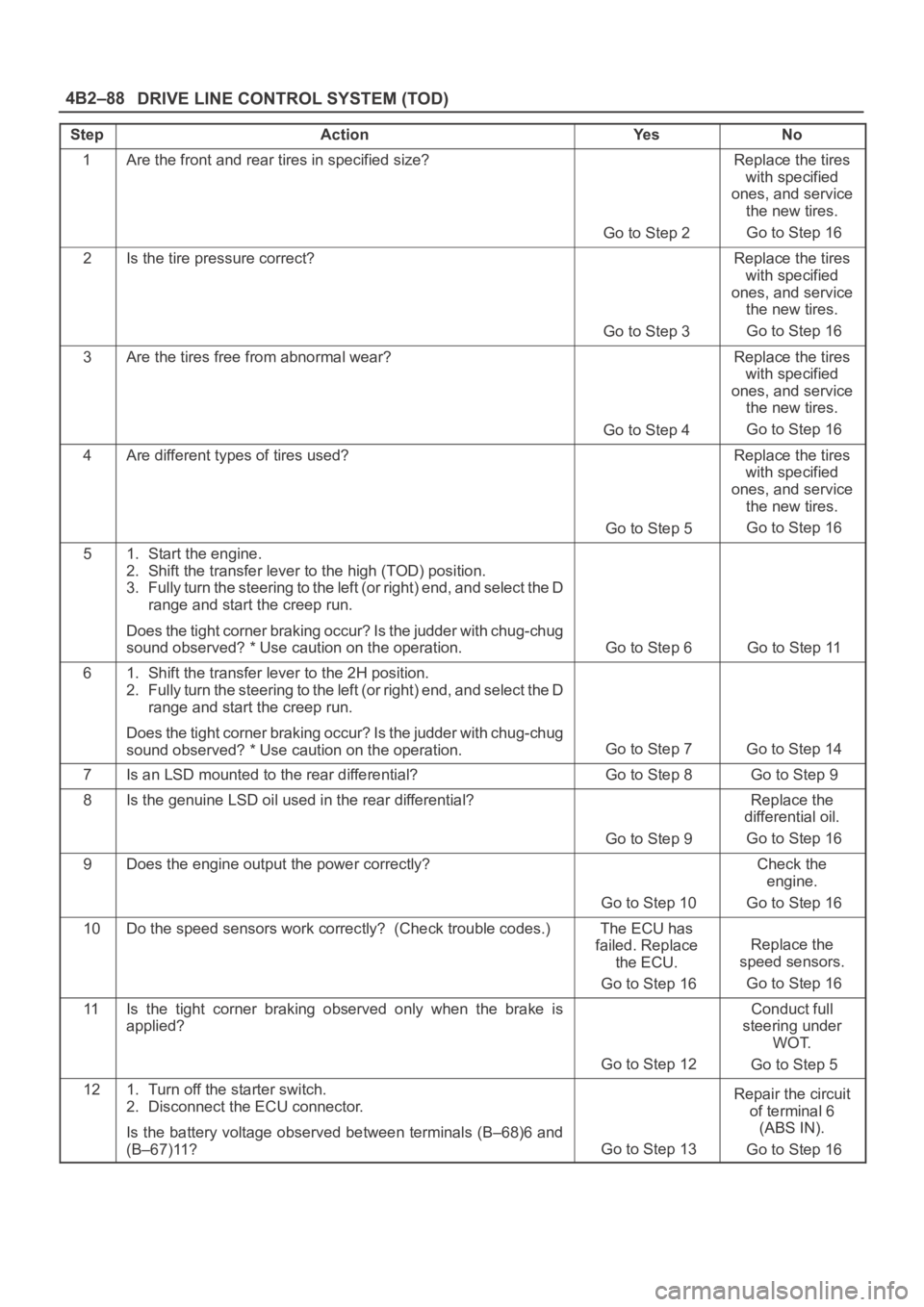

StepActionYe sNo

1Are the front and rear tires in specified size?

Go to Step 2

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

2Is the tire pressure correct?

Go to Step 3

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

3Are the tires free from abnormal wear?

Go to Step 4

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

4Are different types of tires used?

Go to Step 5

Replace the tires

with specified

ones, and service

the new tires.

Go to Step 16

51. Start the engine.

2. Shift the transfer lever to the high (TOD) position.

3. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 6 Go to Step 11

61. Shift the transfer lever to the 2H position.

2. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the tight corner braking occur? Is the judder with chug-chug

sound observed? * Use caution on the operation.

Go to Step 7 Go to Step 14

7Is an LSD mounted to the rear differential? Go to Step 8 Go to Step 9

8Is the genuine LSD oil used in the rear differential?

Go to Step 9

Replace the

differential oil.

Go to Step 16

9Does the engine output the power correctly?

Go to Step 10

Check the

engine.

Go to Step 16

10Do the speed sensors work correctly? (Check trouble codes.)The ECU has

failed. Replace

the ECU.

Go to Step 16

Replace the

speed sensors.

Go to Step 16

11Is the tight corner braking observed only when the brake is

applied?

Go to Step 12

Conduct full

steering under

WOT.

Go to Step 5

121. Turn off the starter switch.

2. Disconnect the ECU connector.

Is the battery voltage observed between terminals (B–68)6 and

(B–67)11?

Go to Step 13

Repair the circuit

of terminal 6

(ABS IN).

Go to Step 16

Page 667 of 6000

4C–1 DRIVE SHAFT SYSTEM

DRIVELINE/AXLE

DRIVE SHAFT SYSTEM

CONTENTS

Service Precaution 4C–2. . . . . . . . . . . . . . . . . . . . . .

General Description 4C–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 4C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Shaft 4C–4. . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Shaft and Associated Parts 4C–4. . . .

Removal 4C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–5. . . . . . . . . . . . . . . . . .

Oil Seal Replacement 4C–6. . . . . . . . . . . . . . . . . .

Installation 4C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 4C–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Hub and Disc (with Shift on the Fly) 4C–9. .

Disassembled View 4C–9. . . . . . . . . . . . . . . . . . . .

Disassembly 4C–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–10. . . . . . . . . . . . . . . . . .

Reassembly 4C–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Hub and Disc with Manual Locking Hub 4C–14

Disassembled View 4C–14. . . . . . . . . . . . . . . . . . . .

Disassembly 4C–14. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–16. . . . . . . . . . . . . . . . . .

Reassembly 4C–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4C–20. . . . . . . . . . . . .

Special Tools 4C–21. . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Drive Shaft Joint 4C–22. . . . . . . . . . . . . . . . . . .

Front Drive Shaft Joints Replacement 4C–22. . . .

Front Axle Drive Shaft 4C–23. . . . . . . . . . . . . . . . . . .

Front Axle Drive Shaft and Associated

Parts 4C–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4C–24. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–25. . . . . . . . . . . . . . . . . .

Bushing Replacement 4C–25. . . . . . . . . . . . . . . . . . Reassembly 4C–26. . . . . . . . . . . . . . . . . . . . . . . . . .

Shift On The Fly System 4C–28. . . . . . . . . . . . . . . . .

Shift On The Fly System and Associated

Parts 4C–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4C–28. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–30. . . . . . . . . . . . . . . . . .

Main Data and Specifications 4C–35. . . . . . . . . . .

Special Tools 4C–36. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Propeller Shaft 4C–37. . . . . . . . . . . . . . . . . . . . .

General Description 4C–37. . . . . . . . . . . . . . . . . . . . .

Front Propeller Shaft and Associated Parts 4C–38

Removal 4C–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4C–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly (Except TOD 4

4) 4C–40. . . . . . . . .

Universal Joint Disassembly 4C–41. . . . . . . . . . . .

Inspection and Repair 4C–42. . . . . . . . . . . . . . . . . .

Universal Joint Reassembly 4C–45. . . . . . . . . . . . .

Reassembly (Except TOD 4

4) 4C–46. . . . . . . . . .

Main Data and Specifications 4C–47. . . . . . . . . . .

Rear Propeller Shaft 4C–48. . . . . . . . . . . . . . . . . . . . .

General Description 4C–48. . . . . . . . . . . . . . . . . . . . .

Rear Propeller Shaft and Associated Parts 4C–48

Removal 4C–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4C–49. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4C–50. . . . . . . . . . . . . . . . . . . . . . . . . .

Universal Joint Disassembly 4C–51. . . . . . . . . . . .

Inspection and Repair 4C–52. . . . . . . . . . . . . . . . . .

Universal Joint Reassembly 4C–53. . . . . . . . . . . . .

Reassembly 4C–54. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4C–55. . . . . . . . . . .

Page 668 of 6000

4C–2

DRIVE SHAFT SYSTEM

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

This publication contains essential removal, installation,

adjustment and maintenance procedures.

The front axle utilizes a central disconnect type front

axle/transfer case system.

The drive axles are completely flexible assemblies,

consisting of inner and outer constant velocity (CV) drive

shaft joints connected by an axle shaft.

For description of propeller shaft and universal joint, refer

to Front/Rear Propeller Shaft in this section.

Page 722 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–1

DRIVELINE/AXLE

TRANSFER CASE (STANDARD TYPE)

CONTENTS

Service Precaution 4D1–1. . . . . . . . . . . . . . . . . . . . . .

General Description 4D1–2. . . . . . . . . . . . . . . . . . . . .

Transfer Rear Oil Seal 4D1–8. . . . . . . . . . . . . . . . . . .

Removal 4D1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4D1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Case Assembly 4D1–9. . . . . . . . . . . . . . . . .

Removal 4D1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4D1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Rear Cover Assembly

(4WD Switch Model) 4D1–11. . . . . . . . . . . . . . . . . . . .

Transfer Rear Cover Assembly and

Associated Parts 4D1–11. . . . . . . . . . . . . . . . . . . . . .

Removal 4D1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4D1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4D1–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4D1–17. . . . . . . . . . . . . . . . . .

Reassembly 4D1–17. . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Rear Cover Assembly

(Except 4WD Switch Model) 4D1–19. . . . . . . . . . . . . . Transfer Rear Cover Assembly and

Associated Parts 4D1–19. . . . . . . . . . . . . . . . . . . . . .

Removal 4D1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4D1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4D1–23. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4D1–24. . . . . . . . . . . . . . . . . .

Reassembly 4D1–24. . . . . . . . . . . . . . . . . . . . . . . . . .

Detent, Shift Arm, and Interlock Pin 4D1–26. . . . . . . .

Disassembled View 4D1–26. . . . . . . . . . . . . . . . . . . .

Disassembly 4D1–26. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4D1–28. . . . . . . . . . . . . . . . . .

Reassembly 4D1–28. . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Case Assembly 4D1–30. . . . . . . . . . . . . . . . .

Disassembled View 4D1–30. . . . . . . . . . . . . . . . . . . .

Disassembly 4D1–31. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4D1–33. . . . . . . . . . . . . . . . . .

Reassembly 4D1–37. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4D1–43. . . . . . . . . . . . .

Special Tools 4D1–46. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 768 of 6000

4D2–1 TRANSFER CASE (TOD)

DRIVELINE/AXLE

TRANSFER CASE (TOD)

CONTENTS

Service Precaution 4D2–1. . . . . . . . . . . . . . . . . . . . . .

Transfer Case Assembly 4D2–2. . . . . . . . . . . . . . . . .

Removal 4D2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4D2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Rear Oil Seal 4D2–5. . . . . . . . . . . . . . . . . . .

Transfer Rear Oil Seal and Associated

Parts 4D2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 4D2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4D2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOD ECU 4D2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 4D2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4D2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Repair 4D2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 4D2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Case 4D2–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 4D2–9. . . . . . . . . . . . . . . . . . . .

Disassembly 4D2–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4D2–10. . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Cover Assembly 4D2–12. . . . . . . . . . . . . . . .

Disassembled View 4D2–12. . . . . . . . . . . . . . . . . . . .

Disassembly 4D2–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 4D2–14. . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Case Assembly Clutch Pack and

Clutch Cam 4D2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 4D2–16. . . . . . . . . . . . . . . . . . . . Disassembly 4D2–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Sprocket and Mechanical Lock 4D2–18. . . . . . . . . . . .

Disassembled View 4D2–18. . . . . . . . . . . . . . . . . . . .

Disassembly 4D2–18. . . . . . . . . . . . . . . . . . . . . . . . . .

Output Shafts and Shift Control Shaft 4D2–20. . . . . .

Disassembled View 4D2–20. . . . . . . . . . . . . . . . . . . .

Disassembly 4D2–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Case 4D2–23. . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 4D2–23. . . . . . . . . . . . . . . . . . . .

Disassembly 4D2–24. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4D2–26. . . . . . . . . . . . . . . . . .

Transfer Case 4D2–30. . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 4D2–30. . . . . . . . . . . . . . . . . . . .

Reassembly 4D2–30. . . . . . . . . . . . . . . . . . . . . . . . . .

Output Shafts and Shift Control Shaft 4D2–34. . . . . .

Disassembled View 4D2–34. . . . . . . . . . . . . . . . . . . .

Reassembly 4D2–34. . . . . . . . . . . . . . . . . . . . . . . . . .

Sprocket and Mechanical Lock 4D2–37. . . . . . . . . . . .

Disassembled View 4D2–37. . . . . . . . . . . . . . . . . . . .

Reassembly 4D2–37. . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Pack and Clutch Cam 4D2–39. . . . . . . . . . . . .

Disassembled View 4D2–39. . . . . . . . . . . . . . . . . . . .

Reassembly 4D2–39. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4D2–41. . . . . . . . . . . . .

Special Tools 4D2–43. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.