service OPEL FRONTERA 1998 Owner's Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1054 of 6000

ENGINE COOLING6B–1

ENGINE

ENGINE COOLING

CONTENTS

Service Precaution 6B–1. . . . . . . . . . . . . . . . . . . . . .

General Description 6B–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 6B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Draining and Refilling Cooling System 6B–6. . . . .

Water Pump 6B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water Pump and Associated Parts 6B–7. . . . . . .

Removal 6B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermostat 6B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermostat and Associated Parts 6B–8. . . . . . . .

Removal 6B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 6B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radiator 6B–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radiator and Associated Parts 6B–9. . . . . . . . . .

Removal 6B–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6B–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Belt and Cooling Fan 6B–12. . . . . . . . . . . . . . .

Drive Belt and Associated Parts 6B–12. . . . . . . . .

Inspection 6B–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6B–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6B–13. . . . . . . . . . . . .

Special Tool 6B–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1059 of 6000

6B–6

ENGINE COOLING

Draining and Refilling Cooling

System

Before draining the cooling system, inspect the system

and perform any necessary service to ensure that it is

clean, does not leak and is in proper working order. The

engine coolant (EC) level should be between the “MIN”

and “MAX” lines of reserve tank when the engine is cold.

If low, check for leakage and add EC up to the “MAX” line.

There should not be any excessive deposit of rust or

scales around the radiator cap or radiator filler hole, and

the EC should also be free from oil.

Replace the EC if excessively dirty.

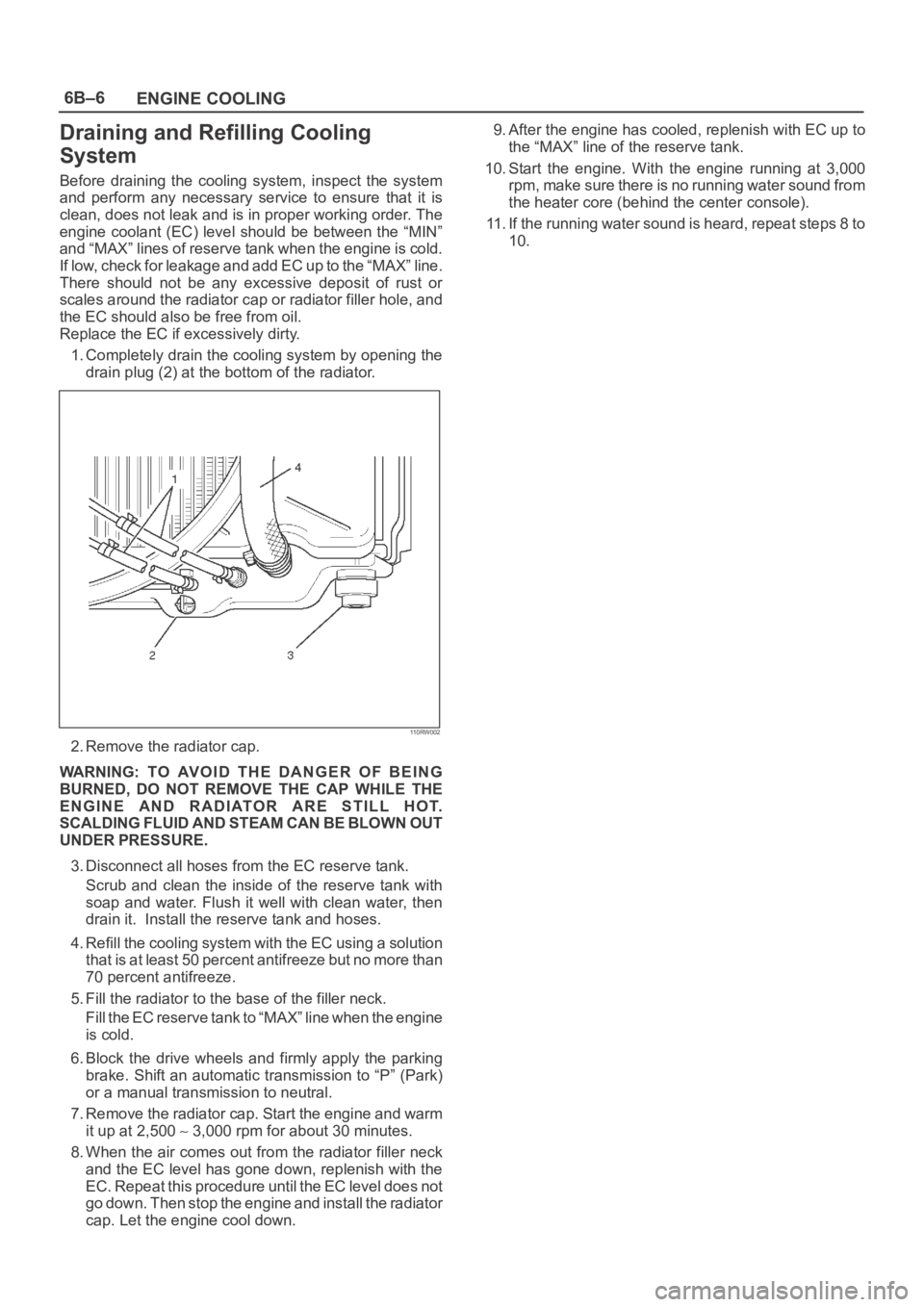

1. Completely drain the cooling system by opening the

drain plug (2) at the bottom of the radiator.

110RW002

2. Remove the radiator cap.

WARNING: TO AVOID THE DANGER OF BEING

BURNED, DO NOT REMOVE THE CAP WHILE THE

ENGINE AND RADIATOR ARE STILL HOT.

SCALDING FLUID AND STEAM CAN BE BLOWN OUT

UNDER PRESSURE.

3. Disconnect all hoses from the EC reserve tank.

Scrub and clean the inside of the reserve tank with

soap and water. Flush it well with clean water, then

drain it. Install the reserve tank and hoses.

4. Refill the cooling system with the EC using a solution

that is at least 50 percent antifreeze but no more than

70 percent antifreeze.

5. Fill the radiator to the base of the filler neck.

Fill the EC reserve tank to “MAX” line when the engine

is cold.

6. Block the drive wheels and firmly apply the parking

brake. Shift an automatic transmission to “P” (Park)

or a manual transmission to neutral.

7. Remove the radiator cap. Start the engine and warm

it up at 2,500

3,000 rpm for about 30 minutes.

8. When the air comes out from the radiator filler neck

and the EC level has gone down, replenish with the

EC. Repeat this procedure until the EC level does not

go down. Then stop the engine and install the radiator

cap. Let the engine cool down.9. After the engine has cooled, replenish with EC up to

the “MAX” line of the reserve tank.

10. Start the engine. With the engine running at 3,000

rpm, make sure there is no running water sound from

the heater core (behind the center console).

11. If the running water sound is heard, repeat steps 8 to

10.

Page 1068 of 6000

6C–1

ENGINE FUEL

ENGINE

ENGINE FUEL

CONTENTS

Service Precaution 6C–1. . . . . . . . . . . . . . . . . . . . . .

General Description 6C–2. . . . . . . . . . . . . . . . . . . . .

Fuel Metering 6C–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter 6C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter and Associated Parts 6C–4. . . . . . . . .

Removal 6C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6C–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

In–Tank Fuel Filter 6C–5. . . . . . . . . . . . . . . . . . . . .

Fuel Pump Flow Test 6C–5. . . . . . . . . . . . . . . . . . .

Fuel Pump 6C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pump and Associated Parts 6C–6. . . . . . . .

Removal 6C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pump Relay 6C–7. . . . . . . . . . . . . . . . . . . . . . . .

General Description 6C–7. . . . . . . . . . . . . . . . . . . . .

Fuel Tank 6C–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fuel Tank and Associated Parts 6C–7. . . . . . . . .

Removal 6C–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tube / Quick – Connect Fittings 6C–8. . . . . . .

Precautions 6C–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Cautions During Work 6C–8. . . . . . . . . . . . . . . . . .

Removal 6C–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reuse of Quick–Connector 6C–10. . . . . . . . . . . . . . .

Assembling Advice 6C–10. . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge Unit 6C–11. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge Unit and Associated Parts 6C–11. . .

Removal 6C–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filler Cap 6C–12. . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6C–12. . . . . . . . . . . . . . . . . . . . .

Inspection 6C–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6C–12. . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1080 of 6000

ENGINE ELECTRICAL6D1–1

ENGINE

ENGINE ELECTRICAL

CONTENTS

Service Precaution 6D1–1. . . . . . . . . . . . . . . . . . . . . .

Battery 6D1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6D1–2. . . . . . . . . . . . . . . . . . . .

Diagnosis 6D1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Charging 6D1–3. . . . . . . . . . . . . . . . . . . . . . Jump Starting 6D1–3. . . . . . . . . . . . . . . . . . . . . . . . .

Battery Removal 6D1–4. . . . . . . . . . . . . . . . . . . . . .

Battery Installation 6D1–4. . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D1–5. . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1081 of 6000

6D1–2

ENGINE ELECTRICAL

Battery

General Description

There are six battery fluid caps on top of the battery.

These are covered by a paper label.

The battery is completely sealed except for the six small

vent holes on the side. These vent holes permit the

escape of small amounts of gas generated by the battery.

This type of battery has the following advantages over

conventional batteries:

1. There is no need to add water during the entire

service life of the battery.

2. The battery protects itself against overcharging.

The battery will refuse to accept an extensive charge.

(A conventional battery will accept an excessive

charge, resulting in gassing and loss of battery fluid.)

3. The battery is much less vulnerable to self discharge

than a conventional type battery.

Diagnosis

1. Visual Inspection

Inspect the battery for obvious physical damage, such as

a cracked or broken case, which would permit electrolyte

loss.

Replace the battery if obvious physical damage is

discovered during inspection.

Check for any other physical damage and correct it as

necessary.

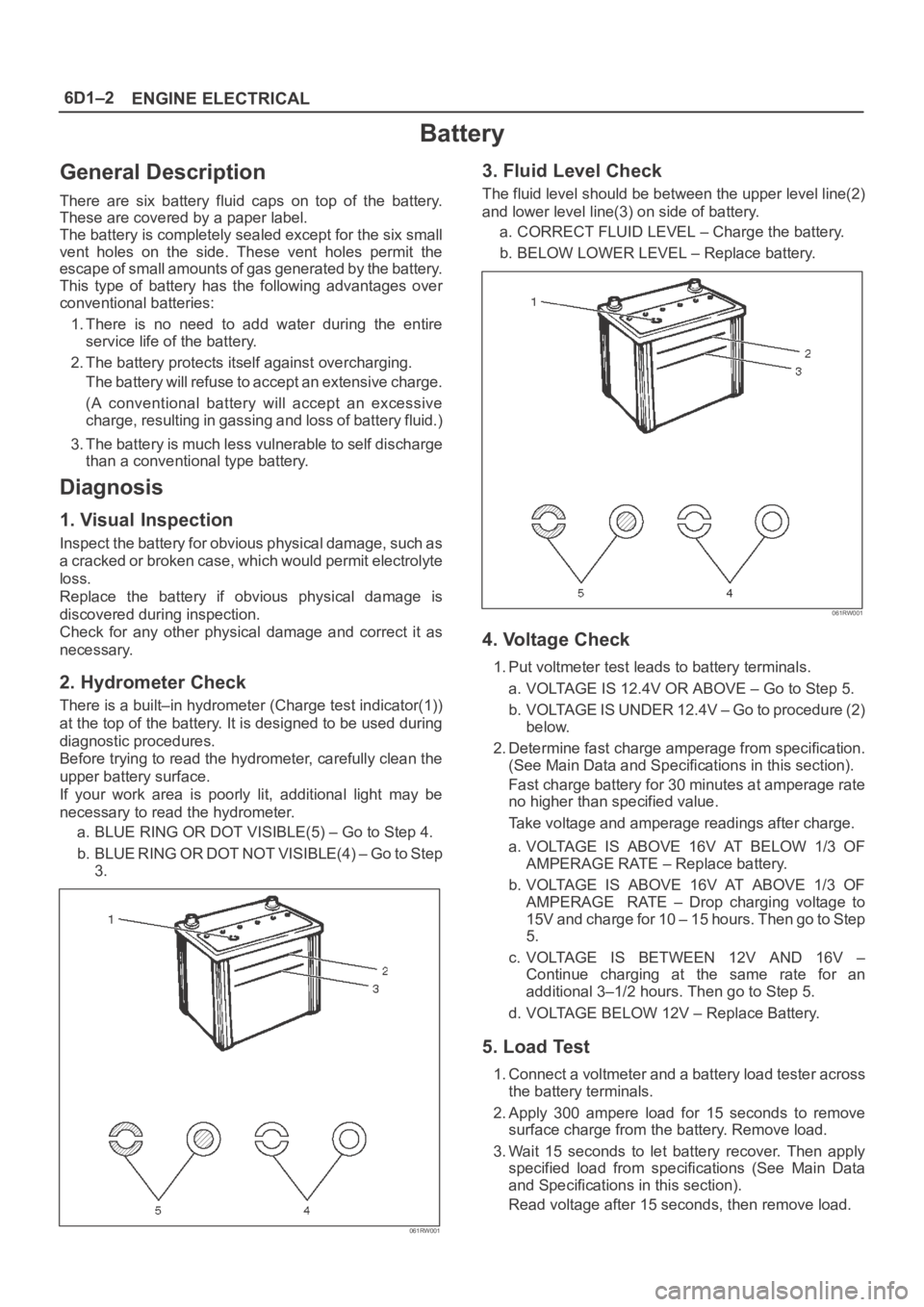

2. Hydrometer Check

There is a built–in hydrometer (Charge test indicator(1))

at the top of the battery. It is designed to be used during

diagnostic procedures.

Before trying to read the hydrometer, carefully clean the

upper battery surface.

If your work area is poorly lit, additional light may be

necessary to read the hydrometer.

a. BLUE RING OR DOT VISIBLE(5) – Go to Step 4.

b . B L U E R I N G O R D O T N O T V I S I B L E ( 4 ) – G o t o S t e p

3.

061RW001

3. Fluid Level Check

The fluid level should be between the upper level line(2)

and lower level line(3) on side of battery.

a. CORRECT FLUID LEVEL – Charge the battery.

b. BELOW LOWER LEVEL – Replace battery.

061RW001

4. Voltage Check

1. Put voltmeter test leads to battery terminals.

a. VOLTAGE IS 12.4V OR ABOVE – Go to Step 5.

b. VOLTAGE IS UNDER 12.4V – Go to procedure (2)

below.

2. Determine fast charge amperage from specification.

(See Main Data and Specifications in this section).

Fast charge battery for 30 minutes at amperage rate

no higher than specified value.

Take voltage and amperage readings after charge.

a. VOLTAGE IS ABOVE 16V AT BELOW 1/3 OF

AMPERAGE RATE – Replace battery.

b. VOLTAGE IS ABOVE 16V AT ABOVE 1/3 OF

AMPERAGE RATE – Drop charging voltage to

15V and charge for 10 – 15 hours. Then go to Step

5.

c. VOLTAGE IS BETWEEN 12V AND 16V –

Continue charging at the same rate for an

additional 3–1/2 hours. Then go to Step 5.

d. VOLTAGE BELOW 12V – Replace Battery.

5. Load Test

1. Connect a voltmeter and a battery load tester across

the battery terminals.

2. Apply 300 ampere load for 15 seconds to remove

surface charge from the battery. Remove load.

3. Wait 15 seconds to let battery recover. Then apply

specified load from specifications (See Main Data

and Specifications in this section).

Read voltage after 15 seconds, then remove load.

Page 1082 of 6000

ENGINE ELECTRICAL6D1–3

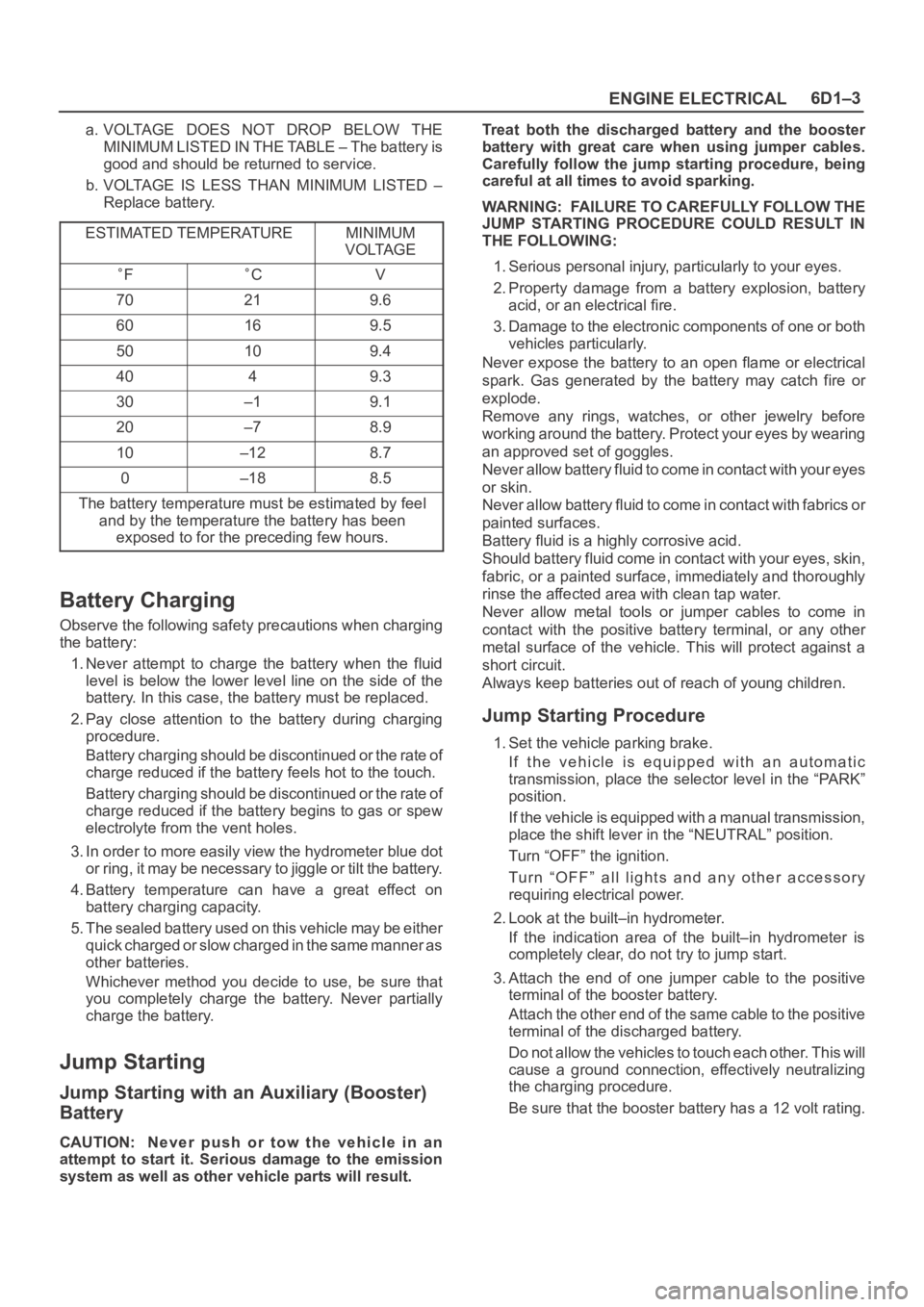

a. VOLTAGE DOES NOT DROP BELOW THE

MINIMUM LISTED IN THE TABLE – The battery is

good and should be returned to service.

b. VOLTAGE IS LESS THAN MINIMUM LISTED –

Replace battery.

ESTIMATED TEMPERATURE

MINIMUM

VOLTAGE

FCV

70219.6

60169.5

50109.4

4049.3

30–19.1

20–78.9

10–128.7

0–188.5

The battery temperature must be estimated by feel

and by the temperature the battery has been

exposed to for the preceding few hours.

Battery Charging

Observe the following safety precautions when charging

the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during charging

procedure.

Battery charging should be discontinued or the rate of

charge reduced if the battery feels hot to the touch.

Battery charging should be discontinued or the rate of

charge reduced if the battery begins to gas or spew

electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue dot

or ring, it may be necessary to jiggle or tilt the battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be either

quick charged or slow charged in the same manner as

other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

Jump Starting

Jump Starting with an Auxiliary (Booster)

Battery

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: FAILURE TO CAREFULLY FOLLOW THE

JUMP STARTING PROCEDURE COULD RESULT IN

THE FOLLOWING:

1. Serious personal injury, particularly to your eyes.

2. Property damage from a battery explosion, battery

acid, or an electrical fire.

3. Damage to the electronic components of one or both

vehicles particularly.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode.

Remove any rings, watches, or other jewelry before

working around the battery. Protect your eyes by wearing

an approved set of goggles.

Never allow battery fluid to come in contact with your eyes

or skin.

Never allow battery fluid to come in contact with fabrics or

painted surfaces.

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your eyes, skin,

fabric, or a painted surface, immediately and thoroughly

rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of reach of young children.

Jump Starting Procedure

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector level in the “PARK”

position.

If the vehicle is equipped with a manual transmission,

place the shift lever in the “NEUTRAL” position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built–in hydrometer.

If the indication area of the built–in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the positive

terminal of the discharged battery.

Do not allow the vehicles to touch each other. This will

cause a ground connection, effectively neutralizing

the charging procedure.

Be sure that the booster battery has a 12 volt rating.

Page 1086 of 6000

6D2–1

IGNITION SYSTEM

ENGINE

IGNITION SYSTEM

CONTENTS

Service Precaution 6D2–1. . . . . . . . . . . . . . . . . . . . . .

General Description 6D2–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 6D2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Coil 6D2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6D2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6D2–3. . . . . . . . . . . . . . . . . .

Installation 6D2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug 6D2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Removal 6D2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6D2–4. . . . . . . . . . . . . . . . . .

Installation 6D2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Angle Sensor 6D2–5. . . . . . . . . . . . . . . . .

Removal 6D2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6D2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D2–6. . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1092 of 6000

6D3–1 STARTING AND CHARGING SYSTEM

ENGINE

STARTING AND CHARGING SYSTEM

CONTENTS

Service Precaution 6D3–1. . . . . . . . . . . . . . . . . . . . . .

Starting System 6D3–2. . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6D3–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 6D3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter 6D3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6D3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6D3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 6D3–6. . . . . . . . . . . . . . . . . . . .

Disassembly 6D3–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6D3–9. . . . . . . . . . . . . . . . . .

Reassembly 6D3–13. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D3–15. . . . . . . . . . .

Charging System 6D3–18. . . . . . . . . . . . . . . . . . . . . . . . General Description 6D3–18. . . . . . . . . . . . . . . . . . . . .

General On–Vehicle Inspection 6D3–18. . . . . . . . . . .

Generator 6D3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6D3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6D3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6D3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 6D3–20. . . . . . . . . . . . . . . . . . . .

Disassembly 6D3–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6D3–23. . . . . . . . . . . . . . . . . .

Reassembly 6D3–24. . . . . . . . . . . . . . . . . . . . . . . . . .

Bench Test 6D3–25. . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D3–26. . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1118 of 6000

6E–1 ENGINE DRIVEABILITY AND EMISSIONS

ENGINE

ENGINE DRIVEABILITY AND EMISSIONS

CONTENTS

Specifications 6E–5. . . . . . . . . . . . . . . . . . . . . . . . .

Tightening Specifications 6E–5. . . . . . . . . . . . . . .

Vehicle Type Specifications 6E–5. . . . . . . . . . . . .

Diagrams and Schematics 6E–6. . . . . . . . . . . . . . . .

PCM Wiring Diagram (1 of 11) 6E–6. . . . . . . . . . .

PCM Wiring Diagram (2 of 11) For EC,

THAILAND, SOUTH EAST ASIA, LATIN

AMERICA, GULF, SAUDI, CHINA. 6E–7. . . . . .

PCM Wiring Diagram (3 of 11) For SOUTH

AFRICA and EXP. 6E–8. . . . . . . . . . . . . . . . . . . . .

PCM Wiring Diagram (4 of 11) 6E–9. . . . . . . . . . .

PCM Wiring Diagram (5 of 11) 6E–10. . . . . . . . . . .

PCM Wiring Diagram (6 of 11) For

AUSTRALIA, THAILAND, SOUTH EAST

ASIA, LATIN AMERICA, GULF, SAUDI,

LATIN AMERICA. 6E–11. . . . . . . . . . . . . . . . . . . . .

PCM Wiring Diagram (7 of 11) For EC. 6E–12. . .

PCM Wiring Diagram (8 of 11) For EXPORT

and SOUTH AFRICA. 6E–13. . . . . . . . . . . . . . . . .

PCM Wiring Diagram (9 of 11) Except EXP

and SOUTH AFRICA 6E–14. . . . . . . . . . . . . . . . . .

PCM Wiring Diagram (10 of 11) For

EXPORT and SOUTH AFRICA 6E–15. . . . . . . . .

PCM Wiring Diagram (11 of 11) 6E–16. . . . . . . . . .

PCM Pinouts 6E–17. . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way Red

Connector – Row “A” 6E–17. . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way Red

Connector – Row “B” 6E–19. . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way White

Connector – Row “C” (For EC) 6E–20. . . . . . . . . .

PCM Pinout Table, 32-Way White

Connector – Row “C” (For except EC) 6E–21. . .

PCM Pinout Table, 32-Way White

Connector – Row “D”

(For except EXPORT and SOUTH

AFRICA) 6E–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way White

Connector – Row “D”

(For EXPORT and SOUTH AFRICA) 6E–23. . . . .

PCM Pinout Table, 32-Way Blue

Connector – Row “E”

(For except EXPORT and SOUTH

AFRICA) 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Pinout Table, 32-Way Blue

Connector – Row “E”

(For EXPORT and SOUTH AFRICA) 6E–26. . . . .

PCM Pinout Table, 32-Way Blue

Connector – Row “F” 6E–27. . . . . . . . . . . . . . . . . .

Component Locators 6E–28. . . . . . . . . . . . . . . . . . . .

Engine Component Locator (This illustration

is based on RHD model.) 6E–28. . . . . . . . . . . . . . Engine Component Locator Table 6E–29. . . . . . . .

Engine Component Locator Table 6E–31. . . . . . . .

Undercarriage Component Locator 6E–32. . . . . .

Undercarriage Component Locator Table

(Automatic Transmission) 6E–32. . . . . . . . . . . . . .

Undercarriage Component Locator Table

(Manual Transmission) 6E–33. . . . . . . . . . . . . . . .

Fuse and Relay Panel (Underhood

Electrical Center) 6E–33. . . . . . . . . . . . . . . . . . . . .

Sensors and Miscellaneous Component

Locators 6E–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 6E–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–37. . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–37. . . . . . . . . . . . .

DTC Stored 6E–37

. . . . . . . . . . . . . . . . . . . . . . . . . . .

No DTC 6E–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Matching Symptom 6E–37. . . . . . . . . . . . . . . . .

Intermittents 6E–37. . . . . . . . . . . . . . . . . . . . . . . . . .

No Trouble Found 6E–37. . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–37. . . . . . . . . . . . . . . .

General Service Information 6E–38. . . . . . . . . . . . . .

OBD Serviceablity Issues 6E–38. . . . . . . . . . . . . . .

Maintenance Schedule 6E–38. . . . . . . . . . . . . . . . .

Visual / Physical Engine Compartment

Inspection 6E–38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge of Tools Required 6E–38. . . . . .

Serial Data Communications 6E–38. . . . . . . . . . . . . .

Class II Serial Data Communications 6E–38. . . . .

On-Board Diagnostic (OBD) 6E–39. . . . . . . . . . . . . .

On-Board Diagnostic Tests 6E–39. . . . . . . . . . . . .

Comprehensive Component Monitor

Diagnostic Operation 6E–39. . . . . . . . . . . . . . . . . .

Common OBD Terms 6E–40. . . . . . . . . . . . . . . . . .

The Diagnostic Executive 6E–40. . . . . . . . . . . . . . .

DTC Types 6E–41. . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–42. . . . . . . . . . . . . . . .

Reading Diagnostic Trouble Codes Using

A Tech 2 6E–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Tech 2 6E–43. . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Features 6E–43. . . . . . . . . . . . . . . . . . . . . . .

Getting Started 6E–44. . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedure (For Example) 6E–44. . . . .

DTC Modes 6E–45. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC Information Mode 6E–46. . . . . . . . . . . . . . . . .

Injector Balance Test 6E–46. . . . . . . . . . . . . . . . . . .

EGR Control Test 6E–47. . . . . . . . . . . . . . . . . . . . . .

Idle Air Control System Test 6E–48. . . . . . . . . . . . .

Page 1121 of 6000

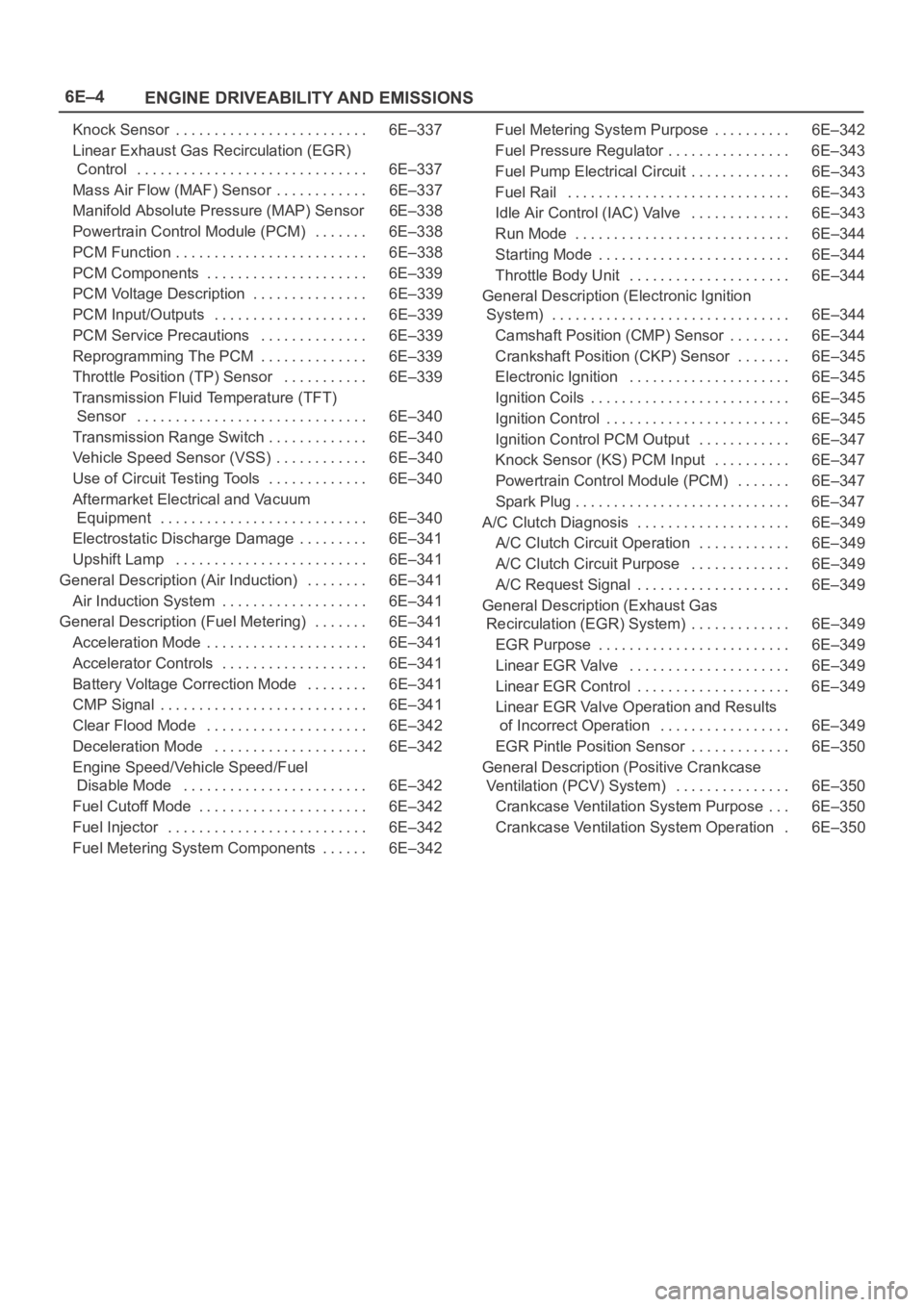

6E–4

ENGINE DRIVEABILITY AND EMISSIONS

Knock Sensor 6E–337. . . . . . . . . . . . . . . . . . . . . . . . .

Linear Exhaust Gas Recirculation (EGR)

Control 6E–337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mass Air Flow (MAF) Sensor 6E–337. . . . . . . . . . . .

Manifold Absolute Pressure (MAP) Sensor 6E–338

Powertrain Control Module (PCM) 6E–338. . . . . . .

PCM Function 6E–338. . . . . . . . . . . . . . . . . . . . . . . . .

PCM Components 6E–339. . . . . . . . . . . . . . . . . . . . .

PCM Voltage Description 6E–339. . . . . . . . . . . . . . .

PCM Input/Outputs 6E–339. . . . . . . . . . . . . . . . . . . .

PCM Service Precautions 6E–339. . . . . . . . . . . . . .

Reprogramming The PCM 6E–339. . . . . . . . . . . . . .

Throttle Position (TP) Sensor 6E–339. . . . . . . . . . .

Transmission Fluid Temperature (TFT)

Sensor 6E–340. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Range Switch 6E–340. . . . . . . . . . . . .

Vehicle Speed Sensor (VSS) 6E–340. . . . . . . . . . . .

Use of Circuit Testing Tools 6E–340. . . . . . . . . . . . .

Aftermarket Electrical and Vacuum

Equipment 6E–340. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrostatic Discharge Damage 6E–341. . . . . . . . .

Upshift Lamp 6E–341. . . . . . . . . . . . . . . . . . . . . . . . .

General Description (Air Induction) 6E–341. . . . . . . .

Air Induction System 6E–341. . . . . . . . . . . . . . . . . . .

General Description (Fuel Metering) 6E–341. . . . . . .

Acceleration Mode 6E–341. . . . . . . . . . . . . . . . . . . . .

Accelerator Controls 6E–341. . . . . . . . . . . . . . . . . . .

Battery Voltage Correction Mode 6E–341. . . . . . . .

CMP Signal 6E–341. . . . . . . . . . . . . . . . . . . . . . . . . . .

Clear Flood Mode 6E–342. . . . . . . . . . . . . . . . . . . . .

Deceleration Mode 6E–342. . . . . . . . . . . . . . . . . . . .

Engine Speed/Vehicle Speed/Fuel

Disable Mode 6E–342. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Cutoff Mode 6E–342. . . . . . . . . . . . . . . . . . . . . .

Fuel Injector 6E–342. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Metering System Components 6E–342. . . . . . Fuel Metering System Purpose 6E–342. . . . . . . . . .

Fuel Pressure Regulator 6E–343. . . . . . . . . . . . . . . .

Fuel Pump Electrical Circuit 6E–343. . . . . . . . . . . . .

Fuel Rail 6E–343. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Idle Air Control (IAC) Valve 6E–343. . . . . . . . . . . . .

Run Mode 6E–344. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting Mode 6E–344. . . . . . . . . . . . . . . . . . . . . . . . .

Throttle Body Unit 6E–344. . . . . . . . . . . . . . . . . . . . .

General Description (Electronic Ignition

System) 6E–344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft Position (CMP) Sensor 6E–344. . . . . . . .

Crankshaft Position (CKP) Sensor 6E–345. . . . . . .

Electronic Ignition 6E–345. . . . . . . . . . . . . . . . . . . . .

Ignition Coils 6E–345. . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Control 6E–345. . . . . . . . . . . . . . . . . . . . . . . .

Ignition Control PCM Output 6E–347. . . . . . . . . . . .

Knock Sensor (KS) PCM Input 6E–347

. . . . . . . . . .

Powertrain Control Module (PCM) 6E–347. . . . . . .

Spark Plug 6E–347. . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/C Clutch Diagnosis 6E–349. . . . . . . . . . . . . . . . . . . .

A/C Clutch Circuit Operation 6E–349. . . . . . . . . . . .

A/C Clutch Circuit Purpose 6E–349. . . . . . . . . . . . .

A/C Request Signal 6E–349. . . . . . . . . . . . . . . . . . . .

General Description (Exhaust Gas

Recirculation (EGR) System) 6E–349. . . . . . . . . . . . .

EGR Purpose 6E–349. . . . . . . . . . . . . . . . . . . . . . . . .

Linear EGR Valve 6E–349. . . . . . . . . . . . . . . . . . . . .

Linear EGR Control 6E–349. . . . . . . . . . . . . . . . . . . .

Linear EGR Valve Operation and Results

of Incorrect Operation 6E–349. . . . . . . . . . . . . . . . .

EGR Pintle Position Sensor 6E–350. . . . . . . . . . . . .

General Description (Positive Crankcase

Ventilation (PCV) System) 6E–350. . . . . . . . . . . . . . .

Crankcase Ventilation System Purpose 6E–350. . .

Crankcase Ventilation System Operation 6E–350.